Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Messen Und Pruefen

Caricato da

Sandi MadeCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Messen Und Pruefen

Caricato da

Sandi MadeCopyright:

Formati disponibili

Transparency 1 von 81

Manufacturing Technology I

Lecture 2

Measuring Measuring and and Testing Testing in in Production Production

Prof. Dr.-Ing. F. Klocke

Transparency 2 von 81

! Measuring and Testing in Manufacturing Technology

! Geometrical Manufacturing Errors

! Metrology

! Surface Properties

! Conclusion

Structure of the Lecture on Measuring and Testing

WZL

Transparency 3 von 81

Manufacturing Errors by Disturbances

WZL

static disturbances

- mounting errors

- deflection

- ...

dynamic

disturbances

- self controlled vibrations

- seperatly excited vibrations

e. g. fundament

- ...

thermal

disturbances

- internal heat sources

- expansions

- process heat

- ambient influences

- ...

tool wear

- cutting edge offset

- relief face wear

- relief face roughness

- grinding wheel wear

- ...

process

Transparency 4 von 81

Types of Manufacturing Errors

WZL

systematic errors

system conditional

reproduceable under equal circumstances

corrigible- resp. compensable

examples:- geometrical errors of machine guides

- lacking stiffness of machine structure

cannot be described systematically

to seperate sytematic fromrandomerrors the use of

statistisc methods is necessary

examples:- process caused vibrations

- tool wear

- mannerism of examiner

stochastic errors

Transparency 5 von 81

Measuring resp. Testing in der Production

there is no absolute accuracy

there are always deviations resp. faults

deviations of an attribute from set point are tolerated for functionality

and are to be checked

securing the functionality of a workpiece

minimisation of error potential in production

goods receipt

during manufacturing

after assembling

random sampling

statistically

100 %-verification

WZL

why

when

how

Transparency 6 von 81

Measuring and Testing

WZL

experimental procedure to determine of a measured value and/or a

physical measurand. This value is indicated as multiple of a unit

and/or a reference value. From the conjunction of several measured

values results the measurement.

the measurement result comprises the circumstances and the

measurement deviation.

determination whether a fulfills demanded conditions fulfilled, in

particular, if margins of errors or tolerances are kept.

testing can be objective but also subjective

measuring

testing

Source: Pfeifer, WZL

Transparency 7 von 81

! Measuring and Testing in Manufacturing Technology

! Geometrical Manufacturing Errors

! Form Error

! Dimension Fault

! Prosition Error

! Surface Roughness

! Metrology

! Surface Properties

! Conclusion

WZL

Structure of the Lecture on Measuring and Testing

Transparency 8 von 81

Geometrical Production Errors and their Definitions (by Kienzle)

Source: DIN 7462 WZL

roughness form error

deviation of

cylindricity

f

z

= d

a

- d

i

d

i

d

i d

a

shaft bore

d

i

d

a

d

i

d

a

location error

e

size error

tolerance

Transparency 9 von 81

Influence of a Change of Passive Power on the Workpiece Diameter

WZL

1000

600

400

200

N

10

5

0

m

Workpiece material Ck 55 N

Cutting material HW P10

Cutting speed v

c

= 160 m/s

Feed rate f = 0,25 mm

Body geometry:

!

0

= 6

"

0

= 5

#

S

= 0

$

r

= 70

%

r

= 90

r

%

= 0,8 mm

n

o

m

i

n

a

l

d

i

a

m

e

t

e

r

p

a

s

s

i

v

e

p

o

w

e

r

F

P

d

e

f

e

c

t

o

f

s

i

z

e

feed rate direction

feed direction

feed direction

Transparency 10 von 81

Examples for Surface Irregularity (DIN 4760)

WZL

Surface irregularity

(as a contoured cut presented reinforced)

Examples for the kind

of deviation

Examples for the

reason of formation

1

st

Order: Deviation of form unevenness

noncircularity

Error in the gui dance of the machine

tool, deflection of the machine or of

the workpi ece, chucking error,

hardening di stortion, wear

2

nd

Order: Waviness waves Eccentric clampi ng or form defect of

a cutter, vibrati on of the tool machine

or of the tool

3

rd

Order: grooves/scratches Form of the tool cutting edge, feed

rate or infeed of the tool

4

th

Order: ridges

ripples

knobs

Process of the chip formation, (tear

chip, slear chip, built-up edge), material

deformation whil e sand blasting,

gemnation during the galvanically

treatment

5

th

Order: structure Process of crystall izati on, modification

of the surface through chemical affecti on

(e. g. pickl ing), corrosi on mechanism

6

th

Order: lattice structure

of the

materi al

Physical and chemical process in the

synthesis of the matter, tensions and

shear within the crystal lattice

R

o

u

g

h

n

e

s

s

Superposition of the surface irregularities

1

st

- 4

th

order

i mpossible to visuali ze i n a simple manner

impossible to visualize in a simple manner

Transparency 11 von 81

Realization of the Surface Irregularity throgh Surface Cuts

WZL

A

B

G

H

L

C

D

F

E

A

B

E

F

C

D

"

A

B

C

D

profile

profile

profile

vertical section

veritcal section

sloped section

tangential section planes

tangential plane

cross section parallel to

the tangential plane

Vertical cuts Bevel cuts

Tangential section at a plane

A

B

C

D

tangential section plane

cross section

parallel to the

tangential

plane

tangential section lines

real surface

geometrically

perfect

surface

Tangential section at a cylinder

Transparency 12 von 81

Basic Terms in Surface Texture Measurement

Source: nach DIN 4762 / ISO 4287/1 WZL

geometrically ideal profile

actual profile reference profile

m basic profile

R

y

R

p

F

oi

F

ui

X

l

l

v

l

n

y

i

T

H

h

i

h

i

R

m

y

i

= profile excursion

y

p

= profile crown height

y

v

= profile valley depth

F

oi

= material-filled parts

F

ui

= material-free parts

l = reference length

l

t

= total sampling length

l

v

= pre-sampling length

l

n

= after-sampling length

m = middle profile line

l

t

R

y

= maximum profile height

R

p

= maximum profile crown height

R

m

= maximum profile valley depth

H = highest point of the profile

T = deepest point of the profile

h

i

= distance between actual profile and middle profile

y

p

y

v

Transparency 13 von 81

Definition of the Average Peak-to-Valley Height R

Z

Source: DIN 4768 WZL

Z

1

Z

2

Z

3

Z

4

Z

5

l

e

5 x l

e

= l

m

l

n

l

v

l

t

l

v

pre-sampling length

l

e

individual-sampling length

l

m

assessment length

l

n

post-sampling length

l

t

total-sampling length

Z

i

individual peak to valley height

R

max

maximum peak to valley height

R

Z

average peak to valley height

middle

profile line

1

5

R

Z

= Z

i

&

5

i=1

Transparency 14 von 81

Determination of the Carrying Length

WZL Source: DIN 4762

l'

c1

l'

c2

l'

c3 l'

cn

c

geometrical perfect profile

real profile

basic profile

l

n

l

c1

l

c2

l

c3

l

cn

Transparency 15 von 81

!Measuring and Testing in Manufacturing Technology

!Geometrical Manufacturing Errors

!Metrology

! Basics of Measuring

! Measurement Faults

! Measuring- and Testing Equipment for Length- and Form Errors

! Methods and Devices for J udging Technical Surfaces

!Surface Properties

!Conclusion

WZL

Structure of the Lecture on Measuring and Testing

Transparency 16 von 81

Measurement Chain - Information Flow

WZL

measurement

object

detection of measurand

measurement device

sensor

...

signal processing

measurement circuit

measurement amplifier

computer

...

output of measured

value

display

storage

...

measurand

measurement

signal

value

d

i

s

t

u

r

b

a

n

c

e

s

a

m

b

i

e

n

t

i

n

f

l

u

e

n

c

e

s

auxiliary

energy

Transparency 17 von 81

Signal Flow between Measured Quantity and Indication/Display

WZL

measured quantity

display

translator transformer amplifier

transmitter transformer

auxiliary energy supply

Transparency 18 von 81

Measurement Category Conversion and underlying Effects

WZL

Input parameter Effect/Principle Example

mechanic lever/gear/thread-path measurement micrometer screw

dial gauge

elektric pitch variation causes change of capacity capacitive pitch sensor

of a condensator

change of Resistance due to conductor deformation strain gauge

magnetic change of inducti vity of a coil inductive pi tch sensor

resp. des magn.flow according to pi tch variation

Hysteresis for detecction of Barkhausen-noise Barkhausen-noise

thermic beam intensity; thermal effect on R, L, C thermal element

pneumatic change of flow rate according to Bernoulli pneumatic bore

becaus of change of cross section measuring rod

optical interference, diffraction, reflection (Michelson-)interferometer

Transparency 19 von 81

Vibration Forms of Light Waves

WZL

'

2

'

3

#

3

#

1

#

2

#

'

2

'

3

#

time

a

m

p

l

.

a

m

p

l

.

time

a

m

p

l

.

time

time

a

m

p

l

.

time

a

m

p

l

.

interference of two coherent light

rays with equal phase position

(addition of the light intensity)

interference of two coherent light

rays with opposite phase position

'

phase shift

#

wave length

light mixture of various wave lengths

# )

const

' )

0

monochromatic light

# *

const

' )

0

monochromatic coherent light

# *

const

' *

0

Transparency 20 von 81

Interference of the Light

WZL

z = 0, 1, 2 .....

z = 0, 1, 2 .....

n =

sin

"

sin

+

d = z

2n

#

d = ( + z)

2n

#

1

2

,

= 2d n-sin

"

+

#

2

L

V

1

2

F

E

1'

2'

d

A

C C'

B

2'' 1''

"

+

A

B'

B

F

P

P

1

L

Interference at plane-parallel plates

(Fraunhofer Interference)

Interferometer according to Michelson

z ordinal number of the interference

n refractive index

path difference

amplification (

"

= 0)

cancellation (

"

= 0)

Transparency 20 von 81

Interference of the Light

WZL

z = 0, 1, 2 .....

z = 0, 1, 2 .....

n =

sin

!

sin

"

d = z

2n

#

d = ( + z)

2n

#

1

2

$

= 2d n-sin

!

+

#

2

L

V

1

2

F

E

1'

2'

d

A

C C'

B

2'' 1''

!

"

A

B'

B

F

P

P

1

L

Interference at plane-parallel plates

(Fraunhofer Interference)

Interferometer according to Michelson

z ordinal number of the interference

n refractive index

path difference

amplification (

!

= 0)

cancellation (

!

= 0)

Transparency 21 von 81

Inductive Position Encoder

WZL

L

1

L

2

s

r

4

r

3

U

A

U

B

U

A

U

B

C

C =

0

%

r

%

A

d

position encoder

measuring element

position encoder

exit to the

measuring amplifier

output voltage of

the gap bridge

U

A

=

jumper voltage U

B

=

C = capacity

dielectric constant

0

=

%

r

=

%

s = measured displacement

permittivity

A =

plate surface

d =

distance between the plates

Transparency 22 von 81

Fundamental Terms for the Pneumatic Measurement Principle

WZL

d

m

&

h

A

min

flow channel

reference pressure p

s

atmosphere pressure p

a

measuring nozzle

measuring gap

annular gap surface = d

m

.

.

h

'

Transparency 23 von 81

Pneumatic Sensors

Source: Nieberding, Neu WZL

air supply

valve

tactile pin

workpiece

guide body

measuring

nozzle

bore

contact measurement

contactless

measurement

Transparency 24 von 81

!Measuring and Testing in Manufacturing Technology

!Geometrical Manufacturing Errors

! Basics of Measuring

! Measurement Faults

! Measuring- and Testing Equipment for Length- and Form Errors

! Methods and Devices J udging Technical Surfaces

!Surface Properties

!Conclusion

WZL

Structure of the Lecture on Measuring and Testing

Transparency 25 von 81

Causes for Measurement-Variances within Measurements

WZL

WZL

C

sources of

errors within

measurements

measurand:

type of measurand,

type of error

measuring method:

unconsidered

interference, qualification,

"cosine"-error

measuring device:

measurement inaccuracy,

suitability, installation,

measuring forces

preparation:

cleanliness,

calibration

malfunction:

mistake, reading error,

false interpretation,

impatience

operator:

capability, training,

visual acuity, estimation,

concentration

environment:

temperture, air pressure,

humidity, vibrations,

illumination, disturbances

Transparency 26 von 81

!Measuring and Testing in Manufacturing Technology

!Geometrical Manufacturing Errors

! Basics of Measuring

! Measurement Faults

! Measuring- and Testing Equipment for Length- and Form Errors

! Methods and Devices J udging Technical Surfaces

!Surface Properties

!Conclusion

WZL

Structure of the Lecture on Measuring and Testing

Transparency 27 von 81

Taylors Principle Concerning Gauges

Source: Kienzle WZL

reject-gauge reject-gauge

reject-gauge reject-gauge

acceptance-

-gauge

bore hole shaft square-bore hole serration

acceptance-gauge

acceptance-gauge

acceptance-

-gauge

Transparency 28 von 81

Acceptance-Gauge and Reject-Gauge

WZL

should test the complete measuring surface at one time

has to fit to the acceptance workpiece

record any dimension seperatly

size for reject-gauge is lower deviation (shaft)

size for reject-gauge is upper deviation (bore hole)

size for acceptance-gauge is upper deviation (shaft)

size for acceptance-gauge is lower deviation (bore hole)

must not fit to any part of the acceptance workpiece

Acceptance-Gauge

Reject-Gauge

Transparency 29 von 81

Relation between Input and Output Quantity of a Measuring System

WZL

AB

PB

FB

factors

measured quantity

signal

measurement result

input output

Basic function characteristic

functional area FB

proportional band PB

operating range AB

transmission ratio

amplification factor

converter constant

o

u

t

p

u

t

input

Transparency 30 von 81

Micrometer

WZL

A B C D E F G

H

C

1

A measuring anvil

B spindle

C scale case

C

1

distortion nut

D graduated collar

E instep cone

F coupling

G ratchet

H frame

Transparency 31 von 81

Dialgauge Principle

WZL

special design, shock-proof, keeping

almost a constant measuring force

return spring

biasing spring

case

scale

tactile pin

absorber,

built as a

rack on the

outside

Transparency 32 von 81

Optical Lever (Form A)

Source: DIN 879 WZL

tolerance marks

clamping shank

measurement bolt

fine adjustment

28

h6

6

h6

1

8

m

i

n

i

m

u

m

s

i

z

e

4

5

m

a

x

i

m

u

m

s

i

z

e

8

5

m

i

n

i

m

u

m

s

i

z

e

seating bore for the

clamping shank

28 H7

seating bore within

the measurement top

6 H7

1 m

Transparency 33 von 81

Schematical Sketch of the Mikrokator

Source: CE Johannson WZL

adjustment

scale

pointer

angle lever helical compression spring case tactile pin

Transparency 34 von 81

Comparator

WZL

scale case measuring surface swinging follower

biasing spring

needle is moved by swinging

follower and rack by pinion

rack

fine adjustment

scale

Transparency 35 von 81

Measuring Principle of the Autocollimating Telescope

WZL

X'

2

!

2

!

!

fine measuring eye-piece

measuring plane

movable

gap

light source

reversing mirror

convergent lens

crosshair plate

optical axis

objektive lens

plane mirror

Transparency 36 von 81

Pneumatic Distance Measurement

Source: Dolezalek WZL

1 2

3

4

s

s

1

2

h

6

3

4

5

Scheme of the volume measuring procedure

1 air filter

2 pressure regulator

3 flow meter

4 measuring nozzle

Scheme of the speed measuring procedure

1 air filter

2 pressure regulator

3 venturi meter

4 flow off valve

5 measuring nozzle

6 differential pressure meter

Transparency 37 von 81

Transducer Characteristic of a Pneumatic Measurement Device

WZL

supply-nozzle

indicator

measuring-nozzle

workpiece

p

r

e

s

s

u

r

e

p

distance s

D

1

D

2

p

$

s

$

p

s

p

0

Transparency 38 von 81

Pneumatic Test Mandrel

WZL

test piece

measuring nozzle

Transparency 39 von 81

Examples for Pneumatic Measuring

WZL

2.) indication diameter

3.) indication

face-untrueness

1.) indication

face-untrueness

Face-untrueness and diameter measuring

Distance measuring Bevel measuring

A-scale B-scale

Transparency 40 von 81

3-D Coordinate-Measuring Machine

WZL Source: Zeiss

Transparency 41 von 81

!Measuring and Testing in Manufacturing Technology

!Geometrical Manufacturing Errors

! Basics of Measuring

! Measurement Faults

! Measuring- and Testing Equipment for Length- and Form Errors

! Methods and Devices J udging Technical Surfaces

! Devices for Surface Checking

! Devices for Surface Checking

!Surface Properties

!Conclusion

WZL

Structure of the Lecture on Measuring and Testing

Transparency 42 von 81

Profile Cuts of Metal-Removing Machined Surfaces

Source: Mahr WZL

rough and

fine turned

planed

honed

ground

Transparency 43 von 81

Surface Comparison Cluster

Source: Rubert WZL

1

0

6

,

0

3

,

0

1

,

6

1

,

0

0

,

5

5

0

,

0

5

0

,

1

0

,

2

0

,

4

0

,

8

1

,

6

2

,

5

8

,

0

4

,

0

1

6

3

2

5

0

N

7

N

6

N

5

N

4

N

3

N

2

N

1

0

N

9

N

8

N

7

N

6

N

5

I

S

O

R

1

3

0

2

-

1

9

7

1

1

2

,

5

6

,

3

3

,

2

1

,

6

0

,

8

0

,

4

flat lapping

rubbing

flat

grinding

horizontal

milling

face milling longitudinal

turning

r

o

u

g

h

n

e

s

s

R

t

(

m

)

m

e

a

n

r

o

u

g

h

n

e

s

s

R

a

(

m

)

r

o

u

g

h

n

e

s

s

s

i

g

n

a

t

u

r

e

f

i

n

i

s

h

m

a

r

k

D

I

N

1

4

0

m

e

a

n

r

o

u

g

h

n

e

s

s

R

a

(

m

)

r

o

u

g

h

n

e

s

s

R

t

(

m

)

Transparency 44 von 81

Surface Examination with the Blade Ruler

WZL

!

r

(

100 m

light source

blade ruler

view A

gaps up to 1 m visible

view A

workpiece

eye

Transparency 45 von 81

Surface Examination by Marking

WZL

black digit

(marking paste)

light digit

(lowest points)

gray glittering

digits

(supporting points)

iron straightedge

workpiece

marking paste

Transparency 46 von 81

Pneumatic Surface Examination Procedure

WZL

nozzle

measuring chamber

manometer

pressure

differential

measuring nozzle

workpiece

overcurrent

tube

compressed air

Transparency 47 von 81

Condenser Procedure to Examine the Surface

WZL

electrode dielectric

workpiece

indication

Transparency 48 von 81

Principle of the Detection of Dispersed Light

WZL

surface

observation

plane

t

r

a

n

s

m

it

t

e

r

r

e

c

e

iv

e

r

Transparency 49 von 81

WZL

Structure of the Lecture on Measuring and Testing

!Measuring and Testing in Manufacturing Technology

!Geometrical Manufacturing Errors

! Basics of Measuring

! Measurement Faults

! Measuring- and Testing Equipment for Length- and Form Errors

! Methods and Devices J udging Technical Surfaces

! Devices for Surface Checking

! Devices for Surface Checking

!Surface Properties

!Conclusion

Transparency 50 von 81

Construction of the Interference Microscope

WZL

eye

eye-piece

light source

illumination

lens

plane

plate

objective

objective

work piece

division

prism

comparison

mirror

Transparency 50 von 81

Construction of the Interference Microscope

WZL

eye

eye-piece

light source

illumination

lens

plane

plate

objective

objective

work piece

division

prism

comparison

mirror

Transparency 51 von 81

Photos Taken by the Interference Microscope

Source: Zeiss WZL

Ball surface

Copy of a steel surface

Transparency 52 von 81

Measuring the Workpiece Roughness with the Light-Slit Microscope

WZL

f = 0,16 mm

f = 0,20 mm

f = 0,25 mm

f = 0,315 mm

45

45

cutting speed v

c

= 150 m/min

workpiece material steel Ck 45

cutting material HM P 15

exposure t = 1/125 s

microscope enlargement 400 times

Light-slit pictures

feed f = 0,125 mm

light pencil

irradiation

direction

visual

direction

workpiece

border lines

Workscheme of the light-slit method

Transparency 53 von 81

Principle of the Surface Measuring

Source: Mechau WZL

a

b

c

d

e

f

illumination

microscope

prism

test piece

visual field

a Brass turned with a cemented carbide tool.

feed 20 m

b Brass turned with diamond.

feed 15 m

c Brass turned with diamond.

feed 50 m

d Gudgeon pin lapped with crack.

e Lapped gudgeon pin.

f Finepolished glass cylinder.

Transparency 54 von 81

Tracing Device and Tracing Principles

Source: Wiemer WZL

exciter for the

needle stroke oscillator

spring and weight

for the oscillator

absorbtion of the oscillator

search unit

spring

workpiece

tactile pin

principle "Woxen"

feeling-procedure

Transparency 55 von 81

Measuring Principles for Stylus Profilers

WZL

piezoelectric optoelectric

slit

light

source

inductive

spool

soft iron

body

mechanical

crystal body

evaporized

metal layer

Transparency 56 von 81

Laboratory Stylus Profiler

Source: Mahr WZL

Transparency 57 von 81

Various Surface Tracing Systems

WZL

!

! !

/2

h

!

2 h

tracer skid

table

tracer

tracer skid

tracer

guiding skid

tracing arm

tracer

guiding skid

half-rigid system pendulum tracer system reference plane system

various surface tracing systems

causes of failure with various half-rigid tracing systems

tracer

tracer

guiding skid

guiding skid

surface finish trace

Transparency 58 von 81

Separation of Waviness and Roughness throgh Wave Filter

WZL

1

m

250 m

1

m

250 m

1

m

250 m

without wave filter

low-pass filter

high-pass filter

limitating wave length:

!

= 0,75 mm

tracing system: HT 25/6

tracing distance: 10 mm

machining process: superfinishing

arithmetic mean roughness R

a

= 0,75

W-profile (waviness)

P-profile (waviness and roughness)

R-profile (roughness)

Transparency 59 von 81

Profiles of a Surface in Various Presentation Scales

WZL

A

1

0

m

250 m

s

w

25

1

=

A

1

0

m

10 0 m

s

w

10

1

=

A

1

0

m

25 m

s

w

2,5

1

=

A

1

0

m

10 m

s

w

1

1

=

magnification ratio

s

w

vertical

horizontal

=

arithmetic mean roughness R

a

= 2,1 m

employde tracer

for plotting

Transparency 60 von 81

Differentiation of a Surface Profile from ist Reflection

WZL

R

p

1

R

p

1

=

R

t

2

R

t

2

basic profile

real profile

fundamental profile

medium profile

maximum roughness

mean roughness

c. l. a. surface roughness

smoothing depth

R

t1

= R

t2

R

a1

= R

a2

R

z1

= R

z2

R

p1

R

p2

Transparency 61 von 81

Mesurement Example: Detection of Cutting Edge Offset

WZL

tactile system: blade calliper

blade width 0,6 mm

bade angle 60

blade radius 5 m

measurement

output:

250 m

5

m

Transparency 62 von 81

Developement of Cutting Edge Offset

WZL

Tool

K10

(Ti,Al)N

reground

d

0

= 110 mm

!

F

= -10

"

F

= 3

Workpiece

16MnCr5

800HV10

d

2

= 65 mm

#

s = 0,1 mm

Process parameters

v

c

= 100 m/min

f

a

= 2,54 mm/WU

N = 1 mm

-1

h

cu max

= 50 m

parallel feed

with coolant

5 m

250m

Schneidkantenrauheit in Spanflchenebene

relief face form deviation

no. of cuts

3.000

5.000

1.000

0

500 m

60

33

Transparency 63 von 81

Measurement Example: SEM-Analysis

WZL

Tool

K10

(Ti,Al)N

reground

d

0

= 110 mm

!

F

= -10

"

F

= 3

Workpiece

16MnCr5

800HV10

d

2

= 65 mm

#

s = 0,1 mm

Process parameters

v

c

= 100 m/min

f

a

= 2,54 mm/WU

N = 1 mm

-1

h

cu max

= 50 m

parallel feed

with coolant

300 m

3

0

0

m

~

6

0

0

cracks

60 m

60 m

cracks

cutting edge after 5.000 cuts

Transparency 64 von 81

WZL

Structure of the Lecture on Measuring and Testing

!Measuring and Testing in Manufacturing Technology

!Geometrical Manufacturing Errors

!Surface Properties

! Basics

! Properties of Surfaces

! Edge Layer Inspection

!Conclusion

Transparency 65 von 81

Ranges of Use and Stress for Technical Surfaces

Source: H. Czichos WZL

Types and functions

of technical surfaces

Surface stresses Variations and

damages of the surface

exterior surfaces of all kinds of

technical products (visual-, cover-,

signal surfaces,...)

surfaces in contact with fluids

(container, car-body parts,...)

surfaces in contact with moving

bodies (bearings, brakes, gears,...)

surfaces in contact with

microorganisms

not mechanically

stressed (climatic- or

environmental stress)

stress caused by

radiation, temperature

and electricity

absorption

soiling

weathering

passivation

oxydation

surface cinder

electrochemical

stress

corrosion

electrolysis

streaming stress

tribological stress

(frictional stress)

biological stress

cavitation

erosion

deformation by contact

wear

biological damage

surfaces exposed to heat, radiation

or electricity (isolating surface,

electrical contact,...)

surfaces in contact with streaming

fluids (pipes, valves,...)

Transparency 66 von 81

Peripheral Zone Parameters

WZL sourcee: Brinksmeier

Quelle: Brinksmeier, E.

Randzoneneigenschaften

Lunker, Poren,

Risse

Aufwerfungen,

Schollen,

Abl agerungen

Formnderungen

durch Eigen-

spannungen

Spannungen

Di chte

elasti sche

Konstanten

linearer Aus-

dehnungs-

koeffi zient

Wrmeleit-

fhigkeit

Wrme-

kapazitt

spezifischer

elektrischer

Widerstand

Brechungs-

i ndex

Absorptions-

grad

Reflexions-

grad

Permeabili tt

Induktion

Remanenz

Koerziti v-

feldstrke

magnetisches

Rauschen

Magneto-

stri kti on

Phasenan-

ordnung im

Werkstoff

Korngre

Korngrenzen

Textur

Versetzungs-

dichte

Hrte

elementare

Bestandtei le

Stchiometrie

Periodizi tt

Ordnungsgrad

Gittertyp

I FW

geometrisch

chemisch

mechanisch thermisch elektrisch optisch magneti sch Gefge Stoffaufbau

physikalisch

Transparency 67 von 81

Formation Structure of Metallical Surfaces

Source: Schmaltz, Degener WZL

outside boundar layer

Reaction layer of the

inner boundary layer

with the surrounding

atmosphere

inner boundary layer

inhomogenity concerning

stability, hardness,

forming dearce, residual

stress, texture

fundamental structure

outside boundary layer

grease- / oil layer 10 ... 100 m

absorption layer 3 ... 5

oxide layer 10 ... 100

elastically deformed

inner boundary layer > 5 m

plastically deformed

and hardened

elastically and plastically

deformed

Transparency 68 von 81

Plastic Deformation of the Edge Zone while Drilling

WZL

variation new worn

cutting material: HM-coated

material: C15

v

c

: 200 m/min

f: 0,1 mm/U

cutting material: HM-coated

material: C15

v

c

: 100 m/min

f: 0,1 mm/U

cutting material: HM-coated

material: C15

v

c

: 60/30 m/min

f: 0,2 mm/U

Transparency 69 von 81

Edge Zone and Heat-Treatment Data of a Carburizing Steel

WZL

800

HV1

600

500

400

300

200

100

0

0,0 0,5 1,0 1,5

2,0

3,0 mm

1,6

1,2

1,0

0,8

0,6

0,4

0,2

0,0

%

0 2 4 6 8 h 12

C

1050

950

900

850

800

750

700

650

1,0

% C

0,6

0,4

0,2

0,0

T

c

p

0,0 0,5 1,0 1,5 2,0 3,0 mm

carbon gradient

v

i

c

k

e

r

s

h

a

r

d

n

e

s

s

edge distance a

c

a

r

b

o

n

l

e

v

e

l

C

time t

t

e

m

p

e

r

a

t

u

r

e

T

c

a

r

b

o

n

c

o

n

c

a

n

t

r

a

t

i

o

n

Process data:

gas: CO = 23% / H

2

= 46%

carbonizing depth At: 1,40 mm bei C = 0,35 %

oil-quenching at

$

= 60 C

quenching intensity: 25

grain size: 5

Mn

1,15

C Si Cr Ni Mo V Al Cu P

0,16 0,30 0,95 0,00 0,00

0,00

0,04 0,10 0,02

chemical analysi s (L.E. i n %)

hardening gradient

time-temperature gradient

edge distance a

Transparency 70 von 81

Vergleich von Hrteeindrcken bei Verfahrens- und Prflastvariation

WZL

HV 10

Testwerkstck

Randhrte > 800 HV

16MnCr5

Eht

550

= 0,4 + 0,2 mm

Aufma

#

s = 0,1 20 m

Vickers Eindruck:

#

s

0,1 mm

Oberflcheneindruck

bei 800 HV 10

(136 Spitzenwinkel)

(Tiefe ~ 0,3

.

#

s)

HV 0,02

HV 0,1

Rockwelleindruck

entsprechend fr

64 HRC

(120 Spitzenwinkel)

(Tiefe ~ 0,8

.

#

s)

d

2

2

HV =

0,102

.

F

.

2

.

cos(22)

d

Transparency 71 von 81

Structure Parameters

WZL

peripheral zone after case hardening

(etchant: 1 % -ige alk. HNO

3

)

30 m

30 m

structure before case hardening

hardness (-tiefenverlauf)

grain size

phases

- martensite

- retained austenite

segregations

- carbides

texture

grain size

phases

- ferrite

- perlite

segregations

- carbides

- sulfides

texture

hardness

Transparency 72 von 81

WZL

Structure of the Lecture on Measuring and Testing

!Measuring and Testing in Manufacturing Technology

!Geometrical Manufacturing Errors

!Surface Properties

! Basics

! Properties of Surfaces

! Edge Layer Inspection

!Conclusion

Transparency 73 von 81

Interference of a Hardened Zone by Process Interactions

WZL

mechanic thermal

F

Q

basic structure

interference of peripheral zone

tempered zone

white layer

Transparency 74 von 81

Effects of Thermal Damaged Peripheral Zones

WZL

LF

200 m

RF

1000

800

700

600

500

400

300

0 0, 2 0,4 0,6 0,8 1

Distance to surface [mm]

V

i

c

k

e

r

s

h

a

r

d

n

e

s

s

[

H

V

0

,

0

5

]

900

right flank

left flank

gear

pinion

thermally damaged

by grinding

d

w

d

f

RF

LF

200 m

pittings

(right f lank loaded)

grinding burn

lef t f lank not loaded

Transparency 75 von 81

Quelle: E. Brinksmeier

I FW

finished surface

HV

texture

structure cracks

%

&

%

''

residual stresses hardness

direction of processing

Manipulation after Processing

WZL Quelle: IFW, Hannover

Transparency 76 von 81

yield point

l

o

a

d

r

e

l

i

e

f

deformation rate

t

e

n

s

i

l

e

s

t

r

e

s

s

(

+

)

p

r

e

s

s

u

r

e

(

-

)

t

e

n

s

i

o

n

%

yield point

plastic deformation

%

E-

temperature

c

o

o

l

i

n

g

h

e

a

t

i

n

g

hot yield point

t

e

n

s

i

l

e

s

t

r

e

s

s

(

+

)

p

r

e

s

s

u

r

e

(

-

)

(

)

*

%

+

,

*

%

hot yield point

plastic deformation

%

E+

(caused mechanically)

compressive stress

(caused thermically)

tensile stresses

Origin of Residual Stresses

WZL Quelle: Hnscheid, Knig, Lowin

Transparency 77 von 81

Typical Residual Stresses

WZL

0

+

-

depth

r

e

s

i

d

u

a

l

s

t

r

e

s

s

%

E

0

+

-

depth

r

e

s

i

d

u

a

l

s

t

r

e

s

s

%

E

origins of risidual stresses

influence of friction

influence of chipping

thermal

mechanic

thermal

mechanic

0

+

-

depth

r

e

s

i

d

u

a

l

s

t

r

e

s

s

%

E

0

+

-

depth

r

e

s

i

d

u

a

l

s

t

r

e

s

s

%

E

run of the residual stress

mR

mZ

tR

tZ

mR

mZ

tR

tZ

thermally caused

mechanically caused

Transparency 78 von 81

Meaurement of Residual Stress by X-Ray Diffraction

WZL

m

o

n

o

c

h

r

o

m

a

t

i

c

r

a

d

i

a

t

i

o

n

s

e

c

o

n

d

a

r

y

r

a

d

i

a

t

i

o

n

0

1

0

2

P

1

P

2

P

3

A E

B D

$ $

atom

mesh level

distance

d

d

!-

CD=d

.

sin

$

CD=1/2.

!

Bragg:

!

= 2

.

d

hkl

.

sin

$

hkl

hkl: Miller indices

example for indicized

m

esh levels

( 0 1 0 ) ( 1 1 0 )

Transparency 79 von 81

X-Ray Diffractometer for Structure Analysis

WZL source: Seif ert

x-ray tube

detektor

swing table

probe

swing table

Transparency 80 von 81

WZL

Structure of the Lecture on Measuring and Testing

! Measuring and Testing in Manufacturing Technology

! Geometrical Manufacturing Errors

! Metrology

! Surface Properties

! Conclusion

Transparency 81 von 81

Questions

! Explain systematic errors and random errors and name two examples for each. How

can you minimize the effect of these errors on the work result?

! What disturbances influence the production process (one example each)?

! Explain the pneumatic measurement of cylindrical workpieces.

! Explain the measurment of lengths with a interferometer. What is the comparision

standard.

! Why must measurments of high accuracy and high reproducibility be done in an air

conditioned environment?

! Why can it be necessary to determinate the structure of the boundary layer? With what

parameters would you describe the structure (Phases, grain size,

texture-anisotropy)?

! What structure parameters can be determined with a light microscope?

! How are residual stresses caused and how can they be measured?

! Why is the structure of the workpiece affected by the production process (arbitrary

example)?

WZL

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Digging Deeper: Can Hot Air Provide Sustainable Source of Electricity?Documento2 pagineDigging Deeper: Can Hot Air Provide Sustainable Source of Electricity?Рустам ХаджаевNessuna valutazione finora

- Tugas 2-TRK Lanjut Kelompok 3 Andre-Arief-IstiaDocumento18 pagineTugas 2-TRK Lanjut Kelompok 3 Andre-Arief-IstiaAndre Fahriz Perdana HarahapNessuna valutazione finora

- Native Data Sheet Asme b73.1Documento4 pagineNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- Gemh 108Documento20 pagineGemh 108YuvrajNessuna valutazione finora

- Improve On-Time DeliveriesDocumento24 pagineImprove On-Time DeliveriesUdayNessuna valutazione finora

- OurCatholicFaith PowerPoint Chapter1Documento21 pagineOurCatholicFaith PowerPoint Chapter1VinNessuna valutazione finora

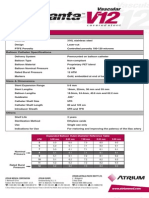

- Advanta V12 Data SheetDocumento2 pagineAdvanta V12 Data SheetJuliana MiyagiNessuna valutazione finora

- 02-Building Cooling LoadsDocumento3 pagine02-Building Cooling LoadspratheeshNessuna valutazione finora

- Sony Cdm82a 82b Cmt-hpx11d Hcd-hpx11d Mechanical OperationDocumento12 pagineSony Cdm82a 82b Cmt-hpx11d Hcd-hpx11d Mechanical OperationDanNessuna valutazione finora

- Shawal 1431 AH Prayer ScheduleDocumento2 pagineShawal 1431 AH Prayer SchedulemasjidibrahimNessuna valutazione finora

- GROSS Mystery of UFOs A PreludeDocumento309 pagineGROSS Mystery of UFOs A PreludeTommaso MonteleoneNessuna valutazione finora

- Reviews: The Global Epidemiology of HypertensionDocumento15 pagineReviews: The Global Epidemiology of Hypertensionrifa iNessuna valutazione finora

- C.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)Documento1 paginaC.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)shabeerNessuna valutazione finora

- Inverse of One-To-One FunctionDocumento4 pagineInverse of One-To-One FunctionKathFaye EdaNessuna valutazione finora

- Proefschrift T. Steenstra - tcm24-268767Documento181 pagineProefschrift T. Steenstra - tcm24-268767SLAMET PAMBUDINessuna valutazione finora

- Lesson 1 Chapter 9 ErosiondepositionDocumento1 paginaLesson 1 Chapter 9 Erosiondepositionapi-249320969Nessuna valutazione finora

- Sika - Bitumen: Bitumen Emulsion Waterproof & Protective CoatingDocumento3 pagineSika - Bitumen: Bitumen Emulsion Waterproof & Protective Coatingdinu69inNessuna valutazione finora

- Scott 2001Documento20 pagineScott 2001Mariana CatiniNessuna valutazione finora

- 4 Force & ExtensionDocumento13 pagine4 Force & ExtensionSelwah Hj AkipNessuna valutazione finora

- Dawn of Solar PV CookingDocumento5 pagineDawn of Solar PV CookingAbhinav AgrawalNessuna valutazione finora

- 1970 - Transformer FMEA PDFDocumento7 pagine1970 - Transformer FMEA PDFSing Yew Lam0% (1)

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Documento31 pagineHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNessuna valutazione finora

- Owner'S Manual: 2023 Chassis CabDocumento444 pagineOwner'S Manual: 2023 Chassis CabDmitry DimasNessuna valutazione finora

- 2015 Nos-Dcp National Oil Spill Disaster Contingency PlanDocumento62 pagine2015 Nos-Dcp National Oil Spill Disaster Contingency PlanVaishnavi Jayakumar100% (1)

- Comparing Exponential NumbersDocumento5 pagineComparing Exponential NumbersMaya RahayuNessuna valutazione finora

- Middle Range Theory Ellen D. Schulzt: Modeling and Role Modeling Katharine Kolcaba: Comfort TheoryDocumento22 pagineMiddle Range Theory Ellen D. Schulzt: Modeling and Role Modeling Katharine Kolcaba: Comfort TheoryMerlinNessuna valutazione finora

- June 2021 QP - Paper 1 (H) Edexcel Chemistry GCSEDocumento28 pagineJune 2021 QP - Paper 1 (H) Edexcel Chemistry GCSEmiapoppycollinsNessuna valutazione finora

- Liver: Anatomy & FunctionsDocumento18 pagineLiver: Anatomy & FunctionsDR NARENDRANessuna valutazione finora

- 14p-220 Mud PumpDocumento2 pagine14p-220 Mud PumpMurali Sambandan50% (2)

- Pediatric EmergenciesDocumento47 paginePediatric EmergenciesahmedNessuna valutazione finora