Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

11 DNV 2.7 3 Portable Offshore Units PDF

Caricato da

Argonauta_navegadorDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

11 DNV 2.7 3 Portable Offshore Units PDF

Caricato da

Argonauta_navegadorCopyright:

Formati disponibili

DNV 2.

7-3

Portable Offshore Units

Subsea Lifting Operations

KranTeknisk Forening

Per ystein Alvr

Stavanger, 28 November 2007

Det Norske Veritas AS. All rights reserved Slide 2 23 November 2007

2.7-3? What is that?

The intention of this lecture is to briefly answer:

What is DNV Standard for Certification 2.7-3?

How should 2.7-3 be used?

This is done by:

Clarifying why 2.7-3 has been issued

Giving a general overview of the content in 2.7-3 (J une

2006)

Describing what will be updated in the next revision

Indicating application of 2.7-3 for subsea

Det Norske Veritas AS. All rights reserved Slide 3 23 November 2007

International Regulations

IMOs MSC/Circ.860 Guidelines for the approval of

offshore containers handled in open seas

proposed to IMO by Norway

states that the International Convention for Safe Containers

(CSC) does not cover Offshore Containers

states that offshore containers should be approved by the

competent authorityor by organizations Duly authorized by

the Administration

states that offshore containers should be inspected annually

Refers to other standards for detail requirements, those listed

are DNV 2.7-1, DNV 2.7-2, EN 12079 and BS 7072 (withdrawn)

Det Norske Veritas AS. All rights reserved Slide 4 23 November 2007

Why 2.7-3?

Experience has shown that Standard for Certification No 2.7-1 "Offshore

Containers, is being used more and more in the industry today than ever

before. As a consequence of this increased demand, DNV customers

have voiced a strong requirement for a need to certify portable offshore

Units that are not shaped like containers, according to Standard for

Certification No 2.7-1.

As a result of this market demand Standard for Certification No 2.7-3 has

been developed, which covers all other types of portable offshore Units,

other than offshore containers. DNV firmly believes that this new

standard will meet the customers need for these services and at the

same time enable DNV to expand in this market segment.

This new Standard has been developed in close co-operation with the

update of the Standard for Certification No 2.7-1.

Det Norske Veritas AS. All rights reserved Slide 5 23 November 2007

Definition

Portable Offshore Units

Definition in SfC 2.7-3: Portable Unit or package with a maximum gross

weight not exceeding 50 tonnes, for repeated or single use with a

primary service function, handled in open seas, to, from or between

fixed and/or floating offshore installations and ships.

Also: Could be lifted subsea!

4 types defined:

- Type A, skids arranged with crash frames

- Type B, skids without crash frames

- Type C, no dedicated skid frame

- Type D, stress skin design

Det Norske Veritas AS. All rights reserved Slide 6 23 November 2007

Content in 2.7-3

GENERAL

Scope

Definitions

List of symbols

Documents for approval and information

National authorities

References

CERTIFICATION PROCEDURES

Introduction

Design Review

Testing and inspection

Certification of existing units

Maintenance of certificate

Summary of procedures

DESIGN

Structural strength

Welding

Design details

Units with tanks

Materials

Prototype Testing

MANUFACTURE

General

Welding

Secondary structure

Production documentation

Production testing

MARKING

Safety marking

Identification markings

Additional information markings (optional)

Other marking

INFORMATION PLATES

General

Operational limitations

Information plate

Inspection plate

OPERATIONAL RESTRICTIONS

PERIODIC EXAMINATION, TESTS AND REPAIRS

General

Inspection, test and repairs on units

Det Norske Veritas AS. All rights reserved Slide 7 23 November 2007

Test if SfC 2.7-3 is applicable

Tests to define type

A, B, C or D

Integrated service?

Use 2.7-2

Container shaped & W<25t?

Use 2.7-1

Tank for dangerous goods?

IMDG Code + 2.7-1

W < 50t?

VMO-Rules

X

Det Norske Veritas AS. All rights reserved Slide 8 23 November 2007

Procedure for Certification

Application sent to DNV.

Order confirmed and fees agreed.

Drawings, documentation and calculations reviewed and approval given

by the approval office.

Prototype offshore Unit manufactured under supervision of the Society's

Surveyor.

Unit tested according to prototype test requirements, witnessed by the

Society's Surveyor.

Production proceeds according to the agreed Quality Plan or

Manufacturing Survey Arrangement. Production tests according to list in

Section 4.5.

DNV surveyor issues Portable Offshore Unit Certificate (form 49.06a) and

affixes emblem.

Det Norske Veritas AS. All rights reserved Slide 9 23 November 2007

Design Requirements - General

Design to promote means for safe handling and transportation.

Selected criteria to cover a transportation event involving sea voyage and

lifting offshore.

Acceptable stress, structural displacement and stiffness.

Units designed for dynamic forces generated when handled in a sea

state of up to Hs = 6m, unless otherwise stated in operational limitations.

Units intended for repeated transportation events and to be mixed with

other frequent handled goods shall be free from protruding parts outside

the envelope of the Unit.

All Units in compliance with this Standard for Certification shall be

evaluated with regard to the risk of uncontrolled skidding and overturning

on a moving ship deck.

Consider type A, B, C or D as defined in section 1.1.

Det Norske Veritas AS. All rights reserved Slide 10 23 November 2007

Design - Structural Strength

Calculation Methods. Only the primary structure shall be included in the

design calculations.

Allowable Stresses. Von Mises equivalent stresses,

e

= 0.85C. For steel:

C = Re = minimum yield stress.

Design Lifting Loads:

- Primary structure: F = 2.5 x MGW x g

- pad eye: Single padeye: RSF = 2 x F

Impact Loads:

- Horizontal impact

- Vertical impact (Drop test)

- Minimum thicknesses

Welding

- Red. factor: Fillet = 0.5, partial = 0.75 and full pen. = 1.0

) ( ) 1 (

2 . 1

Cos n

F

RSF

=

SKL

Sling angle

Det Norske Veritas AS. All rights reserved Slide 11 23 November 2007

Pad Eyes

- Not outside unit

- Dim requirements: D

hole

< R

padeye_pl

T

padeye

> 75% Shackle inside width

- Strength: Req. to combined stress on net area

Other details:

- ISO-corner Castings

- Drainage

- Fork Lift Pockets

- Walls

- Equipment and Supports for equipment

- Lashing

- Tugger points

- Doors and hatches

- Coating and Corrosion Protection

Design Details

Det Norske Veritas AS. All rights reserved Slide 12 23 November 2007

Materials and Manufacture

Design temperature, normally -20 C

Steel quality requirements

Aluminium and other materials

Welding Qualification

Inspection of Welds

Secondary structure

Production documentation

Det Norske Veritas AS. All rights reserved Slide 13 23 November 2007

Testing Requirements

All point lifting test

- Mandatory, maybe omitted for single

transports

- Test load: 2.5 x MGW

2-point Lifting

- DNV decide if necessary

- May not pass calculations

- Test load: 1.5 x MGW

Vertical Impact Test

- Drop or lowering test

- Could be substituted by calculations

less for MGW > 25t

less for MGW > 25t

Test conclusion: Spreader

frame is required!

Det Norske Veritas AS. All rights reserved Slide 14 23 November 2007

Marking

Safety marking

Identification by Certificate number

Information Plate

- Name of manufacturer.

- Month/year of manufacture.

- Manufacturer's serial number.

- Maximum gross weight (kg) at design sling angle.

- Design temperature.

- DNVs Inspector Stamp (Ref. 4.4).

- Operational restrictions (if any).

Inspection Plate

The International

Convention for Safe

Containers, CSC

Det Norske Veritas AS. All rights reserved Slide 15 23 November 2007

The need for stricter operational restrictions The need for stricter operational restrictions

than the general restriction than the general restriction Hs = 6.0m Hs = 6.0m for for

the offshore lift shall be evaluated. the offshore lift shall be evaluated.

Limitations of sea state for the transport Limitations of sea state for the transport

event could be applicable. event could be applicable.

A specially arranged procedure or A specially arranged procedure or

arrangements for handling or sea fastening arrangements for handling or sea fastening

could be required. could be required.

It is advised that an agreement on the It is advised that an agreement on the

possible operational restrictions is possible operational restrictions is

established with DNV in an early stage of established with DNV in an early stage of

the enterprise. the enterprise.

Operational restrictions

Section 7 in SfC (Standard for Certification) 2.7-3 include a text that

unfortunately is rather unclear, but it generally says:

Det Norske Veritas AS. All rights reserved Slide 16 23 November 2007

Plans for Next Revision Slide 1

Improve the definition of the borderbetween 2.7-1 and 2.7-3 including

limitations for units that can be certified according to 2.7-3.

It should be made mandatory to define clearly (upper) operation

limitations. The revised CN shall include (specific) guidance on how to

do this. One proposal is to categorize the units into, say 3 classes with

lift limitations at 6m (as 2.7-1), 4m and 2.5m. The categorization should

be based on the design (i.e. type A, B, C or D), single or multiple use

and weight.

For (very) special units it should be stated that a handling procedure

both for sea transport and offshore lift should be made and presented for

review.

Criteria for sea transport are vaguely described. Design requirements

for the transport to be included.

Design and documentation requirements to lifting sets should be

included (at least) as an option.

Det Norske Veritas AS. All rights reserved Slide 17 23 November 2007

Plans for Next Revision Slide 2

Tables showing test lift weights will be revised/corrected.

Weld type requirements and some manufacturing requirements to be

reviewed.

2.7-1 includes several appendices with useful information. It will be

considered to include something similar in 2.7-3.

Include, as for 2.7-1, a tailor made certificate form.

Description of DNV 2.7-3 emblem, as for 2.7-1, to be included.

Several typing errors and incorrect references will be corrected.

Det Norske Veritas AS. All rights reserved Slide 18 23 November 2007

Next Revision: Chapter 3 Design

Chapter 3 Designwill be considerably updated, e.g.:

- The general design factor - 2.5 for lift, will be a function of, op. lim. Hs,

weight and subsea or not.

- Specific design requirements for transport will be included, normally 1g

- Accept criteria for stress and stability to be clarified.

- Deflection accept criteria to be deleted/updated (clarified why).

- Recommendations for vertical impact calculations.

- Minimum thickness requirement modify considering weight & optional

impact test.

- Padeye design criteria Clarify/update and include 2.7-1 formulae as option.

- Clarify requirements to equipment and equipment supports

- Lashing and tugger points rewrite requirements

- Include more guidance on when 2-point lift test & impact test are required.

- Subsea use (next slide)

Det Norske Veritas AS. All rights reserved Slide 19 23 November 2007

Subsea Design Factor, Lift

Design factor structure: 3.0 (2.8) This covers DAF and LF

Additional factor for padeyes as for lift in air

The following design requirements will be included to cover subsea:

In order to ensure that the unit could be installed without too strict

operational limitations the drag area and volume, including added

volume/mass should be reasonably limited.

The revised 2.7-3 will include some guidance on how to obtain an unit that

do not need any special procedures to be installed.

The recommendations will be further reviewed, but will be something like:

A/Ws < 1.0 where A is drag area and Ws is the submerged weight

V/Ws < 2.0 where V is the volume of the unit + added (water) mass

Det Norske Veritas AS. All rights reserved Slide 20 23 November 2007

Subsea Design Considerations

All air filled members shall be designed for the maximum hydrostatic

pressure, or proper ventilation/water filling shall be ensured.

Placing of lift points below CoG is normally not acceptable.

Lift point should be placed/designed in such a way that the risk of

damage and/or accidental release of rigging is neglectable.

Effect of horizontal wave loads. (tilt of object in splash zone).

Local design for slamming loads.

Tugger points for horizontal and rotational control.

Guiding system for final positioning.

Retrieval loads, if applicable.

A set of additional (for subsea) design considerations, as

indicated in the list below, will be included.

Det Norske Veritas AS. All rights reserved Slide 21 23 November 2007

Subsea Operational Aspects

All assumed operational limitations shall be clearly marked on the unit. This

could be:

Installation wave height/periods (if evaluated/applicable)

Special considerations, e.g. pass splash zone with inclination

Maximum water depth

Allowable loads on tugger points and guiding systems

Sling angles

The installation contractor needs to do a final assessment of the applicable

operation limitations based on the actual installation vessel and procedure.

Installation means on the unit, e.g. as marking, ROV grab bars, skids for

monitoring systems/equipment, should be installed as agreed.

A set of additional (for subsea) operational aspects, as

indicated in the list below, will be included.

Det Norske Veritas AS. All rights reserved Slide 22 23 November 2007

http://webshop.dnv.com/global/

1

2

3

4

Det Norske Veritas AS. All rights reserved Slide 23 23 November 2007

Potrebbero piacerti anche

- Structural Design of Self-Elevating Units (LRFD Method) : DNV-OS-C104Documento41 pagineStructural Design of Self-Elevating Units (LRFD Method) : DNV-OS-C104Chinmaya Ranjan JenaNessuna valutazione finora

- Sevan FPSO ConceptDocumento38 pagineSevan FPSO ConceptthunderNessuna valutazione finora

- Heavy Lift Installation Study of Offshore Structure 2004Documento203 pagineHeavy Lift Installation Study of Offshore Structure 2004Quang-derer75% (4)

- DNV Os H205Documento45 pagineDNV Os H205havona100% (1)

- Mordec Deck Fittings CatalogueDocumento32 pagineMordec Deck Fittings Catalogueseptian nurpratamaNessuna valutazione finora

- SkyCiv Sample DNV 2 7 1 Design Report Example Integrated PDFDocumento11 pagineSkyCiv Sample DNV 2 7 1 Design Report Example Integrated PDFCarlos Eduardo Alvarez SantiagoNessuna valutazione finora

- Pad Eye Designwww - Thenavalarch.com Rev B SI UnitsDocumento10 paginePad Eye Designwww - Thenavalarch.com Rev B SI UnitsndesigngmailNessuna valutazione finora

- DNV LiftingDocumento50 pagineDNV LiftingJuan Francisco Hernandez Reyes100% (3)

- DNV 2.7 3 Portable Offshore Units OverviewDocumento23 pagineDNV 2.7 3 Portable Offshore Units Overviewhelden50229881100% (4)

- NORSOK-Lifting Systems Standard, 2012Documento186 pagineNORSOK-Lifting Systems Standard, 2012Cristina RicanNessuna valutazione finora

- Design For Skid ProcedureDocumento15 pagineDesign For Skid Proceduredesignhub152100% (1)

- Offshore Lifting For Subsea EquipmentDocumento80 pagineOffshore Lifting For Subsea Equipmentnthong100% (2)

- MIL STD 120 Gage InspectionDocumento216 pagineMIL STD 120 Gage Inspectionokamo100% (4)

- DNV Marine Operations Rules For Subsea LiftsDocumento47 pagineDNV Marine Operations Rules For Subsea LiftsAnonymous ugCWo0Acz3100% (1)

- PT Gunanusa Utama Fabricators: Calculation SheetDocumento29 paginePT Gunanusa Utama Fabricators: Calculation SheetRiandi HartartoNessuna valutazione finora

- MOSES Advanced TrainingDocumento4 pagineMOSES Advanced TrainingYudha MeremNessuna valutazione finora

- ABS Fatigue Life Assessment 2014Documento1 paginaABS Fatigue Life Assessment 2014Fandy SipataNessuna valutazione finora

- Subsea Dropped ObjectsDocumento2 pagineSubsea Dropped ObjectsAustin AsuquoNessuna valutazione finora

- DNV Os C104 2014Documento40 pagineDNV Os C104 2014Moe LattNessuna valutazione finora

- Change APItoISODocumento9 pagineChange APItoISOStephen KokoNessuna valutazione finora

- Installation Procedures Offshore Jacket - CompiledDocumento62 pagineInstallation Procedures Offshore Jacket - CompiledErlangga Sada100% (1)

- HTML-PS00001441 enDocumento367 pagineHTML-PS00001441 enMarco Antonio Gutierrez Garduno100% (2)

- Lifting Operations (VMO Standard - Part 2-5) : DNV-OS-H205Documento45 pagineLifting Operations (VMO Standard - Part 2-5) : DNV-OS-H205Vacheron ConstantineNessuna valutazione finora

- OMAE2012 84121 PresentationDocumento16 pagineOMAE2012 84121 PresentationsojanvasudevanNessuna valutazione finora

- DNV RP-H103 Marine Operation Modelling & AnalysesDocumento2 pagineDNV RP-H103 Marine Operation Modelling & AnalysesRamadhani Satya0% (1)

- Hemispherical Head Design ToolDocumento1 paginaHemispherical Head Design Toolnaveen_86Nessuna valutazione finora

- D-002 System Requirements Well Intervention EquipmentDocumento70 pagineD-002 System Requirements Well Intervention Equipmentbrucce13Nessuna valutazione finora

- Calculation Sheet Lifting Set DNV 2.7-1 FOR 20ft PDFDocumento3 pagineCalculation Sheet Lifting Set DNV 2.7-1 FOR 20ft PDFNguyễn Quốc Phượng100% (1)

- Riser DesgnDocumento13 pagineRiser Desgnplatipus_8575% (4)

- DNV-Offshore Raiser Systems-OSS-302 PDFDocumento36 pagineDNV-Offshore Raiser Systems-OSS-302 PDFairlinemembershipNessuna valutazione finora

- DNV - Structure Design of Offshore Ships PDFDocumento252 pagineDNV - Structure Design of Offshore Ships PDFCandraNessuna valutazione finora

- Padeye Deign.Documento14 paginePadeye Deign.Bolarinwa100% (3)

- International StandardDocumento20 pagineInternational StandardRodrigo Simões100% (1)

- 1 - The Different Phases of A Subsea Lift From An Offshore Construction Vessel - KTF 2009Documento48 pagine1 - The Different Phases of A Subsea Lift From An Offshore Construction Vessel - KTF 2009harry_1981Nessuna valutazione finora

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDa EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNessuna valutazione finora

- EC3 - Offshore Padeye DesignDocumento4 pagineEC3 - Offshore Padeye Designscaricatutto100% (1)

- Export SCR Riser Analysis Report - Kim Young TaeDocumento30 pagineExport SCR Riser Analysis Report - Kim Young TaeYoungtae Kim100% (1)

- Calculation Sheet Lifting Set DNV 2Documento3 pagineCalculation Sheet Lifting Set DNV 2yanaziNessuna valutazione finora

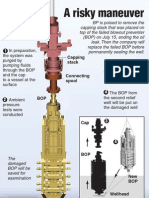

- Diagram of The Blowout PreventerDocumento1 paginaDiagram of The Blowout PreventerThe State NewspaperNessuna valutazione finora

- Har-Bach Marketing, Inc. Padeye Evaluation Safety Warnings/Instructions Project 21721Documento12 pagineHar-Bach Marketing, Inc. Padeye Evaluation Safety Warnings/Instructions Project 21721Damar Budi LaksonoNessuna valutazione finora

- Dokumen - Tips DNVGL ST n001 Marine Operations and Marine WarrantyDocumento7 pagineDokumen - Tips DNVGL ST n001 Marine Operations and Marine WarrantyMich ElleNessuna valutazione finora

- DNV 2.7-1 & 2.7-3 Seminar: DNV 2.7-2, DNV 2.22 & Container-Related Services in DNV HoustonDocumento18 pagineDNV 2.7-1 & 2.7-3 Seminar: DNV 2.7-2, DNV 2.22 & Container-Related Services in DNV HoustoncristianoclemNessuna valutazione finora

- 120kn Gravity Luffing Arm Type Davit 120kn艇架 规格书(中英)Documento8 pagine120kn Gravity Luffing Arm Type Davit 120kn艇架 规格书(中英)Ivan MaltsevNessuna valutazione finora

- Offcom Completa - v.01Documento7 pagineOffcom Completa - v.01Argonauta_navegadorNessuna valutazione finora

- Offcom Completa - v.01Documento7 pagineOffcom Completa - v.01Argonauta_navegadorNessuna valutazione finora

- Wind Turbine Installation VesselsDocumento30 pagineWind Turbine Installation Vesselsyoler478Nessuna valutazione finora

- Figure Union Identification Instructions-NEWDocumento4 pagineFigure Union Identification Instructions-NEWArgonauta_navegadorNessuna valutazione finora

- B. Equivalent Axial (N) and Lateral (Q) Loads: SD SDDocumento2 pagineB. Equivalent Axial (N) and Lateral (Q) Loads: SD SDRahul Malani100% (1)

- Cube TestDocumento7 pagineCube TestMani PathakNessuna valutazione finora

- 3 - DNV Rules For Marine OperationsDocumento48 pagine3 - DNV Rules For Marine OperationsgalvigarciaNessuna valutazione finora

- IMarEST Metocean Procedures GuideDocumento26 pagineIMarEST Metocean Procedures Guidecxb07164100% (1)

- Offcon DNV Zorro SkidDocumento7 pagineOffcon DNV Zorro SkidRAMSINGH CHAUHANNessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolMohammad Kamal HabbabaNessuna valutazione finora

- SACS Software Offshore Structures Design Rev1Documento2 pagineSACS Software Offshore Structures Design Rev1Boonme ChinnaboonNessuna valutazione finora

- Allowable Thickness Diminution For Hull Structure of Offshore ShipsDocumento12 pagineAllowable Thickness Diminution For Hull Structure of Offshore ShipsMido MohamedNessuna valutazione finora

- Subsea StructureDocumento2 pagineSubsea StructureobumuyaemesiNessuna valutazione finora

- Calculation For Hull Strength Construction in Offshore Structures PDFDocumento10 pagineCalculation For Hull Strength Construction in Offshore Structures PDFcxb07164Nessuna valutazione finora

- DNVGL Se 0080Documento27 pagineDNVGL Se 0080Marco CordonNessuna valutazione finora

- DNV Os H205 - 2014 04 Lifting OperationsDocumento45 pagineDNV Os H205 - 2014 04 Lifting OperationsAris8386Nessuna valutazione finora

- Lifting Analysis Preview)Documento4 pagineLifting Analysis Preview)Faisal AjaNessuna valutazione finora

- DNV OS C102 Structural Design of Offshore ShipsDocumento36 pagineDNV OS C102 Structural Design of Offshore ShipsAnis KacemNessuna valutazione finora

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDa EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNessuna valutazione finora

- DLT Strand Jacks - Operating SequencesDocumento52 pagineDLT Strand Jacks - Operating Sequencespranav_ravalNessuna valutazione finora

- Report On GCDocumento35 pagineReport On GCSandeep SuryavanshiNessuna valutazione finora

- DNV 1996Documento22 pagineDNV 1996ankeshkatochNessuna valutazione finora

- Why Good Mooring Systems Go Bad 7 16 14Documento41 pagineWhy Good Mooring Systems Go Bad 7 16 14pradewoNessuna valutazione finora

- Alvaer DNV2.7-3 PDFDocumento23 pagineAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- Portable Offshore UnitDocumento24 paginePortable Offshore UnitshonialamNessuna valutazione finora

- RP c102 - 2002 02 PDFDocumento252 pagineRP c102 - 2002 02 PDFSushant SheteNessuna valutazione finora

- 2.1-16'' 2MDocumento1 pagina2.1-16'' 2MArgonauta_navegadorNessuna valutazione finora

- 2.1-16'' 30MDocumento1 pagina2.1-16'' 30MArgonauta_navegadorNessuna valutazione finora

- 2.1-16'' 10MDocumento1 pagina2.1-16'' 10MArgonauta_navegadorNessuna valutazione finora

- 2.1-16'' 15MDocumento1 pagina2.1-16'' 15MArgonauta_navegadorNessuna valutazione finora

- 2.1-16'' 5MDocumento1 pagina2.1-16'' 5MArgonauta_navegadorNessuna valutazione finora

- 2.1-16'' 20MDocumento1 pagina2.1-16'' 20MArgonauta_navegadorNessuna valutazione finora

- 1.13-16'' 2MDocumento1 pagina1.13-16'' 2MArgonauta_navegadorNessuna valutazione finora

- 1.13-16'' 20mDocumento1 pagina1.13-16'' 20mArgonauta_navegadorNessuna valutazione finora

- 1.25-32'' 10M - 2.5'' 2900Documento1 pagina1.25-32'' 10M - 2.5'' 2900Argonauta_navegadorNessuna valutazione finora

- 1.13-16'' 10MDocumento1 pagina1.13-16'' 10MArgonauta_navegadorNessuna valutazione finora

- 1.13-16'' 15MDocumento1 pagina1.13-16'' 15MArgonauta_navegadorNessuna valutazione finora

- Ball Injector O&m InstructionDocumento12 pagineBall Injector O&m InstructionArgonauta_navegadorNessuna valutazione finora

- 1.13-16'' 30MDocumento1 pagina1.13-16'' 30MArgonauta_navegadorNessuna valutazione finora

- 1.13-16'' 5MDocumento1 pagina1.13-16'' 5MArgonauta_navegadorNessuna valutazione finora

- D 001Documento51 pagineD 001E_Amr_SorourNessuna valutazione finora

- 1.11-16'' 15MDocumento1 pagina1.11-16'' 15MArgonauta_navegadorNessuna valutazione finora

- Tension Lift Frame AssemblyDocumento2 pagineTension Lift Frame AssemblyArgonauta_navegadorNessuna valutazione finora

- 2.starting Up ANSYSDocumento2 pagine2.starting Up ANSYSnishantsinghbmeNessuna valutazione finora

- Introduction AnsysDocumento1 paginaIntroduction AnsysRicardo BrancoNessuna valutazione finora

- Introduction AnsysDocumento1 paginaIntroduction AnsysRicardo BrancoNessuna valutazione finora

- API 53 Principais Mudanças - 4edição Vs 3 EdiçãoDocumento39 pagineAPI 53 Principais Mudanças - 4edição Vs 3 EdiçãoArgonauta_navegadorNessuna valutazione finora

- FCE Well Testing Alert Rev 1 - CompletDocumento6 pagineFCE Well Testing Alert Rev 1 - CompletOscar Gomez GonzalezNessuna valutazione finora

- Pipe Fittings Type ApprovalDocumento5 paginePipe Fittings Type ApprovalArgonauta_navegadorNessuna valutazione finora

- FS2 Episode 6-10Documento24 pagineFS2 Episode 6-10Ian Dante ArcangelesNessuna valutazione finora

- 05 MAS Distributed Constraint OptimizationDocumento124 pagine05 MAS Distributed Constraint Optimizationhai zhangNessuna valutazione finora

- Administrator's Guide For Oracle Internet DirectoryDocumento820 pagineAdministrator's Guide For Oracle Internet Directorygleen lewisNessuna valutazione finora

- Unit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsDocumento6 pagineUnit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsCristina Garcia50% (2)

- Sewage Air ValveDocumento10 pagineSewage Air ValveAhmed TalaatNessuna valutazione finora

- Alfian Dwi Nugroho S.T: Geodetic EngineeringDocumento1 paginaAlfian Dwi Nugroho S.T: Geodetic EngineeringAlfian Dwi NugrohoNessuna valutazione finora

- Unit 2Documento84 pagineUnit 2Ashok (Ak)Nessuna valutazione finora

- NVOC Advisory No. 158Documento2 pagineNVOC Advisory No. 158Pearly RederaNessuna valutazione finora

- Roller Coaster Tycoon 3 ManualDocumento14 pagineRoller Coaster Tycoon 3 Manualjohnlondon125Nessuna valutazione finora

- Air Flow in IncubatorDocumento4 pagineAir Flow in IncubatorsambadeeNessuna valutazione finora

- At The End of This Lecture You Will Be Able To:: - Linux Operating SystemDocumento11 pagineAt The End of This Lecture You Will Be Able To:: - Linux Operating SystemAlex KharelNessuna valutazione finora

- CharCoat CC - Cable Coating - Fireproof Coating - Cable RepairDocumento5 pagineCharCoat CC - Cable Coating - Fireproof Coating - Cable RepairnaveedfndNessuna valutazione finora

- Realtek Wi-Fi SDK For Android KK 4 4Documento15 pagineRealtek Wi-Fi SDK For Android KK 4 4recruitment actNessuna valutazione finora

- Order - 57 Confined Space ProcedureDocumento38 pagineOrder - 57 Confined Space ProcedureJay PrasanthNessuna valutazione finora

- FST-1 (E) 2015yrDocumento3 pagineFST-1 (E) 2015yrRahulBhagatNessuna valutazione finora

- Master List of Doc - Anx 01Documento10 pagineMaster List of Doc - Anx 01yagnaashi9092Nessuna valutazione finora

- SAVA LEAFLET A4 EN TyresDocumento2 pagineSAVA LEAFLET A4 EN TyresFilipposNessuna valutazione finora

- 18-12-07 Rieckermann Indonesia LNG EXTERNAL TMKDocumento34 pagine18-12-07 Rieckermann Indonesia LNG EXTERNAL TMKadiNessuna valutazione finora

- Outlook Folder Appears Empty Even Though There Are Emails in ItDocumento4 pagineOutlook Folder Appears Empty Even Though There Are Emails in ItMartin GreenNessuna valutazione finora

- DIP167 Engineering Graphics Marathi Diploma 284Documento284 pagineDIP167 Engineering Graphics Marathi Diploma 284CIVIL ENGINEERINGNessuna valutazione finora

- Array DSDocumento10 pagineArray DSsriNessuna valutazione finora

- Pe1024-Mb-Mfb030-011200 38 GT#1 MBX PDFDocumento1 paginaPe1024-Mb-Mfb030-011200 38 GT#1 MBX PDFAldo Quispe HuarachiNessuna valutazione finora

- Infineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Documento15 pagineInfineon SPP - I - A15N60C3 DS v03 - 03 EN 53478Jeferson TorresNessuna valutazione finora

- Value1200ELCD/Value1500ELCD/Value2200ELCD User 'S Manual: Important Safety Instructions Basic OperationDocumento2 pagineValue1200ELCD/Value1500ELCD/Value2200ELCD User 'S Manual: Important Safety Instructions Basic OperationDigimonNessuna valutazione finora

- Philips Professional Lighting Price Effective Sept 2013Documento103 paginePhilips Professional Lighting Price Effective Sept 2013nageshwariNessuna valutazione finora

- A New Approach To Defining Human Touch Temperature Standards: July 2010Documento8 pagineA New Approach To Defining Human Touch Temperature Standards: July 2010Edna Odette Melo UscangaNessuna valutazione finora

- FT ExadropDocumento2 pagineFT ExadropABRAHAM MANUEL MEDINA LEYTONNessuna valutazione finora

- TC55 Android KK BSP v2.68 GMS LifeGuard Update 11 ReleaseNotesDocumento9 pagineTC55 Android KK BSP v2.68 GMS LifeGuard Update 11 ReleaseNotesJose De LeonNessuna valutazione finora