Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Naviguard ME - English (Uk) - Issued.06.12.2007

Caricato da

Mohamed FaragDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Naviguard ME - English (Uk) - Issued.06.12.2007

Caricato da

Mohamed FaragCopyright:

Formati disponibili

Naviguard ME Page 1 of 3

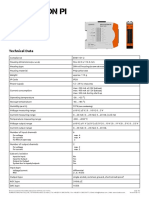

Technical Data

Naviguard ME

Product description

Naviguard ME is a solvent-less two-pack epoxy coating.

Recommended use

A high build, high solids coating for steel subject to extreme atmospheric or mechanical exposure. May be used as a

Tank/Pipe Lining.

Film thickness and spreading rate

Minimum Maximum Typical

Film thickness, dry (m) 200 500 300

Film thickness, wet (m) 205 510 305

Theoretical spreading rate (m/l) 4,9 1,96 3,26

Physical properties

Colour Red, White

Solids (vol %)* 98 2

Flash point 76C 2 (Setaflash)

Gloss Glossy

Gloss retention Fair

Water resistance Excellent

Abrasion resistance Excellent

Solvent resistance Excellent

Chemical resistance Excellent

Flexibility Fair

Compatibility with

cathodic protection

Excellent

*Measured according to ISO 3233:1998 (E)

Surface preparation

All surfaces should be clean, dry and free from contamination. The surface should be assessed and treated in

accordance with ISO 8504.

Bare steel

Cleanliness: Blast cleaning to Sa 2 (ISO 8501-1:2007). Roughness: using abrasives suitable to achieve grade Fine to

Medium G (30-85 m, Ry5) (ISO 8503-2)

Coated surfaces

Clean, dry and undamaged compatible primer. Contact your local Jotun office for more information.

Other surfaces

The coating may be used on other substrates. Please contact your local Jotun office for more information.

Naviguard ME Page 2 of 3

Condition during application

The temperature of the substrate should be minimum 10C and at least 3C above the dew point of the air,

temperature and relative humidity measured in the vicinity of the substrate. The coating should not be exposed to oil,

chemicals or mechanical stress until fully cured.

Application methods

Spray Use airless spray

Brush Recommended for stripe coating and small areas, care must be taken to achieve the specified dry

film thickness.

Application data

Mixing ratio (volume) 3 parts Comp. A (base) to be mixed thoroughly with 1 part Comp. B (curing agent)

Pot life (23C) 50 minutes (Reduced at higher temperature.)

Thinner/Cleaner Jotun Thinner No. 17

Guiding data airless spray

Pressure at nozzle 20 MPa (200 kp/cm, 2800 psi)

Nozzle tip 0.53-0.79 mm (0.021-0.031")

Spray angle 40-80

Filter Check to ensure that filters are clean.

Drying time

Drying times are generally related to air circulation, temperature, film thickness and number of coats, and will be

affected correspondingly. The figures given in the table are typical with:

* Good ventilation (Outdoor exposure or free circulation of air)

* Typical film thickness

* One coat on top of inert substrate

Substrate temperature 10C 23C 40C

Surface dry 8 h 4 h 2 h

Through dry 20 h 10 h 3 h

Cured 14 d 7 d 2.5 d

Dry to recoat, minimum 20 h 10 h 3 h

Dry to recoat, maximum

1

5 d 3 d 2 d

1. The surface must be free from any chalking or any other contamination and if necessary, sufficiently roughened

prior to application.

The given data must be considered as guidelines only. The actual drying time/times before recoating may be shorter or

longer, depending on film thickness, ventilation, humidity, underlying paint system, requirement for early handling and

mechanical strength etc. A complete system can be described on a system sheet, where all parameters and special

conditions could be included.

Typical paint system

On Sa 2:

Naviguard ME 1 - 2 x 300 m (Dry Film Thickness)

Naviguard ME Page 3 of 3

Other systems may be specified, depending on area of use

Storage

The product must be stored in accordance with national regulations. Storage conditions are to keep the containers in a

dry, cool, well ventilated space and away from source of heat and ignition. Containers must be kept tightly closed.

Handling

Handle with care. Stir well before use.

Packing size

12 l Comp. A (base) and 4 l Comp. B (curing agent)

Packing may vary from country to country according to local requirements.

Health and safety

Please observe the precautionary notices displayed on the container. Use under well ventilated conditions. Do not

breathe or inhale mist. Avoid skin contact. Spillage on the skin should immediately be removed with suitable cleanser,

soap and water. Eyes should be well flushed with water and medical attention sought immediately.

For detailed information on the health and safety hazards and precautions for use of this product, we refer to

the Material Safety Data Sheet.

DISCLAIMER

The information in this data sheet is given to the best of our knowledge based on laboratory testing and practical

experience. However, as the product is often used under conditions beyond our control, we cannot guarantee anything

but the quality of the product itself. We reserve the right to change the given data without notice.

Jotun is a World Wide company with factories, sales offices and stocks in more than 50 countries. For your nearest local Jotun address

please contact the nearest regional office or visit our website at www.jotun.com

ISSUED 6 DECEMBER 2007 BY JOTUN

THIS DATA SHEET SUPERSEDES THOSE PREVIOUSLY ISSUED

Potrebbero piacerti anche

- Penguard Stayer - English (Uk) - Issued.06.12.2007Documento3 paginePenguard Stayer - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Coal Tar Epoxy 83 - English (Uk) - Issued.06.12.2007Documento3 pagineCoal Tar Epoxy 83 - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Marathon XHB - English (Uk) - Issued.06.12.2007Documento3 pagineMarathon XHB - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Marathon IQ GF - English (Uk) - Issued.06.12.2007Documento3 pagineMarathon IQ GF - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Penguard Special - English (Uk) - Issued.06.12.2007Documento3 paginePenguard Special - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Tankguard ARDocumento4 pagineTankguard ARSherif Abdelhameed100% (1)

- Hardtop HB - English (Uk) - Issued.06.12.2007Documento3 pagineHardtop HB - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Alkydprimer - English (Uk) - Issued.06.12.2007Documento3 pagineAlkydprimer - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Penguard FC - English (Uk) - Issued.06.12.2007Documento4 paginePenguard FC - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Penguard Midcoat - English (Uk) - Issued.26.11.2010Documento4 paginePenguard Midcoat - English (Uk) - Issued.26.11.2010Faisal NismarNessuna valutazione finora

- Vinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Documento3 pagineVinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Mohamed FaragNessuna valutazione finora

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Documento3 paginePenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Chemtech GM Clear - English (Uk) - Issued.06.12.2007Documento3 pagineChemtech GM Clear - English (Uk) - Issued.06.12.2007Mohamed Farag50% (2)

- Penguard HB: Technical DataDocumento4 paginePenguard HB: Technical DataStephen MalobaNessuna valutazione finora

- TDS - Penguard Express ZP - English (Uk) - Issued.26.11.2010Documento4 pagineTDS - Penguard Express ZP - English (Uk) - Issued.26.11.2010Anindya Aulia PratiwiNessuna valutazione finora

- Safeguard Universal ES - English (Uk) - Issued.06.12.2Documento3 pagineSafeguard Universal ES - English (Uk) - Issued.06.12.2Mohamed FaragNessuna valutazione finora

- TDS - Barrier 90 - English (Uk) - Issued.05.10.2011Documento4 pagineTDS - Barrier 90 - English (Uk) - Issued.05.10.2011ansarALLAAHNessuna valutazione finora

- TDS - Jotacote 410 - Issued.06.12.2007 - 2Documento3 pagineTDS - Jotacote 410 - Issued.06.12.2007 - 2musaismail8863Nessuna valutazione finora

- Barrier ZEP - English (Uk) - Issued.06.12.2007Documento3 pagineBarrier ZEP - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Jotun-Penguard Primer - Tech DataDocumento4 pagineJotun-Penguard Primer - Tech Dataanwarali1975Nessuna valutazione finora

- Jotafloor Topcoat - English (Uk) - Issued.06.12.2007Documento4 pagineJotafloor Topcoat - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Jotaguard 630Documento4 pagineJotaguard 630Christine HermawanNessuna valutazione finora

- Durosan 02 Matt Datasheet " AzadJotun"Documento3 pagineDurosan 02 Matt Datasheet " AzadJotun"AzadAhmadNessuna valutazione finora

- Barrier ZepDocumento3 pagineBarrier ZepJairo Gómez SánchezNessuna valutazione finora

- JOTUN DECO Jotashield Extreme MattDocumento3 pagineJOTUN DECO Jotashield Extreme MattWeasley RonNessuna valutazione finora

- Penguard Primer Datasheet " Azadjotun"Documento3 paginePenguard Primer Datasheet " Azadjotun"AzadAhmadNessuna valutazione finora

- Tds - Penguard Express - English (Uk) - Issued.24.05Documento4 pagineTds - Penguard Express - English (Uk) - Issued.24.05wey5316Nessuna valutazione finora

- TDS+ +Gardex+Primer+ +english+ (Uk) + +issued.12.03.2009Documento3 pagineTDS+ +Gardex+Primer+ +english+ (Uk) + +issued.12.03.2009mas danNessuna valutazione finora

- JotunBitum Ballastic BlackDocumento3 pagineJotunBitum Ballastic BlackMekhmanNessuna valutazione finora

- Jotasealer 07Documento3 pagineJotasealer 07Denden DermawanNessuna valutazione finora

- Penguard Primer PDFDocumento4 paginePenguard Primer PDFheri_prasetyadi7715Nessuna valutazione finora

- TDS - Alkyd Topcoat - English (Uk) - Issued.28.02.2011 JotunDocumento3 pagineTDS - Alkyd Topcoat - English (Uk) - Issued.28.02.2011 JotunmanbkkNessuna valutazione finora

- J Primer TdsDocumento3 pagineJ Primer Tdswey5316Nessuna valutazione finora

- J Stayer TdsDocumento3 pagineJ Stayer Tdswey5316Nessuna valutazione finora

- Jotafloor Sealer - English (Uk) - Issued.06.12.2007Documento3 pagineJotafloor Sealer - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- TDS - Jotashield - English (Uk) - Issued.06.12.2007Documento3 pagineTDS - Jotashield - English (Uk) - Issued.06.12.2007Wisnu SegaraNessuna valutazione finora

- Barrier 90 - English (Uk) - Issued.06.12.2007Documento3 pagineBarrier 90 - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Penguard HB - English (Uk) - Issued.06.12.2007Documento4 paginePenguard HB - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Futura As - English (Uk) - Issued.06.12.2007Documento3 pagineFutura As - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Dura Mastic DatasheetDocumento4 pagineDura Mastic DatasheetBhisamS SallehNessuna valutazione finora

- Hardtop AsDocumento4 pagineHardtop AsulusoynNessuna valutazione finora

- Aluflex - English (Uk) - Issued.06.12.2007Documento3 pagineAluflex - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- JOTUN DECO Jotashield Extreme SilkDocumento3 pagineJOTUN DECO Jotashield Extreme SilkhemajsuryaNessuna valutazione finora

- Submarine Filler - English (Uk) - Issued.06.12.2007Documento4 pagineSubmarine Filler - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- TDS SAFEGUARD EnglishDocumento4 pagineTDS SAFEGUARD EnglishthirdNessuna valutazione finora

- Hardtop Flexi - English (Uk) - Issued.06.12.2007Documento3 pagineHardtop Flexi - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Tds - Penguard Classic - English - Issued.01.03.2005Documento4 pagineTds - Penguard Classic - English - Issued.01.03.2005wey5316Nessuna valutazione finora

- Megayacht Imperial Antifouling DataDocumento3 pagineMegayacht Imperial Antifouling DatakormatekNessuna valutazione finora

- DatasheetDocumento3 pagineDatasheetAbu Hanif Al KabumainyNessuna valutazione finora

- Tds - Penguard Classic ZP - English (Uk) - Issued.19Documento4 pagineTds - Penguard Classic ZP - English (Uk) - Issued.19wey5316Nessuna valutazione finora

- Jotafloor Solvent Free Primer - English (Uk) - Issued.Documento3 pagineJotafloor Solvent Free Primer - English (Uk) - Issued.Mohamed FaragNessuna valutazione finora

- Futura Matt - English (Uk) - Issued.06.12.2007Documento3 pagineFutura Matt - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDa EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesValutazione: 3.5 su 5 stelle3.5/5 (3)

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDa EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNessuna valutazione finora

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionDa EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNessuna valutazione finora

- Detailers Dictionary Volume 2: The Industry StandardDa EverandDetailers Dictionary Volume 2: The Industry StandardNessuna valutazione finora

- Handbook of Seal Integrity in the Food IndustryDa EverandHandbook of Seal Integrity in the Food IndustryNessuna valutazione finora

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentDa EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentValutazione: 4.5 su 5 stelle4.5/5 (3)

- Penguard FC - English (Uk) - Issued.06.12.2007Documento4 paginePenguard FC - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Astm A488Documento1 paginaAstm A488Mohamed FaragNessuna valutazione finora

- Gupco Project / Sidki P/L Project: Joint RegisterDocumento2 pagineGupco Project / Sidki P/L Project: Joint RegisterMohamed FaragNessuna valutazione finora

- Vinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Documento3 pagineVinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Mohamed FaragNessuna valutazione finora

- Bengalac Matt - English (Uk) - Issued.06.12.2007Documento3 pagineBengalac Matt - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Jotun Thinner No. 7 - English (Uk) - Issued.06.12.2007Documento2 pagineJotun Thinner No. 7 - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Jotafloor Solvent Free Primer - English (Uk) - Issued.Documento3 pagineJotafloor Solvent Free Primer - English (Uk) - Issued.Mohamed FaragNessuna valutazione finora

- Jotun Thinner No. 7 - English (Uk) - Issued.06.12.2007Documento2 pagineJotun Thinner No. 7 - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Futura Matt - English (Uk) - Issued.06.12.2007Documento3 pagineFutura Matt - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Marathon - English (Uk) - Issued.06.12.2007Documento5 pagineMarathon - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Jotun Thinner No. 2 - English (Uk) - Issued.06.12.2007Documento3 pagineJotun Thinner No. 2 - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Jotatemp 650 - English (Us) - Issued.11.14.2008Documento4 pagineJotatemp 650 - English (Us) - Issued.11.14.2008Mohamed FaragNessuna valutazione finora

- Spontan Varnish - English (Uk) - Issued.06.12.2007Documento3 pagineSpontan Varnish - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Jotashine - English (Uk) - Issued.06.12.2007Documento3 pagineJotashine - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Copper Alloys For Marine EnvironmentsDocumento32 pagineCopper Alloys For Marine EnvironmentsMohamed FaragNessuna valutazione finora

- Ansi B 16.11Documento34 pagineAnsi B 16.11Elangovan ArumugamNessuna valutazione finora

- Copper Alloys For Marine EnvironmentsDocumento32 pagineCopper Alloys For Marine EnvironmentsMohamed FaragNessuna valutazione finora

- Jotaguard Special 90 - English (Uk) - Issued.06.12.200Documento3 pagineJotaguard Special 90 - English (Uk) - Issued.06.12.200Mohamed FaragNessuna valutazione finora

- Safeguard Universal ES - English (Uk) - Issued.06.12.2Documento3 pagineSafeguard Universal ES - English (Uk) - Issued.06.12.2Mohamed FaragNessuna valutazione finora

- Balloxy HB Light - English (Uk) - Issued.27.06.2008Documento4 pagineBalloxy HB Light - English (Uk) - Issued.27.06.2008Mohamed FaragNessuna valutazione finora

- Jotafloor Screed Primer - English (Uk) - Issued.06.12.Documento3 pagineJotafloor Screed Primer - English (Uk) - Issued.06.12.Mohamed FaragNessuna valutazione finora

- Se-Lett - English (Uk) - Issued.06.12.2007Documento3 pagineSe-Lett - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- SeaQuantum Classic - English (Uk) - Issued.06.12.2007Documento3 pagineSeaQuantum Classic - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Jotun Thinner No. 25 - English (Uk) - Issued.06.12.200Documento2 pagineJotun Thinner No. 25 - English (Uk) - Issued.06.12.200Mohamed FaragNessuna valutazione finora

- Chemclear - English (Uk) - Issued.10.01.2008Documento3 pagineChemclear - English (Uk) - Issued.10.01.2008Mohamed FaragNessuna valutazione finora

- Jotafloor Topcoat - English (Uk) - Issued.06.12.2007Documento4 pagineJotafloor Topcoat - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Pilot II - English (Uk) - Issued.06.12.2007Documento4 paginePilot II - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Infineon Bar64series Ds v01 01 enDocumento15 pagineInfineon Bar64series Ds v01 01 enAbohicham AbhNessuna valutazione finora

- Tps 61197Documento22 pagineTps 61197Sahaly RandNessuna valutazione finora

- How To Adjust The Idle Mixture On Holley CarbsDocumento4 pagineHow To Adjust The Idle Mixture On Holley CarbsIsaias PrestesNessuna valutazione finora

- Joint and Combined Variation: Round Your Answer To Two Decimal PlacesDocumento2 pagineJoint and Combined Variation: Round Your Answer To Two Decimal PlacesMarianne Peligro Marasigan0% (1)

- PW5 Basic Double Busbar Dis 20Documento12 paginePW5 Basic Double Busbar Dis 20Shanthiyaah ArumugamNessuna valutazione finora

- Thomson Chasis ICC17Documento52 pagineThomson Chasis ICC17videosonNessuna valutazione finora

- Lecture-14 Sheet Metal Forming ProcessesDocumento34 pagineLecture-14 Sheet Metal Forming ProcessesDida KhalingNessuna valutazione finora

- Format Final EIM 7 8 Q0Documento7 pagineFormat Final EIM 7 8 Q0herbert rebloraNessuna valutazione finora

- Open Channel FlowDocumento14 pagineOpen Channel FlowHijab Renjana100% (1)

- Ips e PR 850 PDFDocumento73 pagineIps e PR 850 PDFdeyanshu7Nessuna valutazione finora

- Sikadur®-42 PC: Product Data SheetDocumento4 pagineSikadur®-42 PC: Product Data SheetMohammed AwfNessuna valutazione finora

- Bmaxx 4400 JindalDocumento76 pagineBmaxx 4400 JindalRakesh Karan Singh0% (1)

- UT Dallas Syllabus For Ee3350.001 05s Taught by P Rajasekaran (pkr021000)Documento2 pagineUT Dallas Syllabus For Ee3350.001 05s Taught by P Rajasekaran (pkr021000)UT Dallas Provost's Technology GroupNessuna valutazione finora

- C Library Math.h Functions - GeeksforGeeksDocumento11 pagineC Library Math.h Functions - GeeksforGeeksSoumadip Banerjee100% (1)

- DIN - EN-571-1 Penetrent-TestingDocumento18 pagineDIN - EN-571-1 Penetrent-TestingraldelgadomaNessuna valutazione finora

- DM Automatic Irrigation System SpecsDocumento56 pagineDM Automatic Irrigation System SpecsSarfraz AhmadNessuna valutazione finora

- Highway Planning Manual Volume 8 PDFDocumento72 pagineHighway Planning Manual Volume 8 PDFHanz Maca-ayanNessuna valutazione finora

- C - Prog AssDocumento29 pagineC - Prog Assgal_farsyNessuna valutazione finora

- Creating A Use Case Diagram in Rational RoseDocumento2 pagineCreating A Use Case Diagram in Rational RoseRaguramrecNessuna valutazione finora

- 2N Lift1: Brief ManualDocumento12 pagine2N Lift1: Brief ManualMartijnMartensNessuna valutazione finora

- RF Single Site Verification Methodology: Test Tools DescriptionDocumento11 pagineRF Single Site Verification Methodology: Test Tools DescriptionroniNessuna valutazione finora

- Datasheet RevPi AIODocumento2 pagineDatasheet RevPi AIOsebadansNessuna valutazione finora

- Advanced Placement Chemistry: 1991 Free Response QuestionsDocumento15 pagineAdvanced Placement Chemistry: 1991 Free Response QuestionsManasNessuna valutazione finora

- Experiment # 3 Conservation of EnergyDocumento5 pagineExperiment # 3 Conservation of EnergyellatsNessuna valutazione finora

- Simatic Net CP 343-1Documento56 pagineSimatic Net CP 343-1AlexSotelo100% (1)

- Manual Book 500XDocumento72 pagineManual Book 500XDadung PrakosoNessuna valutazione finora

- Getting Started With Openfoam: Eric PatersonDocumento41 pagineGetting Started With Openfoam: Eric PatersonReza Nazari0% (1)

- Rigging Guide 2008Documento222 pagineRigging Guide 2008Alex1Nessuna valutazione finora

- 811 Brochure GrisgoldDocumento20 pagine811 Brochure GrisgoldEmerson RuizNessuna valutazione finora

- Hydro Static Interlocks and Pins in Lifeboat Hook SystemsDocumento2 pagineHydro Static Interlocks and Pins in Lifeboat Hook Systemsdwad82Nessuna valutazione finora