Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Class Work 6-2007 PDF

Caricato da

Pedro Sanchez0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

25 visualizzazioni2 pagineA punch press has sufficient capacity to punch 6 holes 1 in. In diameter in a 0. In. Boiler plate. The maximum force exerted acts on the driving crank with a moment arm of 1. In. A 15-hp 1725-rpm motor drives a centrifugal pump through a single set of 5:1 reduction gears. Take the shear stress of shaft material as 6,000 psi. Determine the diameter of the shafts on the motor and pump if ordinary steel shaft with standard

Descrizione originale:

Titolo originale

Class work 6-2007.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoA punch press has sufficient capacity to punch 6 holes 1 in. In diameter in a 0. In. Boiler plate. The maximum force exerted acts on the driving crank with a moment arm of 1. In. A 15-hp 1725-rpm motor drives a centrifugal pump through a single set of 5:1 reduction gears. Take the shear stress of shaft material as 6,000 psi. Determine the diameter of the shafts on the motor and pump if ordinary steel shaft with standard

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

25 visualizzazioni2 pagineClass Work 6-2007 PDF

Caricato da

Pedro SanchezA punch press has sufficient capacity to punch 6 holes 1 in. In diameter in a 0. In. Boiler plate. The maximum force exerted acts on the driving crank with a moment arm of 1. In. A 15-hp 1725-rpm motor drives a centrifugal pump through a single set of 5:1 reduction gears. Take the shear stress of shaft material as 6,000 psi. Determine the diameter of the shafts on the motor and pump if ordinary steel shaft with standard

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

1

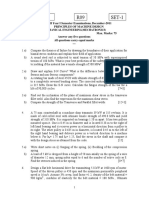

330:148 (g) Machine Design

Class work 6 Shaft design October 29, 2007

1. A machinery shaft is subject to torsion only. The bearings are 8 ft apart. The shaft

transmits 250 hp at 200 rpm. Allowing for a shear stress of 6,000 psi after the allowance

for keyways, what should be the shaft size? (Ans 4.25 in)

2. A punch press has sufficient capacity to punch 6 holes 1 in. in diameter in a 0.75 in.

boiler plate. The maximum force exerted acts on the driving crank with a moment arm of

1.25 in. Considering torsion only, determine the required shaft size that has allowable

shear stress of 9,000 psi. Take the shearing stress of steel as 60,000 psi. (Ans 8.5 in.)

3. A 15-hp 1725-rpm motor drives a centrifugal pump through a single set of 5:1

reduction gears. Take the shear stress of shaft material as 6,000 psi. Determine the

diameter of the shafts on the motor and pump if ordinary steel shaft with standard keys is

used. (Ans 13/16 in; 1.375 in)

4. A 75-hp motor operating at 90 rpm is to drive a lathe in which the loads may be

considered to be suddenly applied and the shocks of a medium intensity. The shaft is

fitted with a standard key. Factor of safety may be taken as 4. Considering torsion only,

what shaft diameter is required if the shat material has a yield stress of 35,000 psi in

tension? (Ans 3.25 in)

5. A machinery shaft supported on bearings 8 ft apart is to transmit 250 hp at 200 rpm

while subjected to a bending load of 1000 lb located at a distance of 2 ft from one

bearing. Allow a shear stress of 6,000 psi and a bending stress of 12,000 psi. What

should be the shaft diameter? (Ans 4.125 in)

6. A shaft is used to transmit 25 kW at 1500 rpm. The material has a yield strength of 300

MPa. The yield shear stress of the material may be taken as 150 MPa. Assuming a factor

of safety of 3, find the diameter of the shaft. (Ans 26 mm)

7. For the shaft shown in Fig. The ratio of belt tension for either belt is 3 : 1. The

maximum tension in the belt is 3000 N. If the ultimate strength is 650 MPa and yield

shear stress is 400 MPa for the shaft material, determine the shaft diameter and angle of

twist when the pulleys are keyed to the shaft. G =0.8 10

5

MPa. Use a factor of safety of

3. Dimensions are in mm. (Ans 40 mm; 0.014 rad; 0.806 deg)

2

8. A shaft is used to transmit 25 kW at 1500 rpm. The material has an yield strength of

300 MPa. The yield shear stress of the material may be taken as 150 MPa. In addition, the

shaft is subjected to a maximum bending moment of 100 Nm due to a pulley. Assuming a

factor of safety of 3, find the diameter of the shaft. (Ans. 30 mm)

9. A shaft of diameter 60 mm is subjected to a shear stress of 40 MPa and has an angle of

twist equal to 0.01 radian. Determine the length of the shaft for G =0.8 10

5

MPa. (Ans.

600 mm)

10. A hollow shaft must carry a torque of 30,000 lb-in. at a shearing stress of 8,000 psi.

The inside diameter is to be 0.65 of the outside diameter. Find the value of the outside

diameter. (Ans. 2.875; 1.875)

11. A 3 ft length of commercial shafting is to transmit 50 hp at 600 rpm through flexible

coupling from an AC motor to a DC generator. The allowable torsional shear stress of the

shaft material is 6,000 psi. Determine the required shaft size. (Ans.

16

11

1 in)

12. A hollow shaft must carry a torque of 3 400 Nm at a shearing stress of 55 MPa. The

inside diameter is to be 0.65 of the outside diameter. Find the value of the outside

diameter. (Ans. 75 mm)

13. The standard cross-section for a flat key which is fitted on a 50 mm diameter shaft is

16 10 mm. The key is transmitting 475 N m torque from the shaft to the hub and is

made of steel with an yield stress of 230 MPa. Assuming a factor of safety of 3, calculate

the length of the key. (Ans. 20 mm)

14. A shaft simply supported on two bearings 20 in. apart carries an 80 lb flywheel, 7in.

to the right of the left bearing. Estimate the critical speed.

Potrebbero piacerti anche

- Solution Manual for 100 Genesys Design Examples: Second EditionDa EverandSolution Manual for 100 Genesys Design Examples: Second EditionNessuna valutazione finora

- MD1 M3 Compiled Ot 1Documento67 pagineMD1 M3 Compiled Ot 1Jiuan AndradaNessuna valutazione finora

- MDlab FinalsDocumento18 pagineMDlab FinalsNarry StrummerNessuna valutazione finora

- Question Bank Numericals DMEDocumento3 pagineQuestion Bank Numericals DMEVanessa SmithNessuna valutazione finora

- Dme 2Documento6 pagineDme 2NITHISH KUMAR M SNessuna valutazione finora

- MD Problem Set 2Documento2 pagineMD Problem Set 2Cllyan ReyesNessuna valutazione finora

- SLIDEDocumento26 pagineSLIDEThắng NguyễnNessuna valutazione finora

- UNIT-5 SpringsDocumento6 pagineUNIT-5 SpringsUday Narasimha100% (2)

- DMM-1 MID-2 Assignment QuestionsDocumento3 pagineDMM-1 MID-2 Assignment Questionsuppada AnilNessuna valutazione finora

- Automobile Design Rev2015Documento6 pagineAutomobile Design Rev2015Rithik Raj RanjuNessuna valutazione finora

- Design ProblemsDocumento13 pagineDesign ProblemsAristotle RiveraNessuna valutazione finora

- Pointers For ReviewDocumento3 paginePointers For ReviewAdriel JohnNessuna valutazione finora

- TUTORIAL 3 Design of Shaft Key and CouplingDocumento2 pagineTUTORIAL 3 Design of Shaft Key and Couplingrip111176100% (1)

- MODEL QUESTION PAPER Mechanical VibrationsDocumento3 pagineMODEL QUESTION PAPER Mechanical VibrationsDarani PriyaNessuna valutazione finora

- Assignment 2Documento3 pagineAssignment 2sonawanepmsNessuna valutazione finora

- Unit I - Shafts: Single ElementDocumento7 pagineUnit I - Shafts: Single Elementchelam101100% (1)

- Machine Design 2 P1 - Review of ShaftingDocumento1 paginaMachine Design 2 P1 - Review of Shafting裴瑞尼Nessuna valutazione finora

- Imp Qoestions MDDocumento3 pagineImp Qoestions MDvenuedNessuna valutazione finora

- Final Design Work SheetDocumento7 pagineFinal Design Work SheetKINDUNessuna valutazione finora

- DMM Question BankDocumento2 pagineDMM Question Bankzubair ahmedNessuna valutazione finora

- Me 2303 Imp QnsDocumento3 pagineMe 2303 Imp QnsAJAY63Nessuna valutazione finora

- Machine Design CouchingDocumento403 pagineMachine Design CouchingJomari DichosoNessuna valutazione finora

- COMPRE EXAM Machine Design No ChoicesDocumento6 pagineCOMPRE EXAM Machine Design No ChoicesJunalin FabroNessuna valutazione finora

- Design ExercisesDocumento13 pagineDesign ExercisesBookieeNessuna valutazione finora

- Me 6503 Design of Machine Elements QBDocumento3 pagineMe 6503 Design of Machine Elements QBDeepak SNessuna valutazione finora

- Dme Imp QuestionsDocumento9 pagineDme Imp QuestionsCAD With RaoNessuna valutazione finora

- ShaftsDocumento1 paginaShaftsNhlaka ZuluNessuna valutazione finora

- Me8593 Iq R17Documento4 pagineMe8593 Iq R17Vaideesh LJNessuna valutazione finora

- Assignment 2Documento1 paginaAssignment 2pethuraNessuna valutazione finora

- gupta PG - No:176) Exercise 9Documento3 paginegupta PG - No:176) Exercise 9mahendra babu mekalaNessuna valutazione finora

- Macdes BoardsDocumento6 pagineMacdes BoardsJerdNessuna valutazione finora

- MDSP Problem Coaching Part 2Documento403 pagineMDSP Problem Coaching Part 2Sadam August Dulom100% (1)

- Chapter I Exercise.Documento6 pagineChapter I Exercise.wabdushukurNessuna valutazione finora

- Internal Test 1Documento3 pagineInternal Test 1Sathish KumarNessuna valutazione finora

- PMD ModelDocumento8 paginePMD ModelDamodara SatyaDeva MadhukarNessuna valutazione finora

- Machine Desig5Documento1 paginaMachine Desig5Francis John S. TanarteNessuna valutazione finora

- Machine Design Exam PDFDocumento6 pagineMachine Design Exam PDFLanz Cruzat100% (1)

- Jollibee Supermeal BDocumento20 pagineJollibee Supermeal BAaron Somera SolisNessuna valutazione finora

- Macine DesignDocumento40 pagineMacine DesignKarl Angelo R. Dela CruzNessuna valutazione finora

- Examples - Shafts: B. Free Body Diagram of Forces A. Chain Drive AssemblyDocumento4 pagineExamples - Shafts: B. Free Body Diagram of Forces A. Chain Drive AssemblyHarish Mohankrishnan NairNessuna valutazione finora

- Machine Elements 1,2Documento35 pagineMachine Elements 1,2Joseph OpinionNessuna valutazione finora

- Machine Design Trial 1Documento13 pagineMachine Design Trial 1JerdNessuna valutazione finora

- Bolts and Power ScrewDocumento1 paginaBolts and Power Screwkim dianonNessuna valutazione finora

- Machine Design Problems - DAY 4Documento1 paginaMachine Design Problems - DAY 4Kers CelestialNessuna valutazione finora

- ED7204-Integrated Mechanical Design QBDocumento7 pagineED7204-Integrated Mechanical Design QBBakkiya RajNessuna valutazione finora

- Plate No RaDocumento5 paginePlate No RaEdelleNessuna valutazione finora

- Dme Lab Sheets Ii Iii IvDocumento4 pagineDme Lab Sheets Ii Iii IvA58Vikas UbovejaNessuna valutazione finora

- 353 35435 ME357 2011 4 2 1 Sheet MD2Documento10 pagine353 35435 ME357 2011 4 2 1 Sheet MD2adel nabhanNessuna valutazione finora

- 9A14503 Principles of Machine DesignDocumento8 pagine9A14503 Principles of Machine DesignsivabharathamurthyNessuna valutazione finora

- Unit 3 BIGDocumento3 pagineUnit 3 BIGVasanth KumarNessuna valutazione finora

- Engine QBDocumento4 pagineEngine QBSapari VelNessuna valutazione finora

- Machine Design Trial 1Documento7 pagineMachine Design Trial 1JerdNessuna valutazione finora

- PhysicsDocumento22 paginePhysicsRed Crazy0% (1)

- Solved Examples (Shafts)Documento14 pagineSolved Examples (Shafts)Aya AyaNessuna valutazione finora

- Sathyabama University: Register NumberDocumento3 pagineSathyabama University: Register NumberCyril JasonNessuna valutazione finora

- Dme Model 2Documento6 pagineDme Model 2YashwanthI-StyleKuttiNessuna valutazione finora

- Assignment 01Documento2 pagineAssignment 01Ratan Sadanandan O MNessuna valutazione finora

- Iii Me Ii Sem Q.bank 2016-17Documento32 pagineIii Me Ii Sem Q.bank 2016-17Abhishek SakatNessuna valutazione finora

- Machine Design Elements and AssembliesDa EverandMachine Design Elements and AssembliesValutazione: 3.5 su 5 stelle3.5/5 (2)

- RSA Signing Is Not RSA DecryptionDocumento6 pagineRSA Signing Is Not RSA DecryptionPedro SanchezNessuna valutazione finora

- Super 7Documento49 pagineSuper 7Pedro SanchezNessuna valutazione finora

- Mcsorley 400Documento49 pagineMcsorley 400GermanHundNessuna valutazione finora

- Win XP SerialDocumento1 paginaWin XP SerialPedro SanchezNessuna valutazione finora

- Adxl 335Documento16 pagineAdxl 335Castro FedericoNessuna valutazione finora

- Nes RomsDocumento21 pagineNes RomsPedro SanchezNessuna valutazione finora

- ASCIIDocumento1 paginaASCIIPedro SanchezNessuna valutazione finora

- LCD Display PinoutDocumento4 pagineLCD Display PinoutYoav GolanNessuna valutazione finora

- Rock Yo Like A HurricaneDocumento4 pagineRock Yo Like A HurricanePedro SanchezNessuna valutazione finora

- IicreceiveDocumento1 paginaIicreceivePedro SanchezNessuna valutazione finora

- Canon in DDocumento8 pagineCanon in DPedro SanchezNessuna valutazione finora

- InstallationGuideV9 2Documento44 pagineInstallationGuideV9 2Pedro SanchezNessuna valutazione finora

- Canon in DDocumento8 pagineCanon in DPedro SanchezNessuna valutazione finora

- MarimbaDocumento5 pagineMarimbaLeonardo D'AngeloNessuna valutazione finora

- Datasheet Brahma (2023)Documento8 pagineDatasheet Brahma (2023)Edi ForexNessuna valutazione finora

- Adolescence Problems PPT 1Documento25 pagineAdolescence Problems PPT 1akhila appukuttanNessuna valutazione finora

- Project - Dreambox Remote Video StreamingDocumento5 pagineProject - Dreambox Remote Video StreamingIonut CristianNessuna valutazione finora

- E Business - Module 1Documento75 pagineE Business - Module 1Kannan V KumarNessuna valutazione finora

- Section ADocumento7 pagineSection AZeeshan HaiderNessuna valutazione finora

- Homelite 18V Hedge Trimmer - UT31840 - Users ManualDocumento18 pagineHomelite 18V Hedge Trimmer - UT31840 - Users ManualgunterivNessuna valutazione finora

- Bridging The Divide Between Saas and Enterprise Datacenters: An Oracle White Paper Feb 2010Documento18 pagineBridging The Divide Between Saas and Enterprise Datacenters: An Oracle White Paper Feb 2010Danno NNessuna valutazione finora

- Capacitor Trip Device CTD-4Documento2 pagineCapacitor Trip Device CTD-4DAS1300Nessuna valutazione finora

- Jmac TempDocumento5 pagineJmac TempDan GerNessuna valutazione finora

- Practice Paper Pre Board Xii Biology 2023-24-1Documento6 paginePractice Paper Pre Board Xii Biology 2023-24-1salamnaseema14Nessuna valutazione finora

- The Path Vol 9 - William JudgeDocumento472 pagineThe Path Vol 9 - William JudgeMark R. JaquaNessuna valutazione finora

- TextdocumentDocumento254 pagineTextdocumentSaurabh SihagNessuna valutazione finora

- Carpentry NC Ii: Daniel David L. TalaveraDocumento5 pagineCarpentry NC Ii: Daniel David L. TalaveraKhael Angelo Zheus JaclaNessuna valutazione finora

- Objective-C Succinctly PDFDocumento110 pagineObjective-C Succinctly PDFTKKNessuna valutazione finora

- The Eye WorksheetDocumento3 pagineThe Eye WorksheetCally ChewNessuna valutazione finora

- A Review On PRT in IndiaDocumento21 pagineA Review On PRT in IndiaChalavadi VasavadattaNessuna valutazione finora

- Amazon VS WalmartDocumento5 pagineAmazon VS WalmartBrandy M. Twilley100% (1)

- Specific Instuctions To BiddersDocumento37 pagineSpecific Instuctions To BiddersShahed Hussain100% (1)

- Review Test 1: Circle The Correct Answers. / 5Documento4 pagineReview Test 1: Circle The Correct Answers. / 5XeniaNessuna valutazione finora

- What Role Does Imagination Play in Producing Knowledge About The WorldDocumento1 paginaWhat Role Does Imagination Play in Producing Knowledge About The WorldNathanael Samuel KuruvillaNessuna valutazione finora

- Directorate of Indian Medicines & Homoeopathy, Orissa, Bhubaneswar Listof The Homoeopathic Dispensaries BhadrakDocumento1 paginaDirectorate of Indian Medicines & Homoeopathy, Orissa, Bhubaneswar Listof The Homoeopathic Dispensaries Bhadrakbiswajit mathematicsNessuna valutazione finora

- Opentext Documentum Archive Services For Sap: Configuration GuideDocumento38 pagineOpentext Documentum Archive Services For Sap: Configuration GuideDoond adminNessuna valutazione finora

- Cooperative LinuxDocumento39 pagineCooperative Linuxrajesh_124Nessuna valutazione finora

- Hydraulics Sheet 5 Energy ADocumento19 pagineHydraulics Sheet 5 Energy AMohamed H AliNessuna valutazione finora

- Anglo Afghan WarsDocumento79 pagineAnglo Afghan WarsNisar AhmadNessuna valutazione finora

- Quiz EditedDocumento6 pagineQuiz EditedAbigail LeronNessuna valutazione finora

- LANY Lyrics: "Thru These Tears" LyricsDocumento2 pagineLANY Lyrics: "Thru These Tears" LyricsAnneNessuna valutazione finora

- Pathophysiology: DR - Wasfi Dhahir Abid AliDocumento9 paginePathophysiology: DR - Wasfi Dhahir Abid AliSheryl Ann PedinesNessuna valutazione finora

- 0801871441Documento398 pagine0801871441xLeelahx50% (2)