Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Standard Burner Configurations Use Modulated Combustion

Caricato da

mick2560Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Standard Burner Configurations Use Modulated Combustion

Caricato da

mick2560Copyright:

Formati disponibili

Standard burner configurations use modulated combustion, in which the amount of

gas and/or air admitted through all the burners in the same zone is adjusted by a

proportioning valve driven by an actuator motor, which is in turn driven by the output

of the zone's loop controller. The burners can be set up with constant excess air

(only the gas is modulated), or the gas and air can be separately modulated in

tandem, in an attempt to preserve a given flame stoichiometry. When the demand is

low, the gas+air is also low, as is the flame size at the burners, and the flame size

(and velocity) increase with increasing demand as the proportioning valve is opened.

Pulsed combustion replaces this "amplitude modulation" approach with "frequency

modulation". In a pulsed combustion setup, the burners are always run at 100%

capacity (and thus also at their highest output velocity), and varying energy demand

is accommodated by changing the amount of time the burners are kept at high-fire.

For example, a 40% demand is achieved by having the burners fire at 100%

capacity, but only for 40% of the time in any given interval, with the balance of the

interval being either off, or at a minimal-energy low-fire setting. This results in the

same amount of overall energy delivery as would be obtained from modulated

burners running at 40% of capacity, but the characteristics of the overall combustion

from the two approaches are quite different, and pulsed combustion provides many

advantages which have motivated (and justified) the adoption of pulsed combustion

in the United States over the past 15 years.

TYPICAL PULSED BURNER INSTALLATION

Combustion air is led to the burner through the air pulse valve. When the air pulse

valve is closed, a low-fire bypass tube provides sufficient air flow to maintain a

small, stable pilot flame; when open, the burner operates at maximum output. The

burner alternates between these two combustion settings, with an on/off duty cycle

determined by the PID loop controllers % output demand for that combustion zone.

High-fire control impulses, generated by the Kiltel supervisory system and burner

control panel, are typically 3-5 seconds duration.

A cross-feed air line is led from the burner air inlet (downstream from the air pulse

valve) to the gas ratio regulator, and the regulators gas throughput is modulated by

the pressure in this line. When the air pulse valve is open, the regulator passes its

maximum gas flow, which is adjusted by the limiting gas valve so the burner

produces its greatest high-velocity output at a defined flame stoichiometry. When the

air pulse valve is closed, the amount of gas flow is adjusted at the regulator to

maintain a small stable pilot flame. Modern high-velocity burners designed

specifically for pulsing typically have turn-down ratios (ratio of high-fire to low-fire

output energy delivery) of 20 or more (ie, the burner can maintain a stable low-fire

setting at 5% or less of the burner's maximum output).

The flame safety unit (fsu) monitors the presence of a flame with its flame sensor

(UV or flame rod), and controls gas flow to the burner via a blocking valve which

shuts in case of flameout. A dedicated ignition transformer performs automatic

light-off when the fsu is enabled from the supervisory control system. FSUs are

required for all burners on periodic kilns, and for any tunnel kiln burner where the kiln

temperature is less than 1400F and will not ensure autoignition of admitted gas in

the event of flame failure at the burner.

Since the burners operation is limited to high- and low-fire only, the flame

characteristics and burner tuning can be optimized precisely, resulting in the highest

possible combustion efficiency (vs. conventional modulated operation), as well as

the lowest possible NOx production (for a given burner design). All of Kiltels

pulsed combustion installations have reduced fuel consumption by at least 12%,

many over 20%.

Multiple burners in the same control zone are all pulsed with same duty cycle, but

each burner is assigned a different firing phase. Staggered pulsing ensures an even

kiln pressure, while high-velocity burner outputs produce the greatest kiln

atmosphere circulation and ensure uniform heat penetration throughout the load.

COMPLETE SUPPORT FOR PULSED COMBUSTION

Kiltel's supervisory system includes complete support for pulsed combustion,

including the logical association of burners with control zones as well as the physical

sourcing of electrical burner-enabling signals. This capability means that pulsed

combustion can be implemented from a Kiltel system without any additional pulse-

control electronics, for considerable savings in cost and efficiency. Pulsed

combustion can be used with both continuous and periodic kilns.

In pulsed combustion, the burner is always run at its maximum high-fire output, and

variable levels of energy deposition are achieved by repeatedly switching the burner

between 100% full-on and nearly-off (typically the smallest stable pilot flame), for

precise amounts of time, combustion "pulses". This requires special fuel and air

valves which can be quickly and repeatedly pulsed, to follow a pulsed electrical

control signal. The Kiltel system translates the controller's output demand into

switched pulsing output signals with on/off timing computed to provide the needed

level of output.

KILTEL's pulse generation algorithm re-evaluates the controller demand each minute

and sends a new set of pulse-timing instructions to each of the pulse generating

modules. Burner pulse control is divided into four regimes, depending on the output

demand level:

The resulting on/off waveforms are generated as a continuous pulse train by each

Kiltel burner control module. This output is generated at the hardware level, without

requiring further intervention from the supervisory program until a change in demand

necessitates new timing instructions.

Multiple burners in a single control zone (ie, which are controlled together to match

the single demand level for that zone) can be pulsed either together or in a

staggered sequence to achieve some degree of randomness. Burner phasing in

this manner can be used to enhance the degree of mixing and load penetration of

the multiple burner flames.

Since each pulsed burner has its own control valves, with independent access to fuel

and air, design considerations such as the assignment of burners to control zones

and the firing order of multiple burners within each zone, are now made as a setup

specification in the control software rather than a permanent design choice executed

in (expensive) plumbing. Burner arrangements and kiln zoning are thus totally

flexible and can easily be modified to achieve optimum performance; this flexibility

also permits kilns to be instantly re-zoned to accommodate changes in ware or in

throughput.

Each burner is assigned a burner number which must be unique and not duplicated

by any other burner on the same or any other kiln in the system. This is used mainly

as a housekeeping quantity within the program (ie, has no operational significance),

but is very useful for burner maintenance, as it will indicate which burner may need

attention in case of any problems.

Each pulsed burner is assigned to a control zone by selecting a burner control pv

from a list of PVs which are all zone controller outputs. By this means, burners can

easily be (re)assigned to any available zone of control. The pulsing output for this

burner (and all others in the same control zone) will be determined by the dynamic

output demand requirements from the loop controller for that zone.

Pulsed burners may or may not be fitted with a Flame Safety Unit (FSU). An FSU

ensures that gas is only supplied to the burner while there is a stable flame; this also

typically includes the capability for auto-ignition (or automatic relight on flame

failure), wherein the FSU will switch on a high-voltage arc to light the flame. All

periodic kiln burners are required (by considerations of engineering safety as well as

legal insurability) to have FSUs; FSUs are optional for tunnel kiln burners in regions

where the temperature is above 1400F which will ensure that any gas admitted

through the burner will auto-ignite, regardless of whether the burner's flame has

gone out. Tunnel kiln burners in preheat zones are thus required to be (retro)fitted

with FSUs. FSU installations provided by Kiltel are always wired on-up-one-down (ie,

each burner's FSU operates independently on that burner's fuel source, and each

burner has its own ignitor).

If the pulsed burner is fitted with an FSU, the FSU is represented by an enable

output which serves as the master light-off permission for that burner (ie, enabling

the FSU may result in light-off; disabling the FSU will stop the burner and shut off the

gas flow), as well as a pilot-on status signal returned from the FSU's flame

detector.

Each burner also has a phase assignment, which specifies how the firing of this

burner will be staggered with respect to other burners in the same control zone; in

most setups each burner in a zone is assigned a separate phase. All burners in a

control zone will have the same output pulsing duty cycle, but it is preferable to

stagger the actual firings to even out the gas delivery into the kiln, as well as to

ensure a degree of randomness in the firing to avoid generating standing patterns of

flow which may allow temperature gradients to be maintained. Having multiple

burners fire in a psuedo-random manner ensures excellent mixing and consequently

high firing uniformity throughout the volume of the kiln.

Potrebbero piacerti anche

- Engineering Standrad For Piping and Instumention DrawingDocumento111 pagineEngineering Standrad For Piping and Instumention DrawingNeo100% (4)

- TJ BrochureDocumento2 pagineTJ Brochuremick2560Nessuna valutazione finora

- B2 Oxy FuelDocumento18 pagineB2 Oxy Fuelmick2560Nessuna valutazione finora

- Design Guide 205 TJ PDFDocumento18 pagineDesign Guide 205 TJ PDFmick2560100% (1)

- OFT ManualDocumento36 pagineOFT Manualmick2560Nessuna valutazione finora

- Psychometric Success Mechanical Reasoning - Practice Test 1 PDFDocumento12 paginePsychometric Success Mechanical Reasoning - Practice Test 1 PDFKonul AlizadehNessuna valutazione finora

- Level 1 Pneumatics Exercises Grey Logo Version Feb 2012Documento89 pagineLevel 1 Pneumatics Exercises Grey Logo Version Feb 2012mick25600% (1)

- Circuit TutorialDocumento8 pagineCircuit Tutorialmick2560Nessuna valutazione finora

- 3 Introduction To Engineering DrawingDocumento14 pagine3 Introduction To Engineering DrawinginboxsweetsNessuna valutazione finora

- Chapter29 Model and Paper Space LayoutsDocumento14 pagineChapter29 Model and Paper Space LayoutsIvo Herid LesmanaNessuna valutazione finora

- Intro Duc TiDocumento13 pagineIntro Duc Timick2560Nessuna valutazione finora

- Catia v5 Assembly DesignDocumento77 pagineCatia v5 Assembly Designapi-3833671100% (16)

- Catia Part02Documento12 pagineCatia Part02luluNessuna valutazione finora

- Catia v5 Assembly DesignDocumento77 pagineCatia v5 Assembly Designapi-3833671100% (16)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Kit 2: Essential COVID-19 WASH in SchoolDocumento8 pagineKit 2: Essential COVID-19 WASH in SchooltamanimoNessuna valutazione finora

- Indirect Teaching Strategy??: Name: Topic: Under SupervisionDocumento9 pagineIndirect Teaching Strategy??: Name: Topic: Under SupervisionSeham FouadNessuna valutazione finora

- Brand Guidelines Oracle PDFDocumento39 pagineBrand Guidelines Oracle PDFMarco CanoNessuna valutazione finora

- CNS Manual Vol III Version 2.0Documento54 pagineCNS Manual Vol III Version 2.0rono9796Nessuna valutazione finora

- MG206 Chapter 3 Slides On Marketing Principles and StrategiesDocumento33 pagineMG206 Chapter 3 Slides On Marketing Principles and StrategiesIsfundiyerTaungaNessuna valutazione finora

- Omae2008 57495Documento6 pagineOmae2008 57495Vinicius Cantarino CurcinoNessuna valutazione finora

- How Can You Achieve Safety and Profitability ?Documento32 pagineHow Can You Achieve Safety and Profitability ?Mohamed OmarNessuna valutazione finora

- GSMDocumento11 pagineGSMLinduxNessuna valutazione finora

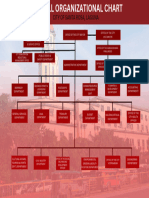

- Org ChartDocumento1 paginaOrg Chart2021-101781Nessuna valutazione finora

- LISTA Nascar 2014Documento42 pagineLISTA Nascar 2014osmarxsNessuna valutazione finora

- TENDER DOSSIER - Odweyne Water PanDocumento15 pagineTENDER DOSSIER - Odweyne Water PanMukhtar Case2022Nessuna valutazione finora

- Study of Means End Value Chain ModelDocumento19 pagineStudy of Means End Value Chain ModelPiyush Padgil100% (1)

- A Varactor Tuned Indoor Loop AntennaDocumento12 pagineA Varactor Tuned Indoor Loop Antennabayman66Nessuna valutazione finora

- Integrated Building Managemnt SystemDocumento8 pagineIntegrated Building Managemnt SystemRitikaNessuna valutazione finora

- 0901b8038042b661 PDFDocumento8 pagine0901b8038042b661 PDFWaqasAhmedNessuna valutazione finora

- Barangay Tanods and The Barangay Peace and OrderDocumento25 pagineBarangay Tanods and The Barangay Peace and OrderKarla Mir74% (42)

- SCHEDULE OF FEES - FinalDocumento1 paginaSCHEDULE OF FEES - FinalAbhishek SunaNessuna valutazione finora

- Step-7 Sample ProgramDocumento6 pagineStep-7 Sample ProgramAmitabhaNessuna valutazione finora

- Catalogue of The Herbert Allen Collection of English PorcelainDocumento298 pagineCatalogue of The Herbert Allen Collection of English PorcelainPuiu Vasile ChiojdoiuNessuna valutazione finora

- Jainithesh - Docx CorrectedDocumento54 pagineJainithesh - Docx CorrectedBala MuruganNessuna valutazione finora

- Volvo B13R Data SheetDocumento2 pagineVolvo B13R Data Sheetarunkdevassy100% (1)

- Bell WorkDocumento26 pagineBell WorkChuột Cao CấpNessuna valutazione finora

- The April Fair in Seville: Word FormationDocumento2 pagineThe April Fair in Seville: Word FormationДархан МакыжанNessuna valutazione finora

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Documento3 pagineEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandNessuna valutazione finora

- Technical Manual: 110 125US 110M 135US 120 135UR 130 130LCNDocumento31 pagineTechnical Manual: 110 125US 110M 135US 120 135UR 130 130LCNKevin QuerubinNessuna valutazione finora

- AdvertisingDocumento2 pagineAdvertisingJelena ŽužaNessuna valutazione finora

- Bondoc Vs PinedaDocumento3 pagineBondoc Vs PinedaMa Gabriellen Quijada-TabuñagNessuna valutazione finora

- Giuliani Letter To Sen. GrahamDocumento4 pagineGiuliani Letter To Sen. GrahamFox News83% (12)

- Prepositions Below by in On To of Above at Between From/toDocumento2 paginePrepositions Below by in On To of Above at Between From/toVille VianNessuna valutazione finora

- COVID Immunization Record Correction RequestDocumento2 pagineCOVID Immunization Record Correction RequestNBC 10 WJARNessuna valutazione finora