Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

G3520 SLD PDF

Caricato da

danielh776Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

G3520 SLD PDF

Caricato da

danielh776Copyright:

Formati disponibili

G3520C

G3520C

INTRODUCTION

INTRODUCTION

!SIGNIFICANT COMPETITIVE ADVANTAGES

!EMISSIONS

!POWER DENSITY

!EFFICIENCY

G3520C

G3520C

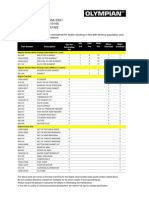

60 Hz,1800 RPM

50 Hz,1500 RPM

NO

x

levels 0.5 & 1.0 g/bhp hr

Successful reliability

tests on three field

units (Germany,

Denmark, and Salt

Lake City)

G3520C

G3520C

Materials on the Web Site

Materials on the Web Site

!LEXE 3883 Product news, Cat G3520C

!LEHE 2832 G3520C 60Hz 130 Deg F Spec Sheet

!LEDE 2779 An idea whose kilowatt hour

has come brochure

!LEDE 2817 G3520C Product brochure

!234-1955 Installation drawing (access via XREF)

!New service manual available

G3520C

G3520C

Engine Design

Engine Design

Design simplicity

Economic potential

G3520C

G3520C

Electronic

Electronic

Controls

Controls

SYSTEM OPERATION

Master ECM

Slave ECM

G3520C

G3520C

Electronic

Electronic

Controls

Controls

MASTER ELECTRONIC CONTROL MODULE (ECM)

Environmentally sealed

Controls most of engine functions

Supports governing of engine

Controls detonation sensors left bank

Controls ignition for left bank

Air/Fuel ratio control

Start/Stop control

G3520C

G3520C

Electronic

Electronic

Controls

Controls

SLAVE ELECTRONIC CONTROL MODULE (ECM)

Environmentally sealed

Controls ignition for right bank

Controls detonation sensors on right bank

G3520C

G3520C

Electronic Controls

Electronic Controls

GOVERNS THE ENGINE RPM

Actual speed is detected via engine speed/timing

sensor

ECM communicates with the throttle via the CAN

data link (standard type)

Used only with the fuel valve and throttle on the

C model

G3520C

G3520C

Electronic Controls

Electronic Controls

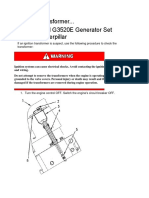

CONTROL OF IGNITION

Each cylinder has an ignition transformer

ECM sends a pulse of approximately 108 volts to

the primary coil

G3520C

G3520C

Electronic Controls

Electronic Controls

Input from the customer

Gas analysis required

Caterpillar software, LEKQ6378

Program the ECM

G3520C

G3520C

Electronic Controls

Electronic Controls

Density of air/fuel mixture in manifold

ECM calculates actual density

Actual density compared to desired density

Continual process with loads greater then 25%

Configuration parameter programmed into ECM

G3520C

G3520C

Start/Stop Control

Start/Stop Control

Parameters

Parameters

Cycle crank time

Engine over crank time

Engine pre-lube time out period

Engine speed drop time

G3520C

G3520C

Start/Stop Control

Start/Stop Control

Parameters

Parameters

Driven equipment delay time

Engine purge cycle time

Engine cool down duration

Crank terminate speed

G3520C

G3520C

Monitoring System

Monitoring System

MASTER ECM

Monitors engine operation

Monitors electronic system

Generates fault codes

Issues warning codes

Shuts down engine depending on severity

G3520C

G3520C

Monitoring System

Monitoring System

INTEGRATED TEMPERATURE SENSING MODULE

(ITSM)

Monitors cylinder

thermocouples

Monitors turbocharger

thermocouples

Sends signals regarding

parameters to the ECM

Open circuits cause diagnostic codes

G3520C

G3520C

Monitoring System

Monitoring System

PARAMETERS

Low system voltage

High engine coolant temperature

Low engine coolant temperature

Engine over speed

High engine oil temperature

High oil filter differential pressure

G3520C

G3520C

ELECTRONIC IGNITION SYSTEM

Ignition transformers

Spark plugs

(Holes are offset

for swirling action)

G3520C

G3520C

Fuel System

Fuel System

AIR/FUEL RATIO

Raptor

Fuel metering device

G3520C

G3520C

Air Inlet and Exhaust

Air Inlet and Exhaust

AFTERCOOLER

G3520C

G3520C

Air Inlet and Exhaust

Air Inlet and Exhaust

COMPRESSOR BYPASS

SURGE PROTECTION

G3520C

G3520C

Air Inlet and Exhaust

Air Inlet and Exhaust

EXHAUST MANIFOLD

G3520C

G3520C

Air Inlet and Exhaust

Air Inlet and Exhaust

TURBOCHARGER

G3520C

G3520C

Lubrication System

Lubrication System

PISTON COOLING

JETS

SPIN ON FILTERS

G3520C

G3520C

Cooling System

Cooling System

Jacket water pump SCAC pump

G3520C

G3520C

Cooling System

Cooling System

Jacket water pump SCAC pump

G3520C

G3520C

Basic Engine

Basic Engine

CYLINDER BLOCK, LINERS, HEADS

Pistons, rings and connecting rods

Crankshaft

Camshaft

G3520C

G3520C

Electrical System

Electrical System

24 VDC power supply

30 Amps continuous power

Starting motor protection

Will not engage above 0 rpm

Starting motor disengages @

300 rpm (adjustable by

customer)

G3520C

G3520C

SUMMARY

Fuel efficiency

O

2

sensor

Charge density

Turbochargers

Exhaust wrap

Two stage aftercooler

Various attachments

Raptor

G3520C

G3520C

Fuel Efficiency

Fuel Efficiency

Big advantage over the A and B engines

Production expected in 3

rd

or 4

th

quarter

Retrofits for the B models available

G3520C

G3520C

O

O

2

2

Sensor

Sensor

G3520C

No O

2

sensor

Patented Charge Density system

Periodic calibration unnecessary

G3520B

O

2

sensor will be eliminated

Warranty costs reduced

Maintenance costs reduced

G3520C

G3520C

50 Hertz Single

Turbocharger

G3520C

G3520C

Segmented Exhaust Wrap

Segmented Exhaust Wrap

SPRING CLIPS SECURE INDIVIDUAL PIECES

G3520C

G3520C

Outboard Exhaust Wrap

Outboard Exhaust Wrap

G3520C

G3520C

Segmented Exhaust Wrap

Segmented Exhaust Wrap

PRE-FORMED AND FITTED

EXHAUST WRAPS

G3520C

G3520C

Two Stage Aftercooler

Two Stage Aftercooler

FIRST STAGE JWAC

SECOND STAGE

SCAC/OC

G3520C

G3520C

Ignition System

Ignition System

Master ECM

Left side

Slave ECM

Right side

G3520C

G3520C

Ignition System

Ignition System

DRY COIL

G3520C

G3520C

Ignition System

Ignition System

PRE COMBUSTION

CHAMBER SPARK PLUG

G3520C

G3520C

Crankcase Breathers

Crankcase Breathers

NOT ON THE VALVE

COVERS

TWO SETS ON REAR

CORNERS

G3520C

G3520C

Thermostats

Thermostats

TOP HOUSING USES 8

THERMOSTATS FOR

INCREASED FLOW.

G3520C

G3520C

Integrated Temperature

Integrated Temperature

Sensing Module (ITSM)

Sensing Module (ITSM)

24

THERMOCOUPLES

G3520C

G3520C

Raptor

Raptor

Feedback sensors monitor

Fuel pressure

Fuel temperature

Pressure differential

Regulates and meters fuel

Mounted on or close to engine

G3520C

G3520C

Questions/ Discussion

Questions/ Discussion

Seize the moment of excited curiosity on

any subject to solve your doubts; for if

you let it pass, the desire may never

return, and you may remain in ignorance.

Potrebbero piacerti anche

- G3520C Series Gas EngineDocumento47 pagineG3520C Series Gas Engineammargakhar100% (2)

- G3606 - Lehw0039-02 P1Documento4 pagineG3606 - Lehw0039-02 P1Martin KratkyNessuna valutazione finora

- G3608 Spec SheetDocumento4 pagineG3608 Spec SheetTu Pham100% (1)

- Datasheet G3516 1200 RPMDocumento4 pagineDatasheet G3516 1200 RPMVerita SanjuánNessuna valutazione finora

- Quick Start Guide 4.1 en 4.2 LEXE0186-00Documento2 pagineQuick Start Guide 4.1 en 4.2 LEXE0186-00Luis JesusNessuna valutazione finora

- 2 G3600 A3 System OperationDocumento67 pagine2 G3600 A3 System Operation巴啦啦Nessuna valutazione finora

- (REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 EnginesDocumento16 pagine(REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 Enginesvictor.cipriani100% (1)

- 1.3.1. LEHE1448-02r - G3512HDocumento7 pagine1.3.1. LEHE1448-02r - G3512HJuan Valdivieso100% (2)

- G3600 A4 Brochures PDFDocumento4 pagineG3600 A4 Brochures PDFVictor NunezNessuna valutazione finora

- DJC Parts Onan Cummins PDFDocumento130 pagineDJC Parts Onan Cummins PDFStalin Paul Rodriguez LeonNessuna valutazione finora

- Kohler Gas Generator 60rzgDocumento4 pagineKohler Gas Generator 60rzgPankaj KambleNessuna valutazione finora

- Start Up G3500 PDFDocumento33 pagineStart Up G3500 PDFPancho ALNessuna valutazione finora

- Operation Maintenance G-3500 3rcDocumento116 pagineOperation Maintenance G-3500 3rcJorge Enrique Fuentes MarinNessuna valutazione finora

- Electric Power GenerationDocumento496 pagineElectric Power Generationbill100% (1)

- LEKQ7511 G3400 Engine BasicsDocumento46 pagineLEKQ7511 G3400 Engine BasicsSyed Mohammad Naveed100% (3)

- fr6672 QSK78-G7 PDFDocumento4 paginefr6672 QSK78-G7 PDFacere18100% (1)

- Eq Generacion Electrica Iluminacion Olympian GEP150Documento5 pagineEq Generacion Electrica Iluminacion Olympian GEP150Gianni EscalanteNessuna valutazione finora

- Manual de Peças - c1250d6Documento90 pagineManual de Peças - c1250d6Otoniel santos de abreu100% (1)

- Detonation SensorDocumento1 paginaDetonation Sensormiguel oswaldo gonzalez benitezNessuna valutazione finora

- KTA38-G1 EnglishDocumento7 pagineKTA38-G1 EnglishAlberto100% (2)

- Cat 3516Documento4 pagineCat 3516Muhammad IshfaqNessuna valutazione finora

- Sebp4321 20 00 AllDocumento785 pagineSebp4321 20 00 AllNataly Mendoza100% (1)

- Cristian Makes and ModelsDocumento54 pagineCristian Makes and ModelsIgnacio Real BuffelliNessuna valutazione finora

- 9 - Gas A&I G3500-G3300 Ignition, Starting and Engine Protection SystemsDocumento37 pagine9 - Gas A&I G3500-G3300 Ignition, Starting and Engine Protection Systemsosama100% (2)

- Overhaul (Major) : Manual de Operación y MantenimientoDocumento3 pagineOverhaul (Major) : Manual de Operación y Mantenimientozona amrullohNessuna valutazione finora

- 13 - Gas A&I G3500 Commissioning Guide.Documento56 pagine13 - Gas A&I G3500 Commissioning Guide.osamaNessuna valutazione finora

- Gep33-3 RPLDocumento2 pagineGep33-3 RPLJorge Gustavo GoyecheaNessuna valutazione finora

- RAPTOR Valve Sizing DiagramDocumento2 pagineRAPTOR Valve Sizing Diagramwagner_guimarães_1Nessuna valutazione finora

- Transformadores de Sensado CaterpillarDocumento1 paginaTransformadores de Sensado CaterpillarRoberto EspinNessuna valutazione finora

- PERKINS 2206a-E13tag5 Electropak Pn1882Documento2 paginePERKINS 2206a-E13tag5 Electropak Pn1882Patricia J ÁngelesNessuna valutazione finora

- Specsheet 3516 1825 kVA PrimeDocumento6 pagineSpecsheet 3516 1825 kVA PrimeYusman EkaNessuna valutazione finora

- CAT - 3516H Engine OverspeedsDocumento3 pagineCAT - 3516H Engine Overspeedswagner_guimarães_1Nessuna valutazione finora

- Cat G3512H: Gas Generator SetsDocumento4 pagineCat G3512H: Gas Generator SetsZaka ZaheeriNessuna valutazione finora

- Cat Electronic Technician 2019A v1.0 Configuration: Parameter ValueDocumento3 pagineCat Electronic Technician 2019A v1.0 Configuration: Parameter ValueMohamed Mohamed100% (1)

- Cat 3520 Ignition TransformerDocumento9 pagineCat 3520 Ignition TransformerRashid Mahmood Jaat0% (1)

- 500kW User ManualDocumento83 pagine500kW User ManualvanhoackdNessuna valutazione finora

- Manual Partes Generador DFH-A, B, C, D Con Motor QST 30 PDFDocumento121 pagineManual Partes Generador DFH-A, B, C, D Con Motor QST 30 PDFedgar100% (1)

- Cat G3520C Engine Coal Mine GasDocumento6 pagineCat G3520C Engine Coal Mine GasJSH100Nessuna valutazione finora

- Dse8600 Series Dse Configuration Suite ManualDocumento165 pagineDse8600 Series Dse Configuration Suite ManualGustavo Pereira100% (1)

- Magnum Diesel Generator Mmg35 Parts ManualDocumento52 pagineMagnum Diesel Generator Mmg35 Parts ManualKomatsu Nna100% (1)

- FG WilsonDocumento14 pagineFG WilsonMiguel Guerrero Hermosilla100% (1)

- Especificaciones Tecnicas AVR Stamford SX440Documento4 pagineEspecificaciones Tecnicas AVR Stamford SX440MH..2023Nessuna valutazione finora

- Data Sheet G3520CDocumento3 pagineData Sheet G3520CIwaiter100% (3)

- Ajax Igtb Electronic GovernorDocumento2 pagineAjax Igtb Electronic GovernorAnonymous CD0suI9Nessuna valutazione finora

- QSK60 G6Documento2 pagineQSK60 G6Jhan Carlos HuamaniNessuna valutazione finora

- ONAN DJC MEP 003A ManualDocumento243 pagineONAN DJC MEP 003A ManualscyrosNessuna valutazione finora

- PSBU-021-QSK50 - 1750 - 1825kVA-Rev-2 - 19 June 2018Documento4 paginePSBU-021-QSK50 - 1750 - 1825kVA-Rev-2 - 19 June 2018hadNessuna valutazione finora

- 6286-2 Web - AFM PDFDocumento434 pagine6286-2 Web - AFM PDFshahzad100% (1)

- Emcp II For MuiDocumento208 pagineEmcp II For MuiDiego Morales100% (1)

- G3512 SpecDocumento4 pagineG3512 SpecnunkpNessuna valutazione finora

- Caterpillar InstallationDocumento297 pagineCaterpillar InstallationBustershiithaPortugues100% (1)

- QSK19G PerformanceDocumento5 pagineQSK19G PerformancetroyNessuna valutazione finora

- Air Fuel Ratio Control 3516BDocumento4 pagineAir Fuel Ratio Control 3516Bwagner_guimarães_1Nessuna valutazione finora

- Caterpillar 3516C Genset Specification SheetsDocumento6 pagineCaterpillar 3516C Genset Specification SheetsMTU650100% (1)

- Motor Cat g3520 - SLD Service TrainingDocumento43 pagineMotor Cat g3520 - SLD Service TrainingVictor NunezNessuna valutazione finora

- g3520c Natural Gas For 1950Documento6 pagineg3520c Natural Gas For 1950Shahzad AliNessuna valutazione finora

- CaterpilarDocumento4 pagineCaterpilarpangestu66100Nessuna valutazione finora

- Gas EngineDocumento6 pagineGas EngineMRizwanSadiq313Nessuna valutazione finora

- Epg Spec 1500 KvaDocumento5 pagineEpg Spec 1500 Kvakvramanan_1Nessuna valutazione finora

- Dynamometer: Theory and Application to Engine TestingDa EverandDynamometer: Theory and Application to Engine TestingNessuna valutazione finora

- F-09772 1 StageDocumento2 pagineF-09772 1 Stagedanielh776Nessuna valutazione finora

- B 1412 CC - DrawingDocumento1 paginaB 1412 CC - Drawingdanielh776Nessuna valutazione finora

- B 1412 CC - DrawingDocumento1 paginaB 1412 CC - Drawingdanielh776Nessuna valutazione finora

- B 1411 U - DrawingDocumento1 paginaB 1411 U - Drawingdanielh776Nessuna valutazione finora

- B 1411 U - DrawingDocumento1 paginaB 1411 U - Drawingdanielh776Nessuna valutazione finora

- Guia PokemonDocumento85 pagineGuia Pokemondanielh776Nessuna valutazione finora

- F-09772 1 StageDocumento2 pagineF-09772 1 Stagedanielh776Nessuna valutazione finora

- F-09772 2 StageDocumento1 paginaF-09772 2 Stagedanielh776Nessuna valutazione finora

- Fundamentals of Orifice Measurement 209KB PDFDocumento18 pagineFundamentals of Orifice Measurement 209KB PDFmasimeriseNessuna valutazione finora

- 2018fwc South America Es SpanishDocumento1 pagina2018fwc South America Es Spanishdanielh776Nessuna valutazione finora

- SFA CFS Framing Guide Final 2Documento12 pagineSFA CFS Framing Guide Final 2manishnparmarNessuna valutazione finora

- Installation Guide For Aspenone V 7.1Documento11 pagineInstallation Guide For Aspenone V 7.1danielh776Nessuna valutazione finora

- Secuencia de Eventos: "From The Wellhead Through The Pipeline Hanover People Perform."Documento7 pagineSecuencia de Eventos: "From The Wellhead Through The Pipeline Hanover People Perform."danielh776Nessuna valutazione finora

- Secuencia de Eventos: "From The Wellhead Through The Pipeline Hanover People Perform."Documento7 pagineSecuencia de Eventos: "From The Wellhead Through The Pipeline Hanover People Perform."danielh776Nessuna valutazione finora

- Ajuste Modulo SPM-ADocumento8 pagineAjuste Modulo SPM-Adanielh776Nessuna valutazione finora

- Table of Content 2004-SPANISHDocumento1 paginaTable of Content 2004-SPANISHdanielh776Nessuna valutazione finora

- VR6 - Voltage Regulators - Engine Training Division - CATERPILLARDocumento35 pagineVR6 - Voltage Regulators - Engine Training Division - CATERPILLARpevareNessuna valutazione finora

- DX5 Cross SectionalDocumento6 pagineDX5 Cross Sectionaldanielh776Nessuna valutazione finora

- Les 13. Sistema EIS PDFDocumento37 pagineLes 13. Sistema EIS PDFdanielh776Nessuna valutazione finora

- VR6 Voltage Regulator - Pruebas y Ajustes - CATERPILLARDocumento30 pagineVR6 Voltage Regulator - Pruebas y Ajustes - CATERPILLARCesar Alfonso Saldivar MontoyaNessuna valutazione finora

- 2301A Load Sharing & Speed ControlDocumento52 pagine2301A Load Sharing & Speed ControlLuis Alberto LopezNessuna valutazione finora

- Les 01. Introduccion1 PDFDocumento13 pagineLes 01. Introduccion1 PDFdanielh776100% (2)

- Les 02. Diesel Vs Gas PDFDocumento25 pagineLes 02. Diesel Vs Gas PDFdanielh776100% (1)

- Conectores Electricos PDFDocumento103 pagineConectores Electricos PDFdanielh776100% (1)

- 3500B Engine For Power Modules PDFDocumento2 pagine3500B Engine For Power Modules PDFdanielh776Nessuna valutazione finora

- DSBDA ORAL Question BankDocumento6 pagineDSBDA ORAL Question BankSUnny100% (1)

- AVR 3kVA 220VCA DatasheetDocumento2 pagineAVR 3kVA 220VCA DatasheetdulcesinestesiaNessuna valutazione finora

- Asphalt and Asphalt Mixtures PPT2023Documento53 pagineAsphalt and Asphalt Mixtures PPT2023Brian ReyesNessuna valutazione finora

- ErrorDocumento28 pagineErrorバネガス ネストルNessuna valutazione finora

- Bharat Sanchar Nigam Limited: Office of The Executive Engineer (Civil) BSNL Civil Division, Imphal - 795001, ManipurDocumento47 pagineBharat Sanchar Nigam Limited: Office of The Executive Engineer (Civil) BSNL Civil Division, Imphal - 795001, Manipurvivekananda sharmaNessuna valutazione finora

- S W A N 1 0 0 0: Installation InstructionsDocumento2 pagineS W A N 1 0 0 0: Installation InstructionsLuisAlbertoSaldañaRmzNessuna valutazione finora

- 994-0152 G500 Substation Gateway Instruction Manual V200 R1Documento114 pagine994-0152 G500 Substation Gateway Instruction Manual V200 R1Mateus GaronciNessuna valutazione finora

- Analysis of Vibration Detection Using Active Controller in The Smart Cantilever Composite Beam With LQR and Fuzzy TechniquesDocumento10 pagineAnalysis of Vibration Detection Using Active Controller in The Smart Cantilever Composite Beam With LQR and Fuzzy TechniquesTJPRC PublicationsNessuna valutazione finora

- Hydraulic System For AIRBUS 330 AirlinerDocumento5 pagineHydraulic System For AIRBUS 330 AirlinerAhmed SharinNessuna valutazione finora

- Linux Lab ManualDocumento373 pagineLinux Lab ManualsrinubasaniNessuna valutazione finora

- New Text DocumentDocumento4 pagineNew Text Documentjutt1Nessuna valutazione finora

- ZXWR RNC (V3.07.310) Radio Network Controller Performance Index ReferenceDocumento419 pagineZXWR RNC (V3.07.310) Radio Network Controller Performance Index ReferenceWilmer Brito GonzalezNessuna valutazione finora

- Special Topic Presentation: Subject: Wireless Communication Topic: Global System For Mobile CommunicationDocumento18 pagineSpecial Topic Presentation: Subject: Wireless Communication Topic: Global System For Mobile Communicationtabish khatriNessuna valutazione finora

- UWG IT Security PlanDocumento111 pagineUWG IT Security PlanManuel SantanaNessuna valutazione finora

- Aluminium ProfileDocumento23 pagineAluminium ProfileRobert CedeñoNessuna valutazione finora

- Pioneer Vsx-1122 Vsx-922-k Rrv4320 Av ReceiverDocumento7 paginePioneer Vsx-1122 Vsx-922-k Rrv4320 Av ReceiverAlex Ramirez0% (1)

- PIC16f877 Based Simple Calculator ProjectDocumento13 paginePIC16f877 Based Simple Calculator ProjectBizuneh getuNessuna valutazione finora

- SAILOR 77 Fleet+ Installation Manual PDFDocumento61 pagineSAILOR 77 Fleet+ Installation Manual PDFAnonymous nC9gpUWPNessuna valutazione finora

- ITM Mining Sept 2017Documento8 pagineITM Mining Sept 2017Mclaren Woro100% (1)

- Electrical Network Analysis (EE2004) : Circuit Analysis in S-DomainDocumento31 pagineElectrical Network Analysis (EE2004) : Circuit Analysis in S-DomainMuhammad YousafNessuna valutazione finora

- PHD 2021 Entrance and Admission NoticeDocumento1 paginaPHD 2021 Entrance and Admission Noticevivek soniNessuna valutazione finora

- SCE-CNF-VAS VAS Configuration Document V1 1Documento11 pagineSCE-CNF-VAS VAS Configuration Document V1 1fran0% (1)

- sm53453 1Documento20 paginesm53453 1zoltanpdcNessuna valutazione finora

- Pmguru OnlineDocumento167 paginePmguru OnlineGaurav KhamkarNessuna valutazione finora

- Android Application Development: Broadcast ReceiverDocumento37 pagineAndroid Application Development: Broadcast ReceiverAbdul RaoufNessuna valutazione finora

- Lecture01 IntroDocumento20 pagineLecture01 IntroRijy LoranceNessuna valutazione finora

- ms880 Car Specific Cable Set - 53985Documento11 paginems880 Car Specific Cable Set - 53985SamuelNessuna valutazione finora

- Whats NewDocumento17 pagineWhats NewcosminconstantinNessuna valutazione finora

- AWS - Lambda QuizletDocumento20 pagineAWS - Lambda QuizletchandraNessuna valutazione finora

- UML DIAGRAMS For Hospital ManagementDocumento8 pagineUML DIAGRAMS For Hospital ManagementDeepak M Krishna100% (4)