Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Skorpion zinc mine grade control

Caricato da

Christian CRDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Skorpion zinc mine grade control

Caricato da

Christian CRCopyright:

Formati disponibili

The Southern African Institute of Mining and Metallurgy The Fourth Southern African Conference on

Base Metals

Gail Gnoinski

Page 103

GRADE CONTROL BLENDING AND SELECTIVITY

FOR OPTIMAL PROCESS PERFORMANCE AT

THE SKORPION ZINC MINE, NAMIBIA

G B GNOINSKI

Namzinc (Pty) Ltd, Private Bag 2003, Rosh Pinah, Namibia

Tel: +264 63 271 2408, Fax: +264 63 271 2425

Email: ggnoinski@skorpionzinc.com.na

ABSTRACT

The Skorpion Zinc Mine and Refinery is situated approximately 25 km north of Rosh

Pinah, south-western Namibia. The supergene zinc oxide deposit at Skorpion is hosted

in a volcano-sedimentary succession within the para-autochthonous Port Nolloth Zone

of the Gariep Belt. Rock types hosting the ore deposit include altered and

metamorphosed volcaniclastic and clastic sediments, limestone and rhyolite.

At Skorpion, the metallurgical process is unique and the plant design requires minimal

fluctuations within a selected feed grade. In addition, the presence of limestone inter-

fingered with ore in some areas of the deposit results in dilution problems which may

increase gangue acid consumption and therefore processing costs. Hence, selective

mining is necessary to ensure the delivery of suitable ore to the processing plant, in

order to keep the overall operating costs at a minimum.

A complex control system is in place and is capable of a high degree of selectivity. The

paper describes the grade control system in place at Skorpion Mine which ensures that

the qualities of the blocks planned for mining and the material being mined meet the

stringent process requirements of the refinery, i.e zinc grade, gangue acid consumption

and deleterious elements that may impact on the efficiency and costs of the

metallurgical process.

Keywords: Skorpion zinc, zinc oxide, supergene, volcano-sedimentary, grade control

1. INTRODUCTION

The Skorpion Zinc Mine is situated approximately 25 km from Rosh Pinah, Namibia

(Figure 1). The supergene zinc oxide deposit at Skorpion is hosted in Late Proterozoic

altered and metamorphosed volcaniclastic and clastic sediments, limestone and rhyolite

of the Port Nolloth Zone of the Gariep Belt (Borg et al. 2003). The supergene deposit is

thought to have formed primarily from the oxidation of a sulphide-bearing precursor

and carbonate wall rock replacement (Hitzman et al., 2003).

The Southern African Institute of Mining and Metallurgy The Fourth Southern African Conference on

Base Metals

Gail Gnoinski

Page 104

Figure 1. Location and structural setting of the Skorpion non-sulphide zinc deposit.

The major zinc-bearing minerals present at Skorpion are generally smithsonite (zinc

carbonate), sauconite (zinc clay) and hemimorphite (zinc silicate). Minor ore minerals

include tarbuttite, chalcophanite and zinalsite. Other minerals present in the deposit

include copper oxide minerals like malachite, digenite, chalcocite and chrysocolla, as

well as copper sulphide minerals like pyrite, sphalerite, and chalcopyrite have been

reported (Borg et al. 2003).

Estimated resources are of the order of 18 million tonnes at an average grade of 11.3 %

Zn and a 14 year life of mine. The mineralised ore body extends to a depth of 420m.

U-Th/He thermochronometry dating of the zinc phosphate mineral, tarbuttite, constrains

the time of oxide mineralisation at Skorpion to between 42 Ma and 70 Ma. Ar-Ar step-

heating age data for K-bearing romanechite from the Skorpion deposit yielded two

clusters of middle Miocene to upper Eocene ages (Gutzmer, 2006).

2. THE IMPORTANCE OF GRADE CONTROL AT SKORPION

The Skorpion Zinc mining and refinery operations present a different paradigm, because

metallurgical processes are not designed around expected variations in the feed grade from the

open-pit where mining costs are conventionally kept low. Skorpion operations are such that

the mining costs are relatively low compared to the metallurgical processing costs. The

metallurgical process is unique and the plant design requires a feed grade within a narrow

range, typically 10 -12 % Zn. Within a selected feed grade, the requirement is that

fluctuations must be minimal.

The Southern African Institute of Mining and Metallurgy The Fourth Southern African Conference on

Base Metals

Gail Gnoinski

Page 105

In addition, the presence of limestone inter-fingered with ore in some areas of the deposit

results in dilution problems which may increase gangue acid consumption and therefore

processing costs. Hence, selective mining is necessary to ensure the delivery of suitable ore

to the processing plant, in order to keep the overall operating costs at a minimum.

Grade Control, together with operational management and mine planning ensures that the

qualities of the blocks planned for mining and the material being mined meet the stringent

process requirements of the refinery, in terms of zinc grade, gangue acid consumption and

deleterious elements that may impact on the efficiency and costs of the metallurgical process.

3. THE GRADE CONTROL PROCESS

A complex system is in place that is capable of a high degree of control and selectivity. A

dedicated team of grade control operators undertake blast hole sampling, spot grade

perimeters in the open-pit and control loading and dumping of material to and from low-,

medium- and high-grade ore stockpile destinations. Waste and marginal ore are also

separated to different destinations. The degree of selectivity in the open-pit serves to

minimise dilution and allows for blending from a range of stockpiles. A tracking database

monitors ore tonnes and grades on stockpiles to enable optimal blending for the required plant

process performance.

The grade control process is described below:

DRILLING: Drill burden and spacing are based on the rock types present at Skorpion , e.g. 4

m x 4 m in ore and 6 m x 6 m in waste material (Figure 2).

SAMPLING: Samples and drill chips are collected over intervals of 2.5m, 5m or 10m. Large

samples (>5kg) are riffle split at the drill rig (Figure 2).

Figure 2. Blast-hole drilling and grade control sampling at the DM45 drill rig.

The Southern African Institute of Mining and Metallurgy The Fourth Southern African Conference on

Base Metals

Gail Gnoinski

Page 106

ASSAYS: Routine XRF analysis of Zn, Ca, Fe, Mn and Cu concentrations in pressed powder

pellets are performed by the on-site Skorpion Laboratory.

QUALITY CONTROL: The Quality Control Procedure specifies the use of quality control

(QC) samples to track laboratory performance. At least 5% of the grade control samples are

submitted for analysis comprises QC specimens. The QC samples used for this purpose

include matrix-matched certified reference material (MM-CRM), rig duplicate samples,

internal geology blanks, laboratory replicates and laboratory blank samples.

The purpose of quality control is to minimise biases, confirm whether laboratory assays are

correct to within a defined degree of accuracy and precision and to detect the presence of

carryover contamination between samples.

BLASTING: Blast designs and techniques are based on the different rock and alteration

types. Fragmentation versus minimum movement of material is optimised when a particular

powder factor is selected.

MODELLING: Survey borehole collar co-ordinates, geology (rock types, ZincZap and

HCl reactions) and assay results are captured in a database. Block modelling is undertaken

over appropriate levels (smu = 5m x 5m x 2.5m) depending on continuity of geology and

grade, using a customised DATAMINE Grade Control System developed by Bloy Mineral

Resource Evaluation (BMRE) software. Mining perimeters are delineated based on assay

results and gangue acid consumption calculations. Grade and tonnage evaluation reports and

loading plans outlining mining perimeters in the open-pit are then generated.

ORE TRACKING: Mining equipment implemented for ore extraction is optimal for selective

mining. Material from the pit is transported to various stockpile destinations. These include

high-grade (>13% Zn), medium-grade (9 - 13% Zn), low-grade (4 - 9% Zn) and marginal (1 -

4% Zn) ore stockpiles. Limestone (Ca >28%) from the pit is mined for plant acid

neutralisation purposes. Material with Zn <1% is designated for the waste stockpile.

Spotting and recording of ore types and tracking of tonnages and grades, according to

mining perimeters and loading plans, is undertaken in-pit by a dedicated team of geology

operators. A stockpile tallyman records material delivered to the correct stockpiles.

DATA MANAGEMENT: The ore tracking data are captured in a Tallies Database. The

database is important for calculating the grade and tonnage of material tipped onto the various

stockpiles. A well-managed tallies database is important for effective grade control and

blending. This allows for a continuous feed through elimination of fluctuations resulting in

homogenised feed grade.

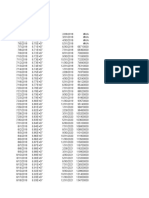

STOCKPILE MANAGEMENT AND BLENDING

Stockpile tipping and reclaiming faces are strictly monitored and surveyed (Figure 3). Ore is

reclaimed perpendicular to the tipping direction. The average grade of a particular stockpile

is the average grade of ore mined during a certain stockpile building period. Ore from the

stockpiles is blended to the required grade before feeding to a stacker-reclaimer for further

homogenisation.

The Southern African Institute of Mining and Metallurgy The Fourth Southern African Conference on

Base Metals

Gail Gnoinski

Page 107

Figure 3. Ore is tipped at stockpiles (high-, medium- and low- grades) from which it is

reclaimed and blended for the metallurgical plant.

4. CONCLUSIONS

The operational requirements at Skorpion mine are such that a complex system is in place that

is capable of a high degree of control and selectivity.

A dedicated team of grade control operators undertake blast hole sampling, spot grade

perimeters in the open-pit and control loading and dumping of material to and from low,

medium and high grade ore stockpile destinations.

Quality control ensures that grade control samples are representative and laboratory biases are

minimised. Laboratory assays are confirmed correct to within a defined degree of accuracy

and precision and the presence of carryover contamination between sample is monitored.

Mining equipment implemented for ore extraction is optimal for selective mining.

Disciplined blasting, loading and hauling of material from the pit to various destinations and

recordings in a well-managed tallies database are important for effective grade control and

blending. This allows for a continuous feed through elimination of fluctuations resulting in

homogenised feed grade.

4 to 5

5 to 6

6 to 7

7 to 8

8 to 9

9 to 10

10 to 11

11 to 12

12 to 13

13 to 14

14 to 15

15 to 20

20 to 30

> 30

% Zn % Zn

P

ile

3

:

>

1

3

%

Z

n

P

ile

3

:

>

1

3

%

Z

n

P

ile

2

:

>

9

%

<

1

3

%

Z

n

P

ile

2

:

>

9

%

<

1

3

%

Z

n

P

ile

1

: p

a

y

lim

it

t

o

9

%

Z

n

P

ile

1

: p

a

y

lim

it

t

o

9

%

Z

n

To the stacker-reclaimer

F

r

o

m

t

h

e

m

i

n

e

4 to 5

5 to 6

6 to 7

7 to 8

8 to 9

9 to 10

10 to 11

11 to 12

12 to 13

13 to 14

14 to 15

15 to 20

20 to 30

> 30

% Zn % Zn

P

ile

3

:

>

1

3

%

Z

n

P

ile

3

:

>

1

3

%

Z

n

P

ile

2

:

>

9

%

<

1

3

%

Z

n

P

ile

2

:

>

9

%

<

1

3

%

Z

n

P

ile

1

: p

a

y

lim

it

t

o

9

%

Z

n

P

ile

1

: p

a

y

lim

it

t

o

9

%

Z

n

To the stacker-reclaimer

4 to 5

5 to 6

6 to 7

7 to 8

8 to 9

9 to 10

10 to 11

11 to 12

12 to 13

13 to 14

14 to 15

15 to 20

20 to 30

> 30

% Zn % Zn

4 to 5

5 to 6

6 to 7

7 to 8

8 to 9

9 to 10

10 to 11

11 to 12

12 to 13

13 to 14

14 to 15

15 to 20

20 to 30

> 30

% Zn % Zn

P

ile

3

:

>

1

3

%

Z

n

P

ile

3

:

>

1

3

%

Z

n

P

ile

2

:

>

9

%

<

1

3

%

Z

n

P

ile

2

:

>

9

%

<

1

3

%

Z

n

P

ile

1

: p

a

y

lim

it

t

o

9

%

Z

n

P

ile

1

: p

a

y

lim

it

t

o

9

%

Z

n

To the stacker-reclaimer To the stacker-reclaimer

F

r

o

m

t

h

e

m

i

n

e

F

r

o

m

t

h

e

m

i

n

e

F

r

o

m

t

h

e

m

i

n

e

Stockpile System

The Southern African Institute of Mining and Metallurgy The Fourth Southern African Conference on

Base Metals

Gail Gnoinski

Page 108

5. REFERENCES

Borg, G., Krner, K., Buxton, M. Armstrong, R. and Merwe, S.W. (2003). Geology of the

Skorpion supregene zinc deposit, southern Namibia. Economic Geology, v. 98,

pp 749 771.

Hitzman, M.W., Reynolds, N. A., Sangster, D.F., Allen, C.R. and Carman, C.E.(2003).

Classification, genesis, and exploration guides for nonsulphide zinc deposits.

Economic Geology, v. 98, pp 685 714.

Gutzmer, J. (2006). Ar-Ar geochronology of Mn

4+

oxihydroxides from the Skorpion

Mine, Namibia implications for ore formation. Technical Report to Anglo

American Plc, Johannesburg, 23pp.

Potrebbero piacerti anche

- Black Mountain MiningDocumento13 pagineBlack Mountain MiningnylravatNessuna valutazione finora

- Technical Services Value Chain Report-1Documento8 pagineTechnical Services Value Chain Report-1Anesu ChimhowaNessuna valutazione finora

- Process Mineralogy As A Key Factor AffecDocumento10 pagineProcess Mineralogy As A Key Factor AffecJerry TshimonaNessuna valutazione finora

- JORC Table 1 Haile Underground Results Feb 2022Documento32 pagineJORC Table 1 Haile Underground Results Feb 2022djabiaNessuna valutazione finora

- Abzalov 2010 YandigradecontrolDocumento11 pagineAbzalov 2010 YandigradecontrolSebastian CastañoNessuna valutazione finora

- Analysis of the Effects of Grind Size on Copper Concentrate ProductionDocumento10 pagineAnalysis of the Effects of Grind Size on Copper Concentrate ProductionMichel M.Nessuna valutazione finora

- v112n04p295 Cyanidation of ReefDocumento6 paginev112n04p295 Cyanidation of ReefergfaradNessuna valutazione finora

- Dzvinamurungu Et Al (2020) - A Process Mineralogical Evaluation of Chromite at Nkomati Nickel Mine, Uitkomst Complex.Documento27 pagineDzvinamurungu Et Al (2020) - A Process Mineralogical Evaluation of Chromite at Nkomati Nickel Mine, Uitkomst Complex.Thomas DzvinamurunguNessuna valutazione finora

- Designing The Optimal Flotation Circuit - The Prominent Hill Case - Barns - DD - From Mill Ops 2010 PDFDocumento10 pagineDesigning The Optimal Flotation Circuit - The Prominent Hill Case - Barns - DD - From Mill Ops 2010 PDFkennedysupNessuna valutazione finora

- Desenho Da USINA NAMIBIADocumento10 pagineDesenho Da USINA NAMIBIApHNessuna valutazione finora

- The Use of Duplicates PDFDocumento10 pagineThe Use of Duplicates PDFLuis Katsumoto Huere AnayaNessuna valutazione finora

- InmaculadaDocumento62 pagineInmaculadaKevinEqNessuna valutazione finora

- GEOMETALURGY: THE KEY TO OPTIMIZING MINERAL RECOVERYDocumento30 pagineGEOMETALURGY: THE KEY TO OPTIMIZING MINERAL RECOVERYKevin MusterNessuna valutazione finora

- Recovery of iron values from iron ore slimes using VPHGMSDocumento6 pagineRecovery of iron values from iron ore slimes using VPHGMSravibelavadiNessuna valutazione finora

- Umar, - Abstrack IndexDocumento2 pagineUmar, - Abstrack IndexRiston Belman SidabutarNessuna valutazione finora

- A Mineralogical Investigation Into The Benefication of Rare EarthDocumento414 pagineA Mineralogical Investigation Into The Benefication of Rare EarthIslom MurodovNessuna valutazione finora

- 171Documento8 pagine171ravibelavadiNessuna valutazione finora

- ALS Metallurgy - Iron Ore Process DevelopmentDocumento8 pagineALS Metallurgy - Iron Ore Process DevelopmentDeepakKumarGoraiNessuna valutazione finora

- Building A Geometallurgical Model For Orapa Diamond Mine, BotswanaDocumento3 pagineBuilding A Geometallurgical Model For Orapa Diamond Mine, BotswanagggNessuna valutazione finora

- Tinashe Tagarira-Eureka Gold Mine-Geology ReportDocumento11 pagineTinashe Tagarira-Eureka Gold Mine-Geology Reporttinashe tagariraNessuna valutazione finora

- Vinayak R V Synbpr (8519) PDFDocumento22 pagineVinayak R V Synbpr (8519) PDFravibelavadiNessuna valutazione finora

- Channel Sampling: Channel Sampling Is Laborious, Tedious, Time Consuming and ExpensiveDocumento7 pagineChannel Sampling: Channel Sampling Is Laborious, Tedious, Time Consuming and ExpensivelovelyNessuna valutazione finora

- Use of Geometallurgy To Predict Tailing Leach Acid Consumption at Olimpic DamDocumento10 pagineUse of Geometallurgy To Predict Tailing Leach Acid Consumption at Olimpic DamWiku PadmonoboNessuna valutazione finora

- Quantitative Clay Mineralogy For A Calcrete-Hosted Uranium Deposit - Innovative Application of Existing Technology On An Unprecedented ScaleDocumento8 pagineQuantitative Clay Mineralogy For A Calcrete-Hosted Uranium Deposit - Innovative Application of Existing Technology On An Unprecedented ScaleAldoNessuna valutazione finora

- Geometallurgical Application in An Underground Gold OperationDocumento10 pagineGeometallurgical Application in An Underground Gold OperationremarkNessuna valutazione finora

- Mineral Resource and Ore Reserve Estimation: Second EditionDocumento14 pagineMineral Resource and Ore Reserve Estimation: Second EditionRenzo YaringañoNessuna valutazione finora

- Monitoreo de Mineral en Fajas TransportadorasDocumento6 pagineMonitoreo de Mineral en Fajas TransportadorasSonlange Shantall CallerNessuna valutazione finora

- Effective Beneficiation of Low Grade Iron Ore Through Jigging OperationDocumento11 pagineEffective Beneficiation of Low Grade Iron Ore Through Jigging OperationOana MovileanuNessuna valutazione finora

- Prieska Metallurgical Flowsheet Test Work SuccessfulDocumento7 paginePrieska Metallurgical Flowsheet Test Work SuccessfulCamila Ordenez OlivaresNessuna valutazione finora

- Texto 1Documento4 pagineTexto 1Valentina ZunigaNessuna valutazione finora

- Interpretation of Flotation Data For The Design of Process PlantsDocumento28 pagineInterpretation of Flotation Data For The Design of Process PlantshNessuna valutazione finora

- Cudeco 5 August 2013Documento10 pagineCudeco 5 August 2013ga6ba5Nessuna valutazione finora

- Draft Eis Jervois Base Metal Appendix C12 Tailings Storage Facility Design ConceptDocumento7 pagineDraft Eis Jervois Base Metal Appendix C12 Tailings Storage Facility Design ConceptLung'waga Nsab'o NkuneNessuna valutazione finora

- Ambuja - Maratha Cement WorksDocumento8 pagineAmbuja - Maratha Cement WorksNihar Ranjan TripathyNessuna valutazione finora

- A Process Mineralogy Approach To Optimize Molybdeniteflotation in CopperDocumento10 pagineA Process Mineralogy Approach To Optimize Molybdeniteflotation in CopperCarlos LopezNessuna valutazione finora

- Blast Fragmentation Optimization at Tarkwa Gold Mine Using 6 Sigma Methodologies. Miss Alexandra Amiel Goldfields Ghana LTD Tarkwa Gold Mine - UsarDocumento24 pagineBlast Fragmentation Optimization at Tarkwa Gold Mine Using 6 Sigma Methodologies. Miss Alexandra Amiel Goldfields Ghana LTD Tarkwa Gold Mine - UsarFabio OliveiraNessuna valutazione finora

- Lateritic Deposits Estimation GuidelinesDocumento4 pagineLateritic Deposits Estimation GuidelinesFerdinand SiahaanNessuna valutazione finora

- Chapter - 6 Conclusions and RecommendationsDocumento2 pagineChapter - 6 Conclusions and RecommendationsNg MeriedNessuna valutazione finora

- Spe 164695 MsDocumento6 pagineSpe 164695 MsMnesNessuna valutazione finora

- Niger Delta Case StudyDocumento6 pagineNiger Delta Case Studymmmd.krmv.00Nessuna valutazione finora

- Bamber 2004Documento12 pagineBamber 2004manuelgltNessuna valutazione finora

- IPTC-18377-MS Mitigating Shale Drilling Problems Through Comprehensive Understanding of Shale FormationsDocumento10 pagineIPTC-18377-MS Mitigating Shale Drilling Problems Through Comprehensive Understanding of Shale FormationsSyafiqNessuna valutazione finora

- Sample Mine EssayDocumento3 pagineSample Mine EssayHeli Senn VentenillaNessuna valutazione finora

- Exploiting The Malleability of Gold For Placer Concentrate Extractionand RecoveryDocumento3 pagineExploiting The Malleability of Gold For Placer Concentrate Extractionand RecoverypHNessuna valutazione finora

- El Efecto de Las Condiciones de Molienda en La Flotación de Una Mena de Cobre SulfuroDocumento4 pagineEl Efecto de Las Condiciones de Molienda en La Flotación de Una Mena de Cobre SulfuroClaudio Galleguillos BeniNessuna valutazione finora

- Characterization of Refractory Behaviour of Complex Gold/silver Ore by Diagnostic LeachingDocumento7 pagineCharacterization of Refractory Behaviour of Complex Gold/silver Ore by Diagnostic Leachingdavid mNessuna valutazione finora

- Goode 1993 (Tails Reclaim)Documento16 pagineGoode 1993 (Tails Reclaim)john_goodeNessuna valutazione finora

- Kinross Gold CorporationDocumento80 pagineKinross Gold CorporationSansão FofeteNessuna valutazione finora

- A Simple and Accurate Method For Ore Reserve Estimation in SLC MinesDocumento15 pagineA Simple and Accurate Method For Ore Reserve Estimation in SLC MinesRalain NgatchaNessuna valutazione finora

- Maximising The Value of Gold Diagnostic LeachingDocumento12 pagineMaximising The Value of Gold Diagnostic LeachingAldoNessuna valutazione finora

- Assignment 1Documento16 pagineAssignment 1i7ech ArtsNessuna valutazione finora

- Reduce The Iron Content in Egyptian Feldspar Ore of Wadi Zirib For Industrial ApplicationsDocumento10 pagineReduce The Iron Content in Egyptian Feldspar Ore of Wadi Zirib For Industrial ApplicationsSoloChicas VentasVallenarNessuna valutazione finora

- Grade and Product Quality of Mineral Sands Using MicroCTDocumento11 pagineGrade and Product Quality of Mineral Sands Using MicroCTabrahamsrs72Nessuna valutazione finora

- Minerals A Process Mineralogical Evaluation of Chromite at The Nkomati Nickel Mine, Uitkomst Complex, South AfricaDocumento28 pagineMinerals A Process Mineralogical Evaluation of Chromite at The Nkomati Nickel Mine, Uitkomst Complex, South AfricaSaghar FarajzadehNessuna valutazione finora

- MPD Assignment 1 R1813370JDocumento8 pagineMPD Assignment 1 R1813370JPanashe kapesiNessuna valutazione finora

- SGS MIN 2001 04 Cyanide Management by SART en 11 09Documento7 pagineSGS MIN 2001 04 Cyanide Management by SART en 11 09Jon CastilloNessuna valutazione finora

- Effects of Varied Process Parameters On Froth Flotation Efficiency: A Case Study of Itakpe Iron OreDocumento9 pagineEffects of Varied Process Parameters On Froth Flotation Efficiency: A Case Study of Itakpe Iron Oresamuel sanchezNessuna valutazione finora

- G-Resources (Martabe Project)Documento11 pagineG-Resources (Martabe Project)Zamri MahfudzNessuna valutazione finora

- MDSW Gujarat03Documento13 pagineMDSW Gujarat03miningnova1Nessuna valutazione finora

- CAPITULO1Documento132 pagineCAPITULO1Christian CRNessuna valutazione finora

- Packer Test TemplateDocumento3 paginePacker Test TemplateChristian CR100% (1)

- Hole Coordinates East North Elevation Azimuth (N°)Documento13 pagineHole Coordinates East North Elevation Azimuth (N°)Christian CRNessuna valutazione finora

- Drill Hole Data RecordsDocumento37 pagineDrill Hole Data RecordsChristian CRNessuna valutazione finora

- Curva Caract.Documento1 paginaCurva Caract.Christian CRNessuna valutazione finora

- Analysis of product prices and IDs from 2012-2015Documento1 paginaAnalysis of product prices and IDs from 2012-2015Christian CRNessuna valutazione finora

- SurferDocumento1 paginaSurferChristian CRNessuna valutazione finora

- 8001-3 LogView Software PDFDocumento2 pagine8001-3 LogView Software PDFChristian CRNessuna valutazione finora

- 8001-3 LogViewDocumento33 pagine8001-3 LogViewChristian CRNessuna valutazione finora

- 8001-3 LogViewDocumento33 pagine8001-3 LogViewChristian CRNessuna valutazione finora

- Minesight Interactive Planner: Calculate Reserves and Generate PlansDocumento1 paginaMinesight Interactive Planner: Calculate Reserves and Generate PlansChristian CRNessuna valutazione finora

- Procedimiento PitresDocumento16 pagineProcedimiento PitresChristian CRNessuna valutazione finora

- Blending Case Study PDFDocumento10 pagineBlending Case Study PDFChristian CRNessuna valutazione finora

- VariographyDocumento8 pagineVariographyChristian CRNessuna valutazione finora

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocumento1 paginaYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterChristian CRNessuna valutazione finora

- ISATIS 2013 Technical ReferencesDocumento260 pagineISATIS 2013 Technical ReferencesChristian CR100% (1)

- Modelamiento Implicito - VULCANDocumento15 pagineModelamiento Implicito - VULCANChristian CRNessuna valutazione finora

- Reserves Reporting Using PITRES1Documento11 pagineReserves Reporting Using PITRES1Javier Aguirre BarahonaNessuna valutazione finora

- Materialdeestudioparteiidiap67-100Documento17 pagineMaterialdeestudioparteiidiap67-100Christian CRNessuna valutazione finora

- Romana Slope Mass Rating PDFDocumento45 pagineRomana Slope Mass Rating PDFzzza100% (5)

- Blending Case Study PDFDocumento10 pagineBlending Case Study PDFChristian CRNessuna valutazione finora

- A Pit Sequence Optimized With Multi-PitDocumento16 pagineA Pit Sequence Optimized With Multi-PitHeber Bladimir Cosme TorresNessuna valutazione finora

- CreepDocumento2 pagineCreepChristian CRNessuna valutazione finora

- ISATIS 2013 Technical ReferencesDocumento260 pagineISATIS 2013 Technical ReferencesChristian CR100% (1)

- DishwallaDocumento7 pagineDishwallaChristian CRNessuna valutazione finora

- Ejercicio I Estadísticas DescriptivasDocumento4 pagineEjercicio I Estadísticas DescriptivasChristian CRNessuna valutazione finora

- Pit Tutorial LayoutDocumento1 paginaPit Tutorial LayoutChristian CRNessuna valutazione finora

- MS2 - Ref Phase2 DISPATCH Real-Time GuideDocumento4 pagineMS2 - Ref Phase2 DISPATCH Real-Time GuideChristian CRNessuna valutazione finora

- Resource Evaluation Week 4Documento87 pagineResource Evaluation Week 4Mon RonquilloNessuna valutazione finora

- Special ProcessDocumento12 pagineSpecial ProcesshcbbNessuna valutazione finora

- Beyond The Feasibility StudyDocumento4 pagineBeyond The Feasibility StudySubrato GhoshNessuna valutazione finora

- BHP Billiton PLC: Company ReportDocumento24 pagineBHP Billiton PLC: Company ReportSamuel DemonsaniNessuna valutazione finora

- Los Calatos 6.5 MtpaDocumento78 pagineLos Calatos 6.5 MtpaCARLOS OSIEL SEBASTIÁN VALDÉSNessuna valutazione finora

- Minerals 11 01178Documento16 pagineMinerals 11 01178Erwin SetiawanNessuna valutazione finora

- Wear and Friction Effects On Energy Consumption in The Mining IndustryDocumento101 pagineWear and Friction Effects On Energy Consumption in The Mining IndustryAhmed IdiNessuna valutazione finora

- 02 Jurnal IMJ June 2008Documento53 pagine02 Jurnal IMJ June 2008Laura JohnsonNessuna valutazione finora

- Mineral Resources PDFDocumento26 pagineMineral Resources PDFanuj sharmaNessuna valutazione finora

- Harmony Gold Mining Co. LtdDocumento3 pagineHarmony Gold Mining Co. LtdJohn FassNessuna valutazione finora

- Geonesis JanuaryDocumento11 pagineGeonesis Januaryachint GoelNessuna valutazione finora

- The Secret of The Machines - NotesDocumento5 pagineThe Secret of The Machines - NotesThe world Of HarshNessuna valutazione finora

- Minerals 10 00351 PDFDocumento21 pagineMinerals 10 00351 PDFJustin Brian MariñasNessuna valutazione finora

- GIEX - PDC Poster PaperDocumento1 paginaGIEX - PDC Poster Papergiex7198Nessuna valutazione finora

- Thermal Conductivity Guide - 40 Materials & GasesDocumento10 pagineThermal Conductivity Guide - 40 Materials & GasesrickyNessuna valutazione finora

- The Mining and Extractive IndDocumento9 pagineThe Mining and Extractive IndHappyNessuna valutazione finora

- Metals Through History and Their UsesDocumento11 pagineMetals Through History and Their UsesCatherine Lai100% (3)

- Myb1 2016 BauxiDocumento15 pagineMyb1 2016 BauxiAgus TriyonoNessuna valutazione finora

- 2008-Africa Research Bulletin - Economic, Financial and Technical SeriesDocumento1 pagina2008-Africa Research Bulletin - Economic, Financial and Technical SeriesManoj GuptaNessuna valutazione finora

- CHAPTER 1 ShssDocumento10 pagineCHAPTER 1 Shssaccventure5Nessuna valutazione finora

- Freeport, Tsingshan to sign copper smelter deal next weekDocumento2 pagineFreeport, Tsingshan to sign copper smelter deal next weekFauzi BahananNessuna valutazione finora

- J1300 Centrifugal Jig DS 2012-09-MTDocumento2 pagineJ1300 Centrifugal Jig DS 2012-09-MTcarlos hurtadoNessuna valutazione finora

- Oil & Gas Field Services GuideDocumento25 pagineOil & Gas Field Services Guidemahfoos aliNessuna valutazione finora

- SUPASIM A Flotation Plant Design and AnaDocumento7 pagineSUPASIM A Flotation Plant Design and Anathethtet28Nessuna valutazione finora

- Advances in HydrometallurgyDocumento190 pagineAdvances in HydrometallurgyRicardo J. Carreño100% (1)

- Timeline of Modern DiscoviriesDocumento3 pagineTimeline of Modern DiscoviriesRico R. CandelarioNessuna valutazione finora

- c-20 Cobalt Layering Flyer 7-16 Web PDFDocumento2 paginec-20 Cobalt Layering Flyer 7-16 Web PDFJeanie TamNessuna valutazione finora

- Metallurgy in Ancient India and JharkhandDocumento5 pagineMetallurgy in Ancient India and JharkhandInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- CIP 2014 Vol 2 Final Accessible PDFDocumento170 pagineCIP 2014 Vol 2 Final Accessible PDFcarlos0s0nchez0aliagNessuna valutazione finora

- E. Common MineralsDocumento19 pagineE. Common MineralsWilma Marquez HabocNessuna valutazione finora