Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A2 102 2014

Caricato da

oprea niculae0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

34 visualizzazioni7 pagineTransformatoare 3

Titolo originale

A2_102_2014

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoTransformatoare 3

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

34 visualizzazioni7 pagineA2 102 2014

Caricato da

oprea niculaeTransformatoare 3

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

21, rue dArtois, F-75008 PARIS

A2-102 CIGRE 2014

http : //www.cigre.org

Post-mortem Analysis of Transformer Insulating Paper and its Relationship to

the Determination of Chemical Markers

J. JALBERT*, M-C. LESSARD and B. GIRARD

Hydro-Qubec

Canada

SUMMARY

Evaluation of the state of insulating paper using chemical markers still presents many challenges.

Analysis of the oil allows the presence of chemical markers to be monitored enabling the condition of

the insulating paper to be assessed without any invasive interventions. Several laboratory models

involving the chemical markers and the degree of polymerization (DP

v

) have been proposed.

Nevertheless, for an accurate interpretation of these markers in a real transformer, it is imperative to

take into account some conceptual design parameters. Indeed, the comparison of equipments with the

same design (shell vs core) and the same type of cooling is essential. It has been shown that cooling

exerts an effect on the temperature distribution in the windings, provoking a distribution of the DP

v

values of the paper in the equipment. Moreover, similarly to water, the measured marker

concentrations in oil are temperature-dependent. Indeed, because of the partition phenomenon between

oil and the solid insulation, most of these markers are kept in the solid insulation and are equilibrated

with oil depending on the temperature and other physico-chemical parameters. In order to follow the

real trend of these species during the transformers service life, it is crucial to correct their

concentrations at a specific temperature, as is done for the water content. Recent publications have

proposed that correction factors be established to take into account this partition phenomenon of

alcohols and furanic derivatives.

Among its fleet of ageing transformers, Hydro-Qubec has the opportunity to access this equipment

before it is dismantled thus obtaining the occasion to propose a post-mortem study of insulating paper

in order to obtain a better relationship between DP

v

and the presence of chemical markers. It should be

mentioned that the transformers studied must include representative values of the oil quality together

with the content of the chemical markers.

Our approach consists in sampling a large amount of paper from each of the different sections of the

windings (LV, HV and neutral) for the most accurate representation of the transformer. One of our

goals is to establish a relationship between the different chemical markers and the state of the paper

insulation. This article discusses recent experience in this field together with some specific cases.

KEYWORDS

Transformer, chemical markers, post-mortem, methanol, furanic derivatives, degree of polymerization.

* jalbert.jocelyn@ireq.ca

1

INTRODUCTION

The interpretation of chemical markers for determining the state of paper insulation in a power

transformer is a subject that still presents many challenges. Analysis of the oil allows the alcohols and

furanic derivatives to be measured and the insulating paper condition to be assessed without any

invasive interventions. To date, several accelerated-ageing studies involving chemical markers and the

degree of polymerization (DP

v

) have been proposed but their application to real equipment is still

under investigation. Recently, a consensus about marker interpretation stipulates that it is imperative

to compared apparatus with the same configuration (shell vs. core) and the same type of cooling (e.g.

ONAF, ODAF) [1], [2]. In fact, the quantity of materials implied (oil and paper) is too different

between a shell and a core design to compare these types of apparatus. Cooling also has an effect on

the temperature distribution in the windings, thus provoking a distribution of DP

v

values of the paper

in the transformer. Similarly to water, the measured marker concentrations in oil are temperature-

dependent. Because of the partition phenomenon between oil and the solid insulation, most of these

markers are kept in the solid insulation and are equilibrated with the oil, depending on the temperature

and other physico-chemical parameters. In order to follow the real trend of these species during the

transformers service life, it is crucial to correct their concentrations at a specific temperature, as is

done for the water content [3]. Recent publications have suggested that correction factors be

established to take this partition phenomenon into account in the interpretation of alcohols and furanic

derivatives [4], [5]. Moreover, Hydro-Qubecs Research Institute (IREQ) is currently involved in two

related CIGRE working groups (A2.45 and A2.D1.46). Their common goals are to establish an

investigative protocol that includes the sampling of paper from the equipment and to determine a

relationship with the different chemical markers.

Among its fleet of ageing transformers that need replacing, Hydro-Qubec has the opportunity to

access these devices as they are dismantled and perform post-mortem studies of the insulating paper of

the scrapped transformers to obtain/validate the relationship between DP

v

and the presence of

chemical markers dissolved in oil. To minimize the associated costs of this initiative, the investigation

was jointly conducted by IREQ and the companies in charge of scrapping. Our approach consists in

sampling a large amount of paper from each of the different sections of the windings at different

places (top, middle and bottom) for the most accurate representation of the transformer DP

v

distribution. Prior to this action, representative oil samples need to be collected to assess the oil quality

together with the content of chemical markers. This article discusses six specific cases with complete

chemical data; where three of these transformers have been dismantled and papers have been sampled.

TRANSFORMER SCRAPPING

Oil characterization

Six open-breathing core-type power transformers built in 1958 coming from the same manufacturer

and placed in the same generation station were investigated (see Figure 1a). These transformers were

initially cooled with OFWF systems and then modified to OFAF cooling systems around the 1990s.

They were insulated with standard Kraft papers (0.11% nitrogen content) and filled with inhibited

naphthenic insulating oil. Oil analysis was performed on the six units before they were scrapped. The

oil acidities were in the range of 0.012 to 0.017 mg KOH/g of oil. Except for the high values of the

CO

2

gas, the DGA results of Table 1 indicate the transformers had no particular problem and

therefore, showed no obvious sign of abnormal or accelerated ageing of their solid insulation.

Paper sampling

For the three units investigated here (#1, #3, #5), the paper was sampled on both the high-voltage

(HV) and the low-voltage (LV) of the three-phase windings (A, B, C). When possible, a complete part

of the disc was selected (see Figure 1b) in order to measure the distribution of the degree of

polymerization (DP

v

). Moreover, the DP

v

measurement was performed on the first paper layer directly

in contact with the oil and on the paper layer directly in contact with the copper. Finally, samples from

the top, middle and bottom of each winding phase were selected. For each case, there were more than

100 DP

v

measurements per transformer. All the measurements (DP

v

, acidity, DGA, and furanic

2

derivatives) were assessed using normalized methods [6-9]; the alcohols were assessed with a method

published elsewhere [10].

a)

b)

Figure 1: Example of a) the transformer investigated and b) a cross section of the LV winding.

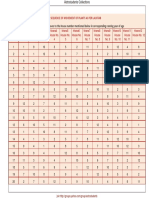

Table 1: Last DGA results taken before the final outage of the six transformers investigated.

Units H

2

(ppm)

CH

4

(ppm)

CO

(ppm)

CO

2

(ppm)

C

2

H

2

(ppm)

C

2

H

4

(ppm)

C

2

H

6

(ppm)

Post-

mortem

1 86 4 322 15947 < LD 34 3 2013

2 19 5 308 6900 < LD 26 3 2014

3 28 3 220 6340 < LD 10 3 2013

4 5 5 155 3307 < LD 17 3 2014

5 22 3 264 10540 < LD 28 4 2012

6 66 7 596 21461 < LD 55 4 N.A.

LD: Limit of detection; N.A.: Not available.

RESULTS AND DISCUSSION

DP

v

measurements

This section presents all the DP

v

statistic distributions observed for case #3. These distributions are

quite similar for the other two cases investigated. For a specific case, the total amount of compiled

data may differ from one distribution to another due to some missing description in the sample

identification.

Figure 2 shows a typical paper DP

v

distribution for the three phases of the LV and HV windings. In

this figure, DP

v

distribution of all the papers collected in the LV and the HV windings without any

distinction of the phase (A, B or C), the position (top, middle or bottom) or the paper layer (oil or

copper side) is taken into account. As expected, the DP

v

of the LV winding is lower than that the one

observed on the HV winding, probably due to their more restricted cooling channels. However, in this

case, the mean values of both windings are near their end of life, with mean DP

v

values of 177 and 306

for the LV and HV windings respectively.

3

50 100 150 200 250 300 350 400 450

0

2

4

6

8

10

12

14

16

Mean=306

n=73

C

o

u

n

t

DP

v

HV

LV

Mean=176

n=27

Figure 2: DP

v

distribution for case #3.

Knowing that this transformer operated with a forced-oil cooling system giving a more

homogeneous temperature distribution along the windings, we would expect the DP

v

distribution

between the top and the bottom to be similar in order of magnitude. Indeed, Figure 3 represents the

DP

v

distributions of three locations on the windings where a small difference is still observed. The top

shows the lowest mean values with an average of 246 compared to the middle, 277, and the bottom

with an average value of 335. Moreover, the dispersion seems greater for the data collected at the top.

100 200 300 400 500

0

1

2

3

4

5

6

7

8

9

10

Mean=335

n=17

Mean=277

n=37

Mean=246

n=48

C

o

u

n

t

DP

v

Top

Middle

Bottom

Figure 3: DP

v

distribution for case #3 at different winding locations.

Finally, Figure 4 presents the distribution for the measurement of the DP

v

of the paper directly in

contact with the oil and in contact with the copper conductor. The distributions are quite similar with

equivalent mean values (291 vs 290). This can be attributed to the good quality of the oil (acidity =

0.012 mgKOH/g oil) which had no detrimental effect on the winding papers directly in contact with

the oil. Tables 2 and 3 summarize all the results and statistics related to the three cases studied.

4

100 200 300 400 500

0

2

4

6

8

10

12

14

16

18

Mean=291

n=41

Mean=290

n=46

C

o

u

n

t

DP

v

Oil side

Copper side

Figure 4: DP

v

distribution in case #3 for different paper layers.

Table 2: Summary of the DP

v

mean values for the three cases investigated.

Units Global HV LV Top Middle Bottom Oil Copper

1 240 277 162 212 244 250 237 264

3 276 306 177 246 277 335 291 290

5 294 329 187 257 301 316 292 301

Table 3: Statistics observed for the three cases studied.

Units Global n StD Minimum Maximum

1 240 116 72 118 439

3 276 100 70 120 387

5 294 129 69 118 388

StD: Standard deviation.

These results confirmed the homogeneous ageing of this transformer. It is interesting to note that,

no matter where the samples are taken, unit #1 always shows the lowest values. However, a more

statistical evaluation could be performed; for example, it could be interesting to compare each winding

separately (A, B, C) to see if there is a difference between their positions. i.e. the paper located

between phases A and B or B and C compared to the paper winding facing tank sides.

Chemical marker measurements

It has been demonstrated that MeOH is directly related to the life of the cellulose by its

proportional generation after the opening of the 1.4- glycosidic bond [11-12]. Moreover, it has been

proposed that EtOH might be generated after high-temperature cellulose degradation [13]. On the

other hand, 2-FAL comes from chemical rearrangements of the degraded by-products of the cellulose

after the bond scissions [14] and exhibits an exponential trend [15]. It is important to note that this

marker is observed when paper or board manufactured by the standard Kraft process is used.

Table 4 shows concentrations of moisture and cellulose chemical markers together with their

corrected values at 20C. These corrections were obtained using equations published in IEC 60422 [3]

and in recent publications [4], [5] for moisture and chemical markers, respectively. For the raw

concentrations data, assuming that, when sampling, all chemical species are in equilibrium between

the oil and the paper insulation, a great discrepancy is noted. For example, of all the markers, case #6

seems to be the worst with concentration values of 7151, 1893 and 3928 ppb for MeOH, EtOH and

2-FAL respectively. Nevertheless, after correcting the concentrations at 20C, the worst-case

assignation changes, depending on the marker concentration. It is important to note here that cases #2

5

and #4 seem to exhibit better paper conditions but unfortunately we have no paper samples to confirm

this behaviour. Since a post-mortem of these transformers is planned in 2014, we will be able to

confirm the correlation of the paper deterioration with the chemical data observed.

Comparing the results obtained at 20C with the global DP

v

(Table 2) for the markers investigated,

a good relationship is observed for MeOH and 2-FAL. In the case of EtOH, as observed in lab ageing

experiments, the ratio MeOH/EtOH is always higher than one, which implies that no hot spot occurred

in these transformers. MeOH < EtOH was observed in some field equipment, probably related to a

high-temperature area in this apparatus [16].

Table 4: Moisture and cellulose chemical marker concentrations.

Units Oil temperature

(C)

H

2

O

(ppm)

MeOH

(ppb)

EtOH

(ppb)

2-FAL

(ppb)

Global

DP

v

40 18 3786 1210 1377

1

20

*

8 1582 616 1108 240

55 30 2190 1132 385

2

20

*

7 502 367 267 N.D.

40 16 2697 1040 1491

3

20

*

7 1127 529 1199 271

55 21 1473 863 400

4

20

*

5 338 280 277 N.D.

60 39 5203 1034 1185

5

20

*

8 977 289 780 294

60 57 7151 1893 3928

6

20

*

12 1343 529 2587 N.A

*

Corrected values, N.D. not determined, N.A. not available.

CONCLUSION

This paper has underlined the importance of normalizing the concentrations of chemical markers

with the oil temperature. This correction ensures a more realistic and accurate correlation between the

marker concentrations and the DP

v

of paper in a transformer. The paper also emphasizes that a post-

mortem analysis in order to draw the complete DP

v

profile of a transformer is crucial for the

applicability of any model. Finally, it opens the way to establishing concentration thresholds with

which to classify the condition of the paper insulation used in transformers in order to achieve more

accurate asset management.

ACKNOWLEDGMENTS

The authors would like to thank L. Jodoin and C. Vailles from Hydro-Qubec for their support in the

post-mortem project. They would also like to thank B. Morin, S. Duchesne and M-J. Vigeant of

Hydro-Qubec for their technical assistance.

BIBLIOGRAPHY

[1] L. Cheim, D. Platts, T. Prevost and S. Xu, Furan analysis for liquid power transformers, IEEE

Electr. Insul. Mag., Vol. 28, No. 2, pp. 38-51, 2012.

[2] CIGR Working Group D1.01.TF 13, Furanic compounds for diagnosis, CIGR Brochure No.

494, April 2012.

[3] IEC 60422, Mineral insulating oils in electrical equipment-supervision and maintenance guide, 3

rd

edition, 2005.

[4] J. Jalbert and M-C. Lessard, Cellulose chemical markers in transformer oil insulation. Part 1:

Temperature correction factors, IEEE Transactions on Dielectrics and Electrical Insulation, vol.

20, Issue 6, p. 2287-2291, December 2013.

6

7

[5] M-C. Lessard and J. Jalbert, Improvement of aging markers diagnostic of transformer solid

insulation, submitted to IEEE CEIDP Conference, Shenzhen, Peoples Republic of China,

October 20-23, 2013.

[6] ASTM D 4243, Standard Test Method for Measurement of Average Viscometric Degree of

Polymerization of New and Aged Electrical Papers and Boards, Vol. 10.02, 1999.

[7] ASTM D 974, Standard Test Method for Acid and Base Number by Color-Indicator Titration,

Vol. 5.01, 2012.

[8] ASTM D 3512, method C, Standard Test Method for Analysis of Gases Dissolved in Electrical

Insulating Oil by Gas Chromatography, Vol. 10.03, 2009.

[9] ASTM D 5837, Standard Test Method for Furanic Compounds in Electrical Insulating Liquids by

High-Performance Liquid Chromatography (HPLC), Vol. 10.03, 2012.

[10] J. Jalbert, S. Duchesne, E-M. Rodriguez-Celis, P. Ttreault, P. Colin, Robust and sensitive

analysis of methanol and ethanol from cellulose degradation in mineral oils, Journal of

Chromatography A 1256:240-245, 2012.

[11] R. Gilbert, J. Jalbert, S. Duchesne, P. Ttreault, B. Morin, Y. Denos Kinetics of the production

of chain-end groups and methanol from the depolymerization of cellulose during the ageing of

paper/oil systems. Part 2: Thermally upgraded insulating paper, Cellulose 17:253-269, 2010.

[12] R. Gilbert, J. Jalbert, P. Ttreault, B. Morin, Y. Denos, Kinetics of the production of chain-end

groups and methanol from the depolymerization of cellulose during the ageing of paper/oil

systems. Part 1: Standard wood Kraft insulation, Cellulose 16:327-338, 2009.

[13] E. Rodriguez-Celis, J. Jalbert, S. Duchesne, B. Noirhomme, and M-C. Lessard, Chemical

markers use for diagnosis and life estimation of power transformers, a preliminary study of their

origins, CIGRE Canada Conference, CIGR-083, 2012.

[14] A. M. Emsley and G. C. Stevens, Kinetics and mechanisms of the low-temperature degradation

of cellulose. Cellulose 1:26-56. 1994.

[15] J. Jalbert, R. Gilbert, P. Ttreault, B. Morin, D. Lessard-Dziel, Identification of a chemical

indicator of the rupture of 1,4--glycosidic bonds of cellulose in an oil-impregnated insulating

paper system, Cellulose 14:295-309, 2007.

[16] Ryadi M., Tanguy A., Jalbert J., Rajotte C., Alcohols based ageing chemical markers for the

diagnosis of transformer cellulosic insulation, CIGRE A2 & D1 Conference, PS2-O-4, Kyoto,

2011.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Aerated Concrete Production Using Various Raw MaterialsDocumento5 pagineAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- Chapter 07Documento16 pagineChapter 07Elmarie RecorbaNessuna valutazione finora

- LITERARY THEORY BY TERRY EAGLETON NotesDocumento6 pagineLITERARY THEORY BY TERRY EAGLETON NotesPrachi SharmaNessuna valutazione finora

- Vectors Notes (Answers)Documento24 pagineVectors Notes (Answers)ScionNessuna valutazione finora

- Power - Factor - Correction - LegrandDocumento24 paginePower - Factor - Correction - LegrandrehanNessuna valutazione finora

- IVISOR Mentor IVISOR Mentor QVGADocumento2 pagineIVISOR Mentor IVISOR Mentor QVGAwoulkanNessuna valutazione finora

- Introduction To SCRDocumento19 pagineIntroduction To SCRAlbin RobinNessuna valutazione finora

- SKF CMSS2200 PDFDocumento2 pagineSKF CMSS2200 PDFSANTIAGONessuna valutazione finora

- Lalkitab Varshphal Chart PDFDocumento6 pagineLalkitab Varshphal Chart PDFcalvinklein_22ukNessuna valutazione finora

- Three Revolutionary Architects - Boullee, Ledoux, and Lequeu PDFDocumento135 pagineThree Revolutionary Architects - Boullee, Ledoux, and Lequeu PDFTran LeNessuna valutazione finora

- Zoom g2 1nu Manual Do Utilizador PDFDocumento56 pagineZoom g2 1nu Manual Do Utilizador PDFEliude Gonçalves FerreiraNessuna valutazione finora

- The Adoption of e Procurement in Tanzani PDFDocumento5 pagineThe Adoption of e Procurement in Tanzani PDFDangyi GodSeesNessuna valutazione finora

- 4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsDocumento4 pagine4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsRUSSELNessuna valutazione finora

- Each Life Raft Must Contain A Few ItemsDocumento2 pagineEach Life Raft Must Contain A Few ItemsMar SundayNessuna valutazione finora

- Backward Forward PropogationDocumento19 pagineBackward Forward PropogationConrad WaluddeNessuna valutazione finora

- BC 672772 RBRS Service TraningDocumento385 pagineBC 672772 RBRS Service TraningTeknik Makina100% (2)

- Efektifitas Terapi Musik Klasik Terhadap Penurunan Tingkat HalusinasiDocumento9 pagineEfektifitas Terapi Musik Klasik Terhadap Penurunan Tingkat HalusinasiAnis RahmaNessuna valutazione finora

- OOPS KnowledgeDocumento47 pagineOOPS KnowledgeLakshmanNessuna valutazione finora

- Gastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterDocumento9 pagineGastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterPier Pasquale TrausiNessuna valutazione finora

- Advanced Work Packaging: A Fit For Purpose ApproachDocumento17 pagineAdvanced Work Packaging: A Fit For Purpose Approachhafidz bandungNessuna valutazione finora

- AIF User Guide PDFDocumento631 pagineAIF User Guide PDFÖzgün Alkın ŞensoyNessuna valutazione finora

- Eurocode Conference 2023 Seters Van Eurocode 7Documento33 pagineEurocode Conference 2023 Seters Van Eurocode 7Rodolfo BlanchiettiNessuna valutazione finora

- Student Workbook: Advance 3Documento31 pagineStudent Workbook: Advance 3Damaris VegaNessuna valutazione finora

- Help SIMARIS Project 3.1 enDocumento61 pagineHelp SIMARIS Project 3.1 enVictor VignolaNessuna valutazione finora

- Dimmable Bulbs SamplesDocumento11 pagineDimmable Bulbs SamplesBOSS BalaNessuna valutazione finora

- Planning Theory Syllabus - 2016Documento24 paginePlanning Theory Syllabus - 2016LakshmiRaviChanduKolusuNessuna valutazione finora

- APPSC GROUP 4 RESULTS 2012 - Khammam District Group 4 Merit ListDocumento824 pagineAPPSC GROUP 4 RESULTS 2012 - Khammam District Group 4 Merit ListReviewKeys.comNessuna valutazione finora

- Catálogo StaubliDocumento8 pagineCatálogo StaubliJackson BravosNessuna valutazione finora

- GARCH (1,1) Models: Ruprecht-Karls-Universit at HeidelbergDocumento42 pagineGARCH (1,1) Models: Ruprecht-Karls-Universit at HeidelbergRanjan KumarNessuna valutazione finora

- Jazz PrepaidDocumento4 pagineJazz PrepaidHoney BunnyNessuna valutazione finora