Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Monthly Inspection Report For Cranes and Hoists

Caricato da

Grace PassiniTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Monthly Inspection Report For Cranes and Hoists

Caricato da

Grace PassiniCopyright:

Formati disponibili

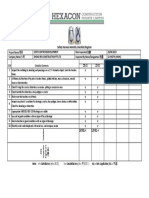

Monthly Inspection Report for Cranes and Hoists

Date of Inspection:

Identification of Crane /

Hoist Inspected:

Department/Location:

Items requiring inspection P F N/A Comments

MARKINGS

Is the rated load of the crane / hoist marked on each side?

Is the pendent control box clearly marked for identification or

function?

OPERATING MECHANISM (BRIDGE, TROLLEY AND HOIST)

Loose bolts or rivets?

Excessive wear, distortion or fractures?

Functioning correctly? (moves smoothly in all directions)

HOOKS (see diagram below table)

Wear and deformation?

Cracks?

Signs of opening between point A and point B?

Signs of elongation between point B and point C?

WIRE ROPE

Deformation, cracks, excessive wear, twists, kinks, crushing or

birdcaging?

Does rope reeving comply with manufacturers

recommendations?

CHAINS (INCLUDING END CONNECTIONS)

Excessive wear, elongation, twisting, cracks or gouges?

Any reduction in rope diameter below nominal diameter due to

loss of core support, internal or external?

RIGGING (NYLON SLINGS)

Excessive wear, torn stitching, punctures, tears or cuts?

Discoloration or deterioration?

Distortion of hardware in the sling?

RIGGING (ALLOY STEEL CHAIN SLINGS)

Cracked, bent, elongated links or other components?

Shackles, eye bolts or other components damaged?

ELECTRICAL SYSTEM

Functioning properly?

Loose connections?

Deterioration (cord frayed at the plug or elsewhere)?

LIMIT SWITCH

Upper limit switch operating correctly?

Signature of Designated Individual conducting the Inspection

NOTE: In the comment section, include serial number or other identifier of hooks and chains. Give completed inspection

form to your supervisor and ensure a copy is sent to the EHS Department for filing.

Length AB 2.050 inches initial (new hook)

Length BC 1.370 inches initial (new hook)

Length AB ___________________________ inches actual

Length BC ___________________________ inches actual

Establish 3 marks A,B,C with a center punch. For ease of in measuring all initial (new

hook) distances will be set to as close to an even number of inches as possible.

Hooks with more than 15% (initial) throat opening shall be replaced. Hooks with more

than a 10 degree twist from the normal plane of the hook shall be replaced. Hooks

with more than 5% elongation shall be replaced.

The designated inspector shall determine whether conditions found during the

inspection constitute a hazard and if a more detailed inspection is required.

Potrebbero piacerti anche

- Corporate Safety & Environmental Inspection ReportDocumento5 pagineCorporate Safety & Environmental Inspection ReportPang Lee ChingNessuna valutazione finora

- EOT Crane Manual IndexDocumento5 pagineEOT Crane Manual IndexGaurav TripathiNessuna valutazione finora

- Job Safety Environmental Analysis Pre-Task BriefingDocumento5 pagineJob Safety Environmental Analysis Pre-Task BriefingFerman TokgözoğluNessuna valutazione finora

- Engineering Operations Job RecordDocumento10 pagineEngineering Operations Job Recordyandere dollie100% (1)

- 25-Ra Use of Portable Pipe Threading MachineDocumento4 pagine25-Ra Use of Portable Pipe Threading MachineAsad AyazNessuna valutazione finora

- Excavator Inspection ChecklistDocumento2 pagineExcavator Inspection ChecklistSiyadarakkalmajeed ArakkalmajeedNessuna valutazione finora

- JOB Description: Position Title Department Position Reports To Job Class Job SummaryDocumento2 pagineJOB Description: Position Title Department Position Reports To Job Class Job SummaryVijay RajaindranNessuna valutazione finora

- First Aid Box Treatment & Inspection Register TemplateDocumento1 paginaFirst Aid Box Treatment & Inspection Register TemplateSn Ahsan100% (1)

- CLIC Catalogue PDFDocumento28 pagineCLIC Catalogue PDFsangram patilNessuna valutazione finora

- Ladders Inspection Register: Location: TSM ARABIADocumento4 pagineLadders Inspection Register: Location: TSM ARABIAmuhammad imtiazNessuna valutazione finora

- PPE Issue ReordDocumento1 paginaPPE Issue ReordHuman ResourcesNessuna valutazione finora

- PTW Audit Report SummaryDocumento1 paginaPTW Audit Report SummarybhaskarNessuna valutazione finora

- Water System Test ReportDocumento2 pagineWater System Test ReportNorman MuñizNessuna valutazione finora

- Annex A - Safety Walk Report FormDocumento4 pagineAnnex A - Safety Walk Report FormwvolpeNessuna valutazione finora

- SK Assoicates Authorized DealerDocumento1 paginaSK Assoicates Authorized DealerKamalesh KumarNessuna valutazione finora

- Hot Works Safety ProcedureDocumento4 pagineHot Works Safety ProcedureRachel NoraNessuna valutazione finora

- Hira - 01Documento3 pagineHira - 01Angw BasumataryNessuna valutazione finora

- Ppe Training Record: Department Occupation Type of Ppe Make/Model Name InitialsDocumento3 paginePpe Training Record: Department Occupation Type of Ppe Make/Model Name Initialsvlad100% (1)

- Experienced Lathe Operator/Machinist Job for Manual Lathe Machine OperationDocumento1 paginaExperienced Lathe Operator/Machinist Job for Manual Lathe Machine OperationAd DaNessuna valutazione finora

- Fire Extinguisher Maintenance Inspection ChecklistDocumento9 pagineFire Extinguisher Maintenance Inspection ChecklistSayed Aasim Jawaid100% (1)

- Breaker Driving Machine InspectionDocumento2 pagineBreaker Driving Machine InspectionMochammad AriefNessuna valutazione finora

- HSE Hot Work PermitDocumento3 pagineHSE Hot Work PermitCSD shakthiNessuna valutazione finora

- Permit to Work at HeightsDocumento2 paginePermit to Work at HeightsRj Hush Esguerra100% (1)

- Isolation Work Instruction TemplateDocumento5 pagineIsolation Work Instruction TemplateppnNessuna valutazione finora

- F.e.& Scba InspectionDocumento5 pagineF.e.& Scba InspectionAviects Avie JaroNessuna valutazione finora

- Safety Harness Monthly Checklist-Register JAN23Documento1 paginaSafety Harness Monthly Checklist-Register JAN23Iqbal HossainNessuna valutazione finora

- Lockout-Tagout ProcedureDocumento17 pagineLockout-Tagout ProcedureshaikhbwcNessuna valutazione finora

- Awareness On Working at HeightDocumento3 pagineAwareness On Working at Heightsubhadipmanna8Nessuna valutazione finora

- HSE 05-015a Ladder Inspection RegisterDocumento1 paginaHSE 05-015a Ladder Inspection RegisterQuentin KlynsmithNessuna valutazione finora

- Basic Safety Procedures in High Risk Activities andDocumento14 pagineBasic Safety Procedures in High Risk Activities andEzekiel Domini Quintal0% (2)

- COMPRESSED GAS CYLINDER CHECKLISTDocumento2 pagineCOMPRESSED GAS CYLINDER CHECKLISTPerwez21100% (1)

- Grinding: Thermax Engineering Construction Co. LTD Operational Control ProcedureDocumento2 pagineGrinding: Thermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghNessuna valutazione finora

- CNC Vertical Milling Machine-JOB PROCEDUREDocumento3 pagineCNC Vertical Milling Machine-JOB PROCEDUREpraveen_kumar_119Nessuna valutazione finora

- ZTG Temp Other Gate Pass Request FormatDocumento2 pagineZTG Temp Other Gate Pass Request FormatBhavik Dhami100% (1)

- Monthly ladder checklistDocumento1 paginaMonthly ladder checklistJohn Rey AbarcaNessuna valutazione finora

- STA Audit Format-EditableDocumento1 paginaSTA Audit Format-EditableDeepu ChandranNessuna valutazione finora

- Safety Rules and Regulations - For MechanicalWorkshop - Final9!10!17Documento3 pagineSafety Rules and Regulations - For MechanicalWorkshop - Final9!10!17Raheel Neo AhmadNessuna valutazione finora

- Work Procedure of Reverse Osmosis Plant: FN/WI/MT/004/R00 Authorized By: Asst. Manager MechanicalDocumento1 paginaWork Procedure of Reverse Osmosis Plant: FN/WI/MT/004/R00 Authorized By: Asst. Manager MechanicalFahad SarwarNessuna valutazione finora

- Sop Hydraulic Punch and ShearDocumento1 paginaSop Hydraulic Punch and ShearBorislav VulićNessuna valutazione finora

- Site Memorandum 00012: Endorsement Letter For Safety TrainingDocumento1 paginaSite Memorandum 00012: Endorsement Letter For Safety TrainingNick LatumboNessuna valutazione finora

- HSE Inspection Checklist: 1 Safety PromotionDocumento4 pagineHSE Inspection Checklist: 1 Safety PromotionRanjan PrNessuna valutazione finora

- Manual Chain Hoist Inspection Checklist: Health, Safety and Environment Management SystemDocumento1 paginaManual Chain Hoist Inspection Checklist: Health, Safety and Environment Management SystemEdward DineshNessuna valutazione finora

- Critical Task Inventory (CTI)Documento1 paginaCritical Task Inventory (CTI)Salman FareesNessuna valutazione finora

- Sick Leave FormDocumento1 paginaSick Leave FormAlbert NAMNessuna valutazione finora

- Health and Safety Induction SampleDocumento5 pagineHealth and Safety Induction SampleMohamad Hafiz100% (1)

- 5S ChecklistDocumento4 pagine5S ChecklistMohdAzhanBinIshakNessuna valutazione finora

- Sample-Risk Assessment & Safe Work Method StatementDocumento4 pagineSample-Risk Assessment & Safe Work Method StatementioanchiNessuna valutazione finora

- Certificate of Achievement for TOPIC CourseDocumento1 paginaCertificate of Achievement for TOPIC Courseclaire juarezNessuna valutazione finora

- Arc Welding SOPDocumento2 pagineArc Welding SOPMohamedNessuna valutazione finora

- Asian Paints - Prem Gloss EnamelDocumento1 paginaAsian Paints - Prem Gloss EnamelwilliumstNessuna valutazione finora

- ILR Bearing Housing Assembly ProcedureDocumento10 pagineILR Bearing Housing Assembly ProcedureAlejandroZegarraNessuna valutazione finora

- PpeDocumento1 paginaPpeBryan Rey Del Fierro100% (1)

- Method Statement Fisher PlugDocumento5 pagineMethod Statement Fisher PlugChezy629Nessuna valutazione finora

- Permit To Work FormDocumento2 paginePermit To Work FormNate JamesNessuna valutazione finora

- Weekly Hazardous Waste ChecklistDocumento1 paginaWeekly Hazardous Waste ChecklistOM SUTARNessuna valutazione finora

- SOP For Use of Grinder Machines in WorkshopDocumento8 pagineSOP For Use of Grinder Machines in WorkshopFaisal RajaNessuna valutazione finora

- Inspection-Record-AHUDocumento2 pagineInspection-Record-AHUSchwihdi ZakNessuna valutazione finora

- Inspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadDocumento1 paginaInspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadilyasNessuna valutazione finora

- Hot Weather Heat Stress ProcedureDocumento6 pagineHot Weather Heat Stress ProcedureJay-Jay JapsNessuna valutazione finora

- Safe System Of Work A Complete Guide - 2020 EditionDa EverandSafe System Of Work A Complete Guide - 2020 EditionNessuna valutazione finora

- Jacksonville Plant Hazard Hunt ChallengeDocumento1 paginaJacksonville Plant Hazard Hunt ChallengeGrace PassiniNessuna valutazione finora

- Heat Stress PreventionDocumento9 pagineHeat Stress PreventionGrace PassiniNessuna valutazione finora

- Safety Training Ideas Worth StealingDocumento38 pagineSafety Training Ideas Worth StealingGrace Passini100% (5)

- Preparation of Spill Prevention Control & Countermeasure (SPCC) Plan - Guidance DocumentDocumento11 paginePreparation of Spill Prevention Control & Countermeasure (SPCC) Plan - Guidance DocumentGrace PassiniNessuna valutazione finora

- Battle Ready Environmental Warriors: Challenges, Combat and Catalyst For Change BREW C4Documento30 pagineBattle Ready Environmental Warriors: Challenges, Combat and Catalyst For Change BREW C4Grace PassiniNessuna valutazione finora

- Crane and Hoist Daily Pre Operational CheckDocumento1 paginaCrane and Hoist Daily Pre Operational CheckGrace PassiniNessuna valutazione finora

- PPG8 Safe Storage and Disposal of Used OilsDocumento4 paginePPG8 Safe Storage and Disposal of Used OilsGrace PassiniNessuna valutazione finora

- Dental Materials Lecture - Mechanical PropertiesDocumento27 pagineDental Materials Lecture - Mechanical PropertiesFatima SiddiquiNessuna valutazione finora

- Astm A586 04Documento6 pagineAstm A586 04beTxxYNessuna valutazione finora

- DME-Online Class Sep2020-Module 2-PartB PDFDocumento37 pagineDME-Online Class Sep2020-Module 2-PartB PDFMathew John100% (1)

- Fibre Beam ElementDocumento55 pagineFibre Beam Elementmakkusa100% (1)

- SOM One Linear PDFDocumento88 pagineSOM One Linear PDFDinuSkyNessuna valutazione finora

- NASA research on cylindrical shell structures reinforced with internal membersDocumento48 pagineNASA research on cylindrical shell structures reinforced with internal membersMaliOdKužineNessuna valutazione finora

- Optistruct Optimization 90 Vol1 ManualDocumento149 pagineOptistruct Optimization 90 Vol1 Manualgurudev001Nessuna valutazione finora

- Quiz 2 OTDocumento3 pagineQuiz 2 OTFirst LastNessuna valutazione finora

- MODULE 2a - SIMPLE STRAIN - MOM 2019Documento12 pagineMODULE 2a - SIMPLE STRAIN - MOM 2019Precious CabigaoNessuna valutazione finora

- Postbuckling and Collapse AnalysisDocumento8 paginePostbuckling and Collapse AnalysisAtsis Papadopoulos100% (1)

- ChalmersDocumento250 pagineChalmersRory Cristian Cordero RojoNessuna valutazione finora

- Solution Manual For Manufacturing Processes For Engineering Materials 6Th Edition Kalpakjian Schmid 0134290550 9780134290553 Full Chapter PDFDocumento36 pagineSolution Manual For Manufacturing Processes For Engineering Materials 6Th Edition Kalpakjian Schmid 0134290550 9780134290553 Full Chapter PDFnick.fleming516100% (15)

- SOM Strength of Materials exam detailsDocumento2 pagineSOM Strength of Materials exam detailsAli Jarrar JafriNessuna valutazione finora

- Draft Indian Standard Quantitative Classification System of Rock MassDocumento17 pagineDraft Indian Standard Quantitative Classification System of Rock MassLuca BrandiNessuna valutazione finora

- CShanahan Poster NUIGULDocumento2 pagineCShanahan Poster NUIGULBích TrònNessuna valutazione finora

- Spinning CalculationDocumento178 pagineSpinning Calculationamboklate69% (16)

- Analysis of Unstiffened Thin Steelplate Shear Wall (SPSW) Using Anequivalent Truss-Elements ModelDocumento68 pagineAnalysis of Unstiffened Thin Steelplate Shear Wall (SPSW) Using Anequivalent Truss-Elements Modelguojie zhouNessuna valutazione finora

- Plastic AnalysisDocumento23 paginePlastic AnalysisPraveen Kumar R100% (1)

- Creep & FatigueDocumento20 pagineCreep & Fatiguesgk3219Nessuna valutazione finora

- 160 On The Stoney Formula For A Thin Film SubstrateDocumento6 pagine160 On The Stoney Formula For A Thin Film SubstrateJosé Emilio Román de AndaNessuna valutazione finora

- Tensile and Relaxation Testing of HDPE and AcrylicDocumento7 pagineTensile and Relaxation Testing of HDPE and AcrylicjohnNessuna valutazione finora

- Mechanical Properties and Behavior ExplainedDocumento72 pagineMechanical Properties and Behavior ExplainedsabavoonNessuna valutazione finora

- Meyer Nicholas ThesisDocumento207 pagineMeyer Nicholas ThesisDaniel CoelhoNessuna valutazione finora

- Tunnel Full Paper Id Number 306Documento10 pagineTunnel Full Paper Id Number 306Bosko SarenacNessuna valutazione finora

- 16 CmsDocumento4 pagine16 Cmsrajraj3550Nessuna valutazione finora

- Field Instrumentation For SoilDocumento420 pagineField Instrumentation For SoilSafwat El RoubyNessuna valutazione finora

- Master's Thesis FinalDocumento86 pagineMaster's Thesis FinalTünde LőrincziNessuna valutazione finora

- Example Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingDocumento10 pagineExample Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in Bendingcbler100% (10)

- Ultrasonic Flaw DetectionDocumento15 pagineUltrasonic Flaw DetectionLeonardo.martinezNessuna valutazione finora