Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Heat Exchanger

Caricato da

wandee2393Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Heat Exchanger

Caricato da

wandee2393Copyright:

Formati disponibili

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 1

1.0 Title

MEC 554-THERMALFLUIDS LAB

THERMODYNAMICS II LAB

CONCENTRIC TUBE HEAT

EXCHANGER

LECTURER: SITI HAJAR BINTI MOHD YUSOP

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 2

2.0 Abstract

In this experiment, we investigate the effect of flow rate variation on the performance

characteristics of a counter flow concentric tube exchanger and parallel flow tube heat

exchanger. During this experiment, we need to record the temperature different by increased

the volumetric flow rates of 2000, 3000 and 4000 cm

3

/min for both flow of heat exchanger.

After that, we need to calculate the following heat exchanger performance factors: power

emitted, power absorbed, power lost, efficiency, logarithmic mean temperature different and

overall heat transfer coefficient. Generally it can be said that all factors that effects the heat

exchanger performance which is power emitted, power absorbed, power lost efficiency (),

logarithmic mean temperature difference (

m

), and overall heat transfer coefficient (U) were

increased as hot fluid volumetric flow rate increased.

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 3

Table of Contents

1.0 Title............................................................................................................................................. 1

2.0 Abstract ...................................................................................................................................... 2

List of Symbols ........................................................................................................................................ 4

List of figure ......................................................................................................................................... 5

3.0 Introduction and Applications ................................................................................................... 6

4.0 Objectives .................................................................................................................................... 8

5.0 Theory ......................................................................................................................................... 9

6.0 Experimental Procedures ..................................................................................................... 12

6.1 Apparatus/Experimental Setup ............................................................................................... 12

6.2 Procedure .................................................................................................................................... 14

7.0 Result ........................................................................................................................................ 15

7.1 Data recorded ....................................................................................................................... 15

7.2 Sample calculation ................................................................................................................ 16

7.3 Analysis result ....................................................................................................................... 19

8.0 Discussion ................................................................................................................................. 23

9.0 Conclusion ................................................................................................................................ 23

10.0 References ................................................................................................................................ 24

11.0 Appendices ............................................................................................................................... 25

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 4

List of Symbols

A Area over which force (F) acts (m2)

E Elastic modulus (GPa)

F Force (N)

(

Initial dimension in direction i (mm)

T Specimen thickness (m)

Rate of chart displacement (mm/min)

Rate of sample displacement (mm/min)

w Specimen width (m)

Displacement of chart (mm)

Displacement of sample (mm)

Strain

=0 Predicted strain at zero stress

Normal strain in direction i

E Error in the predicted elastic modulus (GPa)

F Error in the force (N)

Change in dimension in direction i (mm)

t Error in the specimen thickness (m)

w Error in the width (m)

=0 Error in the predicted strain at zero stress

Error in the predicted intercept of stress-stain data (MPa)

Error in the stress (MPa)

Predicted intercept of stress-strain data (MPa)

Engineering stress (MPa)

Yield point (MPa)

Ultimate strength (MPa)

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 5

List of figure

Figure 1: Space heater ............................................................................................................................ 7

Figure 2: Cara radiator ............................................................................................................................ 7

Figure 3: Packaged Annular-Space Pastuerizer and Sterilizer ................................................................ 7

Figure 4: Anaerobic Digestion ................................................................................................................. 7

Figure 5: Recuparator ............................................................................................................................. 7

Figure 6: Heat exchanger temperature profiles and Fluid Flow Direction ............................................. 9

Figure 7: Heat exchanger apparatus system diagram (schematic diagram) ......................................... 12

Figure 8: Heat exchanger system .......................................................................................................... 12

Figure 9: Temperature control .............................................................................................................. 13

Figure 10: Cold fluid volumetric flow rate control ................................................................................ 13

Figure 11: Valve diagram for parallel flow and counter flow ............................................................... 13

Figure 12: Hot fluid volumetric flow rate control ................................................................................. 13

Figure 13: Graph 1................................................................................................................................. 20

Figure 14: Graph 2................................................................................................................................. 20

Figure 15: Graph 3................................................................................................................................. 21

Figure 16: Graph 4................................................................................................................................. 21

Figure 17: Graph 5................................................................................................................................. 22

Figure 18: Graph 6................................................................................................................................. 22

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 6

3.0 Introduction and Applications

A heat exchanger is a specialized device that assists in transfer of heat from one fluid

to the other. In some cases, a solid wall may separate the fluids and prevent them from

mixing. In other designs, the fluids may be in direct contact with each other. In the most

efficient heat exchangers, the surface area of the wall between the fluids is maximized while

simultaneously minimizing the fluid flow resistance. Fins or corrugations are sometimes used

with the wall in order to increase the surface area and induce turbulence.

The types of heat exchangers to be tested in this experiment are called parallel-flow

and counter-flow concentric tube heat exchangers. In a parallel-flow heat exchanger, the

working fluid flow in the same direction as it is for counter-flow but, at opposite direction.

The figure below briefly explains the fluid flowing path from both heat exchangers.

There are some important variables or properties that influence the performance of a

heat exchanger. Those variables include the physical properties, the mass flow rates, and the

inlet temperature of the fluids, type of materials used, the configuration and area of the heat

transfer surfaces, and the extent of scale or deposits on the heat transfer surfaces, and the

ambient conditions.

The attempt to match the heat transfer hardware to the heat transfer requirements

within the specified constraints has resulted in numerous types of innovative heat exchanger

design. In the design of heat exchange equipment, heat transfer equations are applied to

calculate this transfer of energy so as to carry it out efficiently and under controlled

conditions. The equipment goes under many names, such as boilers, pasteurizers, jacketed

pans, freezers, air heaters, cookers, ovens, space heaters and so on. The range is too great to

list completely. Perhaps the most commonly known heat exchanger is a car radiator, which

cools the hot radiator fluid by taking advantage of air flow over the surface of the radiator.

Last but not least, Heat exchangers are found widely scattered throughout the food process

industry.

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 7

Figure 2: Cara radiator

Figure 1: Space heater

Figure 4: Anaerobic Digestion Figure 3: Packaged Annular-Space Pastuerizer and

Sterilizer

Figure 5: Recuparator

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 8

4.0 Objectives

The purpose of this experiment is to:

1) To determine which configuration parallel or counter flow is more effective at

transferring heat.

2) To demonstrate the effect of flow rate variation on the performance characteristics of

a parallel-flow concentric tube heat exchanger and also on the counter-flow

concentric tube heat exchanger.

3) To experience the concentric tube heat exchanger in practical.

4) To gain more knowledge and understanding of the concentric tube heat exchanger.

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 9

5.0 Theory

There are two types of flow that being investigated in this experiment which are

parallel flow and counter flow. The figures below shows the differences between the two

flow.

The simplest heat exchanger is one for which the hot and cold fluids move in the same

or opposite directions in a concentric tube (or double-pipe) construction. In the parallel-flow

arrangement, the hot and cold fluids enter at the same end, flow in the same direction, and

leave at the same end. In the counter flow arrangement, the fluids enter at opposite ends, flow

in opposite directions, and leave at opposite ends.

Figure 6: Heat exchanger temperature profiles and Fluid Flow Direction

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 10

There are several important formulas or equations to calculate the performance

characteristics for both parallel-flow and counter-flow concentric tube heat exchangers. The

performance required are power emitted, power absorbed, power lost efficiency (),

logarithmic mean temperature difference (

m

), and overall heat transfer coefficient (U). The

The Efficiency for the Cold Medium is:

The Efficiency for the Hot Medium is:

The Mean Temperature Efficiency is:

The Power Emitted is given below (where

h

is the Volumetric Flow Rate of the hot

fluid):

)

The Power Absorbed is given below (where

c

is the Volumetric Flow Rate of the cold

fluid):

)

The Power Lost is therefore:

The Overall Efficiency () is:

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 11

The Logarithmic Mean Temperature Difference (

m

) is:

) (

)

[

(

)

(

)

]

The Overall Heat Transfer Coefficient (U) is:

Where the Surface Area (A

s

) for this heat exchanger is 0.067 m

2

To obtain the value of Density for both hot water and cold water (

h

&

c

) and Specific

Heat of Hot Water (C

ph

), the method of interpolation is required. As for the Specific Heat

of Cold Water (C

pc

), the value is given in the Property Tables.

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 12

6.0 Experimental Procedures

6.1 Apparatus/Experimental Setup

Figure 8: Heat exchanger system

Figure 7: Heat exchanger apparatus system diagram (schematic

diagram)

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 13

Figure 9: Temperature control

Figure 12: Hot fluid volumetric flow rate

control

Figure 10: Cold fluid volumetric flow

rate control

Figure 11: Valve diagram for parallel flow and counter flow

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 14

6.2 Procedure

1. The experiment for counter-flow heat exchanger operation had been configure.

The required hot water inlet temperature was set to Th,in = 60 c with the

decade switch. The cold water volumetric flow rate ( Vc ) also set to run at a

constant 2000 cm

3

/min.

2. The hot fluid volumetric flow rate (Vh) was initially set to 1000 cm

3

/min. The

six temperature readings in the following table was recorded. The readings for

volumetric flow rates of 2000, 3000 and 4000 cm

3

/min was repeated.

3. Values for density (

and

) and constant pressure specific heat (

and

)

for the cold fluids at a temperature of

and for the hot fluids at a

temperature of

was discovered.

4. The following heat exchanger performance factors such as power emitted,

power absorbed, power lost, efficiency (), logarithmic mean temperature

difference (

), and overall heat transfer coefficient (U) had been calculated

and recorded in the tables by using the data.

5. The result was discussed by comparing the effect of changing the volumetric

flow rate of the hot fluid on each of these heat exchanger performance factors.

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 15

7.0 Result

7.1 Data recorded

A. Concentric Tube Heat Exchanger in Parallel Flow

V

h

(cm

3

/min)

T

h,in

(

0

C) T

h,mid

(

0

C) T

h,out

(

0

C) T

c,in

(

0

C) T

c,mid

(

0

C) T

c,out

(

0

C)

1000 60 47 46 28 31 33

2000 60 53 52 28 34 36

3000 60 53 54 28 34 37

4000 60 54 55 28 35 39

Table 1: Data for parallel flow

From table A-9 ( Properties of saturated water )

At T

c,in

= 28C &T

h,in

= 60C

Properties are:

c

= 996.4 kg/m

3

C

pc

= 4178.8 J/kg.K

h

= 983.3 kg/m

3

C

ph

= 4185 J/kg.K

B. Concentric Tube Heat Exchanger in Counter Flow

V

h

(cm

3

/min)

T

h,in

(

0

C) T

h,mid

(

0

C) T

h,out

(

0

C) T

c,in

(

0

C) T

c,mid

(

0

C) T

c,out

(

0

C)

1000 60 51 48 27 30 34

2000 60 53 61 27 32 37

3000 60 53 53 27 33 38

4000 60 54 54 27 34 39

Table 2: Data for counter flow

From table A-9 ( Properties of saturated water )

At T

c,in

= 27C &T

h,in

= 60C.

Properties are:

c

= 996.6 kg/m

3

C

pc

= 4179.2 J/kg.K

h

= 983.3 kg/m

3

C

ph

= 4185 J/kg.K

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 16

7.2 Sample calculation

A. Experiment A: [Example of parallel-flow at 2000 cm

3

/min (3.333 x 10

-5

m

3

/s)]

i. Power emitted

( )

ii. Power absorbed

Power Absorbed = V

c

c

C

pc

(T

c,out

T

c,in

)

= (3.333 x10

-5

) (996.4) (4178.8) (36 - 28)

= 1110.25 W

iii. Power lost

Power lost = Power Emitted Power Absorbed

= (1097.25 1110.25) W

= -13 W

iv. Efficiency ()

% 101

% 100

1097.25

1110.25

% 100

=

=

=

ed PowerEmitt

bed PowerAbsor

q

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 17

v. Logarithmic mean temperature difference (T

m

)

C

T T

T T

T T T T

T

T

T T

T

o

out c out h

in c in h

out c out h in c in h

m

08 . 23

16

32

ln

16 32

) (

) (

ln

) ( ) (

ln

, ,

, ,

, , , ,

2

1

2 1

=

|

.

|

\

|

=

(

(

=

|

|

.

|

\

|

A

A

A A

= A

vi. Overall heat transfer coefficient (U)

) . /( 98 . 717

) 08 . 23 )( 067 . 0 (

1110.25

2

C m W

T A

bed PowerAbsor

U

o

m s

=

=

A

=

vii To calculate the efficiency for the cold medium, n

c

= 25 %

viii To calculate the efficiency for the hot mecium, n

h

= 18.75 %

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 18

viii To calculate the mean temperature effieiency, n

mean

= 31.25 %

B. Experiment B

Calculate all heat exchanger performance factors which are power emitted,

power absorbed, power lost, efficiency (), logarithmic mean temperature

difference (

), and overall heat transfer coefficient (U) exactly the same as

experiment A.

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 19

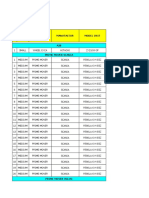

7.3 Analysis result

A. Experiment A: Concentric Tube Heat Exchanger in Parallel Flow

V

h

Power

Emitted

Power

Absorbed

Power

Lost

Efficiency T

m

U

n

c

n

h

n

mean

(cm

3

/min)

(W) (W) (W) (, %) (C) W/(m

2

.

0

C)

% % %

1000 614.72 693.89 -79.17 112.88 22.20 466.51 15.63 43.75 29.69

2000 1097.25 1110.25 -13 101 23.08 717.98 25 25 25

3000 1234.53 1110.22 124.31 89.93 24.47 677.17 28.13 18.75 23.44

4000

1372.69 1526.56 -153.87 111.21 23.87 954.52 34.38 15.63 25.01

B. Experiment B: Concentric Tube Heat Exchanger in Counter Flow

V

h

Power

Emitted

Power

Absorbed

Power

Lost

Efficiency T

m

U

n

c

n

h

n

mean

(cm

3

/min)

(W) (W) (W) (, %) (C) W/(m

2

.

0

C)

% % %

1000 526.9 971.73 -44.3 184.42 23.41 619.54 21.21 36.36 28.79

2000 1234.41 1388.19 -153.78 112.46 28.14 736.29 30.30 -3.03 13.64

3000 1440.29 1527.01 -86.72 106.02 23.94 952.01 33.33 21.21 27.27

4000

1372.69 1665.83 -18.96 101.15 23.87 1041.61 36.36 18.18 27.27

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 20

0

200

400

600

800

1000

1200

1400

1600

0 500 1000 1500 2000 2500 3000 3500 4000 4500

P

o

w

e

r

E

m

i

t

t

e

d

,

(

W

)

Volumetric Flow Rate,(Vh), m/s

Graph of Power Emitted,(W) vs Volumetric Flow

Rate,(m/s)

Parallel flow

Counter flow

0

200

400

600

800

1000

1200

1400

1600

1800

0 500 1000 1500 2000 2500 3000 3500 4000 4500

P

o

w

e

r

A

b

s

o

r

b

e

d

,

(

W

)

Volumetric Flow Rate,(Vh), m/s

Graph of Power Absorbed,(W) vs Volumetric Flow

Rate,(m/s)

Parallel flow

Counter flow

Figure 13: Graph 1

Figure 14: Graph 2

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 21

-200

-150

-100

-50

0

50

100

150

0 500 1000 1500 2000 2500 3000 3500 4000 4500

P

o

w

e

r

A

b

s

o

r

b

e

d

,

(

W

)

Volumetric Flow Rate,(Vh), m/s

Graph of Power Absorbed,(W) vs Volumetric Flow

Rate,(m/s)

Parallel flow

Counter flow

0

20

40

60

80

100

120

140

160

180

200

0 500 1000 1500 2000 2500 3000 3500 4000 4500

E

f

f

i

c

i

e

n

c

y

,

(

%

)

Volumetric Flow Rate,(Vh), m/s

Graph of Efficiency,(%) vs Volumetric Flow

Rate,(m/s)

Parallel flow

Counter flow

Figure 15: Graph 3

Figure 16: Graph 4

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 22

0

5

10

15

20

25

30

0 500 1000 1500 2000 2500 3000 3500 4000 4500

L

o

g

a

r

i

t

h

m

i

c

M

e

a

n

T

e

m

p

e

r

a

t

u

r

e

D

i

f

f

e

r

e

n

c

e

(

m

)

Volumetric Flow Rate,(Vh), m/s

Graph of Logarithmic Mean Temperature vs

Volumetric Flow Rate,(m/s)

Parallel flow

Counter flow

0

200

400

600

800

1000

1200

0 500 1000 1500 2000 2500 3000 3500 4000 4500

O

v

e

r

a

l

l

H

e

a

t

T

r

a

n

s

f

e

r

C

o

e

f

f

i

c

i

e

n

t

(

U

)

Volumetric Flow Rate,(Vh), m/s

Graph of Overall Heat Transfer Coefficient (U)

vs Volumetric Flow Rate,(m/s)

Parallel flow

Counter flow

Figure 17: Graph 5

Figure 18: Graph 6

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 23

8.0 Discussion

This part of report is individually hand written. The result of each member is attched with

this report.

9.0 Conclusion

This part of report is individually hand written. The result of each member is attched with

this report.

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 24

10.0 References

Websites:

1) Car radiator diagram downloaded from :

http://www.northernradiators.co.uk/cms_media/images/250x250_fitbox-

nrg_car_radiators2.jpg [Accessed 18/10/14]

2) Introduction for heat exchanger:

http://www.nzifst.org.nz/unitoperations/httrapps1.htm [Accessed 18/10/14]

3) Heat exchanger applications:

http://www.fivesgroup.com/FivesCryogenie/EN/Expertise/Products/HeatExchangerA

pplications/Pages/Applicationsofheatexchangers.aspx [Accessed 18/10/14]

4) Space heater diagram:

http://sustainability.williams.edu/files/2010/02/space-heater.jpg [Accessed 18/10/14]

Books:

1) Eastop & McConkey, Applied Thermodynamics for Engineering Technologists 5

th

Edition, Prentice Hall, 1993.

2) Yunus A. Vengeland Micheal A. Boles, Thermodynamics An Engineering

Approach,7

th

edition in SI units, 2011 , The McGraw-Hill Companies.

3) Thermodynamics, An Engineering Approach Sixth Edition (SI Units), Yunus A.

Cengel & Michael A. Boles).

THERMODYNAMICS II

CONCENTRIC TUBE HEAT EXCHANGER

EMD5M5A

Page | 25

11.0 Appendices

Potrebbero piacerti anche

- CHAPTER 2 LEFM Edited31Mac2014Documento50 pagineCHAPTER 2 LEFM Edited31Mac2014wandee2393100% (1)

- Discussion and Conclusion For Marcet BoilersDocumento2 pagineDiscussion and Conclusion For Marcet BoilersMasrulIsmail75% (4)

- Full Report A Flow Pass Circular CylinderDocumento21 pagineFull Report A Flow Pass Circular CylinderHaziq Pazli67% (3)

- MEM554 - Thermalfluids Lab Computer Linked RefrigerationDocumento25 pagineMEM554 - Thermalfluids Lab Computer Linked Refrigerationsayabudakcomey75% (12)

- Report Fluid Friction TestDocumento12 pagineReport Fluid Friction TestAbdul Fatah Najmi60% (5)

- Heat Exhanger Individual ReportDocumento16 pagineHeat Exhanger Individual ReportMusa OtoNessuna valutazione finora

- Heat Transfer in Plate Heat Exchangers PDFDocumento64 pagineHeat Transfer in Plate Heat Exchangers PDFmjaric81Nessuna valutazione finora

- Experiment About Air-Conditioning UnitDocumento32 pagineExperiment About Air-Conditioning UnitVerlon Vincent100% (1)

- Heat Exchanger ReportDocumento13 pagineHeat Exchanger ReportGâmãł Äbđuł HäqNessuna valutazione finora

- Heat Exchanger Lab ReportDocumento15 pagineHeat Exchanger Lab ReportOmar Samir100% (1)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersDa EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersValutazione: 4 su 5 stelle4/5 (13)

- Oracle Mid Exam Sem 1Documento2 pagineOracle Mid Exam Sem 1Ardie Gucci100% (1)

- Converge&Diverge Lab ReportDocumento28 pagineConverge&Diverge Lab ReportIrfan Syafiq40% (5)

- CH 02 - Intro To HVAC SystemsDocumento38 pagineCH 02 - Intro To HVAC Systemswandee2393Nessuna valutazione finora

- Lab Report Shell &tube Heat ExchangerDocumento27 pagineLab Report Shell &tube Heat Exchangerfahmirased67% (3)

- LS2 - Variation in Refrigeration Coefficient of Performance at Various Operating ConditionsDocumento7 pagineLS2 - Variation in Refrigeration Coefficient of Performance at Various Operating ConditionsFaez Feakry100% (1)

- Drag Force in Flow Over A BodyDocumento11 pagineDrag Force in Flow Over A Bodyamin67% (3)

- PLAN UPDATE 2020 r1Documento101 paginePLAN UPDATE 2020 r1David SusantoNessuna valutazione finora

- Natural and Force Convection Lab ReportDocumento43 pagineNatural and Force Convection Lab Reportloqmannazli100% (1)

- Drag Force Full ReportDocumento29 pagineDrag Force Full ReportAbdul RahmanNessuna valutazione finora

- Lab 5 Heat ExchangerDocumento13 pagineLab 5 Heat ExchangerNur Syuhaidah100% (1)

- Air CondDocumento34 pagineAir CondAmir Aiman67% (6)

- Transport Lab Report Experiment 3Documento18 pagineTransport Lab Report Experiment 3nurul nabilah bt khairul anuar100% (2)

- Lab Report of Heat ExchangerDocumento8 pagineLab Report of Heat ExchangerSalam Albaradie100% (7)

- T10 (Muhammad Syakir Bin Rosdi Ad200104)Documento9 pagineT10 (Muhammad Syakir Bin Rosdi Ad200104)Munib khanNessuna valutazione finora

- BETA-2 Pancake Geiger TubeDocumento4 pagineBETA-2 Pancake Geiger TubeqqazertyNessuna valutazione finora

- Data Loss PreventionDocumento24 pagineData Loss PreventionhelmaaroufiNessuna valutazione finora

- Refrigeration Lab CompleteDocumento17 pagineRefrigeration Lab CompleteSyahirzabidiNessuna valutazione finora

- FConvert Free YouTube Converter Downloader Convert To MP3, MP4Documento2 pagineFConvert Free YouTube Converter Downloader Convert To MP3, MP4FConvert Free YouTube ConverterNessuna valutazione finora

- Concentric Tube Heat Exchanger Lab ReportDocumento22 pagineConcentric Tube Heat Exchanger Lab Reportizham hakimi50% (6)

- Table of Content: Lab Report SOLTEQ Concentric Tube Heat Exchanger Unit (HE:104-PD)Documento46 pagineTable of Content: Lab Report SOLTEQ Concentric Tube Heat Exchanger Unit (HE:104-PD)iwe1234100% (2)

- Tubular Heat Exchanger Lab ReportDocumento21 pagineTubular Heat Exchanger Lab ReportMuhammad Zafrulhafiz80% (5)

- Compressible Flow in A Convergent - Divergent NozzleDocumento10 pagineCompressible Flow in A Convergent - Divergent NozzleNeville Lawless75% (8)

- Heat Exchanger Lab ReportDocumento5 pagineHeat Exchanger Lab ReportRam Krishna Singh79% (29)

- Ballastless TracksDocumento20 pagineBallastless TracksYacoub Cheikh67% (3)

- Heat Pump (Lab Report) - 2 CompleteDocumento14 pagineHeat Pump (Lab Report) - 2 CompleteNova April57% (7)

- Refrigeration LabDocumento16 pagineRefrigeration LabFaizal IbrahimNessuna valutazione finora

- CompressibleDocumento27 pagineCompressiblezulfarizan100% (1)

- Lab Heat ExchangerDocumento16 pagineLab Heat Exchangerbaiti_atiqah86% (7)

- LAB 3 Drag Force Flow Over A Body ReportDocumento26 pagineLAB 3 Drag Force Flow Over A Body Report000Nessuna valutazione finora

- Heat ExchangerDocumento21 pagineHeat ExchangersedamyrulNessuna valutazione finora

- Concentric Tube Heat Exchanger ReportDocumento19 pagineConcentric Tube Heat Exchanger Reportillyzl100% (1)

- Flow Pass A Circular CylinderDocumento3 pagineFlow Pass A Circular CylinderAdry AqilNessuna valutazione finora

- Performance of Pumps 2015Documento16 paginePerformance of Pumps 2015Aman Redha0% (1)

- Faculty of Mechanical Engineering Thermafluid Lab (Mec 554)Documento14 pagineFaculty of Mechanical Engineering Thermafluid Lab (Mec 554)muhdhanisuitmNessuna valutazione finora

- Concentric Tube Heat ExchangerDocumento19 pagineConcentric Tube Heat ExchangerBen Widdowson100% (2)

- Lab Manual Thermodynamics Nozzle EfficiencyDocumento6 pagineLab Manual Thermodynamics Nozzle EfficiencyMuhammad Firdaws0% (2)

- Heat Pump LabDocumento2 pagineHeat Pump LabJeremy Tay0% (2)

- Boiler Lab ReportDocumento6 pagineBoiler Lab ReportYomal Wijesinghe0% (2)

- Program: Bachelor of Engineering (Hons) Mechanical Course: Thermalfluids Lab Code: MEC 554Documento7 pagineProgram: Bachelor of Engineering (Hons) Mechanical Course: Thermalfluids Lab Code: MEC 554NHNessuna valutazione finora

- Drag Force in Flow Over A BodyDocumento21 pagineDrag Force in Flow Over A BodyHazril Lifebooks100% (12)

- Thermal Conductivity of Liquid & GasesDocumento8 pagineThermal Conductivity of Liquid & Gases078614196486% (7)

- Energy BalanceDocumento16 pagineEnergy BalancewizlanNessuna valutazione finora

- Lab Report Performance of A Steam Plant LatestDocumento16 pagineLab Report Performance of A Steam Plant LatestM Asrar SidonNessuna valutazione finora

- RESULT Conclusion and Discussion LAB 7Documento11 pagineRESULT Conclusion and Discussion LAB 7Fiena Azmi50% (2)

- Lab Convection ForcedDocumento5 pagineLab Convection ForcedFarid Adnan100% (1)

- Properties Measurement PVT ManuscriptDocumento5 pagineProperties Measurement PVT ManuscriptAtqh AzmnNessuna valutazione finora

- Transport Lab Report Experiment 2Documento16 pagineTransport Lab Report Experiment 2faranimohamed75% (4)

- Exp 6 Free & Forced Convection Heat ExchangerDocumento19 pagineExp 6 Free & Forced Convection Heat ExchangerGriezmann Haziq50% (2)

- Lab Compresible Flow.Documento17 pagineLab Compresible Flow.AlifZaidi100% (1)

- Drag Force ReportDocumento15 pagineDrag Force Reportwandee2393100% (1)

- BK16110252 - Experiment V1 - KM31401-1718-II - REPORTDocumento6 pagineBK16110252 - Experiment V1 - KM31401-1718-II - REPORThasmikaNessuna valutazione finora

- Heat ExchangerDocumento33 pagineHeat ExchangerIbrahim DanladiNessuna valutazione finora

- Nidalmarwanadelexchanger 150103071855 Conversion Gate02Documento68 pagineNidalmarwanadelexchanger 150103071855 Conversion Gate02Vijay MajumdarNessuna valutazione finora

- F2 DP 2015 Ayas Mehmet MASTER THESIS - PdfinalcorrectionDocumento66 pagineF2 DP 2015 Ayas Mehmet MASTER THESIS - PdfinalcorrectionSyed YousufuddinNessuna valutazione finora

- Experimental Investigations On A Compact Heat Exchanger and Optimization Using Taguchi TechniqueDocumento7 pagineExperimental Investigations On A Compact Heat Exchanger and Optimization Using Taguchi TechniqueesatjournalsNessuna valutazione finora

- An-Najah National University Faculty of Engineering Chemical Engineering DepartmentDocumento64 pagineAn-Najah National University Faculty of Engineering Chemical Engineering Departmentريم تكروريNessuna valutazione finora

- Design of An Interrupted-Plate Heat Exchanger Used in A Liquid-PistonDocumento11 pagineDesign of An Interrupted-Plate Heat Exchanger Used in A Liquid-PistonparamopedroNessuna valutazione finora

- Report 4Documento4 pagineReport 4wandee2393Nessuna valutazione finora

- Report 2Documento4 pagineReport 2wandee2393Nessuna valutazione finora

- Report 2Documento4 pagineReport 2wandee2393Nessuna valutazione finora

- Seminar Summary: Title Lecturer Date/Place Organizer Confirmation of Attendance Contents Summary Hot ForgingDocumento4 pagineSeminar Summary: Title Lecturer Date/Place Organizer Confirmation of Attendance Contents Summary Hot Forgingwandee2393Nessuna valutazione finora

- Seminar Summary: Title Lecturer Date/Place Organizer Confirmation of Attendance Contents Summary Hot ForgingDocumento4 pagineSeminar Summary: Title Lecturer Date/Place Organizer Confirmation of Attendance Contents Summary Hot Forgingwandee2393Nessuna valutazione finora

- Seminar Summary: Title Lecturer Date/Place Organizer Confirmation of Attendance Contents Summary Composite TechnologyDocumento4 pagineSeminar Summary: Title Lecturer Date/Place Organizer Confirmation of Attendance Contents Summary Composite Technologywandee2393Nessuna valutazione finora

- 2.math VectorDocumento80 pagine2.math Vectorwandee2393Nessuna valutazione finora

- Seminar Summary: Title Lecturer Date/Place Organizer Confirmation of Attendance Contents Summary Hot ForgingDocumento4 pagineSeminar Summary: Title Lecturer Date/Place Organizer Confirmation of Attendance Contents Summary Hot Forgingwandee2393Nessuna valutazione finora

- 3.0 Findings: 3.1 Profile of The RespondentsDocumento10 pagine3.0 Findings: 3.1 Profile of The Respondentswandee2393Nessuna valutazione finora

- CH 05 - Cooling Load Estimation PDFDocumento45 pagineCH 05 - Cooling Load Estimation PDFwandee2393Nessuna valutazione finora

- KOREAN CultureDocumento6 pagineKOREAN Culturewandee2393Nessuna valutazione finora

- QuestionnaireDocumento4 pagineQuestionnairewandee2393Nessuna valutazione finora

- RecommendationsDocumento1 paginaRecommendationswandee2393Nessuna valutazione finora

- Refrigeration SystemDocumento26 pagineRefrigeration Systemwandee2393Nessuna valutazione finora

- Control ActionDocumento11 pagineControl Actionwandee2393Nessuna valutazione finora

- Chapter 5 FCP (10jun2014)Documento19 pagineChapter 5 FCP (10jun2014)wandee2393Nessuna valutazione finora

- Full Report - ENTDocumento45 pagineFull Report - ENTwandee239383% (6)

- CH 03 - Pshychrometry PDFDocumento18 pagineCH 03 - Pshychrometry PDFwandee2393Nessuna valutazione finora

- Chapter 4 EpfmDocumento23 pagineChapter 4 Epfmwandee2393Nessuna valutazione finora

- Complete AllDocumento17 pagineComplete Allwandee2393Nessuna valutazione finora

- CHAPTER 3 SmallScaleYieldingDocumento15 pagineCHAPTER 3 SmallScaleYieldingNaimi AzizNessuna valutazione finora

- BEL - Shophaholic ContentsDocumento24 pagineBEL - Shophaholic Contentswandee2393Nessuna valutazione finora

- Heat ExchangerDocumento25 pagineHeat Exchangerwandee2393Nessuna valutazione finora

- ProfessionalismDocumento51 pagineProfessionalismwandee2393100% (1)

- 3.0 Findings: 3.1 Profile of The RespondentsDocumento10 pagine3.0 Findings: 3.1 Profile of The Respondentswandee2393Nessuna valutazione finora

- QuestionnaireDocumento4 pagineQuestionnairewandee2393Nessuna valutazione finora

- Exercise State Space Representation (TDOF)Documento17 pagineExercise State Space Representation (TDOF)wandee2393Nessuna valutazione finora

- ProfessionalismDocumento12 pagineProfessionalismwandee2393Nessuna valutazione finora

- 7-67-0012 Rev 3 Short Sliding Support On ExistingDocumento1 pagina7-67-0012 Rev 3 Short Sliding Support On Existingprince jaswalNessuna valutazione finora

- Cascaded Transformers:: Figure 1.basic 3 Stage Cascaded TransformerDocumento3 pagineCascaded Transformers:: Figure 1.basic 3 Stage Cascaded TransformeryugendraraoknNessuna valutazione finora

- Activities Pm.Documento13 pagineActivities Pm.jona llamasNessuna valutazione finora

- Electoral ListDocumento189 pagineElectoral ListAhmadShazebAzharNessuna valutazione finora

- Capr-I En229Documento13 pagineCapr-I En229Anonymous WglGv0GNessuna valutazione finora

- Fifths emDocumento5 pagineFifths emcoolguy19895Nessuna valutazione finora

- Classifications of KeysDocumento13 pagineClassifications of KeyssyampnaiduNessuna valutazione finora

- Fopid Controller and It's ApplicationDocumento6 pagineFopid Controller and It's Applicationshreeja dasguptaNessuna valutazione finora

- Eletrical Motor OffshoreDocumento38 pagineEletrical Motor OffshoreandreisraelNessuna valutazione finora

- CCS Week 4 CBLMDocumento6 pagineCCS Week 4 CBLMethel roseNessuna valutazione finora

- Dual-Phase, Quick-PWM Controllers For IMVP-IV CPU Core Power SuppliesDocumento45 pagineDual-Phase, Quick-PWM Controllers For IMVP-IV CPU Core Power Supplieslucian1961Nessuna valutazione finora

- 2015 - Catalog - ABB Cable Accessories 12-42 KV - English - CSE-A FamilyDocumento12 pagine2015 - Catalog - ABB Cable Accessories 12-42 KV - English - CSE-A FamilyAnonymous oKr1c2WNessuna valutazione finora

- Cebu Technological University: Republic of The PhilippinesDocumento2 pagineCebu Technological University: Republic of The PhilippinesEngelbert RespuestoNessuna valutazione finora

- CATIA Cloud of PointsDocumento141 pagineCATIA Cloud of Points4953049530100% (1)

- 01 - Motor Protection Circuit Breakers - 01 - 20 PDFDocumento20 pagine01 - Motor Protection Circuit Breakers - 01 - 20 PDFMostafa ShannaNessuna valutazione finora

- Alternator LSA42.3j enDocumento12 pagineAlternator LSA42.3j enArdi Wiranata PermadiNessuna valutazione finora

- F 1069 - 87 R99 - Rjewnjk - PDFDocumento6 pagineF 1069 - 87 R99 - Rjewnjk - PDFRománBarciaVazquezNessuna valutazione finora

- ME8595 SyllabusDocumento1 paginaME8595 SyllabusDeepak sakthiNessuna valutazione finora

- Scarabeo 200 I e 0910Documento66 pagineScarabeo 200 I e 0910ΧΑΡΑΛΑΜΠΟΣΣΕΛΙΜΗΣNessuna valutazione finora

- Fluid MechDocumento2 pagineFluid MechJade Kristine CaleNessuna valutazione finora

- 1 Input Data: Profis Anchor 2.8.1Documento7 pagine1 Input Data: Profis Anchor 2.8.1Manu MohanNessuna valutazione finora

- Angoca Db2 Cheat Sheet For DevelopmentDocumento3 pagineAngoca Db2 Cheat Sheet For DevelopmentTanveer AhmedNessuna valutazione finora

- Ad-All Ss Pressure GaugeDocumento5 pagineAd-All Ss Pressure Gaugepankaj doshiNessuna valutazione finora

- Criterion 6 Facilities and Technical Support 80: With Computer Systems GCC and JDK SoftwareDocumento6 pagineCriterion 6 Facilities and Technical Support 80: With Computer Systems GCC and JDK SoftwareVinaya Babu MNessuna valutazione finora