Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Benzoic Acid Info

Caricato da

Fighter_ace_97Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Benzoic Acid Info

Caricato da

Fighter_ace_97Copyright:

Formati disponibili

FROM WIKIPEDIA

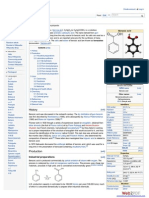

Benzoic acid

From Wikipedia, the free encyclopedia

Benzoic acid

Benzoic acid crystals

IUPAC name[hide]

Benzoic acid

Other names[hide]

Carboxybenzene; E210; Dracylic acid; Phenylmethanoic acid;

Benzenecarboxylic acid

Identifiers

CAS number 65-85-0

PubChem 243

ChemSpider 238

UNII 8SKN0B0MIM

EC number 200-618-2

DrugBank DB03793

KEGG D00038

MeSH benzoic+acid

ChEBI CHEBI:30746

ChEMBL CHEMBL541

RTECS number DG0875000

Beilstein Reference 636131

Gmelin Reference 2946

3DMet B00053

Jmol-3D images Image 1

Image 2

SMILES

[show]

InChI

[show]

Properties

Molecular formula C7H6O2

Molar mass 122.12 g mol

1

Appearance Colorless crystalline solid

Odor faint, pleasant odor

Density 1.2659 g/cm

3

(15 C)

1.0749 g/cm

3

(130 C)

[1]

Melting point 122.41 C (252.34 F; 395.56 K)

[5]

Boiling point 249.2 C (480.6 F; 522.3 K)

[6]

370 C (698 F; 643 K)

decomposes

[1]

Solubility in water 1.7 g/L (0 C)

2.7 g/L (18 C)

3.44 g/L (25 C)

5.51 g/L (40 C)

21.45 g/L (75 C)

56.31 g/L (100 C)

[1][2]

Solubility soluble

in acetone, benzene,CCl4, CHCl3, alcohol, ethyl

ether, hexane, phenyls, liquid ammonia, acetates

Solubility inmethanol 30 g/100 g (-18 C)

32.1 g/100 g (-13 C)

71.5 g/100 g (23 C)

[1]

Solubility inethanol 25.4 g/100 g (-18 C)

47.1 g/100 g (15 C)

52.4 g/100 g (19.2 C)

55.9 g/100 g (23 C)

[1]

Solubility inacetone 54.2 g/100 g (20 C)

[1]

Solubility in olive oil 4.22 g/100 g (25 C)

[1]

Solubility in 1,4-

Dioxane

55.3 g/100 g (25 C)

[1]

log P 1.87

Vapor pressure 0.16 Pa (25 C)

0.19 kPa (100 C)

22.6 kPa (200 C)

[3]

Acidity (pKa) 4.202

[4]

Refractive index(nD) 1.5397 (20 C)

1.504 (132 C)

[1]

Viscosity 1.26 mPa (130 C)

Structure

Crystal structure Monoclinic

Molecular shape planar

Dipole moment 1.72 D in Dioxane

Thermochemistry

Specific 146.7 J/mol K

[3]

heat capacity C

Std molar

entropy S

o

298

167.6 J/mol K

[1]

Std enthalpy of

formation fH

o

298

-385.2 kJ/mol

[1]

Std enthalpy of

combustioncH

o

298

3228 kJ/mol

[3]

Hazards

MSDS JT Baker

GHS pictograms

[7]

GHS signal word Danger

GHS hazard

statements

H318, H335

[7]

GHS precautionary

statements

P261, P280,P305+351+338

[7]

EU Index Not listed

EU classification

Xi

R-phrases R37, R41

S-phrases S26, S39

Main hazards Irritant

NFPA 704

1

2

0

Flash point 121.5 C (250.7 F; 394.6 K)

[6]

Autoignition 571 C (1,060 F; 844 K)

[6]

temperature

LD50 1700 mg/kg (rat, oral)

Related compounds

Related carboxylic

acids

Hydroxybenzoic acids

Aminobenzoic acids,

Nitrobenzoic acids,

Phenylacetic acid

Related compounds Benzaldehyde,

Benzyl alcohol,

Benzoyl chloride,

Benzylamine,

Benzamide

Except where noted otherwise, data are given for materials in

their standard state (at 25 C (77 F), 100 kPa)

(verify) (what is: / ?)

Infobox references

Benzoic acid /bnzo.k/, C7H6O2 (or C6H5COOH), is a colorless crystalline solid and a

simple aromatic carboxylic acid. The name is derived from gum benzoin, which was for a long time

its only known source. Benzoic acid occurs naturally in many plants

[8]

and it serves as an

intermediate in the biosynthesis of many secondary metabolites. Salts of benzoic acid are used as

food preservatives and benzoic acid is an important precursor for the industrial synthesis of many

other organic substances. The salts and esters of benzoic acid are known

as benzoates /bnzo.et/.

Contents

[hide]

1 History

2 Production

o 2.1 Industrial preparations

o 2.2 Laboratory synthesis

2.2.1 By hydrolysis

2.2.2 From benzaldehyde

2.2.3 From bromobenzene

2.2.4 From benzyl alcohol

2.2.5 From benzyl chloride

2.2.6 Historical preparation

3 Uses

o 3.1 Precursor to plasticizers

o 3.2 Precursor to sodium benzoate and related preservatives

o 3.3 Medicinal

o 3.4 Benzoyl chloride

o 3.5 Niche and laboratory uses

4 Biology and health effects

5 Reactions

o 5.1 Aromatic ring

o 5.2 Carboxyl group

6 References

7 External links

History[edit]

Benzoic acid was discovered in the sixteenth century. The dry distillation of gum benzoin was first

described by Nostradamus (1556), and then by Alexius Pedemontanus (1560) and Blaise de

Vigenre (1596).

[9]

Pioneer work in 1830 through a variety of experiences based on amygdalin, obtained from bitter

almonds (the fruit of Prunus dulcis) oil by Pierre Robiquet and Antoine Boutron-Charlard, two French

chemists, had produced benzaldehyde

[10]

but they failed in working out a proper interpretation of the

structure of amygdalin that would account for it, and thus missed the identification of

the benzoyl radical C7H5O. This last step was achieved some few months later (1832) by Justus von

Liebig and Friedrich Whler, who determined the composition of benzoic acid.

[11]

These latter also

investigated how hippuric acid is related to benzoic acid.

In 1875 Salkowski discovered the antifungal abilities of benzoic acid, which was used for a long time

in the preservation of benzoate-containing cloudberry fruits.

[12]

It is also one of the chemical compounds found in castoreum. This compound is gathered from the

beaver plant food.

[13]

Production[edit]

Industrial preparations[edit]

Benzoic acid is produced commercially by partial oxidation of toluene with oxygen. The process is

catalyzed by cobalt or manganese naphthenates. The process uses cheap raw materials, and

proceeds in high yield.

[citation needed]

U.S. production capacity is estimated to be 126,000 tonnes per year

(139,000 tons), much of which is consumed domestically to prepare

other industrial chemicals.

Laboratory synthesis[edit]

Benzoic acid is cheap and readily available, so the laboratory

synthesis of benzoic acid is mainly practiced for its pedagogical

value. It is a common undergraduate preparation.

Benzoic acid can be purified by recrystallization from water because

of its high solubility in hot water and poor solubility in cold water.

The avoidance of organic solvents for the recrystallization makes

this experiment particularly safe.

[14]

The solubility of benzoic acid in

over 40 solvents with references to original sources can be found as

part of the Open Notebook Science Challenge

[15]

By hydrolysis[edit]

Like other nitriles and amides, benzonitrile and benzamide can be

hydrolyzed to benzoic acid or its conjugate base in acid or basic

conditions.

From benzaldehyde[edit]

The base-induced disproportionation of benzaldehyde,

the Cannizzaro reaction, affords equal amounts of benzoate

and benzyl alcohol; the latter can be removed by distillation.

From bromobenzene[edit]

Bromobenzene can be converted to benzoic acid by "carbonation"

of the intermediate phenylmagnesium bromide.

[16]

This synthesis

offers a convenient exercise for students to carry out a Grignard

reaction, an important class of carboncarbon bond forming

reaction in organic chemistry.

[17][18]

From benzyl alcohol[edit]

Benzyl alcohol is refluxed with potassium permanganate or other

oxidizing reagents in water. The mixture is hot filtered to remove

manganese dioxide and then allowed to cool to afford benzoic acid.

From benzyl chloride[edit]

Benzoic acid can be prepared by oxidation of benzyl chloride in the

presence of alkaline KMnO4:

C6H5CH2Cl + 2 KOH + 2 [O] C6H5COOH + KCl + H2O

Historical preparation[edit]

The first industrial process involved the reaction

of benzotrichloride (trichloromethyl benzene) with calcium

hydroxide in water, using iron or iron salts as catalyst. The

resulting calcium benzoate is converted to benzoic acid

with hydrochloric acid. The product contains significant amounts

of chlorinated benzoic acid derivatives. For this reason, benzoic

acid for human consumption was obtained by dry distillation of

gum benzoin. Food-grade benzoic acid is now produced

synthetically.

Uses[edit]

Benzoic acid is mainly consumed in the production of phenol by

oxidative decarboxylation at 300400 C:

[19]

C6H5CO2H + 1/2 O2 C6H5OH + CO2

The temperature required can be lowered to 200 C by the

addition of catalytic amounts of copper(II) salts. The phenol

can be converted to cyclohexanol, which is a starting

material for nylon synthesis.

Precursor to plasticizers[edit]

Benzoate plasticizers, such as the glycol-, diethylenegylcol-

, and triethyleneglycol esters, are obtained

by transesterification of methyl benzoate with the

corresponding diol. Alternatively these species arise by

treatment of benzoylchloride with the diol. These

plasticizers are used similarly to those derived

from terephthalic acid ester.

Precursor to sodium benzoate and related

preservatives[edit]

Benzoic acid and its salts are used as a food preservatives,

represented by the E-numbers E210, E211, E212,

and E213. Benzoic acid inhibits the growth

of mold, yeast

[20]

and some bacteria. It is either added

directly or created from reactions with

its sodium, potassium, or calcium salt. The mechanism

starts with the absorption of benzoic acid into the cell. If the

intracellular pH changes to 5 or lower, the anaerobic

fermentation of glucosethrough phosphofructokinase is

decreased by 95%. The efficacy of benzoic acid and

benzoate is thus dependent on the pH of the food.

[21]

Acidic

food and beverage like fruit juice (citric acid), sparkling

drinks (carbon dioxide), soft drinks (phosphoric

acid), pickles (vinegar) or other acidified food are preserved

with benzoic acid and benzoates.

Typical levels of use for benzoic acid as a preservative in

food are between 0.050.1%. Foods in which benzoic acid

may be used and maximum levels for its application are

controlled by international food law.

[22][23]

Concern has been expressed that benzoic acid and its salts

may react with ascorbic acid (vitamin C) in some soft

drinks, forming small quantities of benzene.

[24]

See also: Benzene in soft drinks

Medicinal[edit]

Benzoic acid is a constituent of Whitfield's ointment which is

used for the treatment of fungal skin diseases such

as tinea, ringworm, and athlete's foot.

[25][26]

As the principal

component of benzoin resin, benzoic acid is also a major

ingredient in both tincture of benzoin and Friar's balsam.

Such products have a long history of use as

topical antiseptics and inhalant decongestants.

Benzoic acid was used as an expectorant, analgesic,

and antiseptic in the early 20th century.

[27]

Benzoyl chloride[edit]

Benzoic acid is a precursor to benzoyl chloride, C6H5C(O)Cl

by treatment with thionyl chloride, phosgene or one of

the chlorides of phosphorus. is an important starting

material for several benzoic acid derivates likebenzyl

benzoate, which is used in artificial flavours and insect

repellents.

Niche and laboratory uses[edit]

In teaching laboratories, benzoic acid is a common

standard for calibrating a bomb calorimeter.

[28]

Biology and health effects[edit]

Benzoic acid is relatively nontoxic. It is excreted as hippuric

acid.

[29]

Benzoic acid is metabolized by butyrate-CoA

ligase into an intermediate product, benzoyl-CoA,

[30]

which

is then metabolized by glycine N-acyltransferase into

hippuric acid.

[31]

Benzoic acid occurs naturally as do its esters in many plant

and animal species. Appreciable amounts have been found

in most berries (around 0.05%). Ripe fruits of

several Vaccinium species (e.g., cranberry, V. vitis

macrocarpon; bilberry, V. myrtillus) contain as much as

0.030.13% free benzoic acid. Benzoic acid is also formed

in apples after infection with the fungus Nectria galligena.

Among animals, benzoic acid has been identified primarily

in omnivorous or phytophageous species, e.g., in viscera

and muscles of the Rock Ptarmigan (Lagopus muta) as well

as in gland secretions of male muskoxen (Ovibos

moschatus) or Asian bull elephants (Elephas maximus).

[32]

Gum benzoin contains up to 20% of benzoic acid and 40%

benzoic acid esters.

[33]

Cryptanaerobacter phenolicus is a bacterium species that

produces benzoate from phenol via 4-hydroxybenzoate

[34]

Benzoic acid is present as part of hippuric acid (N-

benzoylglycine) in urine of mammals,

especially herbivores (Gr. hippos = horse; ouron = urine).

Humans produce about 0.44 g/L hippuric acid per day in

their urine, and if the person is exposed to toluene or

benzoic acid, it can rise above that level.

[35]

For humans, the World Health Organization's International

Programme on Chemical Safety (IPCS) suggests a

provisional tolerable intake would be 5 mg/kg body weight

per day.

[32]

Cats have a significantly lower tolerance against

benzoic acid and its salts than ratsand mice. Lethal dose

for cats can be as low as 300 mg/kg body weight.

[36]

The

oral LD50 for rats is 3040 mg/kg, for mice it is 1940

2263 mg/kg.

[32]

In Taipei, Taiwan, a city health survey in 2010 found that

30% of dried and pickled food products had too much

benzoic acid, which may affect the liver and kidney,

[37]

along

with more serious issues like excessive cyclamate.

Reactions[edit]

Reactions of benzoic acid can occur at either the aromatic

ring or at the carboxyl group:

Aromatic ring[edit]

Electrophilic aromatic substitution reaction will take

place mainly in 3-position due to the electron-

withdrawing carboxylic group; i.e. benzoic acid

is meta directing.

The second substitution reaction (on the right) is slower

because the first nitro group is

deactivating.

[38]

Conversely, if an activating group

(electron-donating) was introduced (e.g., alkyl), a

second substitution reaction would occur more readily

than the first and the disubstituted product might

accumulate to a significant extent.

Carboxyl group[edit]

All the reactions mentioned for carboxylic acids are also

possible for benzoic acid.

Benzoic acid esters are the product of the acid

catalysed reaction with alcohols.

Benzoic acid amides are more easily available by

using activated acid derivatives (such as benzoyl

chloride) or by coupling reagents used in peptide

synthesis like DCC and DMAP.

The more active benzoic anhydride is formed by

dehydration using acetic anhydride or phosphorus

pentoxide.

Highly reactive acid derivatives such as acid

halides are easily obtained by mixing

with halogenation agents like phosphorus

chlorides or thionyl chloride.

Orthoesters can be obtained by the reaction of

alcohols under acidic water free conditions

with benzonitrile.

Reduction to benzaldehyde and benzyl alcohol is

possible using DIBAL-H, LiAlH4 or sodium

borohydride.

The copper

catalysed decarboxylation of benzoate to benzene

may be effected by heating in quinoline. Also,

Hunsdiecker decarboxylation can be achieved by

forming the silver salt and heating. Benzoic acid

can also be decarboxylated by heating with an

alkali hydroxide or calcium hydroxide.

Potrebbero piacerti anche

- Gravimetric Analysis: Dr. Mohammed Najim Al-Hialy College of Pharmacy University of MosulDocumento43 pagineGravimetric Analysis: Dr. Mohammed Najim Al-Hialy College of Pharmacy University of MosulMarci MunirNessuna valutazione finora

- Soal Termodinamika 1Documento7 pagineSoal Termodinamika 1Tiara Andini0% (1)

- 05Documento18 pagine05gatototNessuna valutazione finora

- Organic Chemistry ExperimentDocumento7 pagineOrganic Chemistry ExperimentKayla RhodesNessuna valutazione finora

- College of Arts and Sciences: CHM 215 Organic Chemistry IDocumento3 pagineCollege of Arts and Sciences: CHM 215 Organic Chemistry INajmul Puda PappadamNessuna valutazione finora

- Fig. 1.2. Connection of Positive ClipperDocumento15 pagineFig. 1.2. Connection of Positive ClipperElle GabrielNessuna valutazione finora

- Chapter 7and8 - MAT112Documento5 pagineChapter 7and8 - MAT112aai_apex100% (1)

- Recrystallization in Organic Chemistry LabDocumento5 pagineRecrystallization in Organic Chemistry Labrc865Nessuna valutazione finora

- EXPERIMENT CalorimeterDocumento15 pagineEXPERIMENT CalorimeterFath BondNessuna valutazione finora

- Colligative Properties and Determination of Molar MassesDocumento7 pagineColligative Properties and Determination of Molar MassesRoshini FelixNessuna valutazione finora

- Report Sheet-Results and DiscussionsDocumento3 pagineReport Sheet-Results and DiscussionsSpace MonkeyNessuna valutazione finora

- Organic ChemistryDocumento60 pagineOrganic ChemistryPavani PrabhakarNessuna valutazione finora

- Chapter 1aDocumento8 pagineChapter 1aJan Angela Almiranes0% (1)

- Sample Formal Report in Organic ChemistryDocumento10 pagineSample Formal Report in Organic ChemistryAudrey CobankiatNessuna valutazione finora

- 3Cps5Nos13 17Documento59 pagine3Cps5Nos13 17Rafael DirainNessuna valutazione finora

- E1 CalorimetryDocumento2 pagineE1 CalorimetryDeidei LopezNessuna valutazione finora

- Experiment 10!Documento26 pagineExperiment 10!Jerico Hercules MutiaNessuna valutazione finora

- Experiment 4: Effect of Concentration and Temperature On Rate of Reaction (Dissappearing Cross)Documento24 pagineExperiment 4: Effect of Concentration and Temperature On Rate of Reaction (Dissappearing Cross)Malini RajeshNessuna valutazione finora

- Name of Students: Rucha Lokhande, Rucha Dhavale, Prajakta Kulal, Isha Meshram Under Guidance of DR - Tanushree BhattacharjeeDocumento41 pagineName of Students: Rucha Lokhande, Rucha Dhavale, Prajakta Kulal, Isha Meshram Under Guidance of DR - Tanushree BhattacharjeeIsha MeshramNessuna valutazione finora

- Enoolate Chemistry ExcerciesDocumento15 pagineEnoolate Chemistry ExcerciesClara CarreraNessuna valutazione finora

- Physical Chemistry LabDocumento11 paginePhysical Chemistry LabBreyonnaMorganNessuna valutazione finora

- Experiment 4. Electrochemical Cells. Ocampo. 3CHEM1 PDFDocumento6 pagineExperiment 4. Electrochemical Cells. Ocampo. 3CHEM1 PDFEsmeralda A OcampoNessuna valutazione finora

- Organic Chemistry Different TestDocumento5 pagineOrganic Chemistry Different TestNera AyonNessuna valutazione finora

- Experiment 3 - Determination of Density PDFDocumento6 pagineExperiment 3 - Determination of Density PDFOxford North100% (1)

- Determination of R - Lab Report ExampleDocumento3 pagineDetermination of R - Lab Report Exampleapi-239855791Nessuna valutazione finora

- Experiment 9 Organic Chemistry LabDocumento7 pagineExperiment 9 Organic Chemistry LabRhodelyn TolentinoNessuna valutazione finora

- Deriving Rate Laws Using The Steady-State Approximation - Part IDocumento4 pagineDeriving Rate Laws Using The Steady-State Approximation - Part IGürkan KarakaşNessuna valutazione finora

- 08 Chapter3Documento25 pagine08 Chapter3Longdien AnngaiNessuna valutazione finora

- Qualitative Analysis of Organic CompoundsDocumento22 pagineQualitative Analysis of Organic CompoundsKarisseGarciaNessuna valutazione finora

- Journal-1-Molecular Modeling in Organic ChemistryDocumento8 pagineJournal-1-Molecular Modeling in Organic ChemistryRochelle Joyce Olmilla BersaminNessuna valutazione finora

- The Ideal Gas MixtureDocumento86 pagineThe Ideal Gas MixtureMariaAlejandraReyesNessuna valutazione finora

- LecithinDocumento14 pagineLecithinMichael UrrutiaNessuna valutazione finora

- India Bix MCQ'sDocumento5 pagineIndia Bix MCQ'sarslanjameelmalikNessuna valutazione finora

- Potential Energy Diagrams: Chemical Kinetics Mrs. KayDocumento12 paginePotential Energy Diagrams: Chemical Kinetics Mrs. KaySarahHoppNessuna valutazione finora

- CHEM 160 Formal Lab Report IDocumento10 pagineCHEM 160 Formal Lab Report IDatoya BrownNessuna valutazione finora

- OrganicDocumento3 pagineOrganickaifiiNessuna valutazione finora

- Chapter 6 Reactions of Haloalkanes: S 2Documento8 pagineChapter 6 Reactions of Haloalkanes: S 2Roberto SIlvaNessuna valutazione finora

- Organic Chemistry - Amine 2Documento24 pagineOrganic Chemistry - Amine 2Reinaldyf AdnnNessuna valutazione finora

- Chemical EquilibriumDocumento23 pagineChemical EquilibriumArihant BedagkarNessuna valutazione finora

- Organic Chemistry Lab Caffeine ExtractionDocumento8 pagineOrganic Chemistry Lab Caffeine Extractionrubu azuNessuna valutazione finora

- Chem 31.1 Organic Chemistry - Hydrocarbo PDFDocumento8 pagineChem 31.1 Organic Chemistry - Hydrocarbo PDFVilmer IyanaNessuna valutazione finora

- Lab Report On Solid Liquid Equilibrium in A Binary SystemDocumento7 pagineLab Report On Solid Liquid Equilibrium in A Binary SystemAyaz BhattiNessuna valutazione finora

- Sample ProblemsDocumento48 pagineSample Problemsapi-3856754Nessuna valutazione finora

- Chem 112.1 - Exer 2 PostlabDocumento7 pagineChem 112.1 - Exer 2 PostlabGerry Mark GubantesNessuna valutazione finora

- BangbangDocumento5 pagineBangbangAutumn JohnsonNessuna valutazione finora

- Physical Chemistry: Electrochemistry II: Voltaic or Galvanic Cells Suhaschandra GhoshDocumento46 paginePhysical Chemistry: Electrochemistry II: Voltaic or Galvanic Cells Suhaschandra GhoshLy Que UyenNessuna valutazione finora

- Synthesis of Oil of WintergreenDocumento16 pagineSynthesis of Oil of WintergreenvarunNessuna valutazione finora

- Chemistry of Aromatics CompoundsDocumento16 pagineChemistry of Aromatics CompoundsOfudje Edwin AndrewNessuna valutazione finora

- Alpha Carbon Chemistry - Enols and EnolatesDocumento49 pagineAlpha Carbon Chemistry - Enols and EnolatesKuku MandavaNessuna valutazione finora

- Determination of The Concentration of Acetic Acid in VinegarDocumento16 pagineDetermination of The Concentration of Acetic Acid in VinegarFirdaus HaziqNessuna valutazione finora

- Note 1475054739Documento10 pagineNote 1475054739Thiyaga RajanNessuna valutazione finora

- Organic Chemistry - Resolution of IbuprofenDocumento9 pagineOrganic Chemistry - Resolution of IbuprofenJames Ernest Baker-taylor100% (1)

- Execises - Organic Chemistry Chapter 2 Part 1Documento2 pagineExecises - Organic Chemistry Chapter 2 Part 1Michelle ChicaizaNessuna valutazione finora

- (L1-L6) Refrigeration and LiquefactionDocumento26 pagine(L1-L6) Refrigeration and LiquefactionFardin Faruk KhanNessuna valutazione finora

- Benzoic AcidDocumento10 pagineBenzoic AcidMuhd Harith Mahyuddin100% (1)

- Benzoic AcidDocumento11 pagineBenzoic Acidأديان مهدي شاكر جبرNessuna valutazione finora

- En Wikipedia Org BenzaDocumento5 pagineEn Wikipedia Org BenzaXixiux LuciaNessuna valutazione finora

- Adipic Acid - Wikipedia PDFDocumento24 pagineAdipic Acid - Wikipedia PDFKalpesh DetheNessuna valutazione finora

- Ethanal (Common Name Acetaldehyde) Is An: o o o o o o o o oDocumento9 pagineEthanal (Common Name Acetaldehyde) Is An: o o o o o o o o oYuri YamirnovNessuna valutazione finora

- Through Catalytic TransformationDocumento8 pagineThrough Catalytic TransformationDanny RonayneNessuna valutazione finora