Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Conplast p509

Caricato da

pravi3434Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

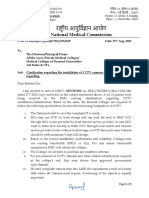

Conplast p509

Caricato da

pravi3434Copyright:

Formati disponibili

Conplast P509*

Water reducing admixture

Dosage

Uses

!

!

To improve the effectiveness of the water content of a

concrete mix.

At higher dosages to provide a cost effective means of

reducing concrete permeability and thereby reducing

water penetration.

Advantages

!

!

!

!

!

Particularly effective in improving compressive

strength of mixes containing PFA and GGBFS.

Water reduction significantly improves compressive

strengths at all ages and increases durability.

Allows workability to be increased without adding

extra water.

Allows specified strength grades to be met at reduced

cement content or increased workability.

Chloride free, safe for use in prestressed and

reinforced concrete.

The optimum dosage of Conplast P509 to meet specific

requirements should always be determined by trials using

the materials and conditions that will be experienced in use.

The normal dosage range is 0.2 to 0.6 litres/100 kg of

cementitious material, including PFA, GGBFS and

microsilica.

Use at other dosages

Dosages outside the normal range quoted above can be

used to meet particular mix requirements. Contact Fosroc

for advice in these cases.

Properties

Appearance:

Specific gravity:

Chloride content:

Air entrainment:

Alkali content:

Standards compliance

Conplast P509 complies with BS 5075 Part 1 and with

ASTM C494 as Type A and Type D, depending on dosage

used.

Conplast P509 complies with the requirements of the

United Kingdom Water Fittings Byelaws Scheme and is

listed in the Directory of Materials as suitable for use in

contact with potable water.

Description

Conplast P509 is a chloride free water-reducing admixture

based on a blend of selected lignosulphonate and

hydrolysed carbohydrate materials. It is supplied as a

brown solution, which instantly disperses in water.

Conplast P509 disperses the fine particles in the concrete

mix, enabling the water content of the concrete to perform

more effectively and improving the consistency of the

concrete. This produces higher levels of workability for the

same water content, allowing benefits such as water

reduction and increased strengths to be taken.

Technical support

Fosroc provides a technical advisory service for on-site

assistance and advice on mix design admixture selection,

evaluation trials and dispensing equipment.

Brown liquid

Typically 1.230 at 2oC

Nil to BS 5075

Typically less than 2% additional

air is entrained at normal

dosages.

Typically less than 4.0 g. Na2O

equivalent/liter of admixture. A

fact sheet on this subject is

available.

Instructions for use

Compatibility

Conplast P509 is compatible with other Fosroc admixtures

in the same concrete mix. All admixtures should be added

to the concrete separately and must not be mixed together

prior to addition. The performance of concrete containing

more than one admixture should be assessed by trial mixes

Conplast P509 is suitable for use with all types of ordinary

Portland cements and cement replacement materials such

as PFA, GGBFS and microsilica.

Effects on stiffening and set

Most water reducing admixtures produce some delay in the

stiffening of concrete, although the degree may vary.

Retardation is affected by factors other than the admixture,

depending on the mix details and conditions involved. Trials

to assess the effects in a particular mix are strongly

recommended if this aspect is of particular importance.

Estimating - packaging

Major factors which may lead to an increase in retardation

include the following:

Conplast P509 is available in drum or bulk supply. For larger

users, storage tanks can be supplied.

a)

Cement replacement materials will usually give

greater levels of retardation than concrete mixes made

with ordinary Portland cement at the same admixture

dosage.

b)

Low temperatures will give higher levels of

retardation for the same admixture dosage. This is

particularly noticeable if cement replacement materials are

used.

Storage

Conplast P509 has a minimum shelf life of 12 months provided

0

0

the temperature is kept within the range of 2 C to 50 C. Should

the temperature of the product fall outside this range then the

Fosroc Technical Service Department should be contacted for

advice.

o

Freezing point: Approximately -4 C

c)

Increased cement contents, which lead to higher

total levels of admixture in a cubic meter of concrete, may

lead to increased retardation being obtained.

Precautions

d)

Changes in cement source or chemistry may lead to

variations in the retardation obtained. The amount of tricalcium aluminate in the cement has been identified as

being one of the main contributory factors in this respect,

with a lower level leading to greater retardation.

Conplast P509 does not fall into the hazard classifications of

current regulations (see notes 1 and 2 below). However, it

should not be swallowed or allowed to come into contact with

skin and eyes.

Increased retardation will be obtained at higher dosage. As a

guideline, dosages of 0.31 litres/100 kg and above are likely

to be in the retarding category.

Dispensing

Health and safety

Suitable protective gloves and goggles should be worn.

Splashes on the skin should be removed with water. In case of

contact with eyes rinse immediately with plenty of water and

seek medical advice. If swallowed seek medical attention

immediately - do not induce vomiting.

The correct quantity of Conplast P509 should be measured by

means of a recommended dispenser. The admixture should

then be added to the concrete with the mixing water to obtain

the best results. Contact Fosroc for advice regarding suitable

equipment and its installation.

For further information consult the Material Safety Data Sheet

available for this product.

Effects of overdosing

Conplast P509 is water based and non-flammable.

An overdose of double the amount of Conplast P509 will

result in significant retardation. Provided that adequate curing

is maintained, the ultimate strength of the concrete will not be

impaired by increased retardation and will generally be

increased. The effects of overdosing will be further increased

if sulphate resisting cement or cement replacement materials

are used.

Cleaning and disposal

Overdosage may also cause increased air entrainment, which

will tend to reduce strength. The degree of this effect will

depend on the particular mix design and overdose level.

Fire

Spillages of Conplast P509 should be absorbed onto sand,

earth or vermiculite and transferred to suitable containers.

Remnants should be hosed down with large quantities of water.

The disposal of excess or waste material should be carried out

in accordance with local legislation under the guidance of the

local waste regulatory authority.

#

#

#

Note 1: CPL Regulations 1984 Supply-Schedule 1

Note 2: HSE publication Guidance Note EH40

See separate data sheet

*Denotes the trade marks of Fosroc International Limited

Fosam Company Limitd

Jeddah Sale Office

Riyadh

Khamis Mushayt

Makkah

Jubail

Tel: (02)608 0999

Tel: (01)482 9303

Tel: (07)250 0469

Tel: (02)542 0869

Tel: (03)362 3904

Fax: (02)635 3330

Fax: (01)482 7562

Fax: (07)250 0469

Fax: (02)542 0869

Fax: (03)362 3875

Jeddah Showroom

Dammam

Yanbu

Medinah

Head Office & Factory

Tel: (02)665 0187

Tel: (03)847 2929

Tel: (03)322 4280

Tel: (04)845 1767

Tel: (02)637 5345

Fax: (02)667 4844

Fax: (03)847 1582

Fax: (03)391 2980

Fax: (04)846 3195

Fax: (02)637 5891

Important note: Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard terms and conditions of

sale, copies of which may be obtained on request. Whist Fosroc endeavors to insure that any advice, recommendation, specification or information it may give

is accurate and correct, it cannot, because it has no direct or continuous control over where how its products are applied, accept any liability either directly or

indirectly arising from the use of its products, whether or not in accordance with any advice, specification, recommendation or information given by it

Potrebbero piacerti anche

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsDa EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNessuna valutazione finora

- Conplast P509: Water Reducing AdmixtureDocumento2 pagineConplast P509: Water Reducing AdmixtureBalasubramanian Ananth100% (1)

- Environmentally Benign Approaches for Pulp BleachingDa EverandEnvironmentally Benign Approaches for Pulp BleachingNessuna valutazione finora

- Conplast P510M: Water Reducing AdmixtureDocumento2 pagineConplast P510M: Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast p510Documento2 pagineConplast p510pravi3434Nessuna valutazione finora

- Conplast RP2000: Retarding Water Reducing AdmixtureDocumento2 pagineConplast RP2000: Retarding Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast sp337Documento3 pagineConplast sp337pravi3434Nessuna valutazione finora

- Conplast PA211: Water Reducing AdmixtureDocumento2 pagineConplast PA211: Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast wp20Documento2 pagineConplast wp20pravi3434Nessuna valutazione finora

- Conplast P211: Water Reducing Concrete AdmixtureDocumento4 pagineConplast P211: Water Reducing Concrete AdmixtureMel AdNessuna valutazione finora

- Conplast RP578: Retarding Water Reducing AdmixtureDocumento3 pagineConplast RP578: Retarding Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast RP264: Retarding Water Reducing AdmixtureDocumento2 pagineConplast RP264: Retarding Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast: Retarding Water Reducing AdmixtureDocumento4 pagineConplast: Retarding Water Reducing AdmixtureBinoy Sankar SarkerNessuna valutazione finora

- Conplast RP2020: Retarding Water Reducing AdmixtureDocumento2 pagineConplast RP2020: Retarding Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast P211Documento4 pagineConplast P211Vipul AroraNessuna valutazione finora

- Conplast RP2000 : Retarding Water-Reducing Admixture DosageDocumento2 pagineConplast RP2000 : Retarding Water-Reducing Admixture Dosagepravi3434Nessuna valutazione finora

- Conplast PA21: Air Entraining and Water Reducing Admixture Formerly Known As Conplast AE21Documento3 pagineConplast PA21: Air Entraining and Water Reducing Admixture Formerly Known As Conplast AE21Tori SmallNessuna valutazione finora

- Conplast P505: High Performance Water Reducing Admix TureDocumento2 pagineConplast P505: High Performance Water Reducing Admix TureVenkata Raju KalidindiNessuna valutazione finora

- Conplast SP432MSDocumento2 pagineConplast SP432MSTori Small100% (1)

- Conplast SP480Documento2 pagineConplast SP480Tori SmallNessuna valutazione finora

- Conplast SD100 : Mix Improving Admixture For Semi-Dry Concrete Uses Typical DosageDocumento4 pagineConplast SD100 : Mix Improving Admixture For Semi-Dry Concrete Uses Typical Dosagepravi3434Nessuna valutazione finora

- Conplast rp264Documento2 pagineConplast rp264pravi3434Nessuna valutazione finora

- Conplast x421Documento2 pagineConplast x421pravi3434Nessuna valutazione finora

- Conplast SP423Documento2 pagineConplast SP423Tori SmallNessuna valutazione finora

- Conplast SP430 0914Documento4 pagineConplast SP430 0914Vipul AroraNessuna valutazione finora

- 1 Brushbond (M)Documento3 pagine1 Brushbond (M)marzuki0202Nessuna valutazione finora

- Conplast SP430Documento2 pagineConplast SP430Tori Small100% (1)

- Conplast SD100: Mix Improving Admixture For Semi-Dry ConcretDocumento3 pagineConplast SD100: Mix Improving Admixture For Semi-Dry ConcretBalasubramanian AnanthNessuna valutazione finora

- Conplast R: Retarding Water Reducing AdmixtureDocumento2 pagineConplast R: Retarding Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast P211 (J)Documento2 pagineConplast P211 (J)Vipul AroraNessuna valutazione finora

- Conplast CN : Calcium Nitrite Corrosion Inhibiting AdmixtureDocumento2 pagineConplast CN : Calcium Nitrite Corrosion Inhibiting AdmixtureacarthurNessuna valutazione finora

- Conplast SP430Documento2 pagineConplast SP430Gowtham RajaNessuna valutazione finora

- Conplast P505Documento2 pagineConplast P505Vipul AroraNessuna valutazione finora

- Conplast wp400Documento2 pagineConplast wp400Venkata RaoNessuna valutazione finora

- Conplast P509 PDFDocumento2 pagineConplast P509 PDFgalfar7100% (1)

- Tds - Pozzolith Ld10Documento2 pagineTds - Pozzolith Ld10hammadali49Nessuna valutazione finora

- Conplast SP430RDocumento2 pagineConplast SP430RTori Small100% (1)

- Conplast AEA: Air Entraining AdmixtureDocumento4 pagineConplast AEA: Air Entraining AdmixtureVenkata Raju KalidindiNessuna valutazione finora

- Delvocrete Stabiliser v6Documento2 pagineDelvocrete Stabiliser v6Ashutosh RawatNessuna valutazione finora

- Conplast SP500Documento2 pagineConplast SP500Venkata Raju KalidindiNessuna valutazione finora

- Conplast SP360 : High Performance Water Reducing Admixture Uses Technical SupportDocumento4 pagineConplast SP360 : High Performance Water Reducing Admixture Uses Technical Supportpravi3434Nessuna valutazione finora

- Conplast CNI : Calcium Nitrite Corrosion Inhibiting AdmixtureDocumento2 pagineConplast CNI : Calcium Nitrite Corrosion Inhibiting AdmixtureMilan BojicNessuna valutazione finora

- Tds-Cplast 114Documento2 pagineTds-Cplast 114Nandi Vardhan Red ENessuna valutazione finora

- Aplast Rp2640: Retarding Water Reducing AdmixtureDocumento4 pagineAplast Rp2640: Retarding Water Reducing Admixturemazen jamalNessuna valutazione finora

- TDS Conmix P5 000 Feb13Documento1 paginaTDS Conmix P5 000 Feb13Vipas MankosolNessuna valutazione finora

- TDS - Flowcable 50Documento2 pagineTDS - Flowcable 50Venkata RaoNessuna valutazione finora

- Conplast RP200Documento2 pagineConplast RP200thoryamaraghyNessuna valutazione finora

- Conplast X421ICDocumento2 pagineConplast X421ICMahadeva PrasadNessuna valutazione finora

- Conplast NCDocumento2 pagineConplast NCBalasubramanian AnanthNessuna valutazione finora

- Conplast NCDocumento2 pagineConplast NCsilswal1988Nessuna valutazione finora

- TDS Conplast SP435 Saudi ArabiaDocumento3 pagineTDS Conplast SP435 Saudi ArabiaEng. Renjith SarmaNessuna valutazione finora

- Conplast CN: Calcium Nitrite Corrosion Inhibiting AdmixtureDocumento2 pagineConplast CN: Calcium Nitrite Corrosion Inhibiting AdmixtureVenkata Raju KalidindiNessuna valutazione finora

- TDS Conmix H2O Stop 019 Oct12Documento2 pagineTDS Conmix H2O Stop 019 Oct12Vipas MankosolNessuna valutazione finora

- Conplast SD110Documento2 pagineConplast SD110talatzahoorNessuna valutazione finora

- en-INT - Flocrete SP42.21052012022601Documento2 pagineen-INT - Flocrete SP42.21052012022601Mohammed AlkhateebNessuna valutazione finora

- Conplast PA21 (S) : Water Reducing Air Entraining AgentDocumento4 pagineConplast PA21 (S) : Water Reducing Air Entraining AgentVenkata Raju KalidindiNessuna valutazione finora

- Conplast SP431R TDSDocumento2 pagineConplast SP431R TDSBiruckNessuna valutazione finora

- Aplast SP Alph18 R-526: AMINO TYPE I High Performance Superplasticising Workability Retention AdmixtureDocumento3 pagineAplast SP Alph18 R-526: AMINO TYPE I High Performance Superplasticising Workability Retention Admixturemazen jamalNessuna valutazione finora

- TDS Conplast SP430 IndiaDocumento2 pagineTDS Conplast SP430 IndiaAnonymous Gb9LeJcINessuna valutazione finora

- Cplast 114: Technical Data SheetDocumento2 pagineCplast 114: Technical Data Sheetraviteja036Nessuna valutazione finora

- Tin CoatDocumento2 pagineTin Coatpravi3434Nessuna valutazione finora

- EucocreteDocumento2 pagineEucocretepravi3434Nessuna valutazione finora

- Tin TopDocumento2 pagineTin Toppravi3434Nessuna valutazione finora

- Tin Top SupremeDocumento2 pagineTin Top Supremepravi3434Nessuna valutazione finora

- Euco SpeedDocumento2 pagineEuco Speedpravi3434Nessuna valutazione finora

- Concrete Top SupremeDocumento2 pagineConcrete Top Supremepravi3434Nessuna valutazione finora

- Flex ConDocumento2 pagineFlex Conpravi3434Nessuna valutazione finora

- Euco SR93Documento2 pagineEuco SR93pravi3434Nessuna valutazione finora

- Cem BondDocumento1 paginaCem Bondpravi3434Nessuna valutazione finora

- CemfixDocumento2 pagineCemfixpravi3434100% (1)

- Cemkem 10Documento2 pagineCemkem 10pravi3434100% (1)

- CemmixDocumento2 pagineCemmixpravi3434Nessuna valutazione finora

- FlotopDocumento2 pagineFlotoppravi3434Nessuna valutazione finora

- Thin Top 100Documento2 pagineThin Top 100pravi3434Nessuna valutazione finora

- Euco 456 BMDocumento1 paginaEuco 456 BMpravi3434Nessuna valutazione finora

- Cmci Cmci: Cemtec P.U. PrimerDocumento1 paginaCmci Cmci: Cemtec P.U. Primerpravi3434Nessuna valutazione finora

- Euco WeldDocumento2 pagineEuco Weldpravi3434Nessuna valutazione finora

- Thin Top 100Documento2 pagineThin Top 100pravi3434Nessuna valutazione finora

- FlotopDocumento2 pagineFlotoppravi3434Nessuna valutazione finora

- Eu Co 456 MortarDocumento2 pagineEu Co 456 Mortarpravi3434Nessuna valutazione finora

- Cmci Cmci: Cemtec 200Documento2 pagineCmci Cmci: Cemtec 200pravi3434Nessuna valutazione finora

- Euco 495 HPDocumento1 paginaEuco 495 HPpravi3434Nessuna valutazione finora

- El As To Poxy PrimerDocumento1 paginaEl As To Poxy Primerpravi3434Nessuna valutazione finora

- Cmci Cmci: CEMTEC 227 P.UDocumento2 pagineCmci Cmci: CEMTEC 227 P.Upravi3434Nessuna valutazione finora

- Neo SealDocumento2 pagineNeo Sealpravi3434Nessuna valutazione finora

- Cmci Cmci: Cemtec 920Documento2 pagineCmci Cmci: Cemtec 920pravi3434Nessuna valutazione finora

- Euco 700Documento2 pagineEuco 700pravi3434Nessuna valutazione finora

- Cmci Cmci: CEMTEC 227 P.SDocumento2 pagineCmci Cmci: CEMTEC 227 P.Spravi3434Nessuna valutazione finora

- Cmci Cmci: Cemtec P.U. PrimerDocumento1 paginaCmci Cmci: Cemtec P.U. Primerpravi3434Nessuna valutazione finora

- Euco 495 HPDocumento1 paginaEuco 495 HPpravi3434Nessuna valutazione finora

- Advanced Statistical Approaches To Quality: INSE 6220 - Week 4Documento44 pagineAdvanced Statistical Approaches To Quality: INSE 6220 - Week 4picalaNessuna valutazione finora

- Conjunctions in SentencesDocumento8 pagineConjunctions in SentencesPunitha PoppyNessuna valutazione finora

- Bofa Turkish Banks-Back On The RadarDocumento15 pagineBofa Turkish Banks-Back On The RadarexperhtmNessuna valutazione finora

- APRStt Implementation Notes PDFDocumento36 pagineAPRStt Implementation Notes PDFCT2IWWNessuna valutazione finora

- Cuentos CADEDocumento6 pagineCuentos CADEMäuricio E. González VegaNessuna valutazione finora

- Catalogue Laboratory Products - Heraeus KulzerDocumento288 pagineCatalogue Laboratory Products - Heraeus KulzerDentaDentNessuna valutazione finora

- Things You Can Do at Burnham ParkDocumento2 pagineThings You Can Do at Burnham ParkBcpo TeuNessuna valutazione finora

- Research Paper On Marketing PlanDocumento4 pagineResearch Paper On Marketing Planfvhacvjd100% (1)

- Story 1Documento3 pagineStory 1api-296631749Nessuna valutazione finora

- Lyka Kendall B. Adres: Personal Na ImpormasyonDocumento2 pagineLyka Kendall B. Adres: Personal Na ImpormasyonKendall BarbietoNessuna valutazione finora

- 2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyDocumento9 pagine2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyNMarkatosNessuna valutazione finora

- MFD16I003 FinalDocumento16 pagineMFD16I003 FinalAditya KumarNessuna valutazione finora

- Automated Facilities Layout Past Present and FutureDocumento19 pagineAutomated Facilities Layout Past Present and FutureJose Luis Diaz BetancourtNessuna valutazione finora

- QuerySurge Models Mappings DocumentDocumento28 pagineQuerySurge Models Mappings Documentchiranjeev mishra100% (1)

- Ch04Exp PDFDocumento17 pagineCh04Exp PDFConstantin PopescuNessuna valutazione finora

- Facultybooklet2011-2012final - 006 (Unlocked by WWW - Freemypdf.com)Documento199 pagineFacultybooklet2011-2012final - 006 (Unlocked by WWW - Freemypdf.com)kalam19892209Nessuna valutazione finora

- Final Notice To Global Girls Degree CollgeDocumento2 pagineFinal Notice To Global Girls Degree CollgeIbn E AdamNessuna valutazione finora

- Introduction To History AnswerDocumento3 pagineIntroduction To History AnswerLawrence De La RosaNessuna valutazione finora

- Book Review Fiction New HereDocumento7 pagineBook Review Fiction New HereFILZAH SYAUQINA BINTI SUBLY Pelajar KPTM IpohNessuna valutazione finora

- Whitepaper ITES Industry PotentialDocumento6 pagineWhitepaper ITES Industry PotentialsamuraiharryNessuna valutazione finora

- Basic Knowledge About WDM Principle ADocumento92 pagineBasic Knowledge About WDM Principle AJosé LópezNessuna valutazione finora

- Industry and Community Project: Jacobs - Creating A Smart Systems Approach To Future Cities Project OutlineDocumento14 pagineIndustry and Community Project: Jacobs - Creating A Smart Systems Approach To Future Cities Project OutlineCalebNessuna valutazione finora

- CCTV Guidelines - Commission Letter Dated 27.08.2022Documento2 pagineCCTV Guidelines - Commission Letter Dated 27.08.2022Sumeet TripathiNessuna valutazione finora

- Chapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsDocumento27 pagineChapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsEdwin ChuenNessuna valutazione finora

- Fh84fr6ht GBR EngDocumento6 pagineFh84fr6ht GBR EngEsmir ŠkreboNessuna valutazione finora

- Ccu 3900alDocumento3 pagineCcu 3900alTourchianNessuna valutazione finora

- Silk Road Ensemble in Chapel HillDocumento1 paginaSilk Road Ensemble in Chapel HillEmil KangNessuna valutazione finora

- Knitting in Satellite AntennaDocumento4 pagineKnitting in Satellite AntennaBhaswati PandaNessuna valutazione finora

- March 2023 (v2) INDocumento8 pagineMarch 2023 (v2) INmarwahamedabdallahNessuna valutazione finora

- Bloomsbury Fashion Central - Designing Children's WearDocumento16 pagineBloomsbury Fashion Central - Designing Children's WearANURAG JOSEPHNessuna valutazione finora

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookDa EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNessuna valutazione finora

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDa EverandSodium Bicarbonate: Nature's Unique First Aid RemedyValutazione: 5 su 5 stelle5/5 (21)

- Guidelines for Chemical Process Quantitative Risk AnalysisDa EverandGuidelines for Chemical Process Quantitative Risk AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Water-Based Paint Formulations, Vol. 3Da EverandWater-Based Paint Formulations, Vol. 3Valutazione: 4.5 su 5 stelle4.5/5 (6)

- Process Plant Equipment: Operation, Control, and ReliabilityDa EverandProcess Plant Equipment: Operation, Control, and ReliabilityValutazione: 5 su 5 stelle5/5 (1)

- Phase Equilibria in Chemical EngineeringDa EverandPhase Equilibria in Chemical EngineeringValutazione: 4 su 5 stelle4/5 (11)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookDa EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNessuna valutazione finora

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesDa EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNessuna valutazione finora

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Bow Ties in Risk Management: A Concept Book for Process SafetyDa EverandBow Ties in Risk Management: A Concept Book for Process SafetyNessuna valutazione finora

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksDa EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNessuna valutazione finora

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDa EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNessuna valutazione finora

- Principles and Case Studies of Simultaneous DesignDa EverandPrinciples and Case Studies of Simultaneous DesignNessuna valutazione finora

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlDa EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlValutazione: 4 su 5 stelle4/5 (4)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Distillation Design and Control Using Aspen SimulationDa EverandDistillation Design and Control Using Aspen SimulationValutazione: 5 su 5 stelle5/5 (2)

- Understanding Process Equipment for Operators and EngineersDa EverandUnderstanding Process Equipment for Operators and EngineersValutazione: 4.5 su 5 stelle4.5/5 (3)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringDa EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillValutazione: 3.5 su 5 stelle3.5/5 (3)

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Da EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Nessuna valutazione finora

- Fundamentals of Risk Management for Process Industry EngineersDa EverandFundamentals of Risk Management for Process Industry EngineersNessuna valutazione finora

- Physical and Chemical Equilibrium for Chemical EngineersDa EverandPhysical and Chemical Equilibrium for Chemical EngineersValutazione: 5 su 5 stelle5/5 (1)

- Transport Phenomena in Heat and Mass TransferDa EverandTransport Phenomena in Heat and Mass TransferJ.A. ReizesValutazione: 5 su 5 stelle5/5 (1)