Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Job Safety Analysis Format

Caricato da

Jamil HossainCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Job Safety Analysis Format

Caricato da

Jamil HossainCopyright:

Formati disponibili

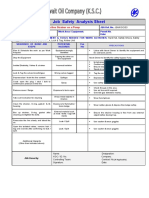

Job Safety Analysis

PHA Ref:

GWP#

Section A: To be filled during planning phase

Work Location: Low temperature separator skid

Task Description:

Vessel entry for visual inspection and taking photograph of new

economizer. (V-351)

Facility Name: JBGP

Date: 08/05/2014

Emergency Contact(Name/Phone Number)

Required PPE: SCBA, basic PPE, full body harness

Chevron (PIC):

Ch-06, 017XXXXXXX

Contractor (PIC): N/A

Required Tools: Hammer, Plyars, Camera, Flash light

Required Equipment: Ejector

Required Procedures: N/A

Scope of Work (Document high level work plan in sequential order):

1.

2.

3.

4.

5.

Remove blind flange & open manway cover

Setup exhaust fan and operate it for air ventilation

Entry into V-351 for internal inspection

Taking Photograph

Close manway door and housekeeping

Department Supervisor Initial: ..WAHID...

Section B: To be filled at site by work team

General Hazards:

Slips, trips, falls

Pinch Points

Low lighting

Dropped Object

Falling from Heights

Moving parts/rotating equipment

Critical protection bypass

Confined space

Pressurized System

Hot/cold surfaces

Adverse weather

Biological Hazards

Noise

Vibration

Heavy Vehicle Movement

Fire/Explosion

Hazardous atmosphere/substances

Simultaneous Operations (SIMOPS)

Arc/Chemical Exposurer

Radiation

Ignition sources

Spill/Release

Heat Stress

Working Alone

Environmental Impact

Overhead Hazards

Other:

see above notes)

Controls/Mitigations

(Area Controller/ Site Sup /

WTL)

Hazard Information (Please

Responsible for Control

Verification

Document Task Steps in

Sequential Order

Person Responsible for

Control Implementation

(any team member)

Notes: Complete the following hazard information for each task step:

i). Document potential hazard(s), ii) how could a team member be seriously injured or killed conducting this step? iii) Could the

hazards associated with this step lead to spill/release? How? , iv) List potential dropped object associated with this step?

1a. Arrange tools and

Equipment

Slip, trip & fall

Insect may bite or come in

contact

Eyes on path

Make noise at hiding area

Janu Mia

Saleheen

1b. Opening flange and man

way cover

Fall from height

Drop blinds, flange

Pinch point

Janu Mia

Saleheen

2a. Setup Exhaust fan

Pinch point

Exhaust fan may fall during

assemble

Person may fall

Ensure 100% tie off. Do not

overreach. Maintain 3 points

contact while climbing.

Hold blinds and flange firmly,

Wear hand gloves, eyes on task

Ensure drop object checklist.

Use hand gloves, eyes on task

Hold firmly, drop object and Ensure

WAH checklist

Saleheen

Wahid

2b. Run Exhaust fan using

pneumatic air

Pressure from air hose

Static charge

Use whip check

Ensure proper grounding

Saleheen

Wahid

Version: Pilot_V3 (10th May 2014)

Check (tick

box) all

Critical

Steps that must

be executed

exactly as

planned &

SWA must

be applied

for any

deviation.

Job Safety Analysis

3. Enter into vessel

O2 deficiencies

Falling inside vessel

4. Taking photograph

Ignition source

Camera, flash light may fall

inside vessel

Slip, trip & fall

Flange may fall

Pinch point between joints

Slip, trip & fall

5a. Close flange joints and doors

5b. House keeping

Gas test, use SCBA

Use life line, rescue plan

Eyes on path

Perform gas test

Secure camera and flash light while

using inside vessel

Eyes on path

Hold firmly, Eyes on task

Use hand gloves.

Eyes on path

PHA Ref:

GWP#

Saleheen

Wahid

Saleehin

Rafique

Janu Mia

Saleheen

Janu Mia

Saleheen

Discuss and document the below items:

Potential scenarios and conditions which will trigger Stop Work Authority.

If blinds, doors doesnt remove and secure properly.

If plant air pressure fall down

If proper grounding not used.

If CSE requirement doesnot meet.

Human factors which could potentially impact the safe completion of the task.

(e.g. Performance modes, state of mind, fatigue, error traps, mental slip etc.)

Physical and mental fitness for vessel entry

State of mind

Fatigue

Training and competency

Work Team Members Acknowledgement & JSA Approval

I acknowledge that I understand the contents of this JSA : (Name & Signature)

Rubel

Saleheen

Rana

Taher

Kashem

Wahid

Rafique

JSA Approval Work Team Leader (Name & signature):

Saleheen

Transfer to Work Team Leader (Name & signature):

Rifat (If needed)

Work Completion & Lessons Learned Discussion

Discuss and document the following. Notify Department Supervisor if any opportunity identified.

What Went Well:

Improvement Opportunity (e.g. use of additional procedures,

task steps missing, hazards missing, approvals missing, etc.):

Every steps for CSE followed carefully with trained person and

executed the job safely. Rescue team presence

Considering overhead hazard inside vessel and working at height,

ensure chinstrap with hard hat.

Version: Pilot_V3 (10th May 2014)

Potrebbero piacerti anche

- Job Safety Analysis FormDocumento4 pagineJob Safety Analysis FormMohammed NayeemuddinNessuna valutazione finora

- JSA Cable DisconnectedDocumento4 pagineJSA Cable Disconnectedwendypost730% (1)

- JSA Hydro TestingDocumento1 paginaJSA Hydro TestingZeyad RezkNessuna valutazione finora

- Ra02 - Container OffloadingDocumento3 pagineRa02 - Container OffloadingSamNessuna valutazione finora

- JHA For Tie-In at PCR14-02Documento7 pagineJHA For Tie-In at PCR14-02Francis Enriquez TanNessuna valutazione finora

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentDocumento5 pagineJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiNessuna valutazione finora

- Cold Work PermitDocumento11 pagineCold Work PermitMuneeb Ur Rehman100% (1)

- Work Permit Request For HydrotestingDocumento3 pagineWork Permit Request For HydrotestingZeyad Rezk50% (2)

- Jha New - PWHTDocumento6 pagineJha New - PWHTSalam AlkataluniNessuna valutazione finora

- Job Safety AnalysisDocumento1 paginaJob Safety AnalysisWati KaNessuna valutazione finora

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDocumento4 pagineJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (1)

- JSA-055 Hydro-TestDocumento24 pagineJSA-055 Hydro-TestOmar Dhieb100% (7)

- PP-HSE-FORM-005 PTW-Confined SpaceDocumento2 paginePP-HSE-FORM-005 PTW-Confined SpaceDimas Dwi SwarnaNessuna valutazione finora

- NSRP Project: Confined Space Entry CertificateDocumento1 paginaNSRP Project: Confined Space Entry CertificateThanh Tung DongNessuna valutazione finora

- PVCMS-BMV-HSE-JSA-001 InsulationDocumento6 paginePVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNessuna valutazione finora

- 2F 5 Radiation Risk AssessmentDocumento1 pagina2F 5 Radiation Risk AssessmentNurul SyaheerahNessuna valutazione finora

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Documento4 pagine0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Confined Space Rescue Plan FormDocumento7 pagineConfined Space Rescue Plan FormZulham SurbaktiNessuna valutazione finora

- JSA For Chimney Works 17.09.2021Documento2 pagineJSA For Chimney Works 17.09.2021Brenden PalanithangamNessuna valutazione finora

- Jsa For Ut TestDocumento2 pagineJsa For Ut Testnasar_mahsood50% (2)

- JSA of Drill Machine UseDocumento1 paginaJSA of Drill Machine UseSumair Khalid100% (1)

- Jsa Heat Exchanger Inspection Water Cleaning 2Documento5 pagineJsa Heat Exchanger Inspection Water Cleaning 2halfy safitri100% (2)

- Job Safety Analysis Sheet: Cleaning Suction Strainer On A PumpDocumento1 paginaJob Safety Analysis Sheet: Cleaning Suction Strainer On A Pumpjoshua100% (1)

- JSA For Cable Joint & Termination WorkDocumento2 pagineJSA For Cable Joint & Termination WorkVivek Verma100% (1)

- Jsa Bearing Replacement-OverhaulingDocumento2 pagineJsa Bearing Replacement-Overhaulingashish engineeringNessuna valutazione finora

- Job Safety Analysis Sheet: FacilityDocumento1 paginaJob Safety Analysis Sheet: FacilityjoshuaNessuna valutazione finora

- Petrochina International Jabung LTD.: Job Safety AnalysisDocumento4 paginePetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNessuna valutazione finora

- HIRA 008 Height Work.Documento4 pagineHIRA 008 Height Work.srinibas mohapatraNessuna valutazione finora

- 364 Pre Job Check List High Pressure Hydro Jetting Rev 000Documento2 pagine364 Pre Job Check List High Pressure Hydro Jetting Rev 000asan100% (1)

- SandblastingDocumento2 pagineSandblastingAL SALEH ELECTRONessuna valutazione finora

- JSA Sump CleaningDocumento2 pagineJSA Sump CleaningPanchdev Kumar100% (1)

- 06-F03 Ohs Introduction & Induction: Safety Induction Training Check-ListDocumento2 pagine06-F03 Ohs Introduction & Induction: Safety Induction Training Check-ListSn AhsanNessuna valutazione finora

- Night Shift Work Inspection ChecklistDocumento1 paginaNight Shift Work Inspection Checklistazer Azer100% (2)

- Jsa FormDocumento3 pagineJsa Formmiaicarba100% (1)

- Jsa For Piping and Erection RevisedDocumento1 paginaJsa For Piping and Erection RevisedDr AnwarNessuna valutazione finora

- Risk Ass - ProcessDocumento4 pagineRisk Ass - ProcessBalakrishnan Sivagnanam SNessuna valutazione finora

- Safety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksDocumento1 paginaSafety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksRísês ÃfrözNessuna valutazione finora

- Working at HeightDocumento28 pagineWorking at HeighteustaquipaixaoNessuna valutazione finora

- Job Hazard Analysis For Desalination of First Effect RetubingDocumento7 pagineJob Hazard Analysis For Desalination of First Effect Retubingmc chesterNessuna valutazione finora

- Jsa For HydrotestDocumento10 pagineJsa For HydrotestAnonymous CcGYhZb080% (5)

- JSA For Purging NitrogenDocumento1 paginaJSA For Purging Nitrogenlina ekawatiNessuna valutazione finora

- Jsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementDocumento13 pagineJsa Formats For Hydrotest of AG GRP PIPING Flushing ReinstatementKhuda Buksh100% (1)

- Job Safety Analysis (Rolling For MS Plates)Documento1 paginaJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- 4.2 Hot Work Permit PDFDocumento1 pagina4.2 Hot Work Permit PDFAneesh babuNessuna valutazione finora

- JSA 08 Gas WeldingDocumento1 paginaJSA 08 Gas Weldingmuthuswamy77Nessuna valutazione finora

- JSA HCK MOC Hot Tap Drilling Rev1Documento6 pagineJSA HCK MOC Hot Tap Drilling Rev1Ijaz Hussain100% (2)

- Health and Safety Induction SampleDocumento5 pagineHealth and Safety Induction SampleMohamad Hafiz100% (1)

- JSA To Check & Repair Heat Tracing System.Documento12 pagineJSA To Check & Repair Heat Tracing System.Chung Trịnh100% (2)

- Blinding and De-BlindingDocumento3 pagineBlinding and De-Blindingkaremkoko33% (3)

- 10 - Cherry Picker Inspection ChecklistDocumento1 pagina10 - Cherry Picker Inspection Checklistsanjeev kumar100% (1)

- Jsa Radiographic Test RTDocumento1 paginaJsa Radiographic Test RTHussein Adnan Fneish100% (1)

- Jha New Format Painting Revision PDFDocumento8 pagineJha New Format Painting Revision PDFNakkolopNessuna valutazione finora

- Dropped Object PreventionDocumento15 pagineDropped Object PreventionAriel Dela CruzNessuna valutazione finora

- Jsa SKDocumento10 pagineJsa SKEngr Tahir UL Haq100% (2)

- Jsa FormDocumento4 pagineJsa FormjihadspiritNessuna valutazione finora

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDocumento4 pagineJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (2)

- Confined Space Entry Permit Model FormDocumento2 pagineConfined Space Entry Permit Model Formramod100% (1)

- 05.JHA-Site Survey For TR-9702A Transformer Marshalling Box Wiring Verification at Substation EDocumento5 pagine05.JHA-Site Survey For TR-9702A Transformer Marshalling Box Wiring Verification at Substation EFrancis Enriquez TanNessuna valutazione finora

- JSA G20 Scaffolding (Erection, Dismantling)Documento4 pagineJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- Jsa Installation of HV ApparatusDocumento6 pagineJsa Installation of HV ApparatusLuqman OsmanNessuna valutazione finora

- CL57T V4.0Documento14 pagineCL57T V4.0dimitriNessuna valutazione finora

- B I o G R A P H yDocumento17 pagineB I o G R A P H yRizqia FitriNessuna valutazione finora

- LM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorDocumento21 pagineLM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorcgmannerheimNessuna valutazione finora

- John L. Selzer - Merit and Degree in Webster's - The Duchess of MalfiDocumento12 pagineJohn L. Selzer - Merit and Degree in Webster's - The Duchess of MalfiDivya AggarwalNessuna valutazione finora

- Amount of Casien in Diff Samples of Milk (U)Documento15 pagineAmount of Casien in Diff Samples of Milk (U)VijayNessuna valutazione finora

- BSC HTM - TourismDocumento4 pagineBSC HTM - Tourismjaydaman08Nessuna valutazione finora

- 2022 WR Extended VersionDocumento71 pagine2022 WR Extended Versionpavankawade63Nessuna valutazione finora

- Impact of Pantawid Pamilyang Pilipino Program On EducationDocumento10 pagineImpact of Pantawid Pamilyang Pilipino Program On EducationEllyssa Erika MabayagNessuna valutazione finora

- Congenital Cardiac Disease: A Guide To Evaluation, Treatment and Anesthetic ManagementDocumento87 pagineCongenital Cardiac Disease: A Guide To Evaluation, Treatment and Anesthetic ManagementJZNessuna valutazione finora

- Hans Belting - The End of The History of Art (1982)Documento126 pagineHans Belting - The End of The History of Art (1982)Ross Wolfe100% (7)

- Quarter 1-Week 2 - Day 2.revisedDocumento4 pagineQuarter 1-Week 2 - Day 2.revisedJigz FamulaganNessuna valutazione finora

- Mosfet Irfz44Documento8 pagineMosfet Irfz44huynhsang1979Nessuna valutazione finora

- BrochureDocumento3 pagineBrochureapi-400730798Nessuna valutazione finora

- Umwd 06516 XD PDFDocumento3 pagineUmwd 06516 XD PDFceca89Nessuna valutazione finora

- IMCI Chart BookletDocumento43 pagineIMCI Chart Bookletmysticeyes_17100% (1)

- Speech On Viewing SkillsDocumento1 paginaSpeech On Viewing SkillsMera Largosa ManlaweNessuna valutazione finora

- 50114a Isolemfi 50114a MonoDocumento2 pagine50114a Isolemfi 50114a MonoUsama AwadNessuna valutazione finora

- Tool Charts PDFDocumento3 pagineTool Charts PDFtebengz100% (2)

- Astm B19Documento6 pagineAstm B19Davor IbarraNessuna valutazione finora

- Algoritm BackTracking EnglezaDocumento6 pagineAlgoritm BackTracking Englezaionutz_67Nessuna valutazione finora

- IEC TC 56 Dependability PDFDocumento8 pagineIEC TC 56 Dependability PDFsaospieNessuna valutazione finora

- (1921) Manual of Work Garment Manufacture: How To Improve Quality and Reduce CostsDocumento102 pagine(1921) Manual of Work Garment Manufacture: How To Improve Quality and Reduce CostsHerbert Hillary Booker 2nd100% (1)

- Bachelor of Arts in Theology: Christian Apologetics/ Seventh-Day Adventist Contemporary IssuesDocumento13 pagineBachelor of Arts in Theology: Christian Apologetics/ Seventh-Day Adventist Contemporary IssuesRamel LigueNessuna valutazione finora

- rp10 PDFDocumento77 paginerp10 PDFRobson DiasNessuna valutazione finora

- In Flight Fuel Management and Declaring MINIMUM MAYDAY FUEL-1.0Documento21 pagineIn Flight Fuel Management and Declaring MINIMUM MAYDAY FUEL-1.0dahiya1988Nessuna valutazione finora

- Escaner Electromagnético de Faja Transportadora-Steel SPECTDocumento85 pagineEscaner Electromagnético de Faja Transportadora-Steel SPECTEdwin Alfredo Eche QuirozNessuna valutazione finora

- Apple Change ManagementDocumento31 pagineApple Change ManagementimuffysNessuna valutazione finora

- Head Coverings BookDocumento86 pagineHead Coverings BookRichu RosarioNessuna valutazione finora

- Quiz 140322224412 Phpapp02Documento26 pagineQuiz 140322224412 Phpapp02Muhammad Mubeen Iqbal PuriNessuna valutazione finora

- ყვავილები ელჯერნონისთვისDocumento348 pagineყვავილები ელჯერნონისთვისNia NorakidzeNessuna valutazione finora