Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

213-42424 Seaborne Ethane PDF

Caricato da

niksvaporisDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

213-42424 Seaborne Ethane PDF

Caricato da

niksvaporisCopyright:

Formati disponibili

Working together

for a safer world

Seaborne ethane

A report into the commercial need and technical

requirements for very large ethane carriers

Introduction 2

Part A: Overview of the ethane market 3

1 Ethane what it is and how it is used 3

2 US ethane production 5

2.1 The shale gas boom 5

2.2 The rise and fall of ethane production 5

2.3 Balancing the US ethane market 6

3 US domestic demand for ethane 8

4 Potential overseas markets for US ethane 10

4.1 Europe 10

4.2 Asia 11

5 Securing ethane supply for export

upstream and downstream risks 13

5.1 Infrastructure 13

5.2 Price dynamics 13

5.3 Timing 13

6 Conclusions on the ethane market 14

Part B: Very large ethane carriers

the technical challenges 15

7 The VLEC concept 15

8 Containment systems 16

8.1 Membrane systems 17

8.2 Independent tanks 18

9 The cargo handling system 22

9.1 Cargo pumps 22

9.2 The reliquefaction plant 22

9.3 The inert gas (nitrogen) system 22

9.4 The inert gas (CO

2

) system 22

10 Main propulsion systems ethane as fuel 23

11 The class notation for a VLEC 24

12 Conclusions on the VLEC concept 25

Contents

Seaborne ethane

1

Seaborne ethane

Introduction

Ethane is produced on an industrial scale from natural gas, and as a by-product

of petroleum rening. Global ethane production was estimated at 2.6 million

tonnes (MnT) in 2013, the overwhelming majority in the Middle East and US.

Regional production depends in part on the composition of the natural gas

stream.

The primary use of ethane is in the chemical industry in the production of ethylene, which in

turn is used to produce polyethylene, PVC, ethylene glycol and styrene.

Historically, ethane has been transported in small liqueed ethane/ethylene carriers (LECs)

designed and constructed to carry ethylene (boiling point -104C) as well as ethane and other

normal LPG cargoes. All these vessels have type C containment systems (in effect, pressure

vessels) which limit the size of tanks that can be used. Currently there are only 29 LECs larger

than 10,000m

3

, with the largest having a capacity of 22,000m

3

. It is estimated that the

maximum feasible size of a ships with type C cargo tanks is around 40,000m

3

.

The shale gas boom in the US is likely to result in an oversupply of ethane in the short to

medium term, which presents the opportunity for large scale exports to Europe and/or Asia.

Part A of this report looks more closely at the factors that will inuence the future demand

for transporting ethane cargoes from the US.

Assuming that this demand will require ships with capacities greater than 40,000m

3

means

these ships will be too large for the containment systems that have been used to date. Part B

considers what they might look like.

Our thanks go to Maritime Strategies International Ltd (MSI), a London-based shipping

economics consultancy rm, who helped us carry out the market analysis.

2 www.lr.org/ethane

Seaborne ethane

Ethane is a chemical compound with chemical formula C

2

H

6

. At standard temperature and pressure, ethane is a colourless,

odourless gas.

It is an alkane (single-bond hydrocarbon), second in the series with two carbon atoms, after methane and before propane

and butane.

Ethane is produced on an industrial scale from natural gas, and as a by-product of petroleum rening.

Ethane is typically transported in gaseous form by pipeline, but can be liqueed by cooling to minus 89C at atmospheric

pressure.

The primary use of ethane is in the chemical industry in the production of ethylene by steam cracking; alternative

feedstocks are naphtha and liqueed petroleum gases (propane and butane).

Ethylene is arguably the most important organic chemical. It is converted to polyethylene; to PVC (via ethylene dichloride

and vinyl chloride monomer); to ethylene glycol (via ethylene oxide); and styrene (via ethyl benzene).

Ethane can also be used as a refrigerant in cryogenic refrigeration systems.

Global ethane production was estimated at 2.6 million tonnes (MnT) in 2013, the overwhelming majority in the Middle East

and US. Regional production depends in part on the composition of the natural gas stream.

1. Ethane what is it and how is it used?

Figure 1: Ethylene and its derivatives

P

a

r

t

A

:

A

n

o

v

e

r

v

i

e

w

o

f

t

h

e

e

t

h

a

n

e

m

a

r

k

e

t

Polyethylene

Ethanol

Ethylene oxide

Vinyl acetate

Ethylene glycol

Glycol ethers

Engine coolant

Polyesters

Ethoxylates

1,2 -Dichlor oethane

Tetrachlor oethylene

Trichlor oethylene

Vinyl chloride Vinyl chloride

E

t

h

y

l

e

n

e

3

Seaborne ethane

Figure 2: Visualisation of an ethane molecule

4 www.lr.org/ethane

Seaborne ethane

2.1 The shale gas boom

The rise in US shale gas and oil output has been one of the most signicant developments in the oil and gas sector in the

last decade, transforming the global landscape in terms of production economics and trade.

Shale gas includes methane and higher hydrocarbons collectively known as natural gas liquids (or NGLs). The US Energy

Information Administration (EIA), a widely recognised source of data on US energy production, denes NGLs as pentanes

and LPG (ethane, propane and butane). The dramatic increase in shale gas and NGL output since 2009, including ethane

and LPG, and based on EIA data, is shown in Figure 3.

According to the American Chemistry Council, Growth in domestic shale gas production is helping to reduce US natural gas

prices and create a more stable supply of natural gas for fuel and power. In addition, it is also leading to more affordable

supplies of ethane....

1

0

150

300

450

600

750

900

1,050

30

40

50

60

70

80

90

100

J

a

n

-

2

0

0

0

J

u

l

-

2

0

0

0

J

a

n

-

2

0

0

1

J

u

l

-

2

0

0

1

J

a

n

-

2

0

0

2

J

u

l

-

2

0

0

2

J

a

n

-

2

0

0

3

J

u

l

-

2

0

0

3

J

a

n

-

2

0

0

4

J

u

l

-

2

0

0

4

J

a

n

-

2

0

0

5

J

u

l

-

2

0

0

5

J

a

n

-

2

0

0

6

J

u

l

-

2

0

0

6

J

a

n

-

2

0

0

7

J

u

l

-

2

0

0

7

J

a

n

-

2

0

0

8

J

u

l

-

2

0

0

8

J

a

n

-

2

0

0

9

J

u

l

-

2

0

0

9

J

a

n

-

2

0

1

0

J

u

l

-

2

0

1

0

J

a

n

-

2

0

1

1

J

u

l

-

2

0

1

1

J

a

n

-

2

0

1

2

J

u

l

-

2

0

1

2

J

a

n

-

2

0

1

3

J

u

l

-

2

0

1

3

Billion cu ft/Month

Mn Barrels

NGL of which LPG (inc ethane) Shale Gas (RH Axis)

2.2 The rise and fall of ethane production

The composition of the NGLs extracted varies over time, depending on the characteristics of the elds contributing to

overall production. From 2009, ethane output growth initially outstripped propane and butane, but latterly production has

stalled. Ethanes share of NGL output fell sharply in 2012 and 2013.

The recent volatility in ethane output reects a ceiling to demand rather than limited reserves. Difculties in storing ethane

have created a glut, resulting in a use it or lose it situation. Currently, 200,000 barrels per day are being rejected that

is, left in the natural gas stream. This trend is illustrated in Figure 4. Rejected ethane represents a potential surplus to drive

increased domestic demand or exports. When domestic demand is insufcient there currently is no mechanism to export the

surplus to balance the market.

2. US ethane production

Figure 3: NGL and shale gas output, 2000 to 2013

1 Shale Gas, Competitiveness, and New U.S. Chemical Industry Investment An Analysis of Announced Projects, American Chemistry Council, May 2013

5

Seaborne ethane

Ethane has historically accounted for more than 40% of the raw unfractionated NGL mix. The recent fall in output of

ethane production in 2013, therefore, represents a decoupling from NGL output.

2.3 Balancing the US ethane market

The difculties in matching supply and demand within the US are also a function of the geographical mismatch between centres

of production and consumption, and limits on the amount of ethane that can be transported in natural gas pipelines. The reason

why these pipeilne limits are placed is to prevent the gas from getting too energy rich, which can damage equipment.

The potential to maximise use of US ethane has been enhanced by investment in pipeline capacity that allows better balancing

of internal supply and demand. There are two major examples. First, Sunocos Mariner West and East pipelines will take

ethane from the Marcellus Shale north to Canada or east to Marcus Hook, Pennsylvania and key north eastern markets. The

Mariner West project runs from Houston, Pennsylvania, to Sarnia, Canada, a major petrochemical area. The pipeline will ramp

up to 50,000 barrels per day in the rst quarter of 2014.

Mariner East is scheduled to be fully operational delivering propane and ethane to Marcus Hook in the rst half of 2015.

Sunocos investment will enable it to process, store, chill, and distribute propane and ethane to local, regional and

international markets.

2

This will include a terminal to export ethane to Europe. Original report by MSI

A second key pipeline is ATEX, being developed by Enterprise Products Partners (EPP). ATEX will have an initial capacity of

125,000 barrels per day, terminating at EPPs complex at Mont Belvieu in Texas, which has NGL and petroleum liquid storage,

and can fractionate NGLs to LPG and ethane. ATEX will reputedly link Marcellus-derived ethane to every existing ethylene

production facility in the US and ensure security of supply to support construction of new crackers on the Gulf Coast.

20%

25%

30%

35%

40%

45%

50%

40

60

80

100

120

140

160

J

a

n

-

2

0

0

0

J

u

l

-

2

0

0

0

J

a

n

-

2

0

0

1

J

u

l

-

2

0

0

1

J

a

n

-

2

0

0

2

J

u

l

-

2

0

0

2

J

a

n

-

2

0

0

3

J

u

l

-

2

0

0

3

J

a

n

-

2

0

0

4

J

u

l

-

2

0

0

4

J

a

n

-

2

0

0

5

J

u

l

-

2

0

0

5

J

a

n

-

2

0

0

6

J

u

l

-

2

0

0

6

J

a

n

-

2

0

0

7

J

u

l

-

2

0

0

7

J

a

n

-

2

0

0

8

J

u

l

-

2

0

0

8

J

a

n

-

2

0

0

9

J

u

l

-

2

0

0

9

J

a

n

-

2

0

1

0

J

u

l

-

2

0

1

0

J

a

n

-

2

0

1

1

J

u

l

-

2

0

1

1

J

a

n

-

2

0

1

2

J

u

l

-

2

0

1

2

J

u

l

-

2

0

1

3

J

a

n

-

2

0

1

3

Index Jan 2000 = 100

NGLs Ethane Propane Butanes Ethane Share of NGL (RH Axis)

Figure 4: NGL output and ethane share of NGL, 2000 to 2013

2 http://www.sunocologistics.com/Customers/Business-Lines/Natural-Gas-Liquids-NGLs/NGL-Projects/208/

6 www.lr.org/ethane

Seaborne ethane

EPPs distribution system also supplies its LPG export terminal in Houston where a second export terminal is under development.

These terminals are currently being developed for LPG exports but EPP has signalled a desire to export ethane from the area.

Infrastructure drives production.

These developments set the framework for enhanced use of ethane. It is assumed that the improved distribution network

within the US and export infrastructure will allow the normal relationship between NGL and ethane production to be re-

established by increasing outlets for ethane. As a result, production should rise as shown by the dotted line in Figure 5, in

tandem with further expansion in shale gas and NGL production.

This forecast for ethane production is based on the assumption that ethane output is maximised (at 43% of the NGLs mix).

Applying this assumption to forecasts for NGL production supplied by the EIA (2013) implies that additional supply would

be 0.4 Mn barrels per day (approximately 8.5 MnT) by 2020, compared with 2012 production.

Some forecasters have suggested NGL output could reach 3.1 Mn barrels per day as early as 2016, which they suggest

implies an ethane output increase of as much as 0.6 million barrels per day (13 MnT). Under this scenario, US NGL

production will easily exceed domestic demand.

US ethane data is typically reported in barrels but to assess shipping demand it is helpful to translate it into tonnes.

0.0

0.3

0.6

0.9

1.2

1.5

1.8

2.1

2.4

2.7

3.0

3.3

2

0

0

5

2

0

0

6

2

0

0

7

2

0

0

8

2

0

0

9

2

0

1

0

2

0

1

1

2

0

1

2

2

0

1

3

2

0

1

4

2

0

1

5

2

0

1

6

2

0

1

7

2

0

1

8

2

0

1

9

2

0

2

0

Mn Barrels/Day

NGL Production History

NGL Forecast (EIA Annual Energy Outlook 2013)

Ethane production (RH Axis)

Figure 5: NGL and ethane production over the period to 2020

7

Seaborne ethane

3. US domestic demand for ethane

Ethane competes with LPG and naphtha as a feedstock for the chemical industry. Ethane is generally cheaper, but

cracking crude oil-based feedstocks such as naphtha yields co-products including propylene, butylenes and butadiene,

plus the aromatic products benzene, toluene and xylenes. The latter are valuable in their own right and provide a strong

contribution to net income from the process. Accordingly, the relative economics of alternative feedstocks are complex and

uid, depending on the input costs and realised value of the outputs.

Despite this, the overwhelming cost advantage of ethane in recent years has meant US consumption has increased in

the last ve years, according to data from the International Energy Agency (IEA) shown in Figure 6. This shows total

petrochemical industry inputs rather than just ethylene production. The use of ethane has risen from a low of around 15

MnT in 2008 to nearly 20 MnT in 2012.

0

10

20

30

40

50

60

70

80

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012

MnT

LPG

Naphtha

Ethane

The impact of the rise in cheap ethane supplies has barely begun to be felt, however. Industry leaders believe this change in

feedstock economics signals a golden age for US petrochemicals. A huge investment in ethylene capacity is now underway

in the US that will bear fruit in 2017 and 2018. Other chemical capacity to exploit increased supplies of methane is also

planned, which will include methanol and ammonia. Increased production of a myriad of downstream products is also

planned.

The multiplicity of announced ethylene projects suggests a huge demand for ethane in the coming years, with at least one-

third added to existing capacity, notwithstanding that many projects on the drawing board will not be built.

The indicative forecasts of Maritime Strategies International (MSI) for ethylene capacity and ethane consumption are shown

in Figure 7. It should be noted that a number of US crackers will remain that will continue to use feedstocks other than

ethane. However, it is assumed that all new US ethylene capacity uses this feedstock.

Figure 6: LPG, naphtha and ethane historical consumption in the US, 2000 to 2012

8 www.lr.org/ethane

Seaborne ethane

Our forecast translates into an additional requirement for 13 MnT of ethane by 2018, assuming constant operating rates

and a standard assumption that 1.3 tonnes of ethane is needed to produce 1 tonne of ethylene.

0

10

20

30

40

50

60

2

0

0

0

2

0

0

1

2

0

0

2

2

0

0

3

2

0

0

4

2

0

0

5

2

0

0

6

2

0

0

7

2

0

0

8

2

0

0

9

2

0

1

0

2

0

1

1

2

0

1

2

2

0

1

3

2

0

1

4

2

0

1

5

2

0

1

6

2

0

1

7

2

0

1

8

MnT

Ethylene Capacity Ethane Consumption

Figure 7: Ethylene capacity and ethane consumption over the period to 2018

9

Seaborne ethane

There are wide geographical differences in the use of different feedstocks for ethylene production, as Figure 8 shows, based

on data from the Oil and Gas Journal. Outside the Middle East and North America, ethane use as an ethylene feedstock is

currently limited.

The Middle East has traditionally been the region most reliant on ethane feedstock. There are issues with gas supply in the

region and the next generation of crackers will be oriented towards heavier feedstocks. Despite this, the Middle East is not

considered as a potential outlet for US production.

0

5

10

15

20

25

30

35

40

China Middle East N. America W. Europe North East

Asia

South Asia South East

Asia

MnT

Other

Naphtha (Gas Oil/Kerosene)

LPG/NGL

Ethane

4.1 Europe

Though the remaining ethane consuming markets are tiny in comparison, Europe is the largest and most geographically

advantaged with respect to US ethane. The high-cost European petrochemical industry is generally under pressure from

global competition. IEA data shows a decline in overall chemical industry feedstock consumption in European OECD

countries in recent years, with naphtha the hardest hit. Consumption of LPG has been volatile, while ethane use has

marginally declined and in 2011 totalled 1.7 MnT. Falling North Sea supplies and rising costs are putting existing ethane-

based capacity under threat.

Europe is currently the only conrmed market for US ethane exports, in the process establishing the rst seaborne

international trade in the commodity. In late 2012, INEOS Europe AG announced an agreement with Sunoco to supply

ethane to its Rafnes plant in Norway via the Mariner East pipeline and the terminal system at Marcus Hook in Pennsylvania.

4. Potential overseas markets for US ethane

Figure 8: Geographical differences in the use of different feedstocks for ethylene production

10 www.lr.org/ethane

Seaborne ethane

The Rafnes cracker already has its own import dock which is fed by ethane from within Norway. However, a new storage

tank will be built to facilitate the imports. At the same, a contract has been signed with Evergas for newbuilding shipping

capacity, which is currently under construction in Korea.

The agreement with Sunoco was supplemented in early 2014 by a further deal with Consol Energy, also for the supply

of ethane via the Mariner East infrastructure. Ethane will also now be supplied to INEOS other crackers in Europe, with

engineering assessments being made for the construction of an ethane terminal at Grangemouth in Scotland.

US ethane will have a lower delivered cost than North Sea supplies despite the need for liquefaction and seaborne

transportation. According to INEOS, production costs could be reduced by as much as 40% at Rafnes and by half at

Grangemouth.

The potential European market is, however, fundamentally constrained. INEOS has suggested that realistic candidates for

importing ethane are limited, including Versalis plant, at Dunkirk, and the Wilton plant at Teeside in the UK, which is

owned by Saudi Arabian group Sabic. European naphtha crackers could be converted to take ethane imports, but the cost

could be several hundred million dollars, while access to an import terminal is also a key requirement, limiting the number

of likely candidates.

Assuming that all existing capacity is converted and no naphtha crackers are converted would imply an upper limit to

European imports of 2 MnT per year. Enterprise has been reported to consider the potential European market to be as

great as 415,000 barrels per day of ethane (8 MnT).

4.2 Asia

There is currently no market for ethane in Asian OECD countries because of a lack of domestic supply (due to limited local

oil and gas production). Japan and Korea dominate production among this group. Koreas reliance on naphtha as an input

into its chemical industry is the highest in the world. Increasing volumes of naphtha have been required to feed rising

chemical output, with small dislocations in 2004 and 2008. Japanese feedstock consumption fell in 2011 and remained

below the levels of the middle of the last decade. The role of naphtha and LPG has been under pressure. There is little

likelihood of investment in ethane-based capacity in these countries.

The potential market for US ethane lies beyond these countries in emerging markets. Net additions to global ethylene

capacity over the period to 2018 are shown in Figure 9. The US will lead the expansion, while, as already noted, the Middle

East will also increase but is not seen as a potential market for US ethane.

Capacity will increase substantially in non-OECD Asian countries. The majority of this will be situated in China, while there is

also investment underway in India and South East Asia.

The Asian market for ethane will depend on the conguration of this new ethylene capacity and the economics of ethane

versus naphtha and LPG. Chemical companies in China and India are reportedly considering imported ethane as a feedstock.

Decisions made by those producers in the near future will determine the viability of the very large ethane carrier (VLEC)

concept, as competition hots up for US production.

11

Seaborne ethane

-4

-2

0

2

4

6

8

10

12

14

North

America

Latin

America

W Europe E Europe Africa Middle East North East

Asia

South East

Asia

MnT

2007-2012 2012-2017

Figure 9: Net additions to global ethylene capacity over the period to 2018

12 www.lr.org/ethane

Seaborne ethane

The prospects for US ethane exports reect three key factors: infrastructure, price dynamics and timing. The domestic

ethane market is expected to remain in surplus until the latter years of the decade when the addition of several world

scale ethylene plants drive up demand.

5.1 Infrastructure

As noted already, Sunocos Marcus Hook terminal, which will be supplied by the Mariner East pipeline, is scheduled to start

shipping ethane to Europe in 2015.

Enterprise, a company that has invested heavily to take advantage of the surge in US LPG exports in recent years, is also

considering exporting ethane, adding the second such terminal to shift US ethane overseas, in Houston.

Exports beyond Europe to Asia would require additional investment. LPG export terminals will be capable of receiving very

large gas carriers (VLGCs) of around 80,0000 cubic metres (CuM) for the export of propane and it is assumed that these

terminals could be adapted to handle VLECs to ship ethane.

5.2 Price dynamics

The surplus in US ethane will ensure that prices remain depressed over the coming years. This cheap gas will provide a major

cost advantage to those who are able to access it and use it to produce ethylene. This implies heightened competition for

these supplies when the capability to secure or consume them is realised. Accordingly, longer term, this price advantage

will depend on the relative growth in demand for ethane and the ability of US gas producers to sustain or extend shale gas

output.

5.3 Timing

The paradox of the US ethane glut is that it is preceding the demand that will make best use of it. Domestic downstream

capacity is currently constrained and, although huge investment in new ethylene plants is underway, it will not come on

stream before the latter years of the decade.

Export infrastructure is planned to come on stream from next year, securing prime mover advantage for those who have

access to it. It is easier to develop terminal capacity than downstream petrochemical plant so there remains a window

of opportunity for overseas consumers to obtain long-term ethane supplies today before US demand surges as 2020

approaches.

5. Securing ethane supply for export

upstream and downstream risks

13

Seaborne ethane

6. Conclusions on the ethane market

US ethane production capability is under-used, with approximately 0.2 Mn barrels per day (or 4 MnT per year) rejected in

2013. This under-used capacity to produce ethane will grow in the short term as potential production will rise faster than

near-term domestic US (or regional North American pipeline) demand.

The surplus could rise to as much as 6 MnT per year in 2015 and perhaps 12 MnT by 2020.

However, given the competition for US ethane from new ethylene crackers in the latter years of the decade, it is not clear

that such volumes will be available post 2017. Conrmed new US ethylene capacity will consume at least 7 MnT of ethane.

If all potential new ethylene capacity is used, this gure could account for the entire potential incremental output of US

ethane.

Annual shipments of 1 MnT of ethane could provide employment for 0.18 Mn CuM of shipping capacity, assuming it is

shipped to North Europe, 0.32 Mn CuM if shipped to South Asia and a similar amount to China if the Panama Canal is used.

Newbuilding orders targeted at the ethane trades include those from Evergas (27,500 CuM) and Navigator (35,000 CuM).

These vessels are multi-use, being capable of transporting LNG and ethylene respectively.

Further ethane-capable newbuilding orders would need to be backed by long-term trade agreements. The window of

opportunity to tie up ethane exports and secure tonnage to serve this trade is now open to feed potential markets in

Europe and Asia.

14 www.lr.org/ethane

Seaborne ethane

The International Code for the Construction and Equipment of Ships Carrying Liqueed Gases in Bulk (the IGC Code)

requires that ethane as cargo is carried on at least a type 2G ship, with ammable vapour detection and remote gauging.

Ethane has no other specic features than its ammability and low boiling point (-90C).

Historically, ethane has been transported in small liqueed ethane/ethylene carriers (LECs) designed and constructed

to carry ethylene (boiling point -104C) as well as ethane and other normal LPG cargoes. All these vessels have type

C containment systems and it is estimated that the maximum feasible size of a ship with type C cargo tanks is around

40,000m

3

.

So what would a VLEC (an ethane carrier with a capacity of around 80,000m

3

) look like, given that type C containment

systems are not feasible for this size of ship?

P

a

r

t

B

:

V

L

E

C

s

t

h

e

t

e

c

h

n

i

c

a

l

c

h

a

l

l

e

n

g

e

s

7. The VLEC concept

Figure 10: How a VLEC might look

15

Seaborne ethane

There are two kinds of cargo containment system that could be used for large ethane carriers: membrane systems and

independent tanks (type A, type B and type C). The containment system is a critical aspect of the design and will

signicantly affect both the cargoes that can be carried and the return on investment that the ships are able to achieve.

Table 1 summarises the approval status of a number of different containment systems.

The only solutions that could realistically be used in a VLEC built in the next few years would be a membrane system

suitably adapted for the carriage of ethane, or a type B, SPB design.

Further information on these different systems is outlined in the next section.

8. Containment systems

Containment system Approval methodology Status

Membrane, GTT NO96

Membrane, GT MarkIII

In principle and general or

for particular ship application

Approval in principle (AiP) and general approval

for LNG;

Approval in principle for multi-gas application

(including ethane) by LR in March 2014;

Requirements for general or particular ship

application approval considering GTTs past

experience in fully refrigerated liquid gases (LPG,

etc.) was agreed with GTT and LR in March 2014.

Type A Tank-specic Not considered suitable for cargo below -55C

due to additional double hull need to act as

secondary barrier

Type A, aluminium double

barrier tank (ADBT)

In principle and general Approval in principle for LNG cargo; further

analysis required to obtain general approval

Type B, Moss Tank-specic Widely used in ships carrying LNG;

not currently used for other cargoes

Type B, SPB Tank-specic Limited in-service use carrying LNG;

not currently used for other cargoes

Design under development for its use to

carry ethane

Type B, DSME ACTIB In principle and general Approval in principle for LNG cargo;

further analysis required to obtain general approval

Type C only Tank-specic Currently used in ships carrying ethane;

max capacity ~ 40,000m

3

Table 1: Different containment systems and their approval status

16 www.lr.org/ethane

Seaborne ethane

8.1 Membrane systems

With a membrane system, the ethane will be transported at atmospheric pressure and at a temperature of -90C. Liqueed

ethane is denser than LNG, and hence LNG containment systems such as NO96 or Mark III designs, which have typically

been designed using a cargo density of 0.500 tonnes per cubic metre, would have to be assessed for their suitability to carry

heavier cargoes.

In the framework of approval in principle (AiP) studies, the suitability of GTT systems for multi-gas application has been

demonstrated. The methodology to assess GTTs containment systems under these different constraints (compared to LNG)

has been agreed. First evaluations with multi-gas loadings have been performed while Mark III, Mark III Flex, NO96 and

NO96-L03 systems have been considered.

As usual, dedicated studies will be carried out for ship application (sloshing assessment for instance) taking into account

project input data.

On their own, the increased hydrostatic loads are unlikely to result in stresses in excess of the allowable limits. However

application of dynamic loads due to sloshing may result in exceedences which would result in upgraded reinforcements of

the containment system compared to LNG transport. The sloshing loads will depend on the size, shape and location of the

cargo tanks, the properties of the cargo, and ship motions. The cargo capacity of a VLEC ship (~80,000m

3

) is smaller than a

conventional LNG carrier (135 155,000m

3

) and the size of individual cargo tanks are smaller. The following are some of the

factors affecting magnitude and distribution of the dynamic loading in relation to a conventional LNG carrier:

Smaller tanks will tend to reduce sloshing pressures whereas smaller lower hopper knuckles may partially counter-balance

this benecial effect according to liquid heel.

Ship motions of smaller ships are higher than conventional LNG carrier size, especially for the forward cargo tank. The

consequence on sloshing pressures will depend on the vessel natural periods.

Ship loading cases will be inuenced by the type of gas carried. Heavier gas will lead to more favourable loading case and

more favourable ship motions due to greater draft in case of multigas carrier design.

Increased cargo density will result in higher sloshing pressures.

Figure 11: Mark III (left) and NO96 (right) containment systems

Cargo Density (t/m

3

) Ratio relative to density of LNG

LNG 0.412 1.00

Ethane 0.543 1.09

Ethylene 0.567 1.14

Table 2: Comparison of densities of LNG, ethane and ethylene

17

Seaborne ethane

A detailed sloshing analysis is required to predict the combined effect of these factors, and hence determine the adequate

CCS reinforcement conguration and the authorised lling levels.

It is anticipated that VLECs with membrane containment systems would be designed with either three or four cargo tanks.

The three-tank design would have a wide beam, with two tanks with a capacity of 30,000m

3

and one tank with a capcity of

20,000m

3

. The four-tank design would have similar dimensions to an 80,000m

3

LPG design, with three tanks with a capacity

of 22,0000m

3

and one tank with a capacity of 14,000m

3

.

30 30 20

14 22 22 22

8.2 Independent tanks

The IGC Code includes three types of independent tanks: type A, type B and type C.

In type A and B tanks, the ethane will be transported at atmospheric pressure and at a temperature of -88C or below. In

type C tanks, the ethane is carried under pressure at a temperature below its critical temperature (+32C).

Type A tanks

Type A tanks are designed using conventional structural design standards and it is assumed that a failure of the primary

barrier will result in the entire tank contents being spilled. For LPG (cargo temperature -50C) the inner hull constructed of

conventional steels can act as the secondary barrier. However, for liqueed ethane, conventional steels cannot be used as

the cargo temperature is below -55C; instead, 3.5% nickel steel or other suitable steels would have to be used. In addition,

the inner hull acting as secondary barrier also has to prevent lowering of the temperature of the ship structure to an

unsafe level in case of leakage of the primary barrier (IGC Code, Chapter 4 7.4), which will require additional insulation.

These requirements would signicantly increase construction costs and hence conventional type A cargo tanks are not

considered suitable for the carriage of ethane.

However, there is one variation of type A tank which in future might be suitable for carrying liqueed ethane. The

aluminium double barrier tank (ADBT) has a double skin arrangement, which ensures that the cargo leaking from the

primary barrier would be contained by the secondary barrier independently of the inner hull. The system has only achieved

approval in principle and a more extensive and detailed review will be necessary to obtain the general approval required

before the system could be used on board a ship.

Figure 12: Possible three-tank and four-tank arrangements

18 www.lr.org/ethane

Seaborne ethane

Type B tanks

Type B tanks only require a partial secondary barrier. The capacity of the secondary barrier is calculated from the analysis of

potential failures of the primary barrier. Currently there are two type B tank systems that have been approved: Moss and

self-supporting prismatic (SPB).

A thermal analysis will be required to calculate the impact of ethane contained in the secondary barrier on the hull

structure, following an assumed failure of the primary barrier. A heating system, similar to those tted within cargo tank

cofferdams on membrane ships, may be necessary to avoid having to increase the thermal capacity of the ship hull structure

within the cargo region. Generally, type B tanks dont have any partial lling restrictions.

Moss

There are over one hundred ships in operation with Moss containment systems; all designed for LNG cargoes. An additional

approval would therefore be required to use the system for the carriage of heavier liqueed gases, such as ethane. As the

cargo tanks in a VLEC will be smaller than those used in existing LNG designs, it is expected that this approval would be

straightforward and would not require changes to the design.

SPB

There are approved designs for the construction of SPB tanks using aluminium and stainless steel; however, the in-service

experience is limited to two ships with aluminium tanks which were built by IHI Corporation in 1993.

Lloyds Register is working together with a major shipbuilder to evaluate a new SPB design using 3.5% nickel steel for the

construction of the tanks. The design of the cargo tank, including cargo tank supports and cargo tank insulation, is being

optimised for ethane. The intention is to conrm that the design complies with the applicable Lloyds Register Rules and

Regulations for Gas Carriers and the International Gas Code.

The scope of the work, which is underway, covers the aspects in Table 3, right.

Figure 13: Section of an aluminium double barrier tank (ADBT) Figure 14: Inside a Moss tank

19

Seaborne ethane

Subject area Detail design

Basic engineering

Hull structural design

Cargo tank design

Cargo tank support

Cargo tank insulation

Insulation type approval

Structural analysis

Ship motion

Heat transfer analysis

Hull structure analysis

Tank strength analysis

Detail analysis

Fatigue/Crack/Leak analysis

Cargo tank material 3.5% nickel steel test

Table 3: The scope of work for review of a new SPB design

Figure 15: Section of a self-supporting prismatic (SPB) tank

Figure 14: Inside a Moss tank

20 www.lr.org/ethane

Seaborne ethane

DSME ACTIB (aluminium cargo tank IMO type B)

This system has Lloyds Registers approval in principle for use in LNG carriers up to 214,000m

3

. The cargo tank design would

need to be scaled down for use in a VLEC, and AiP and general approval would be required for the higher density cargo.

Type C tanks

Type C tanks are pressure vessels; for ethane cargoes, these would be semi-pressurised (pressure maintained at around ve

bar) with 200 to 220mm of polyurethane insulation. A reliquefaction plant is used to manage boil off gas and maintain the

temperature of the cargo. A secondary barrier is not required, and generally these tanks have no lling restrictions.

The maximum plate thickness that can be used in the construction of type C tanks is 40 mm due to construction and

fabrication constraints. This limits the cargo carriage capacity even when using bi-lobe designs. New designs of LECs using

bi-lobe type C cargo tanks are being considered with capacities up to 40,000m

3

; designs with larger capacities may not be

practical.

Figure 16: Section of the DSME ACTIB tank (image courtesy of DSME)

21

Seaborne ethane

9.1 Cargo pumps

The cargo pumps are likely to follow standard LPG deep well practice. The discharge pumping rate (pump curve capacity)

will be specied to meet the anticipated discharge terminals requirements. All electrical equipment needs to be suitable for

ethane and any other cargoes that may be loaded.

To date, terminal size has restricted the capacity of LECs. For example, the ExxonMobil terminal in Fife was sized to load

packages of about 10,000 tonnes which predicates ships of 16,000 to 17,000m

3

.

In future, there may be purpose-built terminals to accommodate VLECs (~80,000m

3

); however, LR considers that VLECs

would also have to be designed with ship-to-ship transfer capability to allow lightering to also be undertaken.

9.2 The reliquefaction plant

It is envisaged that the reliquefaction plant would be of a similar design to that installed on the current range of LEG

carriers. The increased cargo capacity will result in increased boil off gas and hence a larger reliquefaction plant will

be required. However, the reduction in tank surface area per unit cargo will result in lower boil off per unit cargo. If a

containment system designed for LNG is used then the boil off per unit cargo would be substantially reduced due to

increased tank insulation.

The rst stage cargo gas Burckhardt (Sulzer) compressor, used in the standard design of multi-stage reliquefaction plants

tted to LEG carriers, should be designed for the lower suction temperatures associated with ethane cargoes.

9.3 The inert gas (nitrogen) system

A nitrogen generating plant and nitrogen system are required to inert the cargo tank inter-barrier space (membrane

systems) and cargo hold (independent tanks) and to facilitate the purging and inerting of the cargo piping before and after

change over cargoes.

9.4 The inert gas (CO

2

) system

In order to dry, inert and gas-free the cargo tanks, a CO

2

generating plant and CO

2

system may be used. Installing this plant

is not required by current statutory regulations but is recommended to provide better operational exibility for the vessel.

9. The cargo handling system

Figure 17: A multi-stage reliquefaction plant

Cargo tank

(liquid)

Cargo compressor

Seawater

Cargo

condenser

Refrigerant

condenser

Refrigerant

condenser

V

a

p

o

u

r

L

i

q

u

i

d

Cargo boil-off vapour is compressed

and condensed against a refrigerant

Evaporated refrigerant is compressed

and condensed against seawater

22 www.lr.org/ethane

Seaborne ethane

In relation to the development of the VLEC concept, Lloyds Register and MAN Diesel have agreed to work together and

issue an approval in principle for the ME-GI engine to use ethane as fuel.

MAN Diesel has agreed to make the necessary design modications to the methane version of the ME-GI and supply the

engines for late 2015, for an anticipated ship delivery in June 2016, and has submitted the documentation required for an

approval in principle.

Some of the changes required to accommodate the higher pressure required for ethane operation (circa 630 bar ethane

pressure with circa 66 bar seal oil pressure) include re-designed fuel valves, control block and piping along with some

material changes. However, while these are not insignicant, the conceptual engine design and the risk management

philosophy will have a very high degree of commonality with the LPG-fuelled ME-LGI engine which is already approved

by LR. LR is therefore ideally placed to advice on the underlying assumptions and experience underpinning the risk

management strategy.

As ethane is not included within the International Gas Code, Lloyds Register is also seeking the agreement of ag

administrations for the use of ethane as a fuel.

10. Main propulsion systems ethane as fuel

23

Seaborne ethane

Generally, the class notation for a VLEC with either SPB or membrane tanks would be:

100A1 Liqueed Gas Carrier, Ship Type 2G, Ethane in [independent prismatic type B tanks], [membrane tanks], minimum

temperature minus 88.8 C, maximum vapour pressure 0.275 bar, in association with a dened list of liqueed gas cargoes,

ShipRight (SDA, FDA Plus, CM, ACS (B)), LI

LMC, UMS

Lloyds RMC (LG)

Notes:

Additional class notations can be assigned at the owners request.

Minimum design temperature can be assigned below minus 88.8C,in accordance with commercial ethane cargoes, subject to

compliance with applicable LR Rules and Regulations.

The value of the maximum density or specic gravity of the dened list of liqueed gas cargoes can also be assigned within

the class notation when required by owners.

11. The class notation for a VLEC

24 www.lr.org/ethane

Seaborne ethane

The demand and timeframe for exporting ethane from the US are uncertain. However, market analysis and recent

developments have provided strong trends for a trade within a short time frame.

In the event that VLECs are required in 2016, there would not be time to develop a new containment system or to undertake

the analysis required to progress existing containment systems with approval in principle to general approval. Therefore, the

options for the containment systems of these ships would be a membrane system or an IMO type B cargo tank.

12. Conclusions on the VLEC concept

25

Leonidas Karistios

Global Gas Technology Market Manager

Lloyds Register Group Limited

Southampton, UK

T +44 (0)2380 249756

M +44 (0)7580 994380

E leonidas.karistios@lr.org

August 2014

Cover image: An ethane molecule

Lloyds Register and variants of it are trading names of Lloyds Register Group Limited, its subsidiaries and afliates.

Copyright Lloyds Register Group Limited. 2014. A member of the Lloyds Register group.

Lloyds Register Group Limited, its afliates and subsidiaries and their respective ofcers, employees or agents are, individually and collectively, referred to in this clause as

Lloyds Register. Lloyds Register assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance on the information or

advice in this document or howsoever provided, unless that person has signed a contract with the relevant Lloyds Register entity for the provision of this information or

advice and in that case any responsibility or liability is exclusively on the terms and conditions set out in that contract.

www.lr.org/ethane

For further information please contact:

Jose Navarro

Principal Specialist for Gas Technology

Lloyds Register Asia

Busan, Korea

T +82 (0)51 640 5079

M +82 (0)10 5067 5079

E jose.navarro@lr.org

Stuart Nicoll

Consultant

Maritime Strategies International Ltd

E stuart.nicoll@msiltd.com

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- GP1200 Ingles PDFDocumento253 pagineGP1200 Ingles PDFJuan Luis Romero Ramirez100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- TC227 Shot Peening WD26910-1 060901Documento13 pagineTC227 Shot Peening WD26910-1 060901Bahadır Uysal100% (1)

- Iso Iec 25020 2007 (E)Documento24 pagineIso Iec 25020 2007 (E)AngélicaNessuna valutazione finora

- VGB-S-013!00!2014-12-En - Construction and Installation Supervision in The Manufacture and Assembly of Water-Tube Boilers and Associated Systems in TheDocumento156 pagineVGB-S-013!00!2014-12-En - Construction and Installation Supervision in The Manufacture and Assembly of Water-Tube Boilers and Associated Systems in TheDimitris Nikou0% (1)

- On Virtual Doctor System For Health Monitoring FinalDocumento23 pagineOn Virtual Doctor System For Health Monitoring FinalChetu ChethanNessuna valutazione finora

- Low Filter Order Digital Equalization for Mobile Device EarphonesDocumento12 pagineLow Filter Order Digital Equalization for Mobile Device EarphonesJuan Sebastian RicoNessuna valutazione finora

- Leviton LEV 25249 SBA PDFDocumento3 pagineLeviton LEV 25249 SBA PDFCarlos TrianaNessuna valutazione finora

- AMC Perfect Validation 2019-2020Documento2 pagineAMC Perfect Validation 2019-2020Dhanasekaran VaiyapuriNessuna valutazione finora

- POST TEST GENeral MATHematics 2nd QuarterDocumento5 paginePOST TEST GENeral MATHematics 2nd QuarterRichard Kate RicohermosoNessuna valutazione finora

- Zhong Wei and Zhang YangDocumento5 pagineZhong Wei and Zhang Yangashish9dubey-16Nessuna valutazione finora

- Studio Iso Booth Console Monitors: Record Plant Ssl-1 SpecificationsDocumento1 paginaStudio Iso Booth Console Monitors: Record Plant Ssl-1 Specificationssoulboy01Nessuna valutazione finora

- GRE Configuration and Interoperability GuideDocumento63 pagineGRE Configuration and Interoperability Guidesrini bNessuna valutazione finora

- Graco Supply Systems - 338921eneuDocumento16 pagineGraco Supply Systems - 338921eneuDanaNessuna valutazione finora

- Społeczność Steam :: Poradnik :: Pathfinder: Kingmaker Cheat Guide Character:Item:kingdom EditingDocumento22 pagineSpołeczność Steam :: Poradnik :: Pathfinder: Kingmaker Cheat Guide Character:Item:kingdom EditingBeki LokaNessuna valutazione finora

- Supplemental Restraint System (SRS) : SectionDocumento60 pagineSupplemental Restraint System (SRS) : SectionSilvio ServinNessuna valutazione finora

- Different Version of Social Networking PlatformDocumento4 pagineDifferent Version of Social Networking PlatformHarshita SinghNessuna valutazione finora

- Continuous Mixing Advantages and Equipment Selection in Industrial Pharmacy LecturesDocumento16 pagineContinuous Mixing Advantages and Equipment Selection in Industrial Pharmacy Lecturesali alasdyNessuna valutazione finora

- MSP430F123Documento44 pagineMSP430F123NagyNessuna valutazione finora

- ZF NMV221 1315 - 751 - 102 - A Technical ManualDocumento6 pagineZF NMV221 1315 - 751 - 102 - A Technical ManualYoseph GetahunNessuna valutazione finora

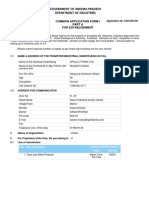

- Common Application Form I Part A For Establishment: Government of Andhra Pradesh Department of IndustriesDocumento3 pagineCommon Application Form I Part A For Establishment: Government of Andhra Pradesh Department of IndustriesLatha YerurNessuna valutazione finora

- Binary Tree and BSTDocumento48 pagineBinary Tree and BSTsri aknthNessuna valutazione finora

- Magnomatics BrochureDocumento4 pagineMagnomatics BrochureVijay17101972Nessuna valutazione finora

- Cost Accounting Final ExamDocumento15 pagineCost Accounting Final ExamSam SumoNessuna valutazione finora

- What Not To Put in A Literature ReviewDocumento6 pagineWhat Not To Put in A Literature Revieweubvhsvkg100% (1)

- BTC 7100Documento78 pagineBTC 7100Nestor Villajuan Luyo0% (1)

- Military Institute of Science and Technology Department of Computer Science and Engineering CSE-305 Array & String Practice ProblemsDocumento2 pagineMilitary Institute of Science and Technology Department of Computer Science and Engineering CSE-305 Array & String Practice ProblemsDurba Binte KalamNessuna valutazione finora

- How Technology Has Changed VolunteeringDocumento9 pagineHow Technology Has Changed VolunteeringSusana Maria Cunha TeixeiraNessuna valutazione finora

- Camera Fundamentals and Parameters in PhotogrammetryDocumento4 pagineCamera Fundamentals and Parameters in PhotogrammetryShizuko Daen LabandaNessuna valutazione finora

- Design Consideration of Gas TurbineDocumento155 pagineDesign Consideration of Gas Turbinecosta59dac9242Nessuna valutazione finora

- Uml Unit-6Documento66 pagineUml Unit-6DURGA PRAKASH SENAPATHINessuna valutazione finora