Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Conplast PA21: Air Entraining and Water Reducing Admixture Formerly Known As Conplast AE21

Caricato da

Tori SmallTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Conplast PA21: Air Entraining and Water Reducing Admixture Formerly Known As Conplast AE21

Caricato da

Tori SmallCopyright:

Formati disponibili

constructive solutions

Page 1

Conpl ast PA21

Ai r ent r ai ni ng and w at er r educ i ng

admi x t ur e f or mer l y k now n as Conpl ast

AE21

Uses

To produce air entrained concrete for increased

durability and resistance to damage by frost and de-

icing salts. Typical applications include concrete roads

and bridge decks, airport runways and taxiways and

other extensive areas of concrete exposed to potential

frost damage

To improve cohesion and workability of concrete mixes

where poorly graded aggregates must be used and

bleeding, segregation or sand runs occur.

To reduce permeability of lean concrete mixes.

To improve stability and cohesion in extruded concrete.

Advant ages

Air entrainment increases the resistance of concrete to

attack by frost and de-icing salts, reducing problems of

surface scaling and concrete failure.

Entrained air bubbles assist in the formation of a stable

cohesive mix, reducing segregation and bleeding.

Air entrainment improves workability and helps produce

a dense, uniform, close textured surface free from

gravel nests and sand runs, further enhancing

durability.

Water reduction allows concrete to be produced with

reduced permeability and increased strength compared

to that obtained with air entrainment alone.

St andar ds c ompl i anc e

Conplast PA21 complies with ASTM C260 and C494 Type

A, and with the uniformity and air entrainment requirements

of BS5075 Part 2.

Conplast PA21 complies with the requirements of the United

Kingdom Water Fittings Byelaws Scheme and is listed in the

Directory of Materials as suitable for use in contact with

potable water under its previous name, Conplast AE21.

Desc r i pt i on

Conplast PA21 is a chloride free air entraining admixture

based on selected sugar reduced lignosulphonates and

compatible surface active agents. It is supplied as a brown

solution which instantly disperses in water.

The surface active agents in Conplast PA21 act at the

interface between the mixing water and cement/aggregate

particles to produce microscopic air bubbles, which are

evenly distributed throughout the concrete.

Tec hni c al suppor t

Fosroc provides a technical advisory service for on-site

assistance and advice on mix design, admixture selection,

evaluation trials and dispensing equipment. Technical data

and guidance can be provided for admixtures and other

products for use with fresh and hardened concrete.

Dosage

The optimum dosage of Conplast PA21 to meet specific

requirement must always be determined by trials using the

materials and conditions that will be experienced in use.

The normal dosage range is 0.25 to 0.60 litre per 100 kg of

cementitious material, including PFA, GGBFS and micro-

silica.

Use at other dosages

Dosages outside the normal range quoted above can be

used if necessary and to meet particular mix requirements,

provided that adequate supervision is available.

Compliance with requirements must be assessed through

trial mixes. Contact Fosroc for advice in these cases.

Pr oper t i es

Appearance: Brown liquid

Specific gravity: Typically 1.175 at 20

o

C

Chloride content: Nil to BS5075

Alkali content: Typically less than 5.0 g.

Na

2

O equivalent per litre of

admixture. A fact sheet on

this subject is available.

I nst r uc t i ons f or use

Checking and control

Once a suitable dosage has been selected, particular care

should be taken to ensure consistency of materials used

and mixing and delivery procedures. Variability in the

cleanliness and grading of the aggregates may have

differing effects on the plasticising and air entraining

properties of the admixture. Air content should be checked

regularly by such means as the pressure method described

in BS1881 and ASTM C231.

Factors affecting air entrainment

A number of factors can affect the air entrainment obtained

for a particular dosage of air entraining admixture, some of

which are listed below. The examples given of changes that

these factors may make to a concrete mix should be taken

as guidelines only and the actual effects in any particular

situation confirmed in trials.

Page 2

Conpl ast PA21

constructive solutions

a) Sands of apparently the same grading may have

significantly different effects on the level of air

entrainment, depending on factors such as silt

content, particle size distribution and particle shape.

Where changes in sand source or content must be

made, or where sand varies within the same source, a

careful check must be made on the effects on air

entrainment.

b) Increased cement fineness will tend to increase air

entrainment. Increased cement content will tend to

decrease air content. Changes in cement source and

type may also lead to changes in the admixture

dosage required to obtain a particular air content.

c) The presence of carbon or organic impurities may

reduce the effectiveness of an air entrainer and

require an increased dosage. This will not usually be

a problem but care may be required when using PFA,

certain pigments or lignite bearing sands.

d) Increased concrete temperature will tend to reduce air

entrainment. Typically a rise from 10

o

C to 32

o

C may

halve the level of air. In normal mixing conditions daily

fluctuations will not give significant variations.

e) Variations of mixer type and transit time may change

the level of air entrainment. Small losses may occur

during pumping. These will generally be consistent for

a given set of conditions. High air contents may

significantly reduce pump efficiency over long pump

distances.

f) Normal compacting procedures will not affect air

entrainment. Prolonged vibration should be avoided.

g) Increased dosages may be required at low workability

levels to achieve the required air content.

Compatibility

Conplast PA21 is compatible with other Fosroc admixtures

used in the same concrete mix. All admixtures should be

added to the concrete separately and must not be mixed

together prior to addition. The resultant properties of

concrete containing more than one admixture should be

assessed by trial mixes.

Conplast PA21 is suitable for use with all types of ordinary

Portland cement. Contact Fosroc Technical Service

Department for advice on use with special cements and

blends containing cement replacement materials.

Dispensing

The correct quantity of Conplast PA21 should be measured

by means of a recommended dispenser. The admixture

should then be added to the concrete with the mixing water

to obtain the best results.

Contact the Fosroc Technical Service Department for advice

regarding suitable dispensing equipment and its installation.

Effects of overdosing

An overdose of double the amount of Conplast PA21 will

result in a significant increase in air entrainment, which will

tend to reduce strength. The degree of this effect will

depend on the particular mix design and overdose level.

An increased plasticising effect will also be obtained,

together with an increase in setting time.

Li mi t at i ons

Conplast PA21 is designed to give both water reduction and

air-entraining properties, changing dosage will change both

at the same time. In situations such as where highly

variable aggregates are used and independent control of the

water reducing and air entraining properties is required then

the use of a combination of admixtures is recommended.

Contact Fosroc Technical Service Department for further

advice.

Est i mat i ng - Pac k agi ng

Conplast PA21 is available in drum or bulk supply. For

larger users, storage tanks can be supplied.

St or age

Conplast PA21 has s minimum shelf life of 12 months

provided the temperature is kept within the range of 2

o

C to

50

o

C. Should the temperature of the product fall outside

this range then the Fosroc Technical Service Department

should be contacted for advice.

Freezing point: Approximately 2

o

C.

Pr ec aut i ons

Health and safety

Conplast PA21 does not fall into the hazard classifications

of current regulations (see notes 1 and 2 below). However,

it should not be swallowed or allowed to come into contact

with skin and eyes.

Suitable protective gloves and goggles should be worn.

Splashes on the skin should be removed with water. In

case of contact with eyes rinse immediately with plenty of

water and seek medical advice. If swallowed seek medical

attention immediately Do not induce vomiting.

For further information consult the Material Safety Data

Sheet available for this product.

Fire

Conplast PA21 is water based and non-flammable.

Telephone: +966 2 637 5345 Fax: +966 2 637 5891 email: fosam@fosroc.com

Regi onal Of f i c es

J eddah Sales Office Tel: (02) 608 0999 Fax: (02) 635 3330 Yanbu Tel: (04) 322 4280 Fax: (04) 391 2980

J eddah Showroom Tel: (02) 665 0187 Fax: (02) 667 4844 Makkah Tel: (02) 542 0869 Fax: (02) 542 0869

Riyadh Tel: (01) 482 9303 Fax: (01) 482 7562 Medinah Tel: (04) 845 1767 Fax: (04) 846 3195

Dammam Tel: (03) 814 1282 Fax: (03) 814 1581 J ubail Tel: (03) 362 3904 Fax: (03) 362 3875

Khamis Mushayt Tel: (07) 250 0469 Fax: (07) 250 0469

Registered Office: Industrial Area, Phase 4, Road No. 414, Street No. 407

Fosam Company Li mi t ed

Head Office

Post Box 11081

J eddah - 21453

Saudi Arabia

w w w .f osr oc .c om

Page 3

Conpl ast PA21

FO SA/CONPLAST PA21/05/A

Important note:

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions

for the Supply of Goods and Services, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that

any advice, recommendation, specification of information it may give is accurate and correct, it cannot, because it has no direct

or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the

use of its products, whether or not in accordance with any advice, specification, recommendation of information given by it.

Cleaning and Disposal

Spillages of Conplast PA21 should be absorbed onto sand,

earth or vermiculite and transferred to suitable containers.

Remnants should be hosed down with large quantities of

water.

The disposal of excess or waste material should be carried

out in accordance with local legislation under the guidance

of the local waste regulatory authority.

Addi t i onal i nf or mat i on

Conplast PA21 was previously known as Conplast AE21.

Note 1: CPL regulations 1984 Supply Schedule 1.

Note 2: HSE publication Guidance Note EH40.

* See separate data sheet.

Potrebbero piacerti anche

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsDa EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNessuna valutazione finora

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionDa EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNessuna valutazione finora

- Conplast PA21 (S) : Water Reducing Air Entraining AgentDocumento4 pagineConplast PA21 (S) : Water Reducing Air Entraining AgentVenkata Raju KalidindiNessuna valutazione finora

- Conplast PA21: Constructive SolutionsDocumento3 pagineConplast PA21: Constructive SolutionstalatzahoorNessuna valutazione finora

- Conplast p509Documento3 pagineConplast p509pravi3434Nessuna valutazione finora

- Conplast AEA: Air Entraining AdmixtureDocumento4 pagineConplast AEA: Air Entraining AdmixtureVenkata Raju KalidindiNessuna valutazione finora

- Conplast AE300: Air Entraining AdmixtureDocumento3 pagineConplast AE300: Air Entraining AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast P211: Water Reducing Concrete AdmixtureDocumento4 pagineConplast P211: Water Reducing Concrete AdmixtureMel AdNessuna valutazione finora

- Conplast RP2020: Retarding Water Reducing AdmixtureDocumento2 pagineConplast RP2020: Retarding Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast x421Documento2 pagineConplast x421pravi3434Nessuna valutazione finora

- Conplast RP578: Retarding Water Reducing AdmixtureDocumento3 pagineConplast RP578: Retarding Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast P510M: Water Reducing AdmixtureDocumento2 pagineConplast P510M: Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast: Retarding Water Reducing AdmixtureDocumento4 pagineConplast: Retarding Water Reducing AdmixtureBinoy Sankar SarkerNessuna valutazione finora

- Conplast p510Documento2 pagineConplast p510pravi3434Nessuna valutazione finora

- Conplast RP2000: Retarding Water Reducing AdmixtureDocumento2 pagineConplast RP2000: Retarding Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast SD100 : Mix Improving Admixture For Semi-Dry Concrete Uses Typical DosageDocumento4 pagineConplast SD100 : Mix Improving Admixture For Semi-Dry Concrete Uses Typical Dosagepravi3434Nessuna valutazione finora

- Conplast P509: Water Reducing AdmixtureDocumento2 pagineConplast P509: Water Reducing AdmixtureBalasubramanian Ananth100% (1)

- Conplast SD100: Mix Improving Admixture For Semi-Dry ConcretDocumento3 pagineConplast SD100: Mix Improving Admixture For Semi-Dry ConcretBalasubramanian AnanthNessuna valutazione finora

- Conplast sp337Documento3 pagineConplast sp337pravi3434Nessuna valutazione finora

- Conplast wp20Documento2 pagineConplast wp20pravi3434Nessuna valutazione finora

- Conplast RP264: Retarding Water Reducing AdmixtureDocumento2 pagineConplast RP264: Retarding Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- 1 Brushbond (M)Documento3 pagine1 Brushbond (M)marzuki0202Nessuna valutazione finora

- Conplast Ae300Documento3 pagineConplast Ae300talatzahoorNessuna valutazione finora

- Conplast RP2000 : Retarding Water-Reducing Admixture DosageDocumento2 pagineConplast RP2000 : Retarding Water-Reducing Admixture Dosagepravi3434Nessuna valutazione finora

- Conplast PA211: Water Reducing AdmixtureDocumento2 pagineConplast PA211: Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast SP430 0914Documento4 pagineConplast SP430 0914Vipul AroraNessuna valutazione finora

- Conplast rp264Documento2 pagineConplast rp264pravi3434Nessuna valutazione finora

- Conplast SP423Documento2 pagineConplast SP423Tori SmallNessuna valutazione finora

- Conplast P211Documento4 pagineConplast P211Vipul AroraNessuna valutazione finora

- Conplast SP432MSDocumento2 pagineConplast SP432MSTori Small100% (1)

- Conplast R: Retarding Water Reducing AdmixtureDocumento2 pagineConplast R: Retarding Water Reducing AdmixtureBalasubramanian AnanthNessuna valutazione finora

- Conplast SP360 : High Performance Water Reducing Admixture Uses Technical SupportDocumento4 pagineConplast SP360 : High Performance Water Reducing Admixture Uses Technical Supportpravi3434Nessuna valutazione finora

- Cebex 031: Constructive SolutionsDocumento3 pagineCebex 031: Constructive SolutionsBalasubramanian AnanthNessuna valutazione finora

- Cebex 031Documento4 pagineCebex 031pravi3434Nessuna valutazione finora

- Conplast P211 (J)Documento2 pagineConplast P211 (J)Vipul AroraNessuna valutazione finora

- TechBrief Air Entraining AdmixturesDocumento2 pagineTechBrief Air Entraining AdmixturesgayathriNessuna valutazione finora

- Conplast X421 - DataSheetDocumento2 pagineConplast X421 - DataSheetmido_20067581Nessuna valutazione finora

- Conplast RP200Documento2 pagineConplast RP200thoryamaraghyNessuna valutazione finora

- Conplast SP480Documento2 pagineConplast SP480Tori SmallNessuna valutazione finora

- TDS Conplast AEA India3Documento4 pagineTDS Conplast AEA India3Santosh MhetreNessuna valutazione finora

- Conplast CN : Calcium Nitrite Corrosion Inhibiting AdmixtureDocumento2 pagineConplast CN : Calcium Nitrite Corrosion Inhibiting AdmixtureacarthurNessuna valutazione finora

- Conplast X421ICDocumento2 pagineConplast X421ICMahadeva PrasadNessuna valutazione finora

- Conplast wp400Documento2 pagineConplast wp400Venkata RaoNessuna valutazione finora

- Module 4Documento10 pagineModule 4Fuck YouNessuna valutazione finora

- Conplast SP430Documento2 pagineConplast SP430Tori Small100% (1)

- TDS Conplast SP430 IndiaDocumento2 pagineTDS Conplast SP430 IndiaAnonymous Gb9LeJcINessuna valutazione finora

- Markplast Flow-30 PDFDocumento3 pagineMarkplast Flow-30 PDFNijjal ShresthaNessuna valutazione finora

- Conplast Ae316 PDFDocumento4 pagineConplast Ae316 PDFdipinnediyaparambathNessuna valutazione finora

- Conplast SP431R TDSDocumento2 pagineConplast SP431R TDSBiruckNessuna valutazione finora

- Rec Plast SP120Documento2 pagineRec Plast SP120Hamza RizviNessuna valutazione finora

- Aplast Rp2640: Retarding Water Reducing AdmixtureDocumento4 pagineAplast Rp2640: Retarding Water Reducing Admixturemazen jamalNessuna valutazione finora

- Cebex 305: Constructive SolutionsDocumento4 pagineCebex 305: Constructive SolutionsBalasubramanian AnanthNessuna valutazione finora

- Conplast CN: Calcium Nitrite Corrosion Inhibiting AdmixtureDocumento2 pagineConplast CN: Calcium Nitrite Corrosion Inhibiting AdmixtureVenkata Raju KalidindiNessuna valutazione finora

- Conplast P505: High Performance Water Reducing Admix TureDocumento2 pagineConplast P505: High Performance Water Reducing Admix TureVenkata Raju KalidindiNessuna valutazione finora

- Hanson Portland Limestone Cement Data SheetDocumento2 pagineHanson Portland Limestone Cement Data Sheetyaser666Nessuna valutazione finora

- en-INT - Flocrete SP42.21052012022601Documento2 pagineen-INT - Flocrete SP42.21052012022601Mohammed AlkhateebNessuna valutazione finora

- HK Conplast RP264 2011.2Documento2 pagineHK Conplast RP264 2011.2Marvin WilliamsNessuna valutazione finora

- TDS Conplast SP435 Saudi ArabiaDocumento3 pagineTDS Conplast SP435 Saudi ArabiaEng. Renjith SarmaNessuna valutazione finora

- Conplast P509 PDFDocumento2 pagineConplast P509 PDFgalfar7100% (1)

- Air Entrained ConcreteDocumento3 pagineAir Entrained Concrete7vortex9Nessuna valutazione finora

- Project: JUAYMAH380/230KV BSP: SL No ADocumento4 pagineProject: JUAYMAH380/230KV BSP: SL No ATori SmallNessuna valutazione finora

- Course Book 6Documento19 pagineCourse Book 6Tori SmallNessuna valutazione finora

- S.No Item Description Start Date Finish Date Status As On 02.04.2016 1 Walkway Around BuildingsDocumento2 pagineS.No Item Description Start Date Finish Date Status As On 02.04.2016 1 Walkway Around BuildingsTori SmallNessuna valutazione finora

- Assets List Against File # 23352: Alfanar ConstructionDocumento1 paginaAssets List Against File # 23352: Alfanar ConstructionTori SmallNessuna valutazione finora

- I Site Progress Civil Works: A 380 KV GIS BuildingDocumento3 pagineI Site Progress Civil Works: A 380 KV GIS BuildingTori SmallNessuna valutazione finora

- 230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Documento10 pagine230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Tori SmallNessuna valutazione finora

- Assets List Against File # 17920: Alfanar ConstructionDocumento1 paginaAssets List Against File # 17920: Alfanar ConstructionTori SmallNessuna valutazione finora

- Prism Online QuestionnaireDocumento2 paginePrism Online QuestionnaireTori SmallNessuna valutazione finora

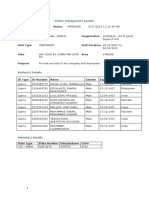

- Request# Status: Visitor Management SystemDocumento1 paginaRequest# Status: Visitor Management SystemTori SmallNessuna valutazione finora

- 7-2-c Form - Gen Consultant PQ Summary Rev-0Documento4 pagine7-2-c Form - Gen Consultant PQ Summary Rev-0Tori SmallNessuna valutazione finora

- Acomplishment Chart 380kVDocumento8 pagineAcomplishment Chart 380kVTori Small100% (1)

- Details of Company Car Expenses (01.12.15)Documento266 pagineDetails of Company Car Expenses (01.12.15)Tori SmallNessuna valutazione finora

- CRC ChecklistDocumento1 paginaCRC ChecklistTori SmallNessuna valutazione finora

- Imam Hussain Sermon at MinaDocumento15 pagineImam Hussain Sermon at MinaTori SmallNessuna valutazione finora

- Expense Sheet: Yasir Nisar Syed Project Engineer (Civil) Khalid AkhterDocumento4 pagineExpense Sheet: Yasir Nisar Syed Project Engineer (Civil) Khalid AkhterTori SmallNessuna valutazione finora

- Main Lab: FT-A-21226 29Y Female SelfDocumento1 paginaMain Lab: FT-A-21226 29Y Female SelfTori SmallNessuna valutazione finora

- Shahrour FreedomDocumento14 pagineShahrour FreedomTori SmallNessuna valutazione finora

- Xi Moisture DiffusivityDocumento9 pagineXi Moisture DiffusivityrudrabirNessuna valutazione finora

- State-Of-The Art Review: Strengthening of Reinforced Concrete Structures - Different Strengthening TechniquesDocumento25 pagineState-Of-The Art Review: Strengthening of Reinforced Concrete Structures - Different Strengthening TechniquesAnika dixitNessuna valutazione finora

- Interview QuestionsDocumento16 pagineInterview QuestionsPavan PatilNessuna valutazione finora

- Ground Slab CourseDocumento36 pagineGround Slab CoursezainalharrisNessuna valutazione finora

- 2021 Austria Optimization of Fly Ash Based Soil Stabilization Using Secondary Admixtures For Sustainable Road ConstructionDocumento14 pagine2021 Austria Optimization of Fly Ash Based Soil Stabilization Using Secondary Admixtures For Sustainable Road Constructionkhodjetelfehm oussamaNessuna valutazione finora

- Chris JoseDocumento183 pagineChris JoseChris Jose ThevermadomNessuna valutazione finora

- Translucent Concrete by Using Optical Fi PDFDocumento3 pagineTranslucent Concrete by Using Optical Fi PDFBidari Putri RosadiNessuna valutazione finora

- Cutting Machine Using Wire SawDocumento10 pagineCutting Machine Using Wire SawMohammad FareedNessuna valutazione finora

- Approval of - Concurewb309-As Concrete Curing CompoundDocumento4 pagineApproval of - Concurewb309-As Concrete Curing Compoundsalman tariqNessuna valutazione finora

- 100-S09influence of Tension Strain On Buckling of Reinforcement in Concrete ColumnsDocumento11 pagine100-S09influence of Tension Strain On Buckling of Reinforcement in Concrete ColumnsshuangyaksaNessuna valutazione finora

- Planning For Project Layout ReportDocumento11 paginePlanning For Project Layout ReportAko C Rence100% (2)

- For Chocking Between Steel & Concrete: Bulletin DescriptionDocumento2 pagineFor Chocking Between Steel & Concrete: Bulletin Descriptionamitparabolicdrugs3Nessuna valutazione finora

- Sika® ViscoCrete® 2100Documento2 pagineSika® ViscoCrete® 2100Ragheb IbrahimNessuna valutazione finora

- Setting Screed Rails For Bridge Deck Paving - tcm45-342826Documento4 pagineSetting Screed Rails For Bridge Deck Paving - tcm45-342826Chewfy1Nessuna valutazione finora

- Study of Compressive Strength of Hollow Sandcrete Blocks Stabilized With Bamboo Leaf AshDocumento4 pagineStudy of Compressive Strength of Hollow Sandcrete Blocks Stabilized With Bamboo Leaf AshVictor OmotoriogunNessuna valutazione finora

- Concrete Road Surface With The Use of Cement Concrete - Selected ResultsDocumento8 pagineConcrete Road Surface With The Use of Cement Concrete - Selected ResultsElber Cuya PillacaNessuna valutazione finora

- Type of Joints in Liquid Retaining StructuresDocumento4 pagineType of Joints in Liquid Retaining StructuresLily100% (2)

- Aci Structural Journal Jan.-Feb. 2015 v. 112 No. 01Documento122 pagineAci Structural Journal Jan.-Feb. 2015 v. 112 No. 01Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (3)

- Shaft LinerDocumento21 pagineShaft LinerAmitNessuna valutazione finora

- 3DCP DanishTechnologicalInstitute NIST 2017Documento13 pagine3DCP DanishTechnologicalInstitute NIST 2017Zarko LazicNessuna valutazione finora

- 444 ProjectDocumento12 pagine444 ProjectRafeeq WazirNessuna valutazione finora

- Case Studies MuseumDocumento12 pagineCase Studies MuseumSunny Sharma100% (1)

- Daily Site Report FormatDocumento10 pagineDaily Site Report FormatAzhar Shaikh0% (1)

- BoQ Unit Price Rekon JORR 2021 (REAL COST) - Rev.02 FINALEDocumento14 pagineBoQ Unit Price Rekon JORR 2021 (REAL COST) - Rev.02 FINALEZulfikar FawziNessuna valutazione finora

- AASHTO - LRFD Bridge Construction Specifications 2017Documento607 pagineAASHTO - LRFD Bridge Construction Specifications 2017Mark El Ramy71% (7)

- Internship Monthly Report 1Documento15 pagineInternship Monthly Report 1Chun LimNessuna valutazione finora

- Korodur Copetti Floor PDFDocumento1 paginaKorodur Copetti Floor PDFIbrahim SahinNessuna valutazione finora

- Sika Waterbar® DWallDocumento2 pagineSika Waterbar® DWalldamithNessuna valutazione finora

- EN 771-5-2011 Plus A1-2015 ABSORÇÃODocumento46 pagineEN 771-5-2011 Plus A1-2015 ABSORÇÃOfabrico20empresaNessuna valutazione finora