Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hazpak: The Ultimate Aerosol Can Disposal

Caricato da

SophiaWrightTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hazpak: The Ultimate Aerosol Can Disposal

Caricato da

SophiaWrightCopyright:

Formati disponibili

A E R O S O L C A N P R O C E S S O R

HAZPAK

TM

EKO Environmental

Di vi si on of MacLean Engi neeri ng

1000 Raglan Street

Collingwood, ON Canada L9Y 3Z1

Ofce:705.445.5707

Cell:226.688.8626

mmackay@macleanengineering.com

HazPak

TM

offers a closed loop recycling system that not only solves

a huge environmental problem, but allows the owner to benefit from

several income streams while effectively doing their part to help stop

global warming and ground water poisoning.

HazPak

TM

Advantages:

100% Recycling of Contents (propellant + container)

0% Waste into Landfills

0% Emissions Released into Atmosphere

Income Streams: Processing Fees, Scrap Value, Fuel Sales

HazPak

TM

Processing Capabilities:

Aerosols, Inks, Paints, Solvents, Varnish, Adhesives,

Sealants, Oil Filters, Small Propane & Gas Cylinders

B.A.T.

BEST AVAILABLE TECHNOLOGY

TO RECYCLE AEROSOL CANS

Specifically Designed for the Aerosol Filler Industry

Leading the World in Toxic Waste Recovery Systems

Division of MacLean Engineering

Leading the World in Toxic Waste Recovery Systems

www.ekocorp.com

www.macleanengineering.com

HAZPAK

TM

Finally, a turn-key processing system that transforms hazardous aerosols and

canned waste products into fully recyclable and saleable byproducts. HazPak

TM

uses state of the art mechanical and gas technology to deal with toxic waste

effectively and safely with 100% diversion from landfills and the atmosphere.

TECHNICAL INFORMATION

HAZPAK 6000

6.00 cu metres

or 1900 kg / hr

18.3 L x 7.4 W x 6.4 H

43,000

As specified

82.5/43.72

12

1.0

29.0 - 56.0

203.2 x 203.2 x variable

560 - 640

966

293

HAZPAK 3000

3.00 cu metres

or 952 kg / hr

12.2 L x 4.6 W x 4.6 H

20,000

As specified

65.25/29.81

6

0.5

12.5 - 31.5

152.4 x 152.4 x variable

280 - 320

483

146

Aerosol cans, hand-held propane torches, shaving cream, hair spray and multitude of

products packaged under pressure are flooding our landfills. They contain hazardous

materials, they are explosive and they have to be disposed of safely, economically and

without harming the environment. Dumping these full and partially full containers

into landfills is not the answer.

The HazPak

TM

by EKO is the answer. Safety and performance are key factors in the

HazPak

TM

system. This state of the art de-packaging densifier can separate and

remove both the propellant and the liquid and save them in separator containment

tanks for recycling or incineration. The metal containers are compacted into a dense

dry briquette with 99 per cent of the liquid removed which makes ideal feed stock for

smelters. The entire operation occurs inside the safety of an air tight vacuum - with

100% diversion from landfills and the atmosphere.

Division of MacLean Engineering

SPECIFICATION

Capacity *

(Paint or Aerosol cans)

Typical footprint (m)

Weight (kg)

Voltage

Kilowatts (Peak/Average)

Nitrogen required / hr (m3)

Hopper Capacity (m3)

Briquette Weight (kg)

Briquette Dimensions (mm)

Steel recovered / hr (kg)

Fluids recovered / hr (kg)

Liquid Gas recovered / hr (kg)

* Assuming full cans

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Graco Agitators and MixersDocumento14 pagineGraco Agitators and Mixerscumpio425428Nessuna valutazione finora

- TK01 - Report - FinalDocumento264 pagineTK01 - Report - FinalHafiz HakimNessuna valutazione finora

- Techinfo Oc500rf enDocumento12 pagineTechinfo Oc500rf enDanang Wiryawan AdityatamaNessuna valutazione finora

- Multiquip Whisperwatttm Generator Dca 15spx3Documento132 pagineMultiquip Whisperwatttm Generator Dca 15spx3Shane De FreitasNessuna valutazione finora

- MEM554 - Thermalfluids Lab Computer Linked RefrigerationDocumento25 pagineMEM554 - Thermalfluids Lab Computer Linked Refrigerationsayabudakcomey75% (12)

- Pre-Designed Steam Turbines en PDFDocumento8 paginePre-Designed Steam Turbines en PDFCriss MereutaNessuna valutazione finora

- Fill Rite PumpsDocumento18 pagineFill Rite PumpsCentral HydraulicsNessuna valutazione finora

- Technical Diary OF Stage-1 (UNIT-1&2) (PTPS, Panipat) : 2 X 110 MW Unit-I & Ii Panipat Thermal Power Station PanipatDocumento138 pagineTechnical Diary OF Stage-1 (UNIT-1&2) (PTPS, Panipat) : 2 X 110 MW Unit-I & Ii Panipat Thermal Power Station PanipatapsNessuna valutazione finora

- XDG XDGX IomDocumento64 pagineXDG XDGX Iomburtay3434Nessuna valutazione finora

- Brochure Explosion Protection en PDFDocumento45 pagineBrochure Explosion Protection en PDFBucur AlexandruNessuna valutazione finora

- F14U2TDN0Documento340 pagineF14U2TDN0Tiberiu IonescuNessuna valutazione finora

- KGSP PDFDocumento12 pagineKGSP PDFEmiZNessuna valutazione finora

- Mitsubishi MSZ Fd25 35vahDocumento2 pagineMitsubishi MSZ Fd25 35vahZachary TaylorNessuna valutazione finora

- FOGO Mitshubishi SpecsDocumento3 pagineFOGO Mitshubishi SpecsAli HussainNessuna valutazione finora

- Design and Fabrication Stirling EngineDocumento54 pagineDesign and Fabrication Stirling Engineermias100% (1)

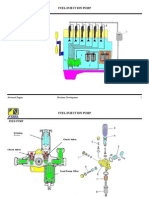

- Fuel Injection Pump Guide: Types, Components & Working PrinciplesDocumento9 pagineFuel Injection Pump Guide: Types, Components & Working PrinciplesJoko Sukariono100% (2)

- Gs 2668 RT 2001g.Documento136 pagineGs 2668 RT 2001g.MladenNessuna valutazione finora

- Om Dx225lcaDocumento273 pagineOm Dx225lcaCoordinador - Mantenimientos100% (2)

- M25 ToolsDocumento40 pagineM25 Toolsabuzer1981Nessuna valutazione finora

- Poe 1 2 Key TermsDocumento2 paginePoe 1 2 Key Termsapi-260948905100% (2)

- Thom-Katt Series: Trailer-Mounted Concrete/Shotcrete PumpsDocumento2 pagineThom-Katt Series: Trailer-Mounted Concrete/Shotcrete PumpsGregory Alejandro Paulino SantanaNessuna valutazione finora

- Volvo ManualDocumento141 pagineVolvo Manualrichieg7777Nessuna valutazione finora

- Aqa Chem1 QP Jun14 PDFDocumento16 pagineAqa Chem1 QP Jun14 PDFKrishna OochitNessuna valutazione finora

- MSH300 Multiserviz Hose 300 Psi: Page 1 of 1Documento1 paginaMSH300 Multiserviz Hose 300 Psi: Page 1 of 1Kuncoro TaufiqNessuna valutazione finora

- Scooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityDocumento8 pagineScooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityAnonymous Mdw6y7Q1Nessuna valutazione finora

- Five-Spot Vs Crestal Waterflood PatternsDocumento4 pagineFive-Spot Vs Crestal Waterflood PatternsWafindraNessuna valutazione finora

- Service Manual #32 2001 - Newer GM V6 MPIDocumento14 pagineService Manual #32 2001 - Newer GM V6 MPIKamen Nestorov0% (1)

- DownstreamDocumento26 pagineDownstreamCésar MenéndezNessuna valutazione finora

- Copic Color Wheel 358Documento1 paginaCopic Color Wheel 358kotoirNessuna valutazione finora

- LNG Carrier Equipment QuotesDocumento4 pagineLNG Carrier Equipment QuotesMavi Ord RojasNessuna valutazione finora