Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

YP47LPBD - SPEC-120927 (47' Slim) PDF

Caricato da

autreraDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

YP47LPBD - SPEC-120927 (47' Slim) PDF

Caricato da

autreraCopyright:

Formati disponibili

YP47LPBD LCD TV Power specification

Rev 1.6

6/65

2011. 01. 17

POWER SPECIFICATION

POWER SPECIFICATION

YP47LPBD LCD TV Power specification

Rev 1.6

7/65

2011. 01. 17

1. INTRODUCTION

1.1 Product Description

This specification defines the input, output, performance characteristics, environment, noise

and safety requirements for a LED power supply.

1.2 Parameter Specification

Unless specification otherwise, all parameters must be met over the limit of temperature Load,

and input voltage.

2. ELECTRICAL REQUIREMENTS

2.1 Input Requirements

2.1.1 Input Voltages

- Normal Voltage: 100 - 240 Vac

- Voltage Range : 90 - 264 Vac

2.1.2 Input Frequency

- Normal Frequency : 50 / 60Hz

- Frequency range : 47 - 63Hz

2.1.3 Input Current

- under 5Arms at 100Vac & load Max

2.1.4 Configuration

- 3 Conductors (Live, Neutral, F.G)

2.1.5 Input Fuse

- The live line side of the input shall have a fuse.

2.1.6 Primary Over Current Protection

- An adequate internal fuse on the AC input line shall be provided.

2.1.7 Inrush Current

The inrush current of power supply shall be less than the rating of its critical components

(including bulk rectifiers and surge limiting device) for all condition of line voltage of 2.1.1

- Cold start : under 80Ap-p at AC 220Vac (Wall-Out) -20at 80Vac

2.1.8 Efficiency

The power supply efficiency shall be more than 80% measure at the 90Vac maximum load

as specified in paragraph 2.2.1 with the AC input set at the nominal voltage.

2.1.9 Power Factor

- over than 0.9 at 90 - 264Vac & max load condition.

YP47LPBD LCD TV Power specification

Rev 1.6

8/65

2011. 01. 17

2.2 Output Requirements

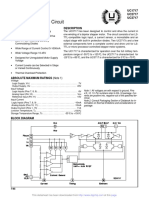

2.2.1 Electrical characteristics

(*1) Ripple Test

1-1) Test : Ripple test(Fig.1)

1-2) Test Point : power output pin

1-3) Probe 47uF & 0.1uF.

1-4) ScopeBandwidth20MhzSetting.

(*2) Inrush current

2-1) powercoverrange.

2-2) spec overvoltage dip,dead

spec .

(*3) Load current : Aging / RQA test standard

* Power On/Off Voltage : 3V ~5V

Switching frequency

Input frequency ( 50 ~60Hz)

Ripple

(Fig.1)

Hz 90 ~260 Frequency

Yes Yes Yes Yes

1.Check Line:

Short to GND

2.Other : Load Max

Yes/NO SCP 6

YES

TBD

TBD

TBD

0.0

-

0.05335

~0.05665

string

Typ 55mA

115 ~170

TBD

115 ~170

158

LED B+

47 3D

Arms - - - - Tolerance

%

Arms

Arms

sec

Arms

Arms

Arms

Vrms

mVp-p

Vrms

Unit

20V 12V

Specification

Stby

3.5V

CONDITION Item NO

TBD

Min 6.5

TBD

TBD

0.0

-

4.0

11.4 ~12.6

350

11.4 ~12.6

12

5 ~99

TBD

Min 5.0

TBD

TBD

0.001

0.006

3.0

3.3 ~3.7

150

3.3 ~3.7

3.5

TBD Range OVP 5

TBD

Possible Range

Refer to (*2)

Current

Inrush

Current

3

TBD Time

Min 4.5

1.Check Line Variable

2.Other : Load Max

Range OCP 4

Range

Dimming 7

0.0 ON Mode Min-2

- Stand by Mode Min-1

2.2 Test & Aging Standard Total Max

Load

Current

(*3)

2

17 ~24 Cross reg1

480

Load Max

(Set Condition)

RIPPLE

17 ~24 Tolerance

20

Load MAX

Rating

Output

Voltage

1

(*1)

YP47LPBD LCD TV Power specification

Rev 1.6

9/65

2011. 01. 17

(*1) Test Point : power output pin

Power Supply Unit

Output Voltage

Load

700mm

Add Electrolytic Capacitor 47+0.1

Oscilloscope

Measurement point

+

Ripple and noise are measured at the end of output cable which are added a 0.1uF ceramic

capacitor and 47uF electrolytic capacitor. ( connected parallel )

(*4) Power turn on system (only E/Load condition)

Power on & Inverter on signal is come from Main Board.

If Main Board is opened, that is electrical load condition,

inverter on signal must be turn on after about 1.5s behind power on signal.

AC & Power on

Drv-on

5.2V/12V/20V

LED B+

Min. 1.5s

2.2.2 Output Voltage Requirement

The total output voltage regulation shall be 5%, including the effects of line voltage variation,

load current, ripple and noise, and the AC component of the load Current.

The effect of dynamic load changes is not included in this limit.

2.2.3 Overshoot

The output overshoot at turn on shall not exceed 10% of normal voltage value with or without

the load connected.

2.2.4 Hold up Time

The power supply shall maintain voltage regulation within the specified limits in paragraph 2.2.1

for at least 20ms after lost of input voltage measure at 100Vac and at maximum output load.

2.2.5 Output Rise Time

At turn on the rise time of output voltage shall be less than 20msec.

Measured from the 10% point to the 90% point of the normal

2.2.6 Power Saving Management [DPMS]

12V 20V

Less then 0.09 Under [230Vac / 50Hz] Wattage [w]

Dont Care (POWER OFF) 0.006 Load [A]

150V 3.5Vst Output Voltage

Test condition

- Temperature: 25room temperature

- Test equipment: Electronic load CR-mode (Continuously resistance)

YP47LPBD LCD TV Power specification

Rev 1.6

10/65

2011. 01. 17

#18 :

Driver On/off

(Inverter On/off)

(DC)

Driver On

Driver Off

3.0V

10msec

DC Off

(AC Off )

#22 :

PWN Dim

(Pulse)

TruMotionPWM #1/#2

Main board Duty 100%

LED driver board Duty 99% 99% holding .

10msec

A/Dim .

2.2.7 LED DRIVER SEQUENCE

#22 :

PWN Dim

(Pulse)

3.0V

No Signal PWM

ON DUTY 15%(TBD)

90Hz ~260Hz

500 msec

10msec

DC Off

(AC Off )

10msec

A/Dim .

PWM dimming LED driver ~

, 5% 5%

, 99%

99% .

#18 :

Driver On/off

(Inverter On/off)

(DC)

Driver On

Driver Off

.

(LED Driver micom initialization)

PWM Dimming frequency Range

: 90~260Hz

No Signal 10000:1

YP47LPBD LCD TV Power specification

Rev 1.6

11/65

2011. 01. 17

#22 :

PWM Dim

(Pulse)

3.0V

500 msec

DC Off

(AC Off )

10msec

500 msec

10msec

Video Mute

10msec

A/Dim .

#18 :

Driver On/off

(Inverter On/off)

(DC)

Driver On

Driver Off

: Video Mute Sequence.

SMART ENERGY SAVING VIDEO MUTE (LED only)

Driver START Timing diagram (LED )

Driver ON

3

Error

Detect

MICOM

Driver ON

(Inverter

ON)

Driver ON

ERROR

(LPB )

Delay 200mS

3

Error

Detect

3

Error

Detect

Driver ON Driver Off / Standby Mode

3.5V

#24 :

Error out

(DC)

#18 :

Driver Off / Standby Mode

0V

1. : LED Error Out =0V , LED Error Out =3.5V

2. : LED Driver LED Error out 3.5V

Monitoring .

3. : MicomError Out Detect 3restart ,

Error Out Driver (inverter) off / Standby Mode.

Driver Sequence Error Out (LED only)

YP47LPBD LCD TV Power specification

Rev 1.6

12/65

2011. 01. 17

on

On

On

Off

On

off

12V,24V

Off(0%)

Floating

Floating

Floating

Floating

Floating

PWM Dim

Off Floating Off

Off Floating On

Off Floating Floating

On (5% ) On On

Off Off On

On (99% ) On On

Driver On Power On

2.2.8. Driver Pin Floating

POWER SEQUENCE

TIME TABLE

Values

Min Typ Max

T1 30

T2

T3 50

T4 20

T5 200

T6

T7 100

T8 ?

Unit msec

AC IN

ST3.5V

Power On

3.5V, 12V,

20V or 24V

Inv.-

On(L)

Power-On Normal Stand-By Normal Power-Off

90%

T

1

T

4

T3

T5

T7

, T43.5V

2.2.9. Power Sequence

YP47LPBD LCD TV Power specification

Rev 1.6

13/65

2011. 01. 17

2.3 Power Output Protection

2.3.1 Over Current Protection(OCP)

The power supply shall not be damaged by over current load.

The OCP function must be operated if current exceed maximum rating.

The OCP point is measured when other output load is a maximum.

At this time, no hardware failure and No fire, when the output voltage decrease to 0V(shutdown)

2.3.2 Over Voltage Protection(OVP)

The voltage will not exceed the upper trip limit.

Noise spikes that exceed the lower trip limit for less than 10will not clamp

the output voltage to zero.

2.3.3 Short Circuit Protection(SCP)

An output short circuit is defined as output impedance of less than 0.1 ohms.

The power supply shall not be damaged by short between DC output and DC ground.

3. RELIABILITY

3.1 Mean Time Between Failure (MTBF)

The power supply shall be designed and produced to have a mean time between failures (MTBF) Of

40,000 operating hours at 90% confidence level while operating under the following condition.

- AC input voltage : 100Vac and 240Vac

- Duty cycle : 6hours ON, 2hours OFF

- Ambient Temp. : 25 2

- Humidity : prevailing condition

3.2 Life/Power On Hours

The power supply must be designed to operate for 40,000 power on hours.

About 5 years at an ambient temperature of 25

3.3 Burn-in Test Condition

More than 4hours at 40(5), Normal input voltage.

AC on/off must be test 1 time after burn-in.

Test condition

- Test equipment: Electronic load CR-mode ( Continuously resistance)

0.055 Each Line

150V 20V 12V 3.5Vst Output Voltage

3.2 1.8 2.8 Aging Load [A]

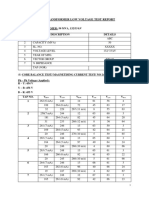

3.4 Mass production Quality Guarantee Test

3.4.1 Temperature management

1) Internal chamber room temperature: 60(582)

2) The internal chamber temperature should be displayed with real-time at outside.

If impossible, must supervise after install a thermometer logger.

3.4.2 Test

1) The test operating time standard is refer to Table 10 and after more than 2 times power

on/off test, have to check something wrong in a power supply before test end.

- On time: 10sec, Off time: 10sec

2) Normally, the test load condition is 80% of written max load at a product specification.

YP47LPBD LCD TV Power specification

Rev 1.6

14/65

2011. 01. 17

more than 2 times (AC source)

On/Off Time: each 10sec

Execute power on/off test during

test

On/Off Test

80% of max load Product specification Load

According to product specification High temperature operating test Test content

MP product(20hr),

4M change product(44hr),

MP 1

st

product(68hr)

Time

60(582)

Chamber

Temperature

Remarks Spec. Item

<Table 10. The management standard of MP quality guarantee test >

3.4.3 Operation/Management

1) The MP quality guarantee test should be proceed continuously without relation

for produced outgoing lot.

2) The serial no. of MP quality guarantee test completion should be attached

a outgoing inspection sheet for lot.

3) In case a problem occurred during test, take action at once and must inform to LG IQA.

3.4.4 Sampling & Test standard time

1) The MP quality guarantee test proceed on below Table 11.

after classify with MP/4M/Development item.

2) The sample is selected on the PCBA which was completed to final inspection

(include aging test).

The Lot means classified a product by day/model at PSU assembly line.

35 30 20 5,001 ~6,000

30 20 15 4,001 ~5,000

30 20 15 3,001 ~4,000

25 15 10 2,001 ~3,000

20 15 10 1,001 ~2,000

68 Hrs

15

44 Hrs

10

20 Hrs

5 0 ~1,000

Time

Sample

quantity

Time

Sample

quantity

Time

Sample

quantity

MP 1st Lot 4M Change MP Lot

Lot size

< Table 11. Sampling / Test standard time >

4. SAFETY & EMS

4.1 Earth Leakage current

The power supply leakage current shall be less than 0.7mA at 100 - 240Vac

( peak : 0.7mA, rms 0.5A )

Safety

YP47LPBD LCD TV Power specification

Rev 1.6

15/65

2011. 01. 17

4.2 Hi-Pot Test (Dielectric withstand voltage)

Live & Neutral to touchable metal : 3000Vac or 4242Vdc / 1 Minute. (Cut-off current : 10mA)

Live & Neutral to Secondary GND : 1500Vac or 2121Vdc / 1 Minute. (Cut-off current : 10mA)

1.8KVac for 1 seconds (mass production)

4.3 Insulation Resistance

Insulation resistance shall be 8M at 500Vdc between primary Live, Neutral line and

secondary.

4.4 Input AC Surge

The power supply withstand 300Vrms input for 10 seconds.

4.5 Surge & Impulse Test

Surge Immunity : 4kV/(L1 ~L2) 3 times, 4kV (L1 ~FG, L2l ~FG) 3 times

Impulse Noise Test : 6kV, Normal / Common mode, Polarity(+,-) / Phase(0 ~360)

Lightning Surge : 2kA, LG Equipment ( Line, Condition 2, Total 8)

4.6 RFI / EMI Standards

The power supply shall comply with a following RFI/EMI standards when tested in a system

configuration.

- F.C.C federal rules and regulations part 15, sub parts B computing device.

- CISPR22, class B. NORDIC/EUROPE

4.7 Safety Standards

The Power Supply Unit shall be tested with the following safety standards.

- UL1310, UL1950 (Safety of information technology equipment) listed. USA

- CSA C22.2, NO234 level 3 output, class 2 output. CANADA

- CB Report : UL60065, IEC60065

5. ENVIRONMENT REQUIREMENTS

5.1 Temperature

- Operating Temp. : -10 ~40(60: No H/W failure, Set condition)

0 ~70(Only PSU)

- Storage Temp. : -20 ~70

5.2 Humidity

- Operation humidity : 30 ~85% non-condensing

- Storage humidity : 5 ~90% non-condensing

5.3 RoHS : Phase / Level 5 / Pb-free

6. Sound noise characteristics

PSU Noise Specification

22.5 dB(a) / 20.u Pa 2.0E-5 Pa

(1/1 octave, A-weighting, to 1khz ~16khz Total overall

Measure Location : Anechoic Room

Measure Condition : At a distance of 60cm mic

Full white pattern, at AC 110V/220V

The max specification

(measure 3 points, at PSU center and left & right on the side)

YP47LPBD LCD TV Power specification

Rev 1.6

16/65

2011. 01. 17

Neutral 3

SK101

YEONHO (90011WR-H03D-S)

GND 2

Live 1

Assignment Pin No.

N.C 7

#2-3 Cathode 8

#1-2 Cathode 4

#1-3 Cathode 5

N.C 6

#2-2 Cathode 9

#2-1 Cathode 10

#1-1 Cathode 3

#2 Anode 12

N.C 11

N.C 2

#1 Anode 1

P204

YEONHO

(20010WR-12A03 (BL))

Assignment Pin No.

SCLK 20 12V 19

DRV ON 18 12V 17

PWM Dim #1 22 12V 21

GND 6 GND 5

20V 4 20V 3

20V 2 Power On 1

3.5 12 3.5V 11

3.5V 10 3.5V 9

GND 8 GND 7

Assignment

Pin

No.

Assignment

Pin

No.

Error Out 24 SIN 23

V-sync 16 GND 15

GND 14 GND 13

P201

YEON HO (SMAW200-H24S)

7. CONNECTORS

7.1 Pin Configuration & Connector

N.C 8

N.C 7

#4-3 Cathode 9

#3-2 Cathode 4

#3-3 Cathode 5

N.C 6

#4-2 Cathode 10

#4-1 Cathode 11

#3-1 Cathode 3

#4 Anode 13

N.C 12

N.C 2

#3 Anode 1

P204

YEONHO

(20010WR-13A03 (BL))

Assignment Pin No.

YP47LPBD LCD TV Power specification

Rev 1.6

17/65

2011. 01. 17

8. PCB Dimension

1. Power Board PCB : 260mm 397mm 1.6(T)mm

2. Component Height : Under AL-Sheet Area 6mm (Max)

Other Area 6.5mm (Max)

3. Lead Cutting : Max 2.3mm

75mm

111.5mm

70.5mm

78mm

77.5mm

34mm

397mm

260mm

20mm

70mm

97mm

YP47LPBD LCD TV Power specification

Rev 1.6

18/65

2011. 01. 17

8-1. Insulation sheet

25

136.1

Potrebbero piacerti anche

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- YP32DVR Power SpecificationDocumento8 pagineYP32DVR Power SpecificationMarcio Antonio Machado0% (1)

- LG - 32lb9rta Me Eay41970901 PDFDocumento139 pagineLG - 32lb9rta Me Eay41970901 PDFLuděk CsibaNessuna valutazione finora

- LGP4247 11SPLDocumento11 pagineLGP4247 11SPLViorel CioataNessuna valutazione finora

- FAN7602B Green Current-Mode PWM Controller: Features DescriptionDocumento17 pagineFAN7602B Green Current-Mode PWM Controller: Features DescriptionNichole RollinsNessuna valutazione finora

- HT7A6003 EMI-Improved Green Mode PWM Controller With Integrated ProtectionsDocumento10 pagineHT7A6003 EMI-Improved Green Mode PWM Controller With Integrated ProtectionsEnéas BaroneNessuna valutazione finora

- Oz9938 PDFDocumento12 pagineOz9938 PDFCarlosNessuna valutazione finora

- Miniature Single-Cell, Fully Integrated Li-Ion, Li-Polymer Charge Management ControllersDocumento24 pagineMiniature Single-Cell, Fully Integrated Li-Ion, Li-Polymer Charge Management ControllersVeronika TothNessuna valutazione finora

- Magia Pensar GrandeDocumento16 pagineMagia Pensar GrandeDayron TorresNessuna valutazione finora

- 4623 FDocumento24 pagine4623 Fante mitarNessuna valutazione finora

- Fan 7314Documento14 pagineFan 7314Kamal NonekNessuna valutazione finora

- Uc2577 AdjDocumento14 pagineUc2577 AdjChandranoola RajuNessuna valutazione finora

- PWBXXXXMD-3W Aislado PDFDocumento2 paginePWBXXXXMD-3W Aislado PDFePotyNessuna valutazione finora

- ADP3180Documento20 pagineADP3180chrizzcloNessuna valutazione finora

- EN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated InductorDocumento16 pagineEN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated Inductorcatsoithahuong84Nessuna valutazione finora

- DRC-24V30W1A Technical DatasheetDocumento11 pagineDRC-24V30W1A Technical Datasheetzivko13Nessuna valutazione finora

- 500 Ma Synchronous Buck Regulator, + 300 Ma LDO With Power-Good OutputDocumento30 pagine500 Ma Synchronous Buck Regulator, + 300 Ma LDO With Power-Good OutputppanagosNessuna valutazione finora

- OB2269Documento12 pagineOB2269Juan Ballon100% (1)

- La 42205Documento7 pagineLa 42205ban4444Nessuna valutazione finora

- Syy155415 CPDocumento3 pagineSyy155415 CPdanutzugheNessuna valutazione finora

- ADP3338 Data SheetsDocumento16 pagineADP3338 Data SheetstarpinoNessuna valutazione finora

- Bd9397efv e PDFDocumento30 pagineBd9397efv e PDFshafiuddin7326Nessuna valutazione finora

- Data Sheet of ADE7751Documento17 pagineData Sheet of ADE7751NithyaNessuna valutazione finora

- C324G Low Power Quad OpAmpDocumento12 pagineC324G Low Power Quad OpAmpwhynot05Nessuna valutazione finora

- LV47002PDocumento9 pagineLV47002PchichedemorenoNessuna valutazione finora

- Delomatic 3, SCM-1, Synchronising-Measuring Module 4921240056 UKDocumento3 pagineDelomatic 3, SCM-1, Synchronising-Measuring Module 4921240056 UKВупсень ПупсеньNessuna valutazione finora

- DM0265Documento19 pagineDM0265liberthNessuna valutazione finora

- 1.5A USB-Friendly Li-Ion Battery Charger and Power-Path Management ICDocumento33 pagine1.5A USB-Friendly Li-Ion Battery Charger and Power-Path Management ICanarchie2008Nessuna valutazione finora

- BD9275FDocumento5 pagineBD9275Fproctep100% (1)

- High Efficiency Low-Side N-Channel Controller For Switching RegulatorsDocumento33 pagineHigh Efficiency Low-Side N-Channel Controller For Switching Regulatorssoft4gsmNessuna valutazione finora

- MCP 3909Documento44 pagineMCP 3909José HeinNessuna valutazione finora

- CD4047BC Low Power Monostable/Astable Multivibrator: General DescriptionDocumento10 pagineCD4047BC Low Power Monostable/Astable Multivibrator: General DescriptionWillianNessuna valutazione finora

- UP220-AE-A Power SupplyDocumento8 pagineUP220-AE-A Power SupplyAndy WilsonNessuna valutazione finora

- NCP 2171Documento19 pagineNCP 2171mari_casuNessuna valutazione finora

- v65d v6 0 Instruction ManualDocumento57 paginev65d v6 0 Instruction ManualMr.K ch100% (1)

- IC 3842 para FonteDocumento8 pagineIC 3842 para FonteTomNedscNessuna valutazione finora

- LM3875TDocumento19 pagineLM3875TJasten S DeleñaNessuna valutazione finora

- HS-2420RH - Fast Sample and HolDocumento8 pagineHS-2420RH - Fast Sample and HolDeepa DevarajNessuna valutazione finora

- Data SheetDocumento7 pagineData Sheetitamar_123Nessuna valutazione finora

- Um - SK200&350 (No Cotek) - 75-1000-0381 - A1Documento18 pagineUm - SK200&350 (No Cotek) - 75-1000-0381 - A1林介浩Nessuna valutazione finora

- Fonte PWS-801Documento20 pagineFonte PWS-801LuizNessuna valutazione finora

- DPA001 - ATX-Dedicated PWM Controller DPA001: Customer Specific Device From ON SemiconductorDocumento18 pagineDPA001 - ATX-Dedicated PWM Controller DPA001: Customer Specific Device From ON Semiconductorsontuyet82Nessuna valutazione finora

- Fuente LG 42LS5700Documento75 pagineFuente LG 42LS5700Christyan LeonNessuna valutazione finora

- Circuito Integrado TA8207KDocumento11 pagineCircuito Integrado TA8207KIberê CamposNessuna valutazione finora

- BD9893FDocumento5 pagineBD9893FAriel NavarreteNessuna valutazione finora

- NCP1337 PWM Current Mode Controller For Free Running Quasi Resonant OperationDocumento14 pagineNCP1337 PWM Current Mode Controller For Free Running Quasi Resonant Operationcorrales_86Nessuna valutazione finora

- MPD 810HDocumento5 pagineMPD 810Hdan22yNessuna valutazione finora

- APW7159ADocumento23 pagineAPW7159AVoicu AdrianNessuna valutazione finora

- Phase ProtektorDocumento3 paginePhase ProtektorChristopher WaltersNessuna valutazione finora

- Datasheet Search Site - WWW - AlldatasheetDocumento15 pagineDatasheet Search Site - WWW - AlldatasheetPanagiotis PanagosNessuna valutazione finora

- Antminer APW9ENDocumento17 pagineAntminer APW9ENZarko RadivojevicNessuna valutazione finora

- Current Mode PWM Controller: Features DescriptionDocumento9 pagineCurrent Mode PWM Controller: Features DescriptionJozo ĆurčićNessuna valutazione finora

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDa EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsValutazione: 3.5 su 5 stelle3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Analog Circuit Design Volume Three: Design Note CollectionDa EverandAnalog Circuit Design Volume Three: Design Note CollectionValutazione: 3 su 5 stelle3/5 (2)

- Composite - Electric WiringDocumento37 pagineComposite - Electric WiringautreraNessuna valutazione finora

- 5800 A8r110 0010Documento13 pagine5800 A8r110 0010autreraNessuna valutazione finora

- LS-H096QNA0 Service Manual PDFDocumento82 pagineLS-H096QNA0 Service Manual PDFautreraNessuna valutazione finora

- 32 Inch LCD Electrical Diagram of ADboard PDFDocumento9 pagine32 Inch LCD Electrical Diagram of ADboard PDFautreraNessuna valutazione finora

- Low-Frequency Amplifier Applications: Package Dimensions FeaturesDocumento4 pagineLow-Frequency Amplifier Applications: Package Dimensions FeaturesautreraNessuna valutazione finora

- Samsung March 2014 Service NewsDocumento22 pagineSamsung March 2014 Service NewsautreraNessuna valutazione finora

- PLD4016FT Service Manual PDFDocumento137 paginePLD4016FT Service Manual PDFautreraNessuna valutazione finora

- Alpine MRV-F900 PDFDocumento45 pagineAlpine MRV-F900 PDFautreraNessuna valutazione finora

- Shenshibrand 140210115543 Phpapp02 PDFDocumento11 pagineShenshibrand 140210115543 Phpapp02 PDFautreraNessuna valutazione finora

- Operators Manual Cec B&W Photoride: Downloaded From Manuals Search EngineDocumento26 pagineOperators Manual Cec B&W Photoride: Downloaded From Manuals Search EngineautreraNessuna valutazione finora

- Stepper Motor Drive Circuit: Features DescriptionDocumento9 pagineStepper Motor Drive Circuit: Features DescriptionautreraNessuna valutazione finora

- Samsung Curve TrainingDocumento33 pagineSamsung Curve Trainingautrera50% (2)

- Amiga Floppy Drive Compatibility List: 3.5 DrivesDocumento8 pagineAmiga Floppy Drive Compatibility List: 3.5 DrivesautreraNessuna valutazione finora

- Samsung UN75J6300 UWK50 PDFDocumento86 pagineSamsung UN75J6300 UWK50 PDFautreraNessuna valutazione finora

- BN44 00520C PDFDocumento3 pagineBN44 00520C PDFautreraNessuna valutazione finora

- Samsung Ue78ju7500t Chassis Uwj50 Uhd-TvDocumento2 pagineSamsung Ue78ju7500t Chassis Uwj50 Uhd-TvautreraNessuna valutazione finora

- PDFDocumento41 paginePDFautreraNessuna valutazione finora

- Samsung Curved LedDocumento1 paginaSamsung Curved LedautreraNessuna valutazione finora

- PDFDocumento157 paginePDFautreraNessuna valutazione finora

- Samsung Ue78ju7500t Chassis Uwj50 Uhd-Tv PDFDocumento120 pagineSamsung Ue78ju7500t Chassis Uwj50 Uhd-Tv PDFautreraNessuna valutazione finora

- GM0465RDocumento18 pagineGM0465RautreraNessuna valutazione finora

- A L A V: Cell Cell Cell Cell Cell-Dyn - Dyn - Dyn - Dyn - DynDocumento105 pagineA L A V: Cell Cell Cell Cell Cell-Dyn - Dyn - Dyn - Dyn - DynautreraNessuna valutazione finora

- Service Manual: DSC-F717Documento24 pagineService Manual: DSC-F717autreraNessuna valutazione finora

- Service ManualDocumento49 pagineService ManualautreraNessuna valutazione finora

- Power Supply Skyworth 8M51BDocumento1 paginaPower Supply Skyworth 8M51BautreraNessuna valutazione finora

- Samsung UN32EH4000 Chasis U71A B PDFDocumento108 pagineSamsung UN32EH4000 Chasis U71A B PDFautrera50% (2)

- Pcs-4000 Schematic Sound BarrierDocumento12 paginePcs-4000 Schematic Sound BarrierautreraNessuna valutazione finora

- Sony dsc-f717Documento56 pagineSony dsc-f717autreraNessuna valutazione finora

- RCX Partial Wraps PDFDocumento2 pagineRCX Partial Wraps PDFMRousstiaNessuna valutazione finora

- Precommissioning Test ReportDocumento5 paginePrecommissioning Test ReportMathur DineshNessuna valutazione finora

- Mini Camera User ManualDocumento4 pagineMini Camera User ManualAndronikus Marintan NapitupuluNessuna valutazione finora

- EYE DiagramDocumento10 pagineEYE DiagramNuwan WeerasekaraNessuna valutazione finora

- ECE404 Microprocessors Design and Interfacing - Lec 01 - Hardware SpecsDocumento6 pagineECE404 Microprocessors Design and Interfacing - Lec 01 - Hardware Specsshafee001Nessuna valutazione finora

- Simulation of Single-ElectronDocumento161 pagineSimulation of Single-Electronمزمل اقبالNessuna valutazione finora

- Powerwave Product CatalogDocumento531 paginePowerwave Product CatalogPedro SpenoulisNessuna valutazione finora

- EECE 301 Signals & Systems: Prof. Mark FowlerDocumento12 pagineEECE 301 Signals & Systems: Prof. Mark FowlerahmdNessuna valutazione finora

- ENG FP28495 Zeppelin BrochureDocumento26 pagineENG FP28495 Zeppelin BrochureCaterina CarboneNessuna valutazione finora

- DCC ProjectDocumento9 pagineDCC ProjectSakhare ParagNessuna valutazione finora

- Chapter 3Documento25 pagineChapter 3ARif HakimNessuna valutazione finora

- Uk048e New Range LediDocumento16 pagineUk048e New Range LediSayed HashemNessuna valutazione finora

- Load Sched Template 1p - 1Documento21 pagineLoad Sched Template 1p - 1Paolo Amurao FranciscoNessuna valutazione finora

- Elecs 3Documento5 pagineElecs 3Lanbert FranciscoNessuna valutazione finora

- AAI-Selection-Procedure - 18952 - Sample Placement Papers PDFDocumento2 pagineAAI-Selection-Procedure - 18952 - Sample Placement Papers PDFSri PuduNessuna valutazione finora

- Design of Analog & Mixed Mode Vlsi Circuits 6 (Compatibility Mode)Documento44 pagineDesign of Analog & Mixed Mode Vlsi Circuits 6 (Compatibility Mode)rahul_agarwal_15Nessuna valutazione finora

- CMQEE 3440A Data SheetDocumento5 pagineCMQEE 3440A Data Sheetnd2b8f4djmNessuna valutazione finora

- MaxTune Intelligent Servo DriveDocumento62 pagineMaxTune Intelligent Servo DrivejuliangoalNessuna valutazione finora

- Evolution To New Thin Film Products: TDK CorporationDocumento33 pagineEvolution To New Thin Film Products: TDK CorporationNewer YeNessuna valutazione finora

- Adaptive Active Phased - Array 'Multifunction' Radars Seminar Report 03Documento21 pagineAdaptive Active Phased - Array 'Multifunction' Radars Seminar Report 03praveenpv7Nessuna valutazione finora

- An-1095 International Rectifier LC FiltersDocumento9 pagineAn-1095 International Rectifier LC FiltersElneto CarriNessuna valutazione finora

- Quanta Zd1 Re SchematicsDocumento38 pagineQuanta Zd1 Re SchematicsPREVISTONessuna valutazione finora

- Studies of Znse and Indium Tin Oxide Based Thin Film Schottky Barriers and Hetero Junctions For Their Electrical and Optical PropertiesDocumento263 pagineStudies of Znse and Indium Tin Oxide Based Thin Film Schottky Barriers and Hetero Junctions For Their Electrical and Optical PropertiesSumbitchalihaNessuna valutazione finora

- Onkyo-Tx SR309Documento56 pagineOnkyo-Tx SR309malickjsNessuna valutazione finora

- WatchdogDocumento10 pagineWatchdogxa yNessuna valutazione finora

- NSN 3G AlarmsDocumento5 pagineNSN 3G AlarmsVugar Ali0% (1)

- Solar Module CellDocumento4 pagineSolar Module CellVinod BabhaleNessuna valutazione finora

- Scan 20150805Documento1 paginaScan 20150805Jrom EcleoNessuna valutazione finora

- Using The Impedance Method: Z JC Z Z Z ZDocumento15 pagineUsing The Impedance Method: Z JC Z Z Z ZAtyia JavedNessuna valutazione finora

- Communication ENggDocumento11 pagineCommunication ENggSantosh VishnuNessuna valutazione finora