Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

LR10005.gb.11-09.01 - SA155R - 2-Pole Product Sheet PDF

Caricato da

Cesar GilDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

LR10005.gb.11-09.01 - SA155R - 2-Pole Product Sheet PDF

Caricato da

Cesar GilCopyright:

Formati disponibili

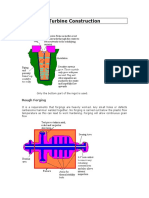

2-Pole Turbine Generators

Rotor Construction

WEG Group

The rotor is designed to withstand cyclic duty and rapid loading.

Radial ventilation provides even cooling. Low vibration levels are

achieved by dynamic balancing and machine design.

s

Field Coils

s coils are made of silver-bearing

s Rotor

strap copper for greater creep

resistance. The coil is accurately formed

to precisely fit in the rotor slot with

minimum distortion. Ventilating slots

are punched in the straight portion of

the coils to allow for radial discharge

of cooling air.

s

s

The rotor body coil slot is lined with a

Nomex

insulating cell formed to the

s

exact shape of the slot. The slot cell

ground insulation level is checked

before the coils are installed.

Each field coil is suspended over a pole

and inserted, turn-by-turn, into the slots.

s

Individual

turns are insulated with

Nomex which is coated with a B-state

resin. The coils are pressed to a specified

size, then heated to cure the resin and

bond the turns. Aluminum alloy slot

wedges are inserted to hold the winding

firmly in place.

s

Rotor Forging and Machining

Rotor Slots

The rotor forging is a special alloy steel

containing nickel, chromium, molybdenum,

and vanadium. It has the physical

properties required to withstand the

stresses encountered over a wide range

of temperature and load conditions. The

forging material is produced from an

electric furnace vacuum degassed ingot.

All forgings are heat treated after the

forging operation and stress relieved after

rough machining. To control quality, a

chemical analysis is made of each heat

cycle, and radial test samples are taken

from the rotor body to indicate the physical

properties. Longitudinal tensile and impact

test specimens are taken from the extra

material at the end of the forging. The

holes from which the radial samples were

taken are tapped and plugged with steel,

and are positioned to be at the centers of

the poles. The forging manufacturer

performs an impact test to determine the

low temperature ductility of the steel. In

addition, ultrasonic tests and magnetic

particle tests are made to assure that the

forging is sound.

Slots for field windings are step milled over

the entire length of the rotor body. They

are milled in a pattern to give the 2-pole

configuration and also to provide liberal

area for field copper. Step milling

minimizes stress level at the roots of the

teeth, one of the most critical parts of the

rotor. Grooves for slot wedges are

accurately machined into the slot walls.

Slots for rotor ventilation are positioned

directly under the rotor coil slots and are

reduced width extensions of the regular

milled coil slots.

Machining radial slots in rotor forging.

s s

A teflon coated strip is placed on top of

the coils to help in providing a controlled

slip plane for coil expansion and

contraction

that occurs during start/stop

s

and loading cycles.

Rotor slots for field winding.

Rotor retaining rings.

Rotor winding process.

Retaining Rings

Retaining rings support the rotor coil end

turns against the centrifugal forces

encountered during high-speed operation.

They are made from forgings that meet

rigid specifications and are resistant to

stress corrosion cracking. Compliance with

these specifications is assured by tests for

physical properties made on prolongations

allowed at the end of the forging.

Ultrasonic tests are conducted to assure

soundness of the forging. Any forging

found to be defective is rejected. Circular

steel plates are shrunk into the outer end

of the retaining ring to add section and to

reduce distortion. The retaining rings are

shrunk on a machined fit on the rotor

body. This fit is calculated to provide firm

centering of the ring on the rotor body

even under overspeed conditions.

Rotor Fans

Steel axial flow fans are fabricated, tested

and balanced. The fans are keyed and

shrunk on the rotor body outboard of the

retainer rings.

Circumferential keys at the rotor body lock

the rings in place. In effect, the retaining

rings nest the end turns inside a shelf or

extension of the rotor body and prevent

displacement and consequential

unbalance. Since the retainers do not

depend on the shaft for support, shaft

deflections cannot transmit forces that

cause such displacements and unbalance.

The field coil end turns are cooled by

air passing circumferentially and axially

between the coils and discharging

through radial slots in the rotor windings

and wedges.

Rotor end turn area.

Brushless Excitation

An axial hole is drilled in to the shaft at the

exciter end and is used to carry DC power

from the exciter, under the bearing journal,

to the main field winding.

Balance And Vibration

Precautions are taken throughout the

design and manufacturing operations to

ensure precise balance and minimize

vibration. For example, account is taken

of the fact that the stiffness of the usual

2-pole rotor varies as the rotor turns.

When the poles are positioned vertically,

the rotor is more resistant to bending

and deflection than when the poles are

horizontal. As the rotor turns, the position

of these planes of stiffness changes twice

each revolution, tending to cause 7,200

vibrations per minute at 3,600 rpm (120

per second). On larger ratings, to reduce

the magnitude of the double frequency

vibrations, transverse slots are milled into

each pole face at intervals along the rotor

body to equalize the rigidity of the rotor in

these two planes.

Similarly, the critical speed of the rotor

is controlled to avoid possible excitation

of bearing oil whip and consequential

vibration. This is accomplished by gradually

stepping down the shaft diameter from

the rotor body so as to provide optimum

shaft stiffness.

The rotor is balanced in three places in a

high speed balancing facility. An overspeed

run is made with the rotor assembled in

the generator.

WEG Group

Electric Machinery

800 Central Avenue NE

Minneapolis, Minnesota 55413

United States

Tel: +1 612 378 8000

Fax: +1 612 378 8051

www.electricmachinery.com

Electric Machinery 2011. Publication NA.10005.gb.11-09.01. Electric Machinery, the Electric Machinery logo and any version thereof are trademarks and service marks of Electric Machinery.

The other names mentioned, registered or not, are the property of their respective companies.

Potrebbero piacerti anche

- 2-Pole Turbine Generators: WEG GroupDocumento12 pagine2-Pole Turbine Generators: WEG GroupVasudev AgrawalNessuna valutazione finora

- LR10004.gb.11-09.01 - SA155S - 2-Pole Product Sheet PDFDocumento2 pagineLR10004.gb.11-09.01 - SA155S - 2-Pole Product Sheet PDFCesar GilNessuna valutazione finora

- 2P TG Stator ConstructionDocumento2 pagine2P TG Stator ConstructionChathura DalugodaNessuna valutazione finora

- Manufacturing and Assembling of Stator and Rotor Inturbo GeneratorsDocumento4 pagineManufacturing and Assembling of Stator and Rotor Inturbo GeneratorsAshfiya YazdaniNessuna valutazione finora

- TDBFP ManulDocumento266 pagineTDBFP ManulJackSparrow8678% (9)

- Machine Design PPT FinalDocumento25 pagineMachine Design PPT FinalRahul Pandey100% (2)

- Generator Testing Project ReportDocumento95 pagineGenerator Testing Project ReportSindhu ManchukondaNessuna valutazione finora

- Welcome To Presentation On Generator Construction by Pawan BhatlaDocumento19 pagineWelcome To Presentation On Generator Construction by Pawan BhatlarahulNranaNessuna valutazione finora

- Generator Testing Project ReportDocumento51 pagineGenerator Testing Project Reportsudheer0% (1)

- Ltps ElectricalDocumento19 pagineLtps ElectricalVikash MaheshwariNessuna valutazione finora

- STC TRS Conventional 02Documento419 pagineSTC TRS Conventional 02battery sectionNessuna valutazione finora

- Rishi Immanuel Arief Piravin Anmol AgilanDocumento37 pagineRishi Immanuel Arief Piravin Anmol AgilanRAMSINGH CHAUHANNessuna valutazione finora

- 3-Phase IM Construction and WorkingDocumento15 pagine3-Phase IM Construction and Working19M647 - SRIRAM ANessuna valutazione finora

- INDUCTIOM MOTOR Students PDFDocumento124 pagineINDUCTIOM MOTOR Students PDFADDIS JOHNNessuna valutazione finora

- 3-Ph Induction MotorDocumento246 pagine3-Ph Induction MotorAn00pgadzillaNessuna valutazione finora

- Generador KatoDocumento20 pagineGenerador KatoVelasquez DavisNessuna valutazione finora

- GeneratorDocumento71 pagineGeneratorDhanesh VyasNessuna valutazione finora

- Introduction To Turbo GeneratorDocumento42 pagineIntroduction To Turbo GeneratorTirumalesh ReddyNessuna valutazione finora

- Design of A Power Screw: Department of Mechanical Engineering, Bharath University, Selaiyur, Chennai, Tamilnadu, IndiaDocumento5 pagineDesign of A Power Screw: Department of Mechanical Engineering, Bharath University, Selaiyur, Chennai, Tamilnadu, IndiaShreenidhiNessuna valutazione finora

- Generator Construction 210 MWDocumento33 pagineGenerator Construction 210 MWPradeep_Vashist100% (1)

- 4, ACT TurbineDocumento23 pagine4, ACT TurbineMeet ZinzuvadiyaNessuna valutazione finora

- NIS Bearing Units Cataloguexsx BgsssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssDocumento162 pagineNIS Bearing Units Cataloguexsx BgsssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssEsca Dwi Nugroho33% (3)

- Study of Turbo-Generators.Documento37 pagineStudy of Turbo-Generators.Brijesh Kumar100% (5)

- Gibe3 HEPP GeneratorDocumento43 pagineGibe3 HEPP Generatorየፐፐፐ ነገርNessuna valutazione finora

- Generator EdcDocumento77 pagineGenerator EdcAJAY KUMAR100% (1)

- Torque Motor1Documento4 pagineTorque Motor1pepenitoNessuna valutazione finora

- Synchronous Motor Construction: GeneralDocumento4 pagineSynchronous Motor Construction: Generaljunaidkhattak10Nessuna valutazione finora

- Symmetrical Faults Part I PDFDocumento39 pagineSymmetrical Faults Part I PDFGunjan lalakiya100% (2)

- GEA-820A Vertical Water Wheel Driven Generators 62 A 3000 KVA. OCRDocumento8 pagineGEA-820A Vertical Water Wheel Driven Generators 62 A 3000 KVA. OCRPablo ThomassetNessuna valutazione finora

- Rotor ManufacturingDocumento4 pagineRotor ManufacturingSatyam MadameNessuna valutazione finora

- Squirrel-Cage Rotor Options For AC Induction MotorsDocumento34 pagineSquirrel-Cage Rotor Options For AC Induction MotorsIhatemanu MilanNessuna valutazione finora

- Utk 1Documento4 pagineUtk 1Rammy BaggaNessuna valutazione finora

- Study of Manufacturing of Steam Turbine BladeDocumento54 pagineStudy of Manufacturing of Steam Turbine BladeVijay Sekhar100% (1)

- Ms InductionDocumento12 pagineMs Inductionashkan aminiNessuna valutazione finora

- Unit 5 Induction Motor: StructureDocumento27 pagineUnit 5 Induction Motor: StructureSivasubramani ShanmugaveluNessuna valutazione finora

- Design of A Power Screw: Department of Mechanical Engineering, Bharath University, Selaiyur, Chennai, Tamilnadu, IndiaDocumento5 pagineDesign of A Power Screw: Department of Mechanical Engineering, Bharath University, Selaiyur, Chennai, Tamilnadu, IndiaWahyu DidierNessuna valutazione finora

- Referance For Marine Engineers by Min Zar TarDocumento208 pagineReferance For Marine Engineers by Min Zar Tarmgboune100% (1)

- Class Work-Induction MotorDocumento61 pagineClass Work-Induction MotorAbhi KNessuna valutazione finora

- Eliminating Rotor ProblemsDocumento6 pagineEliminating Rotor Problemssuzette TabladaNessuna valutazione finora

- KATO GeneratorDocumento20 pagineKATO GeneratormotiondrillNessuna valutazione finora

- Coil Springs1Documento8 pagineCoil Springs1Abhishek ShindeNessuna valutazione finora

- Manufacturing of Turbo GeneratorsDocumento19 pagineManufacturing of Turbo GeneratorsKeerthana Kola100% (1)

- Three Phase Induction Motor ADocumento2 pagineThree Phase Induction Motor AKantharaj ChinnappaNessuna valutazione finora

- BCR Singleroll PDFDocumento8 pagineBCR Singleroll PDFAneuk Naga BiruNessuna valutazione finora

- Online Monitoring DevicesDocumento17 pagineOnline Monitoring Devicesyogi_swarnNessuna valutazione finora

- Synchronous GeneratorDocumento36 pagineSynchronous GeneratorsamselvarajNessuna valutazione finora

- Getting A Good Fit: Selecting The Right Shaft and Housing ToleranceDocumento2 pagineGetting A Good Fit: Selecting The Right Shaft and Housing Toleranceeng13Nessuna valutazione finora

- Introduction To TPIMDocumento37 pagineIntroduction To TPIMLaasya RevillaNessuna valutazione finora

- Turbine ConstructionDocumento7 pagineTurbine ConstructionPrasannaNessuna valutazione finora

- M.E.I.M. 2017 365 Powder Bearings (PM)Documento28 pagineM.E.I.M. 2017 365 Powder Bearings (PM)rohanNessuna valutazione finora

- LR10003.gb.11-09.01 - PRD-308 - 2-Pole Product Sheet PDFDocumento2 pagineLR10003.gb.11-09.01 - PRD-308 - 2-Pole Product Sheet PDFCesar GilNessuna valutazione finora

- Study of Manufacturing of Steam Turbine Blade PDFDocumento54 pagineStudy of Manufacturing of Steam Turbine Blade PDFeasy_astronaut67% (6)

- Manufacturing Method of Cotter JointDocumento10 pagineManufacturing Method of Cotter JointAkshay Jadhav33% (6)

- Kato Engineering Generators Motor Generator Sets Controls Leroy Somer North AmericaDocumento20 pagineKato Engineering Generators Motor Generator Sets Controls Leroy Somer North AmericaJerNessuna valutazione finora

- Crankshaft Construction DesignDocumento10 pagineCrankshaft Construction DesignChockalingam AthilingamNessuna valutazione finora

- Active Magnetic BearingDocumento7 pagineActive Magnetic BearingsomendratrivediNessuna valutazione finora

- Shaffer ShpericalDocumento11 pagineShaffer Shpericaljeinerdt100% (1)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsDa EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsValutazione: 4 su 5 stelle4/5 (1)

- SWOT Analysis - GEOG (EME) 432 - Energy Policy PDFDocumento1 paginaSWOT Analysis - GEOG (EME) 432 - Energy Policy PDFCesar GilNessuna valutazione finora

- PEST AnalysisDocumento2 paginePEST AnalysisCesar GilNessuna valutazione finora

- Fuzzy Clustering ToolboxDocumento77 pagineFuzzy Clustering ToolboxraphthewizardNessuna valutazione finora

- Crown Battery SustainabilityDocumento6 pagineCrown Battery SustainabilityCesar GilNessuna valutazione finora

- Intro2MatlabCh2 PDFDocumento12 pagineIntro2MatlabCh2 PDFCesar GilNessuna valutazione finora

- PEST AnalysisDocumento3 paginePEST Analysisnguyenquocdien@gmail.comNessuna valutazione finora

- STUDY - Fixed or Withdrawable MV Switchgear PDFDocumento6 pagineSTUDY - Fixed or Withdrawable MV Switchgear PDFArun PandeyNessuna valutazione finora

- Electrical Application Substation Design Guide PDFDocumento405 pagineElectrical Application Substation Design Guide PDFHimdad TahirNessuna valutazione finora

- SWOT Analysis Energy Policy CanadáDocumento12 pagineSWOT Analysis Energy Policy CanadáCesar GilNessuna valutazione finora

- ABB Substation Condition Monitoring ScheduleDocumento16 pagineABB Substation Condition Monitoring ScheduleRey Arthur100% (1)

- 07 TransformersDocumento42 pagine07 TransformersRafael FurquimNessuna valutazione finora

- Substation DesignDocumento764 pagineSubstation Designprashious100% (2)

- 220kV GIS Tech Spec - TrackDocumento42 pagine220kV GIS Tech Spec - Trackaravind_k104100% (1)

- 11 Power System Analysis and PlanningDocumento14 pagine11 Power System Analysis and PlanningRafael FurquimNessuna valutazione finora

- SubStation Structure DesignDocumento17 pagineSubStation Structure DesignCesar Gil100% (2)

- Substation Bus Design Current Methods Compared With Field ResultDocumento10 pagineSubstation Bus Design Current Methods Compared With Field ResultCesar GilNessuna valutazione finora

- 09 Energy ManagementDocumento44 pagine09 Energy ManagementRafael FurquimNessuna valutazione finora

- 220kV GIS Tech Spec - TrackDocumento42 pagine220kV GIS Tech Spec - Trackaravind_k104100% (1)

- Spanish Technical Report CMMI V 1 3Documento555 pagineSpanish Technical Report CMMI V 1 3rjsernaqueNessuna valutazione finora

- 06 Products and DevicesDocumento94 pagine06 Products and DevicesRafael FurquimNessuna valutazione finora

- 08 ProtectionDocumento126 pagine08 ProtectionRafael FurquimNessuna valutazione finora

- Lecture02 - Environments and OpenModelicaDocumento11 pagineLecture02 - Environments and OpenModelicaCesar GilNessuna valutazione finora

- Energy Efficient Distribution TransformersDocumento32 pagineEnergy Efficient Distribution TransformersajaykumarparikhNessuna valutazione finora

- A Guide On Power World SimulatorDocumento8 pagineA Guide On Power World SimulatorAhmed Al-lehyaniNessuna valutazione finora

- Weka TutorialDocumento32 pagineWeka TutorialAlgus DarkNessuna valutazione finora

- Edp02 Coordinación Selectiva de Sobrecorriente en BTDocumento22 pagineEdp02 Coordinación Selectiva de Sobrecorriente en BTJose Duran ChaconNessuna valutazione finora

- 2011 Nec Changes - Ieee - 1202Documento46 pagine2011 Nec Changes - Ieee - 1202Cesario GillasNessuna valutazione finora

- Short Circuit StudyDocumento29 pagineShort Circuit StudyPramod B.Wankhade100% (3)

- Iec 61439Documento7 pagineIec 61439goyalp7550% (2)

- Be Sem 8 Automobile Engineering NotesDocumento75 pagineBe Sem 8 Automobile Engineering NotesVaibhav Vithoba Naik100% (7)

- EE-330 Ch-4 Synchronous GeneratorsDocumento110 pagineEE-330 Ch-4 Synchronous GeneratorsDanialNessuna valutazione finora

- Sem QuestionsDocumento11 pagineSem QuestionsRojaNessuna valutazione finora

- Fabrication of Solar Powered Hacksaw: Abhijeet Maurya, Abdul MoqeemDocumento12 pagineFabrication of Solar Powered Hacksaw: Abhijeet Maurya, Abdul MoqeemBADINEHALSANDEEPNessuna valutazione finora

- Engine 3408Documento21 pagineEngine 3408Abd ElGhanY AwdNessuna valutazione finora

- Electric Machines 1Documento54 pagineElectric Machines 1mugammad wasimNessuna valutazione finora

- Reluctance Motor: Ii) A Squirrel Cage Rotor Having Un Symmctrical Magnetic Construction This Is AchievedDocumento2 pagineReluctance Motor: Ii) A Squirrel Cage Rotor Having Un Symmctrical Magnetic Construction This Is AchievedDina GaranNessuna valutazione finora

- DC GeneratorDocumento35 pagineDC GeneratorMohammed Jalaluddin RayeenNessuna valutazione finora

- AC Generator Working Principle and PartsDocumento2 pagineAC Generator Working Principle and Partsibnuhary100% (1)

- AlternatorDocumento25 pagineAlternatorAjay BalarNessuna valutazione finora

- Latest Circuit Description of WDS6 Loco With WW GovernorDocumento13 pagineLatest Circuit Description of WDS6 Loco With WW GovernormajjisatNessuna valutazione finora

- Project Documentation For Multilevel InvertersDocumento89 pagineProject Documentation For Multilevel InvertersAnonymous hm7nSy1ebNessuna valutazione finora

- ECTE323/8323 Power Engineering 2 Spring 2020: A/Prof. Ashish Agalgaonkar Prof. Danny (Sutanto) SoetantoDocumento28 pagineECTE323/8323 Power Engineering 2 Spring 2020: A/Prof. Ashish Agalgaonkar Prof. Danny (Sutanto) SoetantoFUCKYOUNessuna valutazione finora

- (Isidor Kerszenbaum) Inspection of Large SynchronoDocumento190 pagine(Isidor Kerszenbaum) Inspection of Large Synchronohprabowo100% (1)

- Mohsin Khursheed Project FileDocumento46 pagineMohsin Khursheed Project FileMohsin Khursheed Lone50% (2)

- Short Answer Questions Synchronous MachinesDocumento3 pagineShort Answer Questions Synchronous MachinesRushikesh Ramesh KatoreNessuna valutazione finora

- Control of Electric Vehicle PDFDocumento31 pagineControl of Electric Vehicle PDFBrunoZueroNessuna valutazione finora

- Eddy Current BrakesDocumento25 pagineEddy Current BrakesRadu Lucian AlexandruNessuna valutazione finora

- Guide To Low-Voltage Motor Testing - MeggerDocumento44 pagineGuide To Low-Voltage Motor Testing - MeggerJustine Joshua DagondonNessuna valutazione finora

- EM3 - Unit1Documento11 pagineEM3 - Unit1P.V.RAMA SHARMANessuna valutazione finora

- Power and Torque in Synchronous Generators: App MDocumento52 paginePower and Torque in Synchronous Generators: App MHanan ShayiboNessuna valutazione finora

- 2 - Generator Model Validation PDFDocumento62 pagine2 - Generator Model Validation PDFRaihan KamilNessuna valutazione finora

- Rotating Machines and Transformers Unit 3 DC MOTOR CLASS NOTESDocumento76 pagineRotating Machines and Transformers Unit 3 DC MOTOR CLASS NOTESSEDHURAJA SNessuna valutazione finora

- Synchronous GeneratorDocumento86 pagineSynchronous GeneratorAnonymous 9kzuGaY100% (1)

- Unit-I Permanent Magnet Synchronous Motor Ref: Special Electrical Machines by GnanavadivelDocumento51 pagineUnit-I Permanent Magnet Synchronous Motor Ref: Special Electrical Machines by Gnanavadivelnpavank100% (2)

- Presentation On Oil Rig Electrics - ModifiedDocumento42 paginePresentation On Oil Rig Electrics - Modifiedjagdish choudharyNessuna valutazione finora

- What Is A Compound DC MotorDocumento8 pagineWhat Is A Compound DC MotorIan Rafael DeGuzman ReyesNessuna valutazione finora

- Design Study of 2-MW Fully Superconducting Synchronous MotorsDocumento6 pagineDesign Study of 2-MW Fully Superconducting Synchronous MotorsdanielNessuna valutazione finora

- Solar Water Pumping A HandbookDocumento134 pagineSolar Water Pumping A Handbookrobiged100% (2)

- Electrical System: Systems OperationDocumento7 pagineElectrical System: Systems OperationTri WahyuningsihNessuna valutazione finora