Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Calcium Carbonate

Caricato da

mohammadazrai0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

86 visualizzazioni2 pagineCalcium Carbonate

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCalcium Carbonate

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

86 visualizzazioni2 pagineCalcium Carbonate

Caricato da

mohammadazraiCalcium Carbonate

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Further to an earlier successful road based trial, inBulk

Technologies were asked by a large Derbyshire based minerals

supplier to hold a full rail trial for delivery of their product to an

animal feeds company located in Scotland. The trial was

proposed to establish if an intermodal container could be filled

and transported from the Buxton Quarry to other locations on

the main rail network. Previous attempts to use intermodal

equipment had been ruled out due to rail network restrictions

on the line to Buxton. InBulk Technologies had the line re-

measured and set to work to design an ISO-Veyor that could fit

the restricted gauge of line using standard rail wagons.

In the mean time a low platform wagon was obtained to ensure

that there was ample clearance through the many long and

narrow tunnels to Buxton.

Loaded on to a timetabled EWS rail service the ISO-Veyor and

rail wagon was positioned into the loading facility. After a short

time filling had taken place via the 3 top hatches by a gravity fed

system. After filling with 26.6 tonnes of granular Calcium

Carbonate, the train then departed on its overnight journey to a

railhead local to the end customers Glasgow factory.

On arrival at a railhead, the ISO-Veyor can switch from a means

of transport and effectively become a temporary silo. Units can

be stacked when space is at a premium. In this case, the ISO-

Veyor was immediately transferred to a skeletal road trailer for

the onward journey to the final client by truck.

On arrival to the factory, the ISO-Veyor was parked adjacent to

the filling line in a similar way to standard road tankers. The

discharge process began by connecting the ISO-Veyor to the 2

barg tractor compressor unit.

Material Calcium Carbonate LG11 (food-grade)

Application Animal Feeds

Bulk Density 800kg/m

3

Flow Dowlow Quarry, Buxton - Renfrewshire, Scotland

Date November 2003

Unit 20 G Type unit in Carbon Steel for granular materials

The unit was completely discharged after 66 minutes and the

lorry was free to leave the premises after only 1.5 hrs, cutting a

significant amount of time from a normal delivery.

The resounding success of the ISO-Veyor proved that the

Buxton area could be a source of many rail connected materials

than first thought. The G Type ISO-Veyor had also discharged

the product in the same amount of time as a tipping tanker, but

without the need to be tipped. The ISO-Veyors ability to be

discharged from a horizontal position removes the necessity for

expensive, tipping chassis and significantly reduces the

potential from accidents on site.

The trial for Calcium Carbonate illustrates several key

benefits to the industry:

Fully intermodal Capable of any combination of road, rail or ship

Easy to Fill Can be filled in same way as road or rail tankers

Easy to Handle Standard ISO frame allows for standard container lifting

equipment

Easy Horizontal Discharge Simple connection to 2 barg compressor

provides a discharge rate comparable to road tankers

Provides flexible weatherproof storage and reduces dependency on silos

Creates platform for driver controlled deliveries

Overall ISO-Veyors minimise product handling, eliminates

contamination, maintains product quality and also protects

environment from accidental material spillages. Taking these

factors together, ISO-Veyors can significantly reduce the

requirements for intermediate handling, reducing the

requirements for silo construction and dramatically enhances

the overall efficiency of the supply chain.

Shaw Lane Industrial Estate

Doncaster

South Yorkshire DN2 4SE

T +44 (0)1302 321313

F +44 (0)1302 55 4470

1 Redwood Crescent

East Kilbride

Glasgow G75 5PA

T +44 (0)1355 575000

F +44 (0)1355 579600

enquiries@inbulktechnologies.com

www.inbulktechnologies.com

Potrebbero piacerti anche

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Da EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Valutazione: 5 su 5 stelle5/5 (2)

- Gladstone Ports Reclaim Tunnel Spillage ProjectDocumento5 pagineGladstone Ports Reclaim Tunnel Spillage ProjectProdip SarkarNessuna valutazione finora

- Coal Terminal at Port QasimDocumento31 pagineCoal Terminal at Port QasimTariq AzizNessuna valutazione finora

- The Privatisation Classes: A Pictorial Survey of Diesel and Electric Locomotives and Units Since 1994Da EverandThe Privatisation Classes: A Pictorial Survey of Diesel and Electric Locomotives and Units Since 1994Nessuna valutazione finora

- BANDRA WORLI SEA LINK-3rd YrDocumento10 pagineBANDRA WORLI SEA LINK-3rd YrManu Jain50% (2)

- Nepean Conveyors Projects CapabilityDocumento13 pagineNepean Conveyors Projects CapabilityFelipe RibeiroNessuna valutazione finora

- Bulk Solids Conveying For Heavy Industry - Gordon CrawfordDocumento2 pagineBulk Solids Conveying For Heavy Industry - Gordon CrawfordJakesNessuna valutazione finora

- Coal Terminals at PQADocumento31 pagineCoal Terminals at PQAtariq azizNessuna valutazione finora

- Barge Unloading To Conveyor: Project ProfileDocumento1 paginaBarge Unloading To Conveyor: Project ProfilehadeNessuna valutazione finora

- Wind Farm Access Road White PaperDocumento7 pagineWind Farm Access Road White PaperChris FindlayNessuna valutazione finora

- WK 10 - Material Handling System (Conveyors) 2t 2020-2021Documento65 pagineWK 10 - Material Handling System (Conveyors) 2t 2020-2021Mei Lamfao100% (1)

- 9 Engineering of Mechanical System and EquipmentDocumento38 pagine9 Engineering of Mechanical System and EquipmentMinh TríNessuna valutazione finora

- Stackers Active in The StockyardDocumento4 pagineStackers Active in The Stockyardsalkan_rahmanovic810Nessuna valutazione finora

- Locomotives For Heavy Industry-C. Wordsworth-1955Documento64 pagineLocomotives For Heavy Industry-C. Wordsworth-1955Goldburg GoldburgNessuna valutazione finora

- Application of Conveyors For UG HaulageDocumento11 pagineApplication of Conveyors For UG Haulageminerito2211Nessuna valutazione finora

- Bulk Cargo HandlingDocumento15 pagineBulk Cargo HandlingSomayajula SuryaramNessuna valutazione finora

- 1 s2.0 S0167903188907773 MainDocumento11 pagine1 s2.0 S0167903188907773 Main88127050Nessuna valutazione finora

- 2 Pipe Conveyor Installations in The United Kingdom S North East CoalfieldDocumento11 pagine2 Pipe Conveyor Installations in The United Kingdom S North East CoalfieldGregory Nick Toledo VelizNessuna valutazione finora

- EM202357MAR510ENGGDocumento9 pagineEM202357MAR510ENGGRosalie BachillerNessuna valutazione finora

- Boxer eDocumento16 pagineBoxer eIvan ErmolaevNessuna valutazione finora

- Bauxite ComparisonDocumento12 pagineBauxite Comparisondr_drk4503Nessuna valutazione finora

- Case History For Use of Maccaferri Paralink High Strength GeogridDocumento2 pagineCase History For Use of Maccaferri Paralink High Strength Geogridsandycastle100% (1)

- Siwertell Road-Mobile Unloaders Original 32998Documento4 pagineSiwertell Road-Mobile Unloaders Original 32998Gospodin RajkovićNessuna valutazione finora

- Chenab Bridge: P.Anil Kumar 1005-15-741508Documento20 pagineChenab Bridge: P.Anil Kumar 1005-15-741508vsballaNessuna valutazione finora

- Reuse of Shipping Containers PDFDocumento3 pagineReuse of Shipping Containers PDFsyNessuna valutazione finora

- Bulk Material HandlingDocumento5 pagineBulk Material HandlingPrasenjit BhuiyaNessuna valutazione finora

- Vocational Training Report Technical Training Centre: Banaras Locomotive WorksDocumento19 pagineVocational Training Report Technical Training Centre: Banaras Locomotive WorksHerry HerryNessuna valutazione finora

- Falkirk WheelDocumento1 paginaFalkirk WheelIndrajith Jeewan Kumara PereraNessuna valutazione finora

- (579390026) Caso 8 - Uso de Swellex en Grandes HidroelectricasDocumento7 pagine(579390026) Caso 8 - Uso de Swellex en Grandes Hidroelectricaskokolito192Nessuna valutazione finora

- Retrofitting Coanda Screens To Existing Hydroelectric Scheme IntakesDocumento7 pagineRetrofitting Coanda Screens To Existing Hydroelectric Scheme IntakesbarabatinaNessuna valutazione finora

- 56-61 - AS432411995 standardSeptOct12Documento6 pagine56-61 - AS432411995 standardSeptOct12spnaik100% (1)

- Conveying and StoringDocumento28 pagineConveying and StoringTin Nguyen100% (1)

- Basic Power Plant PDFDocumento21 pagineBasic Power Plant PDFAntony ClaranceNessuna valutazione finora

- Atyrau River Port Presentation EngDocumento19 pagineAtyrau River Port Presentation EngRitesh rmsNessuna valutazione finora

- Final PPT NTPC Dadri by VikasDocumento50 pagineFinal PPT NTPC Dadri by VikasTushar PandeyNessuna valutazione finora

- Archicture Design For Green HomesDocumento4 pagineArchicture Design For Green HomessokarankumarNessuna valutazione finora

- In-Pit Crushing and Conveying (IPCC) - A Tried and Tested Alternative To TrucksDocumento8 pagineIn-Pit Crushing and Conveying (IPCC) - A Tried and Tested Alternative To TrucksbamigdimNessuna valutazione finora

- Digger: Ship UnloaderDocumento16 pagineDigger: Ship UnloaderLeonardo CanditoNessuna valutazione finora

- M.V. Rocknes: Scheepsbouw Jacob PinksterDocumento9 pagineM.V. Rocknes: Scheepsbouw Jacob PinksterElias Bin Abdul RahimNessuna valutazione finora

- Pipeline Transportation Technology: An Overview: K. SubramanyaDocumento6 paginePipeline Transportation Technology: An Overview: K. SubramanyaharryicsaNessuna valutazione finora

- Aker Solutions (Wacker) - PAPER (10183) PDFDocumento7 pagineAker Solutions (Wacker) - PAPER (10183) PDFElsherif AlyNessuna valutazione finora

- Week 10 - Material Handling System (Conveyors) 2T 2021-2022Documento66 pagineWeek 10 - Material Handling System (Conveyors) 2T 2021-2022Pitt Andre LozadaNessuna valutazione finora

- Vessel Types: Bulk CarriersDocumento9 pagineVessel Types: Bulk CarriersIban Santana HernandezNessuna valutazione finora

- Trans Load Facility OverviewDocumento8 pagineTrans Load Facility OverviewBrad PritchardNessuna valutazione finora

- Case Study Heavy Haul Line Malmbanan EN PDFDocumento4 pagineCase Study Heavy Haul Line Malmbanan EN PDFArun BabuNessuna valutazione finora

- Kopex Famago Bucket Wheel ExcavatorDocumento20 pagineKopex Famago Bucket Wheel Excavator450gasgasNessuna valutazione finora

- Underground Railway TunnelingDocumento38 pagineUnderground Railway TunnelingSudeep SharmaNessuna valutazione finora

- Reuse of Shipping ContainersDocumento3 pagineReuse of Shipping ContainersMolly0630Nessuna valutazione finora

- Coal Handling System: Shaikh SaifDocumento30 pagineCoal Handling System: Shaikh SaifKrishna SinghNessuna valutazione finora

- Totally Precast Concrete Bridges: ForwardDocumento27 pagineTotally Precast Concrete Bridges: ForwardPECMURUGANNessuna valutazione finora

- Developments in Bulk Material Elevation TechnologyDocumento8 pagineDevelopments in Bulk Material Elevation TechnologyioanchiNessuna valutazione finora

- Inland Waterway Automation VesselDocumento5 pagineInland Waterway Automation VesselAryan Sehgal100% (1)

- 3EA46D986297C5A3Documento71 pagine3EA46D986297C5A3deepak.kothariNessuna valutazione finora

- JOEST SouthAfrica Broschure 2016 09 WebDocumento8 pagineJOEST SouthAfrica Broschure 2016 09 WebKarin AndersonNessuna valutazione finora

- The Design of Padma Multipurpose Bridge - Challenges and Solutions.Documento10 pagineThe Design of Padma Multipurpose Bridge - Challenges and Solutions.Jahidul IslamNessuna valutazione finora

- Brain Conveyor DewateringDocumento20 pagineBrain Conveyor DewateringPeter TabnerNessuna valutazione finora

- Pbe - 200810-Conveying Line Elbows Provide Maintenance-Free OperationDocumento4 paginePbe - 200810-Conveying Line Elbows Provide Maintenance-Free Operation설동하Nessuna valutazione finora

- Case History For Use of Maccaferri Paralink, MacRes and ParawebDocumento4 pagineCase History For Use of Maccaferri Paralink, MacRes and ParawebsandycastleNessuna valutazione finora

- LNG MitsubishiDocumento4 pagineLNG Mitsubishireade2011Nessuna valutazione finora

- Flare Tip FailureDocumento4 pagineFlare Tip FailuremohammadazraiNessuna valutazione finora

- TUV Nord TrainingDocumento39 pagineTUV Nord TrainingmohammadazraiNessuna valutazione finora

- Eng Lang A Exemplars P1 Writing and P2Documento83 pagineEng Lang A Exemplars P1 Writing and P2mohammadazraiNessuna valutazione finora

- Momentum 2 2012.ashxDocumento52 pagineMomentum 2 2012.ashxmohammadazraiNessuna valutazione finora

- Momentum 2 2012.ashxDocumento52 pagineMomentum 2 2012.ashxmohammadazraiNessuna valutazione finora

- Expansion Loop Guideline ExtractDocumento8 pagineExpansion Loop Guideline ExtractmohammadazraiNessuna valutazione finora

- Outreach P2 Math PDFDocumento131 pagineOutreach P2 Math PDFmohammadazraiNessuna valutazione finora

- Notaries Public KL & SelangorDocumento3 pagineNotaries Public KL & SelangormohammadazraiNessuna valutazione finora

- DNV Publication ListDocumento14 pagineDNV Publication ListmohammadazraiNessuna valutazione finora

- ASSAI Booklet Ver2Documento2 pagineASSAI Booklet Ver2mohammadazraiNessuna valutazione finora

- ASSAI Booklet Ver2Documento2 pagineASSAI Booklet Ver2mohammadazraiNessuna valutazione finora

- 3D & 5D Pipe Bend For PipelineDocumento6 pagine3D & 5D Pipe Bend For PipelinemohammadazraiNessuna valutazione finora

- Dupre - Travis Crane Operation and MaintenanceDocumento23 pagineDupre - Travis Crane Operation and MaintenancemohammadazraiNessuna valutazione finora

- Unscheduled DefermentDocumento60 pagineUnscheduled Defermentmohammadazrai50% (2)

- Propane RefrigerationDocumento4 paginePropane RefrigerationmohammadazraiNessuna valutazione finora

- TFP1305 07 2005Documento8 pagineTFP1305 07 2005mohammadazraiNessuna valutazione finora

- Cathelco ElectrochlorinationDocumento8 pagineCathelco ElectrochlorinationmohammadazraiNessuna valutazione finora

- Ameron PSXJFDocumento4 pagineAmeron PSXJFmohammadazraiNessuna valutazione finora

- A - Piping Joint HandbookDocumento161 pagineA - Piping Joint HandbookCharles Tauk100% (30)

- Tema DesignationDocumento12 pagineTema Designationmohammadazrai0% (1)

- SG12 L1 - Rotating Equipment (Pumps)Documento21 pagineSG12 L1 - Rotating Equipment (Pumps)mohammadazraiNessuna valutazione finora

- Cecilia-Puff-Tee-Final-OUSM-Designs-12 MESES A TALLA 8Documento19 pagineCecilia-Puff-Tee-Final-OUSM-Designs-12 MESES A TALLA 8Jose SanchezNessuna valutazione finora

- D 6000Documento6 pagineD 6000os_ja@hotmail.comNessuna valutazione finora

- A Year On A FarmDocumento368 pagineA Year On A FarmvehapkolaNessuna valutazione finora

- Highway-And-Railroad-Engineering SummaryDocumento15 pagineHighway-And-Railroad-Engineering SummaryRodin James GabrilloNessuna valutazione finora

- Presentation On 4G TechnologyDocumento23 paginePresentation On 4G TechnologyFresh EpicNessuna valutazione finora

- NAT-REVIEWER-IN-PHYSICAL EDUCATIONDocumento4 pagineNAT-REVIEWER-IN-PHYSICAL EDUCATIONMira Rochenie CuranNessuna valutazione finora

- Soldier of Fortune PDFDocumento208 pagineSoldier of Fortune PDFNixel SpielNessuna valutazione finora

- TM-8000 HD Manual PDFDocumento37 pagineTM-8000 HD Manual PDFRoxana BirtumNessuna valutazione finora

- American BreakfastDocumento4 pagineAmerican BreakfastHamilton Valenzuela ChipongianNessuna valutazione finora

- 1962 Gibson Johnny SmithDocumento5 pagine1962 Gibson Johnny SmithLuisNessuna valutazione finora

- Awakened Citizen Programme-Report-class VII-2014Documento4 pagineAwakened Citizen Programme-Report-class VII-2014bhsgeneral r m saraswathi50% (4)

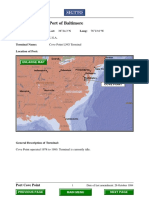

- Port Name: Port of BaltimoreDocumento17 paginePort Name: Port of Baltimoremohd1khairul1anuarNessuna valutazione finora

- 12.5 Collision Theory - ChemistryDocumento15 pagine12.5 Collision Theory - ChemistryAri CleciusNessuna valutazione finora

- Managing Diabetic Foot Ulcers ReadingDocumento21 pagineManaging Diabetic Foot Ulcers Readinghimanshugupta811997Nessuna valutazione finora

- 08 Activity 1 (10) (LM)Documento2 pagine08 Activity 1 (10) (LM)Jhanine Mae Oriola FortintoNessuna valutazione finora

- 02-Building Cooling LoadsDocumento3 pagine02-Building Cooling LoadspratheeshNessuna valutazione finora

- Module 4 Active Faults and Other Earthquake Sources: Learning OutcomeDocumento3 pagineModule 4 Active Faults and Other Earthquake Sources: Learning OutcomeFatima Ybanez Mahilum-LimbagaNessuna valutazione finora

- Math COT 3Documento18 pagineMath COT 3Icy Mae SenadosNessuna valutazione finora

- Reviews: The Global Epidemiology of HypertensionDocumento15 pagineReviews: The Global Epidemiology of Hypertensionrifa iNessuna valutazione finora

- Elements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesDocumento8 pagineElements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesSadman Shaid SaadNessuna valutazione finora

- Nissan Copper LTDDocumento11 pagineNissan Copper LTDankit_shahNessuna valutazione finora

- PPT DIARHEA IN CHILDRENDocumento31 paginePPT DIARHEA IN CHILDRENRifka AnisaNessuna valutazione finora

- Seminar On Solar Mobile Charger: Submitted To: Submitted byDocumento16 pagineSeminar On Solar Mobile Charger: Submitted To: Submitted byAkhila GottemukkulaNessuna valutazione finora

- Top Ten Myths About The BrainDocumento5 pagineTop Ten Myths About The BrainfayazalamaligNessuna valutazione finora

- Gypsum Plasterboard: National Standard of The People'S Republic of ChinaDocumento15 pagineGypsum Plasterboard: National Standard of The People'S Republic of ChinaGarry100% (2)

- Douluo Dalu Volume 05 - Star Dou Forest PDFDocumento141 pagineDouluo Dalu Volume 05 - Star Dou Forest PDFRay Joseph LealNessuna valutazione finora

- PIX4D Simply PowerfulDocumento43 paginePIX4D Simply PowerfulJUAN BAQUERONessuna valutazione finora

- Halfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PDocumento92 pagineHalfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PTulusNessuna valutazione finora

- Socialized HousingDocumento48 pagineSocialized HousingJessieReiVicedoNessuna valutazione finora

- Chapter 3.c (Centroid by Intergration)Documento15 pagineChapter 3.c (Centroid by Intergration)Ariff AziziNessuna valutazione finora

- Guidelines for Chemical Process Quantitative Risk AnalysisDa EverandGuidelines for Chemical Process Quantitative Risk AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDa EverandSodium Bicarbonate: Nature's Unique First Aid RemedyValutazione: 5 su 5 stelle5/5 (21)

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesDa EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesValutazione: 5 su 5 stelle5/5 (1)

- Phase Equilibria in Chemical EngineeringDa EverandPhase Equilibria in Chemical EngineeringValutazione: 4 su 5 stelle4/5 (11)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDa EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNessuna valutazione finora

- Process Plant Equipment: Operation, Control, and ReliabilityDa EverandProcess Plant Equipment: Operation, Control, and ReliabilityValutazione: 5 su 5 stelle5/5 (1)

- The Perfumed Pages of History: A Textbook on Fragrance CreationDa EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationValutazione: 4 su 5 stelle4/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlDa EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlValutazione: 4 su 5 stelle4/5 (4)

- Water-Based Paint Formulations, Vol. 3Da EverandWater-Based Paint Formulations, Vol. 3Valutazione: 4.5 su 5 stelle4.5/5 (6)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- An Applied Guide to Water and Effluent Treatment Plant DesignDa EverandAn Applied Guide to Water and Effluent Treatment Plant DesignValutazione: 5 su 5 stelle5/5 (4)

- Fundamentals of Risk Management for Process Industry EngineersDa EverandFundamentals of Risk Management for Process Industry EngineersNessuna valutazione finora

- A Chemical Engineer in the Palm Oil Milling IndustryDa EverandA Chemical Engineer in the Palm Oil Milling IndustryNessuna valutazione finora

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksDa EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNessuna valutazione finora

- Principles and Case Studies of Simultaneous DesignDa EverandPrinciples and Case Studies of Simultaneous DesignNessuna valutazione finora

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Distillation Design and Control Using Aspen SimulationDa EverandDistillation Design and Control Using Aspen SimulationValutazione: 5 su 5 stelle5/5 (2)

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Da EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Nessuna valutazione finora

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringDa EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillValutazione: 3.5 su 5 stelle3.5/5 (3)

- A New Approach to HAZOP of Complex Chemical ProcessesDa EverandA New Approach to HAZOP of Complex Chemical ProcessesNessuna valutazione finora

- Physical and Chemical Equilibrium for Chemical EngineersDa EverandPhysical and Chemical Equilibrium for Chemical EngineersValutazione: 5 su 5 stelle5/5 (1)

- The Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookDa EverandThe Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookNessuna valutazione finora