Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SLBP Skid Modification

Caricato da

HaleemUrRashidBangashDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SLBP Skid Modification

Caricato da

HaleemUrRashidBangashCopyright:

Formati disponibili

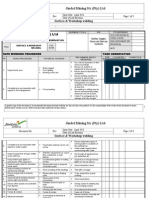

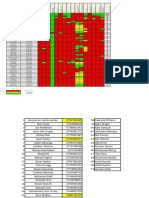

JOB SAFETY ANALYSIS RECORD SHEET

PLANT / EQUIPMENT #

SLBP

DEPARTMENT: CRDD DATE: January 8, 2013

DIVISION\Unit:NRBP/TLR JSA NO.:

ROUTINE JSA NON ROUTINE JSA

Description of job / task:

Skid Modification At Sulayyil Bulk Plant.

Prepared By Reviewed By Approved By

Haleem Ur Rashid Bangash

(Safety Engineer)

Hadi Hammad Al- Hammam Group

Dhafar S. Al-Dossary

References:

GI 2.100 Work Permit System, GI 8.001 Safety Requirements For Scaffolds, Saudi Aramco Scaffold Hand

Book, GI. 6.012 ISOLATION, LOCKOUT AND USE OF HOLD TAGS,G.I. 02.709 Gas Testing Procedure,

G.I. 07.028 Crane Lifts, Types and Procedures

Safety Equipment Required:

Employee is required to wear PPE, Including helmet, safety glasses, hearing protection,Proper gloves, Safety

shoes and FRC, Testing equipment.

Job

Step

#

Sequence of Basic Job

Steps

Potential Hazards Required Hazard Control

1

Job site evaluation, hazard

recognition and

precautions.

Obtain work permit,

- Unsafe (job site) work

condition might pose

hazard.

- Work permit procedure

violation

- Certified work permit issuer and

receiver will conduct joint site

inspection, find out the hazards and

build proper precautions for it.

- Provide and sign Crane critical lift plan

Form SA 9644 (07/07), and crane

operator daily inspection checklist

(03/05) during permit

- Submit welding procedure and keep

one copy at the site

- Use Flagman throughout the job period

wherever necessary.

- Install barricades and warning signs.

- Keep the job site clean

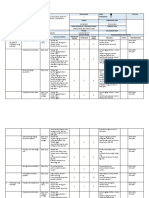

2

Erecting the scaffold

- Scaffold errection related

hazards

- Utilize certified scaffold supervisor

- During erecting only scaffold erection

crew is allowed on the scaffold.

- When the scaffold is completed install

the appropriate tag dully signed by the

scaffold supervisor or supervisor and

inspector per GI 8.001 Safety

Requirements For Scaffolds and Saudi

Aramco Scaffold Hand Book.

- Ensure the scaffold is of appropriate

duty and maintains safely throughout

the job period

- Provide completed Scaffold inspection

checklist dully signed if required.

- Install the ladders for access at each

access as required.

- Dont use damage scaffold

components.

- Install guard rail system and toe boards.

- Scaffolds turn over

- Pesonel injury and falling

- Fire Hazards

- Ensure the base plates residing on firm

ground

- Inspect and Use full body safety

harness and secure it with anchor point

while working on scaffold.

- Use braces for scaffold rigidity/ and

support against collapse.

- Do not work on the scaffold at rain, wind

and dusty conditions.

- Inspect the scaffold after rain, wind and

dusty conditions

- Fastened the components tighetly and

correctly before lifting anything.

- Secure the pulling devices if used from

the scaffold.

- Use ropes and tool box while lifting

something on scaffold.

- Install and tightened all connections

properly.

- Get support while pulling

- Use buddy system while lifting the

planks or tube to the height.

- Use proper base plates for the posts.

- Install proper braces at required

location.

- Use proper PPEs and tools

- Avoid shortcuts

- Isolate the area and install barricades

and warning signs

- Only authorized persons are allowed at

site.

- Dont stay under bussy scaffold

- Use Full body safety harness (FBSH,

PFAS) with shock absorbing lanayards

while working on scaffold

- Tie the PFAS to a rigid and proper

support

- Don not hook it to conduits and facility

pipes or others except rigid platforms

- As per 4 of the JSA and,

- Avoid colliding the scaffold tube to

prevent any spark/ignition, lift up/down

the tubes calmly and safely.

3

Drainin the Product line

- Product spill

- Utilize, ISOALTE, LOCK AND HOLD

OF TAG procedure per GI. 6.02

- Isolate the line from nearest possible

isolation locations from both the ends

USE ONE OF THE FOLLOWING

METHODS FOR DRAIN.

1. (if sucking tanker is not reachable)

- Drain the line into sump pit from a

- Fire hazard

- Respiratory problem

Drain/vent valve using proper size

nipple hose and clamps.

- Drain until the pressure is zero or

minimal and then try a from a flange to

bring the pressure to zero

- For more product drain from multiple

locations at the same time if possible

and safe

- Keep mixing water with the draining

product to lower its flammability and

keep it cool.

2. (when sucking tanker is reachable)

- Provide vacume /sucking tanker at site

- Drain the line from lowest position

easily available for Vacume tanker

Possibly at Pump shelter near Road

crossing # 4

- Ground the vacumme tanker

- Use cut-piece of drum to accumulate

the product spill.

- Drain until the pressure is zero

- Keep mixing water with the draining

product to lower its flammability and

keep it cool.

- As per 4 and of the JSA,

- Purge the line with nitrogen gas or

water wash from a comparative high

position to remove the flammable

product and gas to the air.

- Purge or wash until the gas tester

shows zero reading

- During drain toxic gas will release, so

wear proper respiratory protection all

the time of drian and sucking

4

Cold Cutting / Removal of

spool

- Fire hazard

- Only cold cut the line and use proper

solution for the smooth cutting

operation of the cutter.

- Don not start cutting until it is drained

completely to zero state

- Use only BRASS HAMMER to loose the

bolts, if required

- Soon after cutting, purging/water

washing fix Mechanical / Ballon

stoppers with specific putty type mud to

avoid any possible release to vapors.

- During all hot works, grinding and

welding operation conduct gas test

more frequently to avoid any disaster

- The tester must read zero for

flammable gases, otherwise stop any

hot work until the it reaches to zero

- Switch off mobile phones and other

sources of ignition

- Remove any flammables, combustibles

- Falling and damage to

the pipe Spool

- Drain and Product spill

- Pesonel injury and falling

and oxidizing agents from the site

- Utilize proper fire extinguishers, trained

fire watch and standby man on the site

- Use diesel operating engines only

- Ground all the power operating and

generating equipments..

- Provide critical lift plan as per G.I.

07.028 Crane Lifts, Types and

Procedures and Form SA 9644

- Use certified crane operator and rigger

to lift up/down the spool.

- Inspect the ropes/belts before use

- Use tag line to control and balance the

load and avoid the damage to any part

of facility.

- Don not cut the 4 line until it is properly

tied/support from both the ends with

rigidly supported and load rated chaing

pullys or ropes to avoid its fall down

- If not applicable utilize other acceptable

and safe method.

- As per 3 of the JSA and

- During cutting some minior drain/spill

may occur, so keep some cut piece of

drum or can down side the cutting area

to avoid any spill.

- As per 2 of the JSA

5

Welding / Fabricating of

flanges

- Fire hazard

- As per 4 of the JSA and

- Double check the mechanical /ballon

stopper and Water spray all the area to

cool it down before starting hot work

- Dont Conduct welding and fabrication

activity until the pipe is completely

drained / purged and water washed.

- Ground the generator and welding

machines properly.

- Confine the area remove all

flammables, combustibles and oxidizing

agents from the site

- Use 110V or diesel tools only

- Cover any severs / pits within 75 ft.

- Use fire blanket if necessary.

- Use correct voltage for devices.

- Use splice free electrical cords and

extensions with three prong outlets and

inlets.

- Check the weather is compatible for the

operation, otherwise confine the area.

- Ensure the pipe is free of any

flammables and other contaiminants.

- Use appropriate voltage 110V and fire

proof tools for the mechanical tests

6

Installation of the spools

and Tee.

- Falling and damage to

the pipe Spool and Tee.

- Personel Injury and falling

- Fire hazard

- Use proper lifting techniques

- Use certified crane operator and rigger

to lift up the spool

- Use tag line to control and balance the

load and avoid the damage to any part

of facility.

- Inspect the ropes/belts before use

- Use brass hammer only if required

- As per 2 of JSA

- As per 4 of JSA

7

Dismantling the scaffold

- Pesonel injury and falling

- Fire hazard

- Scaffold turn-over

- As per 2 of the JSA

- As per 4 of the JSA

- As per 2 of the JSA

- Remove the braces at proper time when

needed, otherwise remove it at the end.

8

Restore the system and

clean the site.

- Work permit procedure

violation

- If the area is not cleaned

properly some hazard

may exist to harm.

- Check the area thoroughly and do the

housekeeping,

- Remove all the tools and equipments

- Double check that the area is restored

to healthy and safe condition.

Potrebbero piacerti anche

- Scaffold Erection Procedure GuidelinesDocumento8 pagineScaffold Erection Procedure GuidelinesMohamed AdelNessuna valutazione finora

- Job Safety AnalysisDocumento1 paginaJob Safety AnalysisWati KaNessuna valutazione finora

- Job Safety Analysis - Doc With Penumatic TestingDocumento5 pagineJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- Daily TBT Attendance Record 4Documento1 paginaDaily TBT Attendance Record 4Mobin Thomas AbrahamNessuna valutazione finora

- Ehv SWP Form Lifting Lowering Operation PDF NewDocumento3 pagineEhv SWP Form Lifting Lowering Operation PDF NewSn AhsanNessuna valutazione finora

- JSA Formet New Structural Steel FabricationDocumento7 pagineJSA Formet New Structural Steel Fabricationsakthi venkatNessuna valutazione finora

- DES PRL K.K JSA 001: Coating and Raping Activity in Side and Out Side TankDocumento7 pagineDES PRL K.K JSA 001: Coating and Raping Activity in Side and Out Side TankPerwez21Nessuna valutazione finora

- Safety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksDocumento1 paginaSafety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksRísês ÃfrözNessuna valutazione finora

- Nail Gun Pnuematic Work Method Statement SWMS V8Documento5 pagineNail Gun Pnuematic Work Method Statement SWMS V8ferny.51Nessuna valutazione finora

- Checklist For Generator SetDocumento1 paginaChecklist For Generator SetKrsna ManahanNessuna valutazione finora

- Permit To Work EOH-SP-FORM 531.01Documento2 paginePermit To Work EOH-SP-FORM 531.01Brad EubankNessuna valutazione finora

- Job Safety Analysis Risk Summary SheetDocumento10 pagineJob Safety Analysis Risk Summary SheetMohammad Fazal KhanNessuna valutazione finora

- Jsa FormDocumento3 pagineJsa Formmiaicarba100% (1)

- Appendix A-Job Safety Analysis FormDocumento3 pagineAppendix A-Job Safety Analysis Formjiks_i4uNessuna valutazione finora

- Wire Brush Safety InstructionsDocumento2 pagineWire Brush Safety InstructionsMohamed FaroukNessuna valutazione finora

- PPE Issue ReordDocumento1 paginaPPE Issue ReordHuman ResourcesNessuna valutazione finora

- Argon Welding SafetyDocumento2 pagineArgon Welding SafetyRonald_Bauer4190Nessuna valutazione finora

- Cold Work PermitDocumento11 pagineCold Work PermitMuneeb Ur Rehman100% (1)

- SWP Welder Gas Metal Arc AS560Documento2 pagineSWP Welder Gas Metal Arc AS560Amirul Haris100% (1)

- Proper and Safe Use of Scissor LiftDocumento3 pagineProper and Safe Use of Scissor LiftFajrin M. NatsirNessuna valutazione finora

- Magna Bend SopDocumento1 paginaMagna Bend SopClarkKent Fabro Batucan0% (1)

- EHSWP004 - Hot Work Permit PDFDocumento2 pagineEHSWP004 - Hot Work Permit PDFRand raiNessuna valutazione finora

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocumento2 pagineAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640Nessuna valutazione finora

- General Safety Inspection ChecklistDocumento1 paginaGeneral Safety Inspection ChecklistAyşe BalamirNessuna valutazione finora

- Hydraulic Press ProcedureDocumento2 pagineHydraulic Press ProcedureARMANNessuna valutazione finora

- Welding, Cutting and Hot WorkDocumento6 pagineWelding, Cutting and Hot WorkyahiyaNessuna valutazione finora

- SP-091-C CNC Router SOPDocumento1 paginaSP-091-C CNC Router SOPBorislav VulićNessuna valutazione finora

- Jsa Welding Diesel PipelineDocumento3 pagineJsa Welding Diesel PipelineHow Chin Engineering Sdn BhdNessuna valutazione finora

- Safety FileDocumento1 paginaSafety FileSaikat RamNessuna valutazione finora

- Cutting Torch InstructionDocumento2 pagineCutting Torch Instructionfoxtrot mikeNessuna valutazione finora

- Ladders SopDocumento0 pagineLadders SopEzhil Vendhan PalanisamyNessuna valutazione finora

- Safety Questions For ExaminationDocumento1 paginaSafety Questions For ExaminationAkeem Dwayne Ralph NoelNessuna valutazione finora

- Job Safety Analysis FormDocumento4 pagineJob Safety Analysis FormM.Dimas PrakosoNessuna valutazione finora

- Work Instruction - Welding MCDocumento3 pagineWork Instruction - Welding MCManoj Kt100% (1)

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Documento3 pagineJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNessuna valutazione finora

- JHA Arc WeldingDocumento2 pagineJHA Arc WeldingechaNessuna valutazione finora

- Aeropod Hse Alert - 2014-Finger InjuryDocumento2 pagineAeropod Hse Alert - 2014-Finger InjuryMartin Kenson100% (1)

- Required Documents For ISO 45001 ImplementationDocumento3 pagineRequired Documents For ISO 45001 ImplementationTaufik DolphinNessuna valutazione finora

- JOB SAFETY PLAN Replacement of CylinderDocumento2 pagineJOB SAFETY PLAN Replacement of CylinderMaxi ProNessuna valutazione finora

- Milling MachineDocumento1 paginaMilling MachineJeannie TimothyNessuna valutazione finora

- 704 Area Vehicle Entry ProcedureDocumento11 pagine704 Area Vehicle Entry ProcedureObominuru Egwonor FestusNessuna valutazione finora

- Annex A - Safety Walk Report FormDocumento4 pagineAnnex A - Safety Walk Report FormwvolpeNessuna valutazione finora

- Permit To DigDocumento3 paginePermit To DigMarco DonatiNessuna valutazione finora

- Work Height Check List NewDocumento2 pagineWork Height Check List NewMussadiq RehmanNessuna valutazione finora

- Oxy Acetylene Cutting TorchDocumento2 pagineOxy Acetylene Cutting TorchChristian Makande100% (1)

- JSA For Purging NitrogenDocumento1 paginaJSA For Purging Nitrogenlina ekawati100% (1)

- JSA-01 WeldingDocumento7 pagineJSA-01 WeldingAlfian Novialdi LaksonoNessuna valutazione finora

- Hot Work PermitDocumento1 paginaHot Work PermitKlyneRamirezNessuna valutazione finora

- JSA Steel Truss Erection and CladdingDocumento4 pagineJSA Steel Truss Erection and CladdingCherry BetonioNessuna valutazione finora

- HIRADC Installation PipeDocumento4 pagineHIRADC Installation PipeamizanNessuna valutazione finora

- Night Shift Work Inspection ChecklistDocumento1 paginaNight Shift Work Inspection Checklistazer Azer100% (2)

- Fire Prevention PlanDocumento25 pagineFire Prevention PlanEMILYN DEPOLLONessuna valutazione finora

- Scissor Lift ChecklistDocumento1 paginaScissor Lift ChecklistDIBNESH PANDITA100% (1)

- Standard Operating Procedures of Hand and Power Tool SafetyDocumento3 pagineStandard Operating Procedures of Hand and Power Tool Safetysingenaadam100% (1)

- Daily Tool Box MeetingDocumento1 paginaDaily Tool Box MeetingVipul ShankarNessuna valutazione finora

- Method of Statement For SPI366 Pump Sump Cleaning Without Confined Space EntryDocumento5 pagineMethod of Statement For SPI366 Pump Sump Cleaning Without Confined Space EntryKarpana Devi LetchumananNessuna valutazione finora

- 2 JHA On Shot Grit Blasting1Documento3 pagine2 JHA On Shot Grit Blasting1Akhilesh KumarNessuna valutazione finora

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Documento1 paginaBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashNessuna valutazione finora

- BI 10-02133, March 2020, Safety Statistics ReoportDocumento3 pagineBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- BI 10-02133, WEEK 06, Safety Statistics Reoport NDocumento1 paginaBI 10-02133, WEEK 06, Safety Statistics Reoport NHaleemUrRashidBangash100% (1)

- BI 10-02133, March 23 2020, SAFETY STATISTICSDocumento2 pagineBI 10-02133, March 23 2020, SAFETY STATISTICSHaleemUrRashidBangashNessuna valutazione finora

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Documento1 paginaBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashNessuna valutazione finora

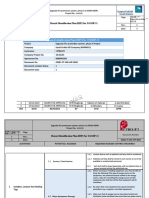

- 20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020Documento27 pagine20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020HaleemUrRashidBangash100% (2)

- 01 Safety Statistics by Haleem Ur Rashid, BI 10-02185Documento3 pagine01 Safety Statistics by Haleem Ur Rashid, BI 10-02185HaleemUrRashidBangashNessuna valutazione finora

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Documento36 pagine5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashNessuna valutazione finora

- BI 10-02133, March 2020, Safety Statistics ReoportDocumento3 pagineBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Documento27 pagineHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNessuna valutazione finora

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDocumento31 pagineHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashNessuna valutazione finora

- 14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020Documento31 pagine14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020HaleemUrRashidBangash100% (1)

- 13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020Documento31 pagine13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020HaleemUrRashidBangashNessuna valutazione finora

- Hazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Documento27 pagineHazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNessuna valutazione finora

- 11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020Documento36 pagine11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020HaleemUrRashidBangashNessuna valutazione finora

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Documento36 pagine4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashNessuna valutazione finora

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Documento36 pagine9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashNessuna valutazione finora

- Haleem Ur Rashid - Lac - QMS - IrcaDocumento1 paginaHaleem Ur Rashid - Lac - QMS - IrcaHaleemUrRashidBangashNessuna valutazione finora

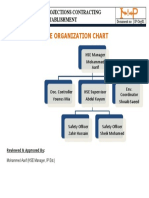

- Hse Organization Chart: Industrial Projections Contracting EstablishmentDocumento1 paginaHse Organization Chart: Industrial Projections Contracting EstablishmentHaleemUrRashidBangash100% (1)

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDocumento31 pagineHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashNessuna valutazione finora

- Fa 1 PDFDocumento1 paginaFa 1 PDFHaleemUrRashidBangashNessuna valutazione finora

- SAOO Safety Orientation Registration Form - PETROJET 03-Mar-20Documento1 paginaSAOO Safety Orientation Registration Form - PETROJET 03-Mar-20HaleemUrRashidBangashNessuna valutazione finora

- Branch of Egyptian Projects Co.: Hse Organization ChartDocumento1 paginaBranch of Egyptian Projects Co.: Hse Organization ChartHaleemUrRashidBangashNessuna valutazione finora

- Hse Organization Chart: Industrial Projections Contracting EstablishmentDocumento1 paginaHse Organization Chart: Industrial Projections Contracting EstablishmentHaleemUrRashidBangash100% (2)

- 60 Training MatrixDocumento4 pagine60 Training MatrixHaleemUrRashidBangashNessuna valutazione finora

- FA BleedingDocumento1 paginaFA BleedingHaleemUrRashidBangashNessuna valutazione finora

- SC-HM910 - HM810 (sm-RQZM0167) PDFDocumento104 pagineSC-HM910 - HM810 (sm-RQZM0167) PDFJory2005Nessuna valutazione finora

- Professional Project ManagementDocumento2 pagineProfessional Project ManagementVirginia Virgie100% (3)

- cm6800 48x8 NewDocumento98 paginecm6800 48x8 Newvijayakumar3661Nessuna valutazione finora

- Karcher Quotation List - 2023Documento12 pagineKarcher Quotation List - 2023veereshmyb28Nessuna valutazione finora

- Hydraulic Backhoe MachineDocumento57 pagineHydraulic Backhoe MachineLokesh SrivastavaNessuna valutazione finora

- C9 Game Guide For VIPsDocumento62 pagineC9 Game Guide For VIPsChrystyanoNessuna valutazione finora

- CeldekDocumento2 pagineCeldekPK SinghNessuna valutazione finora

- Edge Wall Final-ModelDocumento1 paginaEdge Wall Final-ModelAbanoub ShakerNessuna valutazione finora

- Soil-Structure Interaction Effects On The Seismic Response of Low PDFDocumento106 pagineSoil-Structure Interaction Effects On The Seismic Response of Low PDFTariq MahmoodNessuna valutazione finora

- Vibration Isolaton SelectionDocumento24 pagineVibration Isolaton SelectionvelmuruganNessuna valutazione finora

- Tutorial Label MatrixDocumento66 pagineTutorial Label MatrixLuisa Adriana Perez GutierrezNessuna valutazione finora

- Concrete Construction Article PDF - Site Casting Exposed Aggregate WallsDocumento1 paginaConcrete Construction Article PDF - Site Casting Exposed Aggregate WallssonofalexanderNessuna valutazione finora

- 1.1 Iom Miller-Pickingtm Customtm Air Handling Unit (Page 62)Documento84 pagine1.1 Iom Miller-Pickingtm Customtm Air Handling Unit (Page 62)khanh phanNessuna valutazione finora

- Vsphere Esxi Vcenter Server 50 Monitoring Performance GuideDocumento86 pagineVsphere Esxi Vcenter Server 50 Monitoring Performance GuideZeno JegamNessuna valutazione finora

- Vatan Katalog 2014Documento98 pagineVatan Katalog 2014rasko65Nessuna valutazione finora

- Centaour 50 Solar TurbineDocumento2 pagineCentaour 50 Solar TurbineTifano KhristiyantoNessuna valutazione finora

- MSC BMT Excel Spreadsheet For Salmon FisheriesDocumento10 pagineMSC BMT Excel Spreadsheet For Salmon FisheriesYamith.8210hotmail.com PedrozaNessuna valutazione finora

- MKDM Gyan KoshDocumento17 pagineMKDM Gyan KoshSatwik PandaNessuna valutazione finora

- Premium Protection Synthetic Motor Oils (AMO & ARO)Documento2 paginePremium Protection Synthetic Motor Oils (AMO & ARO)brian5786Nessuna valutazione finora

- Applsci 12 02711 v2Documento31 pagineApplsci 12 02711 v2Chandra MouliNessuna valutazione finora

- I.Objectives: Grades 1 To 12 Daily Lesson Log School Grade Level Teacher Learning Area Teaching Dates and Time QuarterDocumento4 pagineI.Objectives: Grades 1 To 12 Daily Lesson Log School Grade Level Teacher Learning Area Teaching Dates and Time QuarterMarryShailaine CletNessuna valutazione finora

- PDFDocumento7 paginePDFJose JohnNessuna valutazione finora

- CV hll3220cw Uke PSGDocumento17 pagineCV hll3220cw Uke PSGczarownikivanovNessuna valutazione finora

- Lutec Katalog PDFDocumento166 pagineLutec Katalog PDFSpeedyNessuna valutazione finora

- ISO9001 2008certDocumento2 pagineISO9001 2008certGina Moron MoronNessuna valutazione finora

- The 'X' Chronicles Newspaper - August 2010Documento50 pagineThe 'X' Chronicles Newspaper - August 2010Rob McConnell100% (1)

- Definition of EbookDocumento14 pagineDefinition of EbookNurul IzzahNessuna valutazione finora

- 797F Off-Highway Truck Transmission System: View A-ADocumento2 pagine797F Off-Highway Truck Transmission System: View A-AramiroNessuna valutazione finora

- Graphics in C LanguageDocumento8 pagineGraphics in C LanguagePattabhi RamaraoNessuna valutazione finora

- Riviera Sponsorship LetterDocumento7 pagineRiviera Sponsorship LetterAnirudh Reddy YalalaNessuna valutazione finora