Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Advanced Manufacturing System (TPM)

Caricato da

1977jul0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

203 visualizzazioni9 pagineAMS

Titolo originale

20140812_Advanced Manufacturing System [TPM]

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoAMS

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

203 visualizzazioni9 pagineAdvanced Manufacturing System (TPM)

Caricato da

1977julAMS

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 9

CH 8 BEKC4883 Advanced Manufacturing System

(C) 2009 The Plant Maintenance Resource Center; JIPM; JIPM-S;

M. Zainon, FKE UTeM. All rights reserved. 1

CHAPTER 8:

INTRODUCTION TO TOTAL

PRODUCTIVE MAINTENANCE (TPM)

BEKC 4883

ADVANCED

MANUFACTURING

SYSTEM

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

1

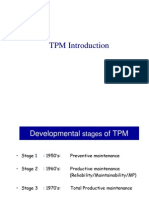

TPM - a production management

method/philosophy, which involves all

employees participation in a newly

defined concept for maintaining

plants and equipment to improve

productivity.

What is Total Productive Maintenance

(TPM)?

TPM can be considered as the medical science of machines

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

2

Goal of TPM

To markedly increase production

while, at the same time,

increasing employees morale

and job satisfaction.

markedly - describes a change or difference in behaviour or a situation

that is very obvious or noticeable

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

3

Founder/Pioneer of TPM

Seiichi Nakajima

"The Founder/Pioneer of TPM"

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

4

TPMs Established Organizations

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

5

Japan Institute of Plant Maintenance

(JIPM)

Japan Institute of Plant Maintenance

Solution Ltd. (JIPM-S)

History of TPM, JIPM & JIPM-S

1961 - The Japan Management Association (JMA) establishes a Plant

Maintenance (PM) Committee.

1964 - A system for awarding PM Awards is established.

1969 - The Plant Maintenance Department is dissolved and the Japan

Institute of Plant Engineers (JIPE) is established.

1971 - The concept of plant maintenance with total participation (Total

Productive Maintenance, TPM) is proclaimed.

1981 - The Japan Institute of Plant Maintenance (JIPM) is launched,

following approval from the Ministry of International Trade and Industry

as charitable corporation.

1989 - The definition of TPM is revised.

1989 - The Society of Plant Engineers Japan (SPEJ) is established.

1990 - The Japan Association of Maintenance and Service Contractors

(JAMSC) is launched.

2005 - JIPM Solutions (JIPM-S) Company Limited is separated and

transferred from JIPM as a profit-seeking corporation.

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

6

CH 8 BEKC4883 Advanced Manufacturing System

(C) 2009 The Plant Maintenance Resource Center; JIPM; JIPM-S;

M. Zainon, FKE UTeM. All rights reserved. 2

Why TPM?

TPM was introduced to achieve the following

most important objectives:

Avoid wastage in a quickly changing

economic environment.

Producing goods without reducing product

quality.

Reduce cost.

Produce a low batch quantity at the earliest

possible time.

Goods send to the customers must be non

defective.

7 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

Similarities and Differences between

TQM and TPM

Similarities between TQM and TPM

The TPM program closely resembles the popular Total Quality

Management (TQM) program.

Many of the tools such as employee empowerment,

benchmarking, documentation, etc. used in TQM are used to

implement and optimize TPM.

Following are the similarities between the two:

1. Total commitment to the program by upper level management

is required in both programmes.

2. Employees must be empowered to initiate corrective action,

and

3. A long range outlook must be accepted as TPM may take a

year or more to implement and is an on-going process.

4. Changes in employee mind-set toward their job responsibilities

must take place as well.

8

The differences between TQM and

TPM

Category TQM TPM

Object

Quality (Output and

Effects)

Equipment (Input

and Cause)

Mains of

Attaining Goal

Systematize the

management. It is

software oriented.

Employees

participation and it

is hardware

oriented

Target Quality for PPM

Elimination of

losses and wastes

9

1. Breakdown Maintenance

2. Preventive Maintenance (1951)

2a. Periodic Maintenance (Time

Based Maintenance - TBM)

2b. Predictive Maintenance

3. Corrective Maintenance (1957)

4. Maintenance Prevention (1960)

Types of Maintenance

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

10

1) Breakdown Maintenance:

Means people waits until equipment fails and

repair it.

Could be used when the equipment failure

does not significantly affect the operation or

production or generate any significant loss

other than repair cost.

Types of Maintenance

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

11

2) Preventive Maintenance (1951):

A daily maintenance (cleaning, lubrication, adjustment,

inspection, repair - CLAIR), design to retain the healthy

condition of equipment and prevent failure through the

prevention of deterioration, periodic inspection or

equipment condition diagnosis, to measure deterioration.

Further divided into periodic maintenance and predictive

maintenance. Just like human life is extended by

preventive medicine, the equipment service life can be

prolonged by doing preventive maintenance.

Types of Maintenance

12 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

CH 8 BEKC4883 Advanced Manufacturing System

(C) 2009 The Plant Maintenance Resource Center; JIPM; JIPM-S;

M. Zainon, FKE UTeM. All rights reserved. 3

2a) Periodic Maintenance (Time Based Maintenance TBM):

Consists of periodically inspecting, servicing and cleaning

equipment and replacing parts to prevent sudden failure and

process problems.

2b) Predictive Maintenance (Condition Based Maintenance

CBM):

Method in which the service life of important part is predicted

based on inspection or diagnosis, in order to use the parts to

the limit of their service life.

Compared to periodic maintenance, predictive maintenance is

condition based maintenance.

It manages trend values, by measuring and analyzing data

about deterioration and employs a surveillance system,

designed to monitor conditions through an on-line system.

Types of Maintenance

13

3) Corrective Maintenance (1957):

It improves equipment and its components

so that preventive maintenance can be

carried out reliably.

Equipment with design weakness must be

redesigned to improve reliability or

improving maintainability

Types of Maintenance

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

14

4) Maintenance Prevention (1960):

It indicates the design of new equipment.

Weakness of current machines are

sufficiently studied (on site information

leading to failure prevention, easier

maintenance and prevents of defects,

safety and ease of manufacturing) and are

incorporated before commissioning a new

equipment.

Types of Maintenance

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

15

P

- Obtain Minimum 80% OPE (Overall Plant Efficiency)

- Obtain Minimum 90% OEE (Overall Equipment Efficiency/Effectiveness)

- Run the machines even in during break time.

Q

Operate in a manner, so that there are no customer complaints.

C

Reduce the manufacturing cost by 30%.

D

Achieve 100% success in delivering the goods as required by the customer.

S

Maintain an accident free environment.

M

Increase the suggestions by 3 times. Develop multi-skilled and flexible workers.

TPM TARGETS (PQCDSM) -

Example

16

TPM OBJECTIVES

Achieve Zero Defects, Zero Breakdown

and Zero Accidents in all functional areas

of the organization.

Involve people in all levels of organization.

Form different teams to reduce defects and

Self Maintenance.

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

17

OEE (Overall Equipment Efficiency)

18

The Formulas

The OEE calculation is based on the three OEE Factors: Availability,

Performance, and Quality (Yield). Here's how each of these factors is

calculated.

1) Availability

Availability takes into account Down Time Loss, and is calculated

as:

Availability = Operating Time / Planned Production Time

OR

A = (MTBF MTTR) / MTBF

MTBF Mean Time Between Failures = Total Running Time / Number of Failures

MTTR Mean Time To Repair = Total Repair Time / Number of Repairs

CH 8 BEKC4883 Advanced Manufacturing System

(C) 2009 The Plant Maintenance Resource Center; JIPM; JIPM-S;

M. Zainon, FKE UTeM. All rights reserved. 4

OEE (Overall Equipment Efficiency)

19

2) Performance

Performance takes into account Speed Loss, and is calculated as:

Performance = Ideal Cycle Time / (Operating Time / Total Pieces)

Ideal Cycle Time is the minimum cycle time that your process can

be expected to achieve in optimal circumstances. It is sometimes

called Design Cycle Time, Theoretical Cycle Time or Nameplate

Capacity.

Since Run Rate is the reciprocal of Cycle Time, Performance can

also be calculated as:

Performance = (Total Pieces / Operating Time) / Ideal Run Rate

Note: Performance is capped at 100%, to ensure that if an error is made in specifying

the Ideal Cycle Time or Ideal Run Rate the effect on OEE will be limited.

OEE (Overall Equipment Efficiency)

20

3) Quality (Yield)

Quality takes into account Quality Loss, and is calculated as:

Quality (Yield) = Good Pieces / Total Pieces

OEE

OEE takes into account all three OEE Factors, and is calculated

as:

OEE = Availability x Performance x Quality (Yield)

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

OEE (Overall Equipment Efficiency)

21

It is very important to recognize that improving OEE is not the only

objective. Take a look at the following data for two production shifts.

OEE Factor Shift 1 Shift 2

Availability 90.0% 95.0%

Performance 95.0% 95.0%

Quality (Yield) 99.5% 96.0%

OEE 85.1% 86.6%

Superficially, it may appear that the second shift is performing better than

the first, since its OEE is higher. Very few companies, however, would

want to trade a 5.0% increase in Availability for a 3.5% decline in Quality!

The beauty of OEE is not that it gives you one magic number; it's that it

gives you three numbers, which are all useful individually as your

situation changes from day to day. And it helps you visualize performance

in simple terms - a very practical simplification.

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

OEE Calculation Example

22

Below are the hypothetical shift data, to be used for a complete OEE calculation, starting with the

calculation of the OEE Factors of Availability, Performance, and Quality (Yield). Note that the same units of

measurement (in this case minutes and pieces) are consistently used throughout the calculations.

Item Data

Shift Length 8 hours = 480 min.

Short Breaks 2 @ 15 min. = 30 min.

Meal Break 1 @ 30 min. = 30 min.

Down Time 47 minutes

Ideal Run Rate 60 pieces per minute

Total Pieces 19,271 pieces

Reject Pieces 423 pieces

Planned Production = [Shift Length - Breaks]

Time = [480 - 60]

= 420 minutes

Operating Time = [Planned Production Time - Down Time]

= [420 - 47]

= 373 minutes

Good Pieces = [Total Pieces - Reject Pieces]

= [19,271 - 423]

= 18,848 pieces

23

Availability = Operating Time / Planned Production Time

= 373 minutes / 420 minutes

= 0.8881 (88.81%)

Performance = (Total Pieces / Operating Time) / Ideal Run Rate

= (19,271 pieces / 373 minutes) / 60 pieces per minute

= 0.8611 (86.11%)

Quality (Yield) = Good Pieces / Total Pieces

= 18,848 / 19,271 pieces

= 0.9780 (97.80%)

Thus, OEE = Availability x Performance x Quality

= 0.8881 x 0.8611 x 0.9780

= 0.7479 (74.79%)

OEE Calculation Example (contd.)

Stage and Steps in Introduction of

TPM in an Organization

STAGE A Preparatory Stage

STAGE B Introduction Stage

STAGE C Implementation Stage

STAGE D Institutionalizing Stage

24 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

CH 8 BEKC4883 Advanced Manufacturing System

(C) 2009 The Plant Maintenance Resource Center; JIPM; JIPM-S;

M. Zainon, FKE UTeM. All rights reserved. 5

Stage and Steps in Introduction of

TPM in an Organization

STAGE A Preparatory Stage

STEP 1 - Announcement by Management to all about TPM introduction

in the organization

Proper understanding, commitment and active involvement of the top

management in needed for this step.

Senior management should have awareness programmes, after which

announcement is made to all.

Publish it in the house magazine and put it in the notice board.

Send a letter to all concerned individuals if required.

STEP 2 - Initial education and propaganda for TPM

Training is to be done based on the need. Some need intensive training

and some just an awareness.

Take people who matters to places where TPM already successfully

implemented.

25 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

Stage and Steps in Introduction of

TPM in an Organization

STAGE A Preparatory Stage (contd.)

STEP 3 - Setting up TPM and departmental committees

TPM includes improvement, autonomous maintenance, quality

maintenance etc., as part of it.

When committees are set up, it should take care of all those needs.

STEP 4 - Establishing the TPM working system and target

Now each area is benchmarked and fix up a target for achievement.

STEP 5 - A master plan for institutionalizing

Next step is implementation leading to institutionalizing where TPM

becomes an organizational culture.

Achieving PM award is the proof of reaching a satisfactory level.

26 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

Stage and Steps in Introduction of

TPM in an Organization

STAGE B Introduction Stage

This is a ceremony and all should be invited, i.e.

suppliers, as they should know that the company

always require quality supply from them; related

companies and affiliated companies, who can be the

customers, sisters concerns, etc. Some may learn and

some can help

Customers will get the communication from the

company that quality output is among their priority.

27 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

Stage and Steps in Introduction of

TPM in an Organization

STAGE C Implementation Stage

In this stage, eight activities are carried out, which are

called eight pillars in the development of TPM activity.

There are activities for establishing system for

production efficiency, initial control system of new

products and equipment, improving the efficiency of

administration and for control of safety and sanitation

as working environment.

5S, Autonomous Maintenance, Focus Improvement, Planned

maintenance, Quality Maintenance, Training, Office TPM, and

Safety, Health & Environment.

28 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

Stage and Steps in Introduction of

TPM in an Organization

STAGE D Institutionalizing Stage

By means of all the activities, one would has reached

maturity stage.

Now is the time for applying for PM award.

Also think of challenging level to which this movement

can be taken.

29 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

Organization Structure for TPM

Implementation

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

30

CH 8 BEKC4883 Advanced Manufacturing System

(C) 2009 The Plant Maintenance Resource Center; JIPM; JIPM-S;

M. Zainon, FKE UTeM. All rights reserved. 6

8 Pillars of TPM

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

31

8 Pillars of TPM Pillar 1: 5S

Japanese Term

English

Translation

Equivalent 'S' term

Seiri Organization Sort

Seiton Tidiness Systematize

Seiso Cleaning Sweep

Seiketsu Standardization Standardize

Shitsuke Discipline Self - Discipline

PILLAR 1 5S

TPM starts with 5S. Problems cannot be clearly seen when the

work place is unorganized. Cleaning and organizing the

workplace helps the team to uncover problems. Making

problems visible is the first step of improvement.

32

8 Pillars of TPM Pillar 2: Jishu

Hozen (J-H)

PILLAR 2 JISHU HOZEN (Autonomous

Maintenance)

This pillar is geared towards developing operators

to be able to take care of small maintenance

tasks,

thus freeing up the skilled maintenance people to

spend time on more value added activity and

technical repairs.

The operators are responsible for up-keeping their

equipment to prevent it from deteriorating.

33 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

Steps in JISHU HOZEN:

Preparation of employees

Initial cleanup of machines

Take counter measures

Fix tentative JH standards

General inspection

Autonomous inspection

Standardization

Autonomous management

8 Pillars of TPM Pillar 2: Jishu

Hozen (J-H)

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

34

8 Pillars of TPM Pillar 3: Kobetsu

Kaizen

PILLAR 3 KOBETSU KAIZEN (Focused Improvement)

"Kai" means change, and "Zen" means good (for the

better).

Basically kaizen is for small improvements, but carried

out on a continual basis and involve all people in the

organization.

Kaizen is opposite to big spectacular innovations.

Kaizen requires no or little investment.

The principle behind is that a very large number of

small improvements are more effective in an

organizational environment than a few improvements of

large value.

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

35

This pillar is aimed at reducing losses in the

workplace that affect our efficiencies.

By using a detailed and thorough procedure

we eliminate losses in a systematic method

using various Kaizen tools.

These activities are not limited to production

areas and can be implemented in

administrative areas as well.

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

36

8 Pillars of TPM Pillar 3: Kobetsu

Kaizen

CH 8 BEKC4883 Advanced Manufacturing System

(C) 2009 The Plant Maintenance Resource Center; JIPM; JIPM-S;

M. Zainon, FKE UTeM. All rights reserved. 7

Tools used in Kaizen:

P-M Analysis

relies on investigational method based upon physical

principles of sciences, causes and effect analysis,

interaction of physical elements, part function, mean life

of components and their characteristics under varying

determinant conditions.

Why-Why Analysis

Summary of Losses

Kaizen Register

Kaizen Summary Sheet

37

8 Pillars of TPM Pillar 3: Kobetsu

Kaizen

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

The objective of TPM is maximization of

equipment effectiveness.

TPM aims at maximization of machine utilization

and not merely machine availability maximization.

As one of the pillars of TPM activities, Kaizen

pursues efficient equipment, operator and material

and energy utilization that is extremes of

productivity and aims at achieving substantial

effects.

Kaizen activities try to thoroughly eliminate 16

major losses.

38

8 Pillars of TPM Pillar 3: Kobetsu

Kaizen

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

16 Major Losses in a Manufacturing

Organization

Loss Category

1. Failure losses - Breakdown loss

2. Setup / adjustment losses

3. Cutting blade loss

4. Start up loss

5. Minor stoppage / Idling loss.

6. Speed loss - operating at low speeds.

7. Defect / rework loss

8. Scheduled downtime loss

Losses that impede equipment

efficiency

9. Management loss

10. Operating motion loss

11. Line organization loss

12. Logistic loss

13. Measurement and adjustment loss

Loses that impede human work

efficiency

14. Energy loss

15. Die, jig and tool breakage loss

16. Yield loss.

Loses that impede effective use of

production resources

Impede: to slow down or cause problems for the advancement or completion of something

39

8 Pillars of TPM Pillar 4: Planned

Maintenance

PILLAR 4 KEIKAKU HOZEN (Planned Maintenance)

It is aimed to have trouble free machines (zero breakdown) and

equipments producing defect free products for total customer

satisfaction.

This breaks maintenance down into 4 "families" or groups

which were defined earlier.

Preventive Maintenance

Breakdown Maintenance

Corrective Maintenance

Maintenance Prevention

With Planned Maintenance, the efforts have been evolved from

a reactive to a proactive method and use trained maintenance

staff to help train the operators to better maintain their

equipment. 40 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

8 Pillars of TPM Pillar 4: Planned

Maintenance

Six Steps in Planned Maintenance:

1) Equipment evaluation and recording present

status.

2) Restore deterioration and improve weakness.

3) Building up information management system.

4) Prepare time based information system, select

equipment, parts and members and map out plan.

5) Prepare predictive maintenance system by

introducing equipment diagnostic techniques and

6) Evaluation of planned maintenance.

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

41

8 Pillars of TPM Pillar 5: Hinshitsu

Hozen (Quality Maintenance)

PILLAR 5 HINSHITSU HOZEN (Quality Maintenance)

It is aimed to have trouble free machines and equipments

producing defect free products for total customer satisfaction.

It is aimed towards customer delight through highest quality

through defect free manufacturing.

Focus is on eliminating non-conformances in a systematic

manner, much like Focused Improvement.

We gain understanding of what parts of the equipment affect

product quality and begin to eliminate current quality concerns,

then move to potential quality concerns.

Transition is from reactive to proactive (Quality Control to Quality

Assurance).

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

42

CH 8 BEKC4883 Advanced Manufacturing System

(C) 2009 The Plant Maintenance Resource Center; JIPM; JIPM-S;

M. Zainon, FKE UTeM. All rights reserved. 8

8 Pillars of TPM Pillar 5: Hinshitsu

Hozen (Quality Maintenance)

PILLAR 5 HINSHITSU HOZEN (Quality Maintenance) (contd.)

QM activities is to set equipment conditions that preclude quality

defects, based on the basic concept of maintaining perfect

equipment to maintain perfect quality of products.

The condition are checked and measure in time series to very that

measure values are within standard values to prevent defects.

The transition of measured values is watched to predict

possibilities of defects occurring and to take counter measures

before hand.

Target (example):

Achieve and sustain customer complaints at ZERO.

Reduce in-process defects by 50 %

Reduce cost of quality by 50 %.

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

43

8 Pillars of TPM Pillar 6: Training

PILLAR 6 TRAINING

It is aimed towards customer delight through highest quality

through defect free manufacturing.

Focus is on eliminating non-conformances in a systematic

manner, much like Focused Improvement.

We gain understanding of what parts of the equipment

affect product quality and begin to eliminate current quality

concerns, then move to potential quality concerns.

Transition is from reactive to proactive (Quality Control to

Quality Assurance).

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

44

PILLAR 6 TRAINING (contd.)

QM activities is to set equipment conditions that preclude

quality defects, based on the basic concept of maintaining

perfect equipment to maintain perfect quality of products.

The condition are checked and measure in time series to

very that measure values are within standard values to

prevent defects.

The transition of measured values is watched to predict

possibilities of defects occurring and to take counter

measures before hand.

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

45

8 Pillars of TPM Pillar 6: Training

PILLAR 7 OFFICE TPM

Office TPM should be started after activating four other

pillars of TPM (JH, KK, QM, PM).

Office TPM must be followed to improve productivity,

efficiency in the administrative functions and identify and

eliminate losses.

This includes analyzing processes and procedures towards

increased office automation.

Office TPM addresses twelve major losses, which are:

1) Processing loss

2) Cost loss including in areas such as procurement,

accounts, marketing, sales leading to high inventories

3) Communication loss

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

46

8 Pillars of TPM Pillar 7: Office

TPM

PILLAR 7 OFFICE TPM (contd.)

4) Idle loss

5) Set-up loss

6) Accuracy loss

7) Office equipment breakdown

8) Communication channel breakdown, telephone and fax

lines

9) Time spent on retrieval of information

10) Non availability of correct on line stock status

11) Customer complaints due to logistics

12) Expenses on emergency dispatches/purchases

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

47

8 Pillars of TPM Pillar 7: Office

TPM

8 Pillars of TPM Pillar 8: Safety,

Health & Environment

PILLAR 8 SAFETY, HEALTH AND ENVIRONMENT

Target : Zero accident, Zero health damage, Zero fires.

In this pillar, focus is on how to create a safe workplace and a

surrounding area that is not damaged by our process or

procedures. This pillar will play an active role in each of the other

pillars on a regular basis.

A committee is constituted for this pillar, which comprises

representative of officers as well as workers. The committee is

headed by Senior vice President ( Technical ). Utmost importance

to Safety is given in the plant. Manager (Safety) is looking after

functions related to safety. To create awareness among

employees various competitions like safety slogans, quiz, drama,

posters, etc. related to safety can be organized at regular

intervals.

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

48

CH 8 BEKC4883 Advanced Manufacturing System

(C) 2009 The Plant Maintenance Resource Center; JIPM; JIPM-S;

M. Zainon, FKE UTeM. All rights reserved. 9

JIPMs TPM Awards Category

1) Award for TPM Excellence, Category B

2) Award for TPM Excellence, Category A

3) Award for Excellence in Consistent TPM

Commitment

4) Special Award for TPM Achievement

5) Advanced Special Award for TPM

Achievement

6) Award for World-class TPM Achievement

2008 TPM Awards List

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

49

CONCLUSION

TPM may be the only thing that stands between success and total

failure for some companies, in todays all time high competition in

industry.

TPM is proven to be a program that works.

TPM can be adapted to work not only in industrial plants, but in

construction, building maintenance, transportation, and in a variety

of other situations.

Employees must be educated and convinced that TPM is not just

another "program of the month" and that management is totally

committed to the program and the extended time frame necessary

for full implementation.

If everyone involved in a TPM program does his or her part, an

unusually high rate of return compared to resources invested may

be expected.

50 (C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

References for Further Readings

P-M Analysis: An Advanced Step

in TPM Implementation, 2004

Authors: Mitsugu Kaneda,

Yoshifumi Kimura, Shirose Kunio

Introduction to TPM: Total

Productive Maintenance, 1989

Author: Seiichi Nakajima

51

References for Further Readings

52

Seiichi Nakajima, "TPM Development Program, 1993.

Japan Institute of Plant Maintenance, TPM for Every Operator,

Productivity Press, 1996.

Leflar, James, Practical TPM: Successful Equipment Management at

Agilent Technologies, Productivity Press, 2001.

Campbell, John D. and Reyes-Picknell, James (2006), Uptime, 2nd

Edition: Strategies for Excellence in Maintenance Management,

Productivity Press.

http://www.jipm.or.jp

http://tpm.jipms.jp

(C) 2009 The Plant Maintenance Resource Center;

JIPM; JIPM-S; M. Zainon, FKE UTeM. All rights

reserved.

Potrebbero piacerti anche

- Event TPM JipmDocumento29 pagineEvent TPM JipmImamRN100% (3)

- TPM Kick-Off: Newsletter From CII TPM Club IndiaDocumento6 pagineTPM Kick-Off: Newsletter From CII TPM Club IndiaNarendran100% (1)

- 2015 TPM Award: Application OutlineDocumento57 pagine2015 TPM Award: Application OutlineGustavo Salguero MoralesNessuna valutazione finora

- Relation Between 7 Major Losses of Equipment and Overall Equipment EfficiencyDocumento2 pagineRelation Between 7 Major Losses of Equipment and Overall Equipment EfficiencySwapnil KhadeNessuna valutazione finora

- An Introduction To Total Pr...Documento9 pagineAn Introduction To Total Pr...Abhinav JainNessuna valutazione finora

- TPMDocumento42 pagineTPMSrinivasan VenkatNessuna valutazione finora

- World Class ManufacturingDocumento17 pagineWorld Class ManufacturingNitin PawarNessuna valutazione finora

- 16 LossesDocumento2 pagine16 LossesShekhar9Nessuna valutazione finora

- Progress at TPM: Newsletter From CII TPM Club IndiaDocumento18 pagineProgress at TPM: Newsletter From CII TPM Club IndiamurilocabriniNessuna valutazione finora

- Training ON TPM: Rapl Production SystemDocumento25 pagineTraining ON TPM: Rapl Production Systemabhijit bhattacherjeENessuna valutazione finora

- DC JoshiDocumento58 pagineDC JoshiImamRNNessuna valutazione finora

- TPM Training TextbookDocumento2 pagineTPM Training TextbookRbc b100% (1)

- Multi SkillDocumento6 pagineMulti SkillK.s. RameshNessuna valutazione finora

- Sona GroupDocumento56 pagineSona GroupbrindatammaNessuna valutazione finora

- Step 0 and 1 Management Part 1Documento14 pagineStep 0 and 1 Management Part 1murilocabriniNessuna valutazione finora

- 30 November 2016 (Wednesday) : Japan Institute of Plant Maintenance (JIPM) Managing Director Satoshi SuzuokiDocumento15 pagine30 November 2016 (Wednesday) : Japan Institute of Plant Maintenance (JIPM) Managing Director Satoshi SuzuokiSelvaraj SimiyonNessuna valutazione finora

- Professional MaintenanceDocumento391 pagineProfessional MaintenanceAimar Vanderlei Ferreira Filho100% (1)

- Improve Business - Kobetsu KaizenDocumento4 pagineImprove Business - Kobetsu KaizenRishabh JainNessuna valutazione finora

- 06 - PMDocumento113 pagine06 - PMMohaiminNessuna valutazione finora

- 16 LossesDocumento9 pagine16 LossesMuthu Vellayappan100% (1)

- Study of JH Implementation ReadyDocumento27 pagineStudy of JH Implementation ReadyNaveen Jangid100% (1)

- Fmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123Documento5 pagineFmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123DanistergladwinNessuna valutazione finora

- Lect14r6oct 06 Pom World Class Manufacturing 110908135935 Phpapp01 PDFDocumento80 pagineLect14r6oct 06 Pom World Class Manufacturing 110908135935 Phpapp01 PDFVivek KumarNessuna valutazione finora

- Jishu Hozen BookDocumento72 pagineJishu Hozen BookCHUTIYA100% (1)

- Total Productive Management: TQM TPM ConsultantDocumento84 pagineTotal Productive Management: TQM TPM Consultantsiruslara6491Nessuna valutazione finora

- Total Productive Maintenance Overview Low ResDocumento28 pagineTotal Productive Maintenance Overview Low ResJogender KumarNessuna valutazione finora

- Kobetsu Kaizen: Maintenance ManagementDocumento34 pagineKobetsu Kaizen: Maintenance ManagementMohammed Rushnaiwala100% (1)

- Autonomous MaintenanceDocumento7 pagineAutonomous Maintenancenavi3281Nessuna valutazione finora

- TPM PT1.5Documento121 pagineTPM PT1.5mmkatta100% (1)

- Implementation of Kobetsu Kaizen Pillar PDFDocumento9 pagineImplementation of Kobetsu Kaizen Pillar PDFLuis JerezNessuna valutazione finora

- JH Step-1 & 2activitiesDocumento34 pagineJH Step-1 & 2activitiesGREENEXE BUSINESS CONSULTANTNessuna valutazione finora

- Basic 5SDocumento117 pagineBasic 5SPrasad PrinceNessuna valutazione finora

- WCMDocumento66 pagineWCMKARLANessuna valutazione finora

- 01.sundram Fasteners LTDDocumento60 pagine01.sundram Fasteners LTDTapash Kumar PalNessuna valutazione finora

- AM BookDocumento45 pagineAM BookGopal KrishnanNessuna valutazione finora

- TPM: Total Productive MaintenanceDocumento88 pagineTPM: Total Productive MaintenanceManu SharmaNessuna valutazione finora

- The World Class Manufacturing Programme at ChryslerDocumento4 pagineThe World Class Manufacturing Programme at ChryslerNarasimharaghavanPuliyurKrishnaswamyNessuna valutazione finora

- TPM PresentationDocumento40 pagineTPM PresentationRahul RajpalNessuna valutazione finora

- Ebook - 9 & 10 Ogos 2022 - Seminar Dan Coaching Intervensi KKP Di Tempat KerjaDocumento127 pagineEbook - 9 & 10 Ogos 2022 - Seminar Dan Coaching Intervensi KKP Di Tempat KerjaAfrina DamyaNessuna valutazione finora

- VSM PDFDocumento52 pagineVSM PDFChip ChopNessuna valutazione finora

- Jishu Hozen Audit Sheet: Area: Equipment Name: Score RemarksDocumento2 pagineJishu Hozen Audit Sheet: Area: Equipment Name: Score RemarksharshavardhanNessuna valutazione finora

- TPS and Lean ProductionDocumento18 pagineTPS and Lean ProductionMikey ChuaNessuna valutazione finora

- Poster Mustafa KonukR2Documento1 paginaPoster Mustafa KonukR2Ansar LawiNessuna valutazione finora

- TPM and The Extended Supply Chain: Tetra Pak Production D.O.O. Gornji Milanovac, Serbia London, Nov 2016Documento36 pagineTPM and The Extended Supply Chain: Tetra Pak Production D.O.O. Gornji Milanovac, Serbia London, Nov 2016Hossam Abdel AzizNessuna valutazione finora

- Pillar: Initial Control or Development ManagementDocumento7 paginePillar: Initial Control or Development ManagementNavneet SharmaNessuna valutazione finora

- TPM IntroductionDocumento61 pagineTPM IntroductionDhriti GoswamiNessuna valutazione finora

- Early Equipment Management WorkshopDocumento4 pagineEarly Equipment Management WorkshopSanjay XavierNessuna valutazione finora

- A Method For TPT ReductionDocumento114 pagineA Method For TPT ReductionEbrahim HanashNessuna valutazione finora

- b2 1 AndoDocumento60 pagineb2 1 AndoSudhagarNessuna valutazione finora

- Capacitor MKPDocumento29 pagineCapacitor MKPMartina KNessuna valutazione finora

- AM - Step 1Documento17 pagineAM - Step 1Sydney DodooNessuna valutazione finora

- Chapter 10. Initial Flow Control ManualDocumento10 pagineChapter 10. Initial Flow Control ManualVivek KumarNessuna valutazione finora

- Jidoka: The Toyota Principle of Building Quality into the ProcessDa EverandJidoka: The Toyota Principle of Building Quality into the ProcessValutazione: 4 su 5 stelle4/5 (2)

- Slide TPM SHEDocumento14 pagineSlide TPM SHEhdjdjNessuna valutazione finora

- OA Final Pulau Sambu Guntung 120605Documento53 pagineOA Final Pulau Sambu Guntung 120605GastongCannavaroNessuna valutazione finora

- PM 1 - 20140801Documento73 paginePM 1 - 20140801arielejosi100% (1)

- Six Sigma - Reduction of Downtime - RE Mill-2 - NewDocumento76 pagineSix Sigma - Reduction of Downtime - RE Mill-2 - NewKiruthiga VelmuruganNessuna valutazione finora

- Autonomous Maintenance (Jishu Hozen)Documento30 pagineAutonomous Maintenance (Jishu Hozen)Vitra PunKgribNessuna valutazione finora

- An Introduction To Total Productive Maintenance (TPM)Documento10 pagineAn Introduction To Total Productive Maintenance (TPM)Ravi AgarwalNessuna valutazione finora

- #Powerof: Availability Centered MaintenanceDocumento14 pagine#Powerof: Availability Centered Maintenance1977julNessuna valutazione finora

- Avinash MechwellDocumento33 pagineAvinash Mechwell1977julNessuna valutazione finora

- Welcome: Advanced Bulk Material Conveying Technologies in Cement IndustryDocumento15 pagineWelcome: Advanced Bulk Material Conveying Technologies in Cement Industry1977julNessuna valutazione finora

- Modefied Cooler2Documento71 pagineModefied Cooler21977jul100% (2)

- PowderDocumento10 paginePowder1977julNessuna valutazione finora

- Chapter 3.7 Cooling TowerDocumento17 pagineChapter 3.7 Cooling TowerDeep DasNessuna valutazione finora

- Loads Adjustable Speed Drives: Starting Inertia ONDocumento6 pagineLoads Adjustable Speed Drives: Starting Inertia ON1977julNessuna valutazione finora

- Maag LGD Lateral Gear Drive For Horizontal MillsDocumento8 pagineMaag LGD Lateral Gear Drive For Horizontal Mills1977julNessuna valutazione finora

- Aspects of Raw Material HomogenizationDocumento25 pagineAspects of Raw Material Homogenization1977julNessuna valutazione finora

- Feeder TypesDocumento54 pagineFeeder Types1977julNessuna valutazione finora

- KPB Transmission Gear Units: For The Bucket Wheel Drive in ExcavatorsDocumento2 pagineKPB Transmission Gear Units: For The Bucket Wheel Drive in Excavators1977julNessuna valutazione finora

- Robuschi BlowersDocumento23 pagineRobuschi Blowers1977jul100% (1)

- VSM TemplateDocumento13 pagineVSM TemplatesigmasundarNessuna valutazione finora

- Chap1:Kaizen Basic EducationDocumento48 pagineChap1:Kaizen Basic Education1977jul100% (2)

- Concept of Production Efficiency: Basic Education of TPMDocumento20 pagineConcept of Production Efficiency: Basic Education of TPM1977julNessuna valutazione finora

- TPM Conference - JIPM - NakanoDocumento38 pagineTPM Conference - JIPM - Nakano1977jul50% (2)

- Simplified Modeling of Clinker Cooling Based On Long Term Industrial DataDocumento5 pagineSimplified Modeling of Clinker Cooling Based On Long Term Industrial Data1977julNessuna valutazione finora

- Instruction Manual 115cx ENGLISHDocumento72 pagineInstruction Manual 115cx ENGLISHRomanPiscraftMosqueteerNessuna valutazione finora

- BKNC3 - Activity 1 - Review ExamDocumento3 pagineBKNC3 - Activity 1 - Review ExamDhel Cahilig0% (1)

- Course DescriptionDocumento54 pagineCourse DescriptionMesafint lisanuNessuna valutazione finora

- Topic 1 - ICT Tools at USP - Theoretical Notes With Google AppsDocumento18 pagineTopic 1 - ICT Tools at USP - Theoretical Notes With Google AppsAvantika PrasadNessuna valutazione finora

- Report-Smaw Group 12,13,14Documento115 pagineReport-Smaw Group 12,13,14Yingying MimayNessuna valutazione finora

- EDB Postgres Failover Manager Guide v2.1Documento86 pagineEDB Postgres Failover Manager Guide v2.1Anggia MauritianaNessuna valutazione finora

- Jones Et - Al.1994Documento6 pagineJones Et - Al.1994Sukanya MajumderNessuna valutazione finora

- Barista Skills Foundation Curriculum enDocumento4 pagineBarista Skills Foundation Curriculum enCezara CarteșNessuna valutazione finora

- A2 UNIT 5 Culture Teacher's NotesDocumento1 paginaA2 UNIT 5 Culture Teacher's NotesCarolinaNessuna valutazione finora

- B0187 B0187M-16Documento9 pagineB0187 B0187M-16Bryan Mesala Rhodas GarciaNessuna valutazione finora

- ProjectDocumento33 pagineProjectPiyush PatelNessuna valutazione finora

- STARCHETYPE REPORT ReLOADED AUGURDocumento5 pagineSTARCHETYPE REPORT ReLOADED AUGURBrittany-faye OyewumiNessuna valutazione finora

- 1 Prof Chauvins Instructions For Bingham CH 4Documento35 pagine1 Prof Chauvins Instructions For Bingham CH 4Danielle Baldwin100% (2)

- DN12278 - 5008 - Indicative Cable Way Route - Rev BDocumento9 pagineDN12278 - 5008 - Indicative Cable Way Route - Rev BArtjoms LusenkoNessuna valutazione finora

- MiddleWare Technology - Lab Manual JWFILESDocumento171 pagineMiddleWare Technology - Lab Manual JWFILESSangeetha BajanthriNessuna valutazione finora

- Operational Readiness and Airport TransferDocumento2 pagineOperational Readiness and Airport TransferochweriNessuna valutazione finora

- Caso Estudio: Reliability Analysis of Power Distribution System. A Case StudyDocumento6 pagineCaso Estudio: Reliability Analysis of Power Distribution System. A Case StudyCarlos HernandezNessuna valutazione finora

- Arithmetic-Progressions - MDDocumento8 pagineArithmetic-Progressions - MDJay Jay GwizaNessuna valutazione finora

- What Is A Fired Heater in A RefineryDocumento53 pagineWhat Is A Fired Heater in A RefineryCelestine OzokechiNessuna valutazione finora

- Evolis SDK Use Latest IomemDocumento10 pagineEvolis SDK Use Latest IomempatrickNessuna valutazione finora

- Catalogue of Archaeological Finds FromDocumento67 pagineCatalogue of Archaeological Finds FromAdrinaNessuna valutazione finora

- Chestionar 2Documento5 pagineChestionar 2Alex AndruNessuna valutazione finora

- Sample Interview Questions For Planning EngineersDocumento16 pagineSample Interview Questions For Planning EngineersPooja PawarNessuna valutazione finora

- Universal and Commercial Banks in The PhilippinesDocumento1 paginaUniversal and Commercial Banks in The Philippinesjohngo888Nessuna valutazione finora

- LYNX 40 Drilling Mud DecanterDocumento2 pagineLYNX 40 Drilling Mud DecanterPierluigi Ciampiconi0% (1)

- Uh 60 ManualDocumento241 pagineUh 60 ManualAnonymous ddjwf1dqpNessuna valutazione finora

- Physico-Chemical Properties of Nutmeg (Myristica Fragrans Houtt) of North Sulawesi NutmegDocumento9 paginePhysico-Chemical Properties of Nutmeg (Myristica Fragrans Houtt) of North Sulawesi NutmegZyuha AiniiNessuna valutazione finora

- Durability of Prestressed Concrete StructuresDocumento12 pagineDurability of Prestressed Concrete StructuresMadura JobsNessuna valutazione finora

- Nature of Science-Worksheet - The Amoeba Sisters HWDocumento2 pagineNature of Science-Worksheet - The Amoeba Sisters HWTiara Daniel25% (4)

- Advanced Physiotherapeutic SyllabusDocumento1 paginaAdvanced Physiotherapeutic SyllabusAnup SharmaNessuna valutazione finora