Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Column Base

Caricato da

Lie Fang0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

74 visualizzazioni4 pagineHow to calculate a base plate

Copyright

© © All Rights Reserved

Formati disponibili

XLS, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoHow to calculate a base plate

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

74 visualizzazioni4 pagineColumn Base

Caricato da

Lie FangHow to calculate a base plate

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

Column Base Worked Example

Taken from "Joints in Steel Construction Moment Connections"

2 x 4 M 30 L1

Mmax = 600 kNm 75

Pmax = 400 kN 150

Pmin = 300 kN bp 150

V = 75 kN 150

hp = 775 mm 75

bp = 480 mm

fcu = 40 MPa 75 450

L1 = 90 mm

sw = 10 mm hp

h = 700 mm

e = 82 mm

py = 325 N/mm

L anchor = 450 mm

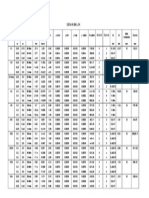

I Moment plus maximum axial force

Check whether there is tension in bolts

First suppose there is no tension in the bolts

b= M/N

1500 mm

Distance to edge of compressive stress block

X/2 = -1112.5 mm

Compression = -41,385 kN

tension in bolts

C = 400 kN

Required design stress = 0.555556 N/mm

mc= 1,868 Nmm/mm

II Moment plus minimum axial force

Bolt tension and concrete Compression

M = 0.6*fcu*bp*X ( h -X/2) - N (h-hp/2)

a -5,760 X

b 8,064,000 X

c -693,750,000

X1 92.09 mm

X2 1,307.91 mm

Substituting into the equations for C and T gives :

C = 1,060.85 kN

T= 760.85 kN

mc = 79,466.85 Nmm/mm

Column Base Worked Example

Taken from "Joints in Steel Construction Moment Connections"

Baseplate thickness

The required plate thickness is the larger value resulting from (a) or (b) below

(a) Compression side bending

mc 79,466.85 Nmm/mm

tp = (4*mc/py)^0.5 = 31.27385 mm

(b) Tension side bending

required base plate thickness

m = 7 mm

tp = (4*mT/(pyp*bp))^0.5 = 11.68602 mm

use tp = 31.2738466 mm

Holding down bolts and anchorage

Holding down bolts

Force T is assumed to be shared equally between all the bolts in the tension row :

314 kN

Force per bolt = 190.2127 kN smaller than

ok!

Anchoring to concrete

Use anchor plate and check the concrete base for punching shear in accordance with BS 8110

anchor plate size =5d x 5d x 0.8 d = 150 x 150 x 24 mm

Assume an effective depth of the holding down bolts, L = 400 mm

The perimeter for punching shear check will encompass the group of four bolts :

(it is assumed that there are no free edges which would reduce the perimeter)

P = (12xL) + P

ap

where,

P

ap

= total perimeter of anchor plates

= 1500

P = 6300 mm

Average shear stress

fv = 0.301925 N/mm

Assuming an area of tension reinforcement less than or equal to 0.15%

Design concrete shrae stress, vc taken from table 3.8 of BS 8110

Vc = 0.35 N/mm > 0.301925

ok

Shear Transfer to Concrete

Check if the horizontal shear is transferred by friction

Available shear resistance = 0.3 x C min = 90 kN > 75 kN

ok

py = 355 MPa t1 c

Fshear 50 kN e3 gb

tf= 5.7 mm

e1 35 mm

n 3 nos

p 50 mm e1

D bolt 20

Dh 22 mm

Ke 1.1 (n-1)p

Single

e3 35 mm

gb 50 mm e1

k 2.5

c 100 mm

t1 10 mm

I Shear Capacity of beam

Basic requirement : Fv < Pv.min (smallest of (0.6*py*Av, 0.7*py*ke*Avnet)

Av = 0.9*(2e1+(n-1)p)*tf

= 872.1 mm

Av net = Av - n*Dh*tf

= 495.9 mm

0.6*py*Av = 185.76 kN

0.7*py*ke*Avnet 135.55 kN

Block Shear (applicable to notch beam only)

Pr = 0.6*py*tw(Lv+Ke*(Lt-k*Dh))

Pr = 203.9688 kN

Lv = e1+(n-1)*p

Lv = 135 mm

Pv = 135.55 kN ok!

II Shear and Bending interacion at the 2nd line of bolts

c = 100 mm > e3+gb = 85 check momen at 2nd line

Fv= 50 kN < 0.75*pmin= 101.6657 low shear

Mcc = 9.746525 kNm > Fv (t1+e3+gb)= 4.75 ok

Axial = 3500 kN

fcu = 48.19277 MPa

D = 609.6 mm

t = 22.2 mm

Areq = 121041.7 mm

b = h = 347.9104 mm

3.14 609.6 -22.2 22.2 2 c = 121041.7

40946.48 + 3688.872 c = 121041.7

c = 21.71265 mm

(D-2t)/2 = 282.6

no overlap

tp = 13.05372 mm

Potrebbero piacerti anche

- Tan Tan 1 Cos: Bishop's Simplified MethodDocumento10 pagineTan Tan 1 Cos: Bishop's Simplified MethodLie FangNessuna valutazione finora

- Truss DepthDocumento1 paginaTruss DepthLie FangNessuna valutazione finora

- Purlin DesignDocumento1 paginaPurlin DesignjanethNessuna valutazione finora

- Wind Calculation: Project Job RefDocumento1 paginaWind Calculation: Project Job RefjanethNessuna valutazione finora

- K ColumnDocumento5 pagineK ColumnjanethNessuna valutazione finora

- Punching Shear CheckDocumento2 paginePunching Shear CheckLie FangNessuna valutazione finora

- ASCEDocumento6 pagineASCELie FangNessuna valutazione finora

- CHS ConnectionDocumento1 paginaCHS ConnectionLie FangNessuna valutazione finora

- Composite BeamDocumento9 pagineComposite BeamLie FangNessuna valutazione finora

- Design Momen BaseDocumento3 pagineDesign Momen BaseLie FangNessuna valutazione finora

- v2 Result (Multi Layer Bar) - Sect 8Documento34 paginev2 Result (Multi Layer Bar) - Sect 8Lie FangNessuna valutazione finora

- 2 Way SlabDocumento6 pagine2 Way SlabLie FangNessuna valutazione finora

- InertiaDocumento2 pagineInertiaLie FangNessuna valutazione finora

- Respon Spektra DisainDocumento10 pagineRespon Spektra DisainLie FangNessuna valutazione finora

- Design Momen BaseDocumento3 pagineDesign Momen BaseLie FangNessuna valutazione finora

- ASCEDocumento6 pagineASCELie FangNessuna valutazione finora

- Beam Design ACIDocumento1 paginaBeam Design ACILie FangNessuna valutazione finora

- CorbelDocumento1 paginaCorbelLie FangNessuna valutazione finora

- Strut and Tie CalculationDocumento8 pagineStrut and Tie Calculationgmazzucco100% (4)

- 2 Way SlabDocumento6 pagine2 Way SlabLie FangNessuna valutazione finora

- Titik BeratDocumento7 pagineTitik BeratLie FangNessuna valutazione finora

- Hilti HSL3Documento6 pagineHilti HSL3Lie FangNessuna valutazione finora

- Purlin CapacityDocumento4 paginePurlin CapacityLie FangNessuna valutazione finora

- Purlin CapacityDocumento4 paginePurlin CapacityLie FangNessuna valutazione finora

- InersiaDocumento8 pagineInersiaLie FangNessuna valutazione finora

- Hilti HSL3Documento6 pagineHilti HSL3Lie FangNessuna valutazione finora

- ConnectionDocumento1 paginaConnectionLie FangNessuna valutazione finora

- CorbelDocumento1 paginaCorbelLie FangNessuna valutazione finora

- GempaDocumento3 pagineGempaLie FangNessuna valutazione finora

- Bolt CapacityDocumento2 pagineBolt CapacityLie FangNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Air Cooled Screw Chiller Performance SpecificationDocumento2 pagineAir Cooled Screw Chiller Performance SpecificationDajuko Butarbutar100% (1)

- RMC Case StudyDocumento2 pagineRMC Case StudyAmer RahmahNessuna valutazione finora

- CP QB PT-3 Harish KumarDocumento3 pagineCP QB PT-3 Harish KumarVISHNU7 77Nessuna valutazione finora

- Druckabschaltventil enDocumento4 pagineDruckabschaltventil enSakthi Sekar CbiNessuna valutazione finora

- TM-1870 AVEVA Everything3D - (2.1) Draw Administration (CN)Documento124 pagineTM-1870 AVEVA Everything3D - (2.1) Draw Administration (CN)yuehui niuNessuna valutazione finora

- PC 4 Product List 2019 - Pc4Documento28 paginePC 4 Product List 2019 - Pc4ShNessuna valutazione finora

- Application of EbwDocumento11 pagineApplication of Ebwsuman kumarNessuna valutazione finora

- Critical Thinking Chapter 9Documento23 pagineCritical Thinking Chapter 9Desny LêNessuna valutazione finora

- 1729Documento52 pagine1729praj24083302Nessuna valutazione finora

- 102DNDocumento2 pagine102DNManuel ZavalaNessuna valutazione finora

- Designing of 3 Phase Induction Motor Blackbook DoneDocumento30 pagineDesigning of 3 Phase Induction Motor Blackbook Donetryd0% (1)

- Eccsa Five Year (2014 15 - 2018 19) Strategic PlanDocumento95 pagineEccsa Five Year (2014 15 - 2018 19) Strategic Planyayehyirad100% (1)

- Hardware Devices Used in Virtual Reality TechnologiesDocumento6 pagineHardware Devices Used in Virtual Reality TechnologiesTheMoon LightNessuna valutazione finora

- 2023 Grades 10-12 Mathematics ATP MediationDocumento14 pagine2023 Grades 10-12 Mathematics ATP Mediationkaybeach007Nessuna valutazione finora

- DMS 48 NormesDocumento11 pagineDMS 48 NormesSonia WittmannNessuna valutazione finora

- The historical evolution of organizational behavior and how it shaped modern managementDocumento3 pagineThe historical evolution of organizational behavior and how it shaped modern managementSaravanan Swagger100% (1)

- A Comparative Study of Different Image Denoising Methods: Afreen Mulla, A.G.Patil, Sneha Pethkar, Nishigandha DeshmukhDocumento6 pagineA Comparative Study of Different Image Denoising Methods: Afreen Mulla, A.G.Patil, Sneha Pethkar, Nishigandha DeshmukherpublicationNessuna valutazione finora

- Theories of SelfDocumento5 pagineTheories of SelfTd Devi AmmacayangNessuna valutazione finora

- Check For Palindrome: Compute GCD and LCMDocumento3 pagineCheck For Palindrome: Compute GCD and LCMAadhi JNessuna valutazione finora

- The Champion Legal Ads: 11-02-23Documento58 pagineThe Champion Legal Ads: 11-02-23Donna S. SeayNessuna valutazione finora

- CDM 856 WheelloaderweichaiengineDocumento1 paginaCDM 856 WheelloaderweichaiengineRusmiyanto YantoNessuna valutazione finora

- OSC - 2015 - Revised - Oct (Power Cables) PDFDocumento118 pagineOSC - 2015 - Revised - Oct (Power Cables) PDFIván P. MorenoNessuna valutazione finora

- L028 Me Dat 01 00122 001 00Documento8 pagineL028 Me Dat 01 00122 001 00sivasan10006098Nessuna valutazione finora

- Exoskeleton Power Requirements Based on Human BiomechanicsDocumento54 pagineExoskeleton Power Requirements Based on Human Biomechanicsja2ja1Nessuna valutazione finora

- The Advantages and Disadvantages If Block ChainDocumento7 pagineThe Advantages and Disadvantages If Block ChainKarthik ShettyNessuna valutazione finora

- Lesson Plan 2 Sine Rule and Cosine RuleDocumento8 pagineLesson Plan 2 Sine Rule and Cosine Ruleapi-280114661Nessuna valutazione finora

- Đề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnDocumento22 pagineĐề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnLily LeeNessuna valutazione finora

- Table of Material Properties For Structural Steel S235, S275, S355, S420Documento4 pagineTable of Material Properties For Structural Steel S235, S275, S355, S420Mouhssine BrahmiaNessuna valutazione finora

- Plyometric Training Programs For Young Soccer Players: A Systematic ReviewDocumento7 paginePlyometric Training Programs For Young Soccer Players: A Systematic ReviewsteNessuna valutazione finora

- BOQ Sample of Electrical DesignDocumento2 pagineBOQ Sample of Electrical DesignAshik Rahman RifatNessuna valutazione finora