Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Director Operations Manufacturing Manager in Boston MA Resume Douglas Ross

Caricato da

DouglasRoss2Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Director Operations Manufacturing Manager in Boston MA Resume Douglas Ross

Caricato da

DouglasRoss2Copyright:

Formati disponibili

Douglas Ross

Kingston, NH 03848

603-702-1448

drinnh@yahoo.com

Senior Manufacturing Operations Manager with a proven track record of company growth,

increasing revenues and profitability. Ability to work effectively in a large or small company

environment bringing organizations together with confident leadership, well defined goals and

objectives and excellent organizational and communication skills.

Professional Experience

LAB Medical Manufacturing, Inc. Billerica, MA

Medical Device Contract Manufacturer

2011-present

Operations Manager

Returned the company to profitability by increasing revenues, instituting continuous

improvement initiatives, driving inventory reductions, reducing raw material costs, improving

labor efficiencies, reducing scrap and rework and ratcheting up the overall sense of urgency

within the management staff and direct labor workforce.

Exceeded revenue and net profit goals in 2012, 2013 and 2014 year-to-date.

Improved labor efficiencies from 50-60% to 85-95% by instituting weekly review of

labor vouchers with production supervisors, engineering and direct labor. Though this

review opportunities for improvement were identified and changes were implemented.

Increased on-time delivery from 60% to 90+% by improving front end production

planning ensuring jobs are started on time, improving WIP control through more detailed

shop scheduling, negotiating shorter lead times with process vendors, virtually

eliminating material shortages by formalizing lead times and increasing adherence to

MRP.

Improved the effectiveness of the engineering department through the implementation of

project management, more fully defined process responsibilities and the insistence of

increased involvement in day-to-day operations.

Maintained 99+% customer quality rating with all customers by proactively addressing of

all internal and customer related quality issues using root cause analysis, comprehensive

direct labor feedback and documented corrective actions.

Increased facility utilization through consolidation of departmental resources and

improved facility layout.

Omni Components Corp Hudson, NH

Medical Implant/Machined Components Contract Manufacturer

2005-2011

Manufacturing Manager

Managed the activities of a three shift operation of a contract manufacturer of high precision, high

volume machined components. Maintained 95% on time delivery performance, 99% quality

rating and met company profit goals while incorporating Lean initiatives, new machine

integration and adhering to all ISO 9001:2008 and 13485 standards.

Implemented efficiency improvements and shop floor controls that resulted in a

42% increase in revenues.

Streamlined processes to reduce cycle times and improve throughput.

Promoted quality initiatives that helped reduce discrepant material and cost of

quality.

Created a safe and organized work environment while maintaining excellent

work force cooperation and teamwork.

Waterline Services, LLC Seabrook, NH

Water/Wastewater Service Company

2001-2005

General Manager

Launched and managed all of the business activities of a startup water and wastewater service

company that produced $1.2M in revenues in its 2nd year of operation.

Managed the company to a profitable status in its first two years of operation.

Developed and implemented job cost reporting methods and led administrative

staff in managing all aspects of finance.

Directed field crews in the completion of project related work including

managing project costs.

Performed all project cost estimates for submittal to municipal representatives.

North American Industries Woburn, MA

Overhead Bridge Crane Manufacturer

1994-2001

Director of Manufacturing

Managed the manufacturing activities of an overhead bridge crane operation. Member of the

company Board of Directors and reported directly to the owner.

Increased annual revenues from $6M to $16M from 1995 to 2000.

Improved manufacturing operation efficiencies by 50% through the

implementation of time studies and accurate labor reporting.

Reduced lead times and past due orders by instituting daily parts tracking,

improved communication with support functions and increased front line

supervisor accountability.

Demanded and achieved improved product quality by creating an in-process

quality control program and improving final inspection documentation.

Textron Inc. Danvers, MA

Aircraft Engine/Aerospace Component Manufacturer

1988-1994

Production Control Manager

Managed the activities of a production control department for a $20M company in the machining

of aircraft engine components. Reported directly to the company president.

Established and maintained annual Manufacturing Plan.

Led manufacturing team in daily production meetings.

Controlled all WIP by ensuring accurate parts tracking, efficient machine loading

and prioritizing all support functions.

Coordinated and executed annual physical inventories.

Education

Bachelor of Science Degree Suffolk University, Boston, MA

References

Furnished upon request

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Final Deck April 12, 2018 Group 6 Group Name: BLAZE 22 Madinmc K33Documento72 pagineFinal Deck April 12, 2018 Group 6 Group Name: BLAZE 22 Madinmc K33Van TisbeNessuna valutazione finora

- Decathlon CaseDocumento15 pagineDecathlon CaseLeena CorahaiNessuna valutazione finora

- Astm A 703 A 703M-07 PDFDocumento15 pagineAstm A 703 A 703M-07 PDFFranciele Kaezala100% (2)

- What Are The Key Purposes of Budgets in Rapidly Growing Companies Such As Axonify?Documento3 pagineWhat Are The Key Purposes of Budgets in Rapidly Growing Companies Such As Axonify?klm klmNessuna valutazione finora

- Bucharest Retail Market 2021Documento15 pagineBucharest Retail Market 2021Mircea MerticariuNessuna valutazione finora

- Biggest Challenges of HR Professionals in COVID-19 PandemicDocumento54 pagineBiggest Challenges of HR Professionals in COVID-19 PandemicSarita MoreNessuna valutazione finora

- Prospectus (Mgvimt)Documento34 pagineProspectus (Mgvimt)satheesh kumar0% (1)

- Volume7 Issue2 Paper7 2023Documento10 pagineVolume7 Issue2 Paper7 2023D2D Study materialNessuna valutazione finora

- Significance/Need of Brand Extension: SeekingDocumento10 pagineSignificance/Need of Brand Extension: SeekingPrabhamohanraj MohanrajNessuna valutazione finora

- Ee Assignment Lu 6Documento6 pagineEe Assignment Lu 6NethiyaaRajendranNessuna valutazione finora

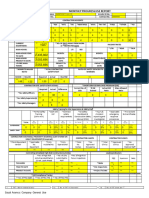

- Contractor Monthly HSE Progress Report FormDocumento2 pagineContractor Monthly HSE Progress Report FormAlok SinghNessuna valutazione finora

- Chapter 9 International Product and Brand MarketingDocumento1 paginaChapter 9 International Product and Brand MarketingKhánh Nguyễn ĐìnhNessuna valutazione finora

- Contabilidad M3Documento13 pagineContabilidad M3Azin RostamiNessuna valutazione finora

- Financial Performance of Ceramics Industry of BangladeshDocumento127 pagineFinancial Performance of Ceramics Industry of BangladeshGazi Shahbaz MohammadNessuna valutazione finora

- NPCIL Tube Fitting SpecificationsDocumento22 pagineNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- Strategic Analysis BoeingDocumento14 pagineStrategic Analysis BoeingKislaya Sharma100% (1)

- Factors Affecting Foreign Direct Investment in Nigeria - InvestSmallDocumento5 pagineFactors Affecting Foreign Direct Investment in Nigeria - InvestSmallKantNessuna valutazione finora

- OPM Resource Cost-Overheads-Component - Class-PeriodsDocumento12 pagineOPM Resource Cost-Overheads-Component - Class-PeriodsAhmedNessuna valutazione finora

- The True Story of The Internet Browser Wars Reflection Paper 1Documento2 pagineThe True Story of The Internet Browser Wars Reflection Paper 1api-499335492Nessuna valutazione finora

- Object Oriented Programming in AbapDocumento3 pagineObject Oriented Programming in Abapmirza_2010Nessuna valutazione finora

- What Are The Elements of The Crime Punished Under The Bouncing Checks Law?Documento18 pagineWhat Are The Elements of The Crime Punished Under The Bouncing Checks Law?Bill Breis100% (1)

- HIGH CARBON 35Cr-45Ni-1Nb: Alloy TypeDocumento2 pagineHIGH CARBON 35Cr-45Ni-1Nb: Alloy TypeSaravanan Pitchandi100% (1)

- Personal Protective Equipment PoliciesDocumento5 paginePersonal Protective Equipment Policiesraja MNessuna valutazione finora

- Joinder in International Commercial Arbitration PDFDocumento27 pagineJoinder in International Commercial Arbitration PDFisadora pazNessuna valutazione finora

- 11 - Chapter 1 PDFDocumento20 pagine11 - Chapter 1 PDFPraveena CNessuna valutazione finora

- The Welding Procedure and Its QualificationDocumento51 pagineThe Welding Procedure and Its QualificationYousef Adel HassanenNessuna valutazione finora

- A5e7b95f1469ba-About Niketan SocietyDocumento4 pagineA5e7b95f1469ba-About Niketan SocietyTaskin Reza KhalidNessuna valutazione finora

- "Audi Report "Marketing Strategies of Audi Nagpur"Documento42 pagine"Audi Report "Marketing Strategies of Audi Nagpur"Deepak Kawde80% (5)

- Wire Cut EdmDocumento2 pagineWire Cut EdmSaurabh Saini0% (1)

- A Case Study O1Documento8 pagineA Case Study O1JULIANO, GRACHELLE A.Nessuna valutazione finora