Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Carburetor Tuning: Understanding Carburetion

Caricato da

Muhammad Rashid Jaidon ⎝⏠⏝⏠⎠80%(5)Il 80% ha trovato utile questo documento (5 voti)

2K visualizzazioni11 pagineCarb Tuning about part machine in motorcycle

Titolo originale

Carb Tuning

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCarb Tuning about part machine in motorcycle

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

80%(5)Il 80% ha trovato utile questo documento (5 voti)

2K visualizzazioni11 pagineCarburetor Tuning: Understanding Carburetion

Caricato da

Muhammad Rashid Jaidon ⎝⏠⏝⏠⎠Carb Tuning about part machine in motorcycle

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 11

Carburetor Tuning

By: Canadian Dave

Understanding Carburetion

Motorcycle carburetion is fairly complex, but a basic understanding of the parts and theory involved

will go a long way to simplify the processes and make fine-tuning your carburetor much less

intimidating. Right off the bat Im going to say this is only intended to be a very basic explanation.

Motorcycle carburetion is quite complex with a number of circuits and conditions acting together to

deliver a measured amount of gasoline and air to your engine. Most of which aren't even mentioned

here. To do it justice you would literally have to write a book and thats not my goal here.

Information from a 1988 to 2000 KDX200/220 Keihin PWK is illustrated here but the principals

are the same for all KDXs.

Basic Motorcycle Carburetor Theory

Pressure can be your friend. Your KDX relays on differences in air pressure to deliver a charge of

gasoline and air into the engine. If you measured the force applied by a column of air above the

Earth youd find that it exerts about 15 pounds of pressure per square inch at sea level. This

pressure is referred to as atmospheric pressure and varies slightly with altitude, meteorological

(weather) conditions etc. but well talk about that later. Air, gasoline etc. will move from an area of

higher pressure to an area of lower pressure until both are equal.

How does your engine produce a pressure differential? As the piston moves past bottom dead

center ( its lowest point ) and back up towards top dead center ( its highest point ) the pressure

above the cylinder increases and the pressure below the cylinder decreases. The reduced pressure

inside the crankcase causes the reed valve to open and outside air, at a higher pressure, to flow

through the carburetor delivering a charge for gasoline and air to the engines crankcase, which is at

a lower pressure. Great so we know how air is drawn through the carburetor and into crankcase

but what about the carburetor how is gasoline combined with the incoming charge of air?

Some times restrictions can be a good thing. If you place a restriction in the path of a flowing

liquid or gas a drop in pressure is created. The pressure before the restriction will be greater than

the pressure after the restriction. Yup were back to that pressure differential thing again. Since the

charge of incoming air must pass through the horn shaped mouth of the carburetor and into the

smaller venturi ( a restriction ), the pressure before the venturi is higher than after. Such a reduction

in pressure will cause an increase in the airs velocity because the same amount of airflow must take

place before the restriction as after it. Velocity will vary directly with the amount of flow, and as the

flow increases a greater pressure differential will occur across the venturi.

Ok so we know that as air is drawn into the carburetor and meets the restriction imposed by the venturi

a pressure differential is created. The atmospheric pressure outside the carburetor is greater than the

pressure inside the carburetor. So why do you care? Because the carburetors float bowl is vented

directly to the outside atmosphere (higher pressure) and connected to the venturi (lower pressure) via

the pilot circuit and the needle jet/ spray bar ( through the main jet ) thats why. If we remember that a

liquid, gas etc. will move from an area of higher pressure to an area of lower pressure until both are

equal we can see how gasoline is introduced into the incoming charge of air. In this case gasoline is

forced from the float bowl up through the pilot and main jet into the carburetors bore where it is delivered

to the crankcase.

Jetting

The Basics- When people talk about jetting a carburetor, tuning a carburetor or "breaking out the

brass" they're talking about manipulating the carburetor's 4 main circuits to optimize gasoline delivery

and therefore engine performance. They might adjust the air screw, adjust the jet needles clip position

or exchanging the pilot (slow) jet, main jet, throttle valve (slide) or jet needle for one of an appropriate

size. A perfectly tuned 2-stroke engine/carburetor delivers a 12.5 to 1 air to fuel ratio.

The Parts- No jet acts independently of the others but rather they work together to deliver

gasoline to the engine. They do however target specific throttle openings and have the most effect is

that area. See below.

The air screw is most effective between idle through

1/8 throttle.

The pilot (slow) jet is most effective between 1/8

through 1/4 throttle.

The slide valve is most effective between 1/8 through

1/2 throttle

The jet needle is most effective between 1/4 through

3/4 throttle.

The main jet is most effective between 3/4 through

wide-open throttle.

Before we get into the different parts of the carburetor and how they effect gasoline

delivery I want to stop for a second and define the terms RICHER and LEANER. I know these

terms can cause some trouble for those who are new to the sport or new to carburetor tuning and

they are often used incorrectly. The terms RICHER and LEANER refer to the amount of

GASOLINE being delivered to the engine and not the amount of oil. If youve done a plug reading

at wide open throttle and the plug indicates you are running rich ( dark brown to black ) this is an

indication that too much gas is being delivered to the engine and not too much oil. I know there are

people that will say "Youre running too rich, try to change your premix ration from 42 parts gas: 1

part oil ( 42:1 ) to 50 parts gas : 1 part oil, that should lean things out a little ". This is in fact

increasing the amount of gasoline ( 8 more parts of gas for each part of oil ) and causing the engine

to run RICHER rather than leaner. If you remember richer and leaner are referring to the amount of

gasoline being delivered this will all make much more sense.

The pilot, or slow circuit, can be adjusted by manipulating two parts: the air screw and the pilot jet.

The air screw controls the flow of air into the circuit. Turning the air screw clockwise reduces the air

flow and richens the circuit. Turning it counter clockwise increases the airflow and leans the circuit.

You can therefore use the air screw to fine tune the pilot circuit. The pilot jet restricts/regulates the

flow of gasoline from the float bowl to the venturi. Pilot jets have a precisely machined orifice/hole

running through their center which gasoline passes through. Increasing the size of the pilot jet ( size

of the hole ) richens the circuit by supplying more gasoline; i.e. removing a 40 pilot jet and installing

a 42 richens the circuit.

The slide/throttle valve has the most effect between 1/8 and 1/4 throttle with a declining effect

up to 1/2 throttle. The throttle valve can be exchanged for one with a greater or smaller cutaway.

The PWK equipped KDX200/220 comes equipped with a #5 or 5mm cutaway. The larger the

cutaway the more air flows to the jet block/nozzle screen leaning the mixture. Exchanging the factory

#5 ( 5mm cutaway ) throttle valve for a #6 (6mm cutaway) would lean the mixture.

The jet needle Has the greatest effect between 1/4 and 3/4 throttle. Its attached directly to the throttle

valve. As the throttle is rolled open or closed the jet needle moves through the needle jets bore exposing

different sections of the jet needles profile to the needle jets inner bore.

Six major elements determine the jet needles effect on fuel delivery - the diameter of the straight section, the

length of the straight section, the jet needles taper, the clip position, the number of tapers and the length of

each tapered section. The number of tapers is normally not changed from what was supplied from the factory.

Ill talk about jet needles in greater detail in the Tuning section.

The Main Jet- regulates the flow of gasoline from to Wide Open Throttle. Like the pilot jet the main

jet has a precisely sized hole drilled through its center. Increasing the size of the main jet ( size of the

hole ) richens the circuit by supplying more gasoline; i.e. removing a 152 main jet and installing a 155

richens the circuit.

Tuning

Before you consider fine tuning your carburetor there are a few things that have to be done. First

you need to install a clean air filter. Second you need to insure the float level is properly set. If the

gasoline level is set too high or too low properly jetting your bike will be impossible. A high float

level will cause it to run rich and a low level cause it to run lean. You can find instructions for setting

you float level here.

Third you need to fill your tank with a fresh load of premixed gasoline. Dont go out and try to jet

your carburetor with the gasoline thats been sitting around in your jerry can for the past month.

Gasoline degrades over time so youll want to start with a fresh batch. While Im talking about

gasoline remember that different gasoline will change your jetting requirements. If you normally run

race gas, straight or use it to cut pump gas, youll want to be sure you have it in your tank when you

head out to tune the carburetor.

You also need to be aware of any potential mechanical problems that can imitate poor jetting. Eric

Gorr has included a number of articles on his web site from his book "Motocross and Off- Road

Motorcycle Performance Handbook". An excellent article on carburetor tuning is included which

covers this topic. Check it out here. If you dont own a copy Id definitely recommend picking one

up. Its chucked full of useful, easy to read information and make a great companion to your factory

service manual.

When making jetting changes make one change at a time and test the result. It's very helpful to keep

a log book for your motorcycle where you can log changes to the jetting, the temperature, altitude

etc and the result. Over time you'll build a jetting history of your bike that you can go back to and

determine what changes you have made. I also include routine maintenance and repairs in my log

book.

Tuning From Idle to Wide Open Throttle, Plug Reading Again this is a good method for

beginners. Once youve gained more experience and are more comfortable with jetting youll start

to relay more on power delivery and how the engine feels until then this is a good method.

If you go back and have a second look at the parts of a carb youll see that gasoline delivery is

dependent on throttle position and not engine speed. Youll also notice that the air screw, pilot jet,

main jet, and jet needle target specific throttle setting. With this information in hand we can easily

identify which circuit is likely the cause of a specific symptom.

Before you head out for a jetting session youll want to mark your throttle grip and housing so you

can easily identify the four major target ranges. I like to use White Out but placing a piece of tape

on the throttle grip and throttle housing and breaking out a marker will work just as well. With the

throttle at idle and your materials in hand draw a straight line across the inner cuff of your throttle

grip and onto the throttle housing. Now twist the grip to WOT and draw a second line on your grip

straight across from the line on your throttle housing. Next find the half way point between the two and

place a third line, this will indicate throttle. Now divide the halves in half again and mark 1/4 and 3/4

throttle. Now with a quick glance you can easily determine the throttle position while jetting.

Nows a good time to stop and talk about plug reading. The color and condition of the spark plug can tell

you a lot about whats happening in your engine. Youll be doing some runs at known throttle settings

and then observing your spark plug to determine the condition of the corresponding circuit i.e. is it lean,

good or rich. Ideally a professional tuner would use a variety of instrumentation and how the engine feels

to fine-tune jetting. For more information on instrumentation check out Eric Gorrs comments on "How to

use carburetor tuning gauges". This method will insure you're in the ballpark so you can start

fine-tuning. When you have more experience and are more confident in your ability to

determine jetting requirements by feel you'll start to phase out this method for 1/4, 1/2

and 3/4 throttle setting and replace it with the jetting by feel method. You'll continue to

use this method for tuning the main jet at WOT. Ill also say that my recommendation for

the appearance of a good plug is going to be slightly different than someone who is

jetting a motocross bike for an experienced rider. The conditions faced by enduro

riders and moto-cross riders are quite different and therefore the jetting requirements

are also slightly different.

Checking the Main Jet Warm up the engine and go for a short ride letting the engine comes up to

its normal operating temperature. Install a brand new plug that's been properly gapped. With the

new plug installed aggressively accelerate through the gears until you reach 4

th

or 5

th

gear. For best

results you should accelerate up a slight up hill section to place additional load on the engine.

Continue to run the engine at WOT for 20 to 30 seconds longer if there is not fear the engine is

running lean. If you suspect the engine is running lean 15 to 20 seconds to give you an indication. At

the end of your full throttle run simultaneously push the kill button, chop the throttle and pull in the

clutch. This procedure is often refereed to as a " plug chop". It is important to perform a plug chop

exactly as described. If you allow the engine to run or leave the throttle open for even a few

seconds after the plug chop the plug reading will be invalid. Now remove the spark plug and

carefully look at its color.

Plug Reading - What does a good plug look like? First you need to know where to look and what to

look for. Ive seen a lot of plug reading instruction that suggest you to look at the general appearance of

the plug. That doesnt work. The easily visible portion of the plug, the upper part of the porcelain and the

electrodes, wont give you an accurate reading. This area is mostly affected by additives in the gasoline

and the oil youre running. To get an accurate indication you want to look down inside the plug where

the porcelain insulator emerges from the steal body of the spark plug. Ideally you should see a ring of

light brown/tan at the lower 1/4 of the porcelain. White is lean and youll need to install the next richer

main jet( larger number ) and do another plug reading. A dark brown to black ring is too rich and youll

need to install the next leaner main jet ( smaller number ). A small flashlight and magnifying glass make

this much easier to see and itll give your friends something to poke fun at. If you ride in a diverse area

with fluctuations in temperature greater than 15 degrees F, and altitude changes dropping more that

3000 feet over the course of the day or you ride in high load conditions ( loose sand, mud, long steep

hills ) adjust the size of your main jet until you reach the ideal condition then install the next richer main

jet which should result in a dark brown plug reading. You'll be loosing a small amount of top end power

in trade for the added confidence that you can ride aggressively over the course of the day without fear

of running lean at WOT.

Checking the Jet Needle Once you have the main jet properly sized you can turn your

attention to the jet needle. Warm up the engine and go for a short ride until the engine comes up to

its normal operating temperature. Install a brand new plug that has been properly gapped. With the

new plug installed accelerate through the gears until you reach 4th gear. For best results you should

find a location that allows you to run safely at half throttle with out having to ex or decelerate to

avoid obstacles etc. A long straight away or well groomed oval track will work the best. Continue

to run the engine at half throttle for more than 60 seconds if possible. Do a plug chop and inspect

the plug. If the plug indicates a lean condition, lower the clip on the needle by one position.

Lowering the clip by one position raises the needle further out of the needle jet allowing more

gasoline to flow, richening the circuit. If the plug is dark brown to black raise the clips position by

one notch to lean the circuit. As a general rule if you need to run the clip in the top position you

should install a leaner jet needle. If you need to run the clip in the bottom position you should install

a richer jet needle. Jet needle selection is something of an art. Watch for an article in the near future

describing PWK jet needle profiles in more detail. This method will give you a good ball park

indication if you jet needle is properly sized. However due to inefficient cylinder scavenging at

lower throttle settings its often little more that a ball park indication and you'll need to fine tune by

feel.

Once you're satisfied with the appearance of the plug turn to the jetting by feel method to fine-tune

the circuit. Gradually roll the throttle open from 1/2 to 3/4 throttle paying particular attention to the

sound and the type of power delivery. Having an experienced friend on the sidelines to listen and

watch the silencer for excessive smoke is also helpful. A rich condition will result in excessive smoke

from the silencer, the plug will often carbon foul and the engine will produce a sputtering/crackling

sound. A lean condition will result in slow throttle response, you twist the throttle but the power

delivery is lethargic and flat. A lean condition results in a tell tale booooooha sound as well. You can

quickly verify a lean condition by pulling the choke half way out. Engaging the choke will deliver

additional fuel to the system and the symptoms of a lean condition should clear up.

A Helping Hand

There's a little tip that'll make changing needle clip positions a breeze. If you're like me you tire of

wrestling the throttle valve spring and collar pretty quickly when it comes time to adjust your needle.

Not to mention the first time you sent a spring loaded collar jettisoning into a dirty mound. Why is it

those " must stay clean" parts always find there way into the grim anyway? This little trick makes

trail side needle adjustment anxiety a thing of the past.

Run to your local tool supply store, hobby shop or what have you and pick up a hemostat. I'm not

talking about the bone crushing size here, a 4 to 5 inch pair will work just great and they'll only set

you back $4 to $5. The best thing about a hemostat is its small enough to carry in your fanny pack

and they apply just enough pressure to prevent the spring and collar from slipping but not enough to

damage the throttle cable. Nurse, hemostat please!

The Pilot Circuit, Tuning from Idle to Throttle -You can use the air screw to help

determine if your pilot jet is appropriately sized. Take your bike for a short ride letting the engine

come up to normal operating temperature. With the engine stopped, transmission in neutral and the

bike on its stand turn the air screw clockwise until it just seats, gentle now its delicate and you

dont need to torque it down just gently seat it. Now turn the air screw a quarter of a turn out so the

engine will fire and start it. Slowly turn the air screw counter clockwise ( out ) until the point where

the engine just reaches the maximum obtainable rpm and continuing to turn the air screw beyond this

point wont increase the engine speed (rpms) any further. I find its easier to hear the rpm increasing

if you set the idle at its lowest possible position without the engine stalling. Youll want to repeat this

procedure a couple times until youre confident that youve found the right spot and that the result is

reproducible. When youre comfortable count the number of turns ( 360 revolutions ) youve

backed the air screw out to reach this point. The normal operating range is between 1 and 1.5 turns

out so if you find the ideal setting is less that 0.75 turns out consider installing the next richer pilot jet

(larger number ). If you find the ideal setting is more than 2 turns out consider installing the next

leaner pilot jet ( smaller number ).

Once you're comfortable you have an appropriate pilot jet installed you want to fine turn the circuit

using the air screw. Starting with the air screw 0.5 turns out adjust the screw an 1/8 of a turn at a

time until youve obtained the best possible throttle response between idle and 1/4 throttle. Continue

to adjust the air screw until the engines throttle response off idle is clean with no hesitation or

bogging. You can test the final results using the same method as you did for checking the jet needle

this time riding in 2

nd

or 3

rd

gear at 1/4 throttle. Remember this is only a ball park indicator your

goal here is to obtain the best possible throttle response not a perfect plug reading.

Because jets have a combined effect over a range of throttle setting its often useful to go back and

recheck your jetting once you have followed this procedure. The second time through you can

broaden the throttle settings to insure theres a good transition between one circuit and another. So

for example slowly roll the throttle open between 1/2 and WOT insuring the transition is progressive

and that the engine doesnt stumble etc. Do the same between 1/8 and 1/2 throttle, 1/4 and 3/4

throttle etc.

The Effect of Temperature, Altitude and

Humidity on Jetting

Once your jetting is set its not necessarily set for life. Changes in air temperature, altitude and

humidity can have an effect on how your engine runs.

If you captured a measured volume of air on a humid 90 F day at sea level or a cool dry 40 F day

at 10,000 feet both would contain about 22% oxygen. The density and therefore the total number of

oxygen molecules however would differ enough to effect the performance of your engine.

Temperature- For most of us changes in air temperature will have the greatest effect on our jetting.

As the air temperature gets colder the air density increases. The air molecules become less active (

move around less ) and therefore take up less space. Because they take up less space more air, and

therefore more oxygen, can fit into a measured volume of air as the temperature decreases. As the

temperature drops the engine will begin to run leaner and more gasoline will need to be added to

compensate. As the temperature increase the engine will begin to run richer and less gasoline will be

needed.

Altitude- Again this is an issue of air density. At sea level atmospheric pressure is around 15 psi and

as the altitude increased the atmospheric pressure decreases. Because less pressure is exerted on a

measured volume of air as the altitude increases the air molecules are able to relax and they take up

more space leaving less space for additional molecules. The higher the altitude the less air in a

measured volume and therefore less oxygen present so jetting will have to be leaned to compensate.

Humidity- Humidity is a measure of how much water vapor is in the air. The higher the humidity the

less space there is for additional molecules of air and therefore oxygen. As the humidity increases there

is less oxygen and therefore the engine runs richer. Jetting that may have been spot on in the cool dry

morning air may start to run rich as the temperature and humidity increase over the course of the day.

Correcting for Changes in Temperature, Altitude

and Humidity

Correction Table-You can use a correction table to roughly determine the appropriate jetting

changes to compensate for changes in temperature, altitude and humidity. Ive included a typical

correction factor chart that has been modified specifically for use with the KDX. To use the chart go

back to your log book and record what jetting is presently installed in your carburetor then

determine what altitude youll be riding at and the temperature. I'm assuming here that you've

already optimized your jetting. Ive used my present jetting as an example. Youll need to slightly

modify the table to fit the specific requirements of your bike but Ill go over that in the example.

Example- Im presently running a 45 pilot jet with the air screw 1.25 turns out, an 1173 jet needle in the

second from the top clip position and a 152 main jet. This jetting was optimized at 20 C and 2240 ft above sea

level. For this example lets assume Im going riding in the mountains where the temperature is 20 C at 9600 ft.

The first thing I do is adjust the bottom of the table so that it reflects the condition where my jetting was

optimized. Using the illustration below as an example I draw a straight line from 20 C horizontally across the

graph until I hit the line that represents 2240 ft., then draw a line vertically to the bottom axis on the graph. This

point becomes 1.0. Adjust the work sheet by subtracting 0.02 for each increment to the left of this point and

adding 0.02 for each increment to the right of this point. My graph now looks like this:

Now using my personalized graph I can calculate what jetting I should install before making the trip to the

mountains. I draw a horizontal line from 20 C over to 10000 ft and then vertically down to determine the

correction factor of 0.95. To find the correct pilot jet size I multiply 45 by 0.95 and the new jet size would be 42.75.

The closest available size is a 42 and Ill fine-tune the pilot circuit with the air screw once I get there. I then

multiply my main jet size ,152, by 0.95 and the new jet size would be 145. Now remember this is intended to give

you a rough indication.

You can print off your own correction factor table here. comi ng soon

Using a correction table should allow you to closely meet the requirements of changing conditions. It

is however intended to be used as a guide. You should always carry an assortment of jetting in your

toolbox and check any jetting suggestions you receive. At a minimum do a plug reading at WOT

after changing your jetting to insure you arent running lean. Jetting recommendations that work well

for one bike may not necessarily work for another even if it is being ridden in the same area with

identical modifications.

Available Keihin Jets Tle main and pilot jets for yheres a list of availabour reference. Ive included

jets sizes commonly used to fine tune PWK equipped KDXs. This includes 1988 to 2000 KDX200/220

as well as second generation KDX250s. There are larger and smaller sizes available that arent listed

here. This list might seem rather long but it includes possible jet sizes for a number of temperatures,

altitudes as well as modified cylinders.

"21 Series" Pilot Jets - 38,40,42,45,48,50,52

" 13 Series " Main Jets 140,142,145,148,150,152,155,158,160,162,165,168,170,172,175,178,180

Jetting Recommendations, a Starting Point

These are intended to be good jetting STARTING POINTS so use them as just that a starting

point. In many instances jetting will be very close if not right on but you'll need to insure youre not

running lean and optimize the jetting from here to meet your individual requirements. At the very

least youll need to do a throttle reading at Wide Open Throttle and insure youre not running lean.

These jetting recommendations are intended for use between sea level and 3000ft with an average

temperature of 73 degrees plus or minus 7 degrees.

1995-2001 KDX200

Stock -Run the stock R1174K jet needle in the second from the

top clip position, 45 pilot jet, 155 main jet and fine-tune the pilot

circuit using the air screw.

With a performance pipe/expansion chamber, the air box lid

removed and the stock or a performance silencer run a 42/45

pilot, R1174K jet needle in the mid clip position, a 152/155

main jet fine tune the pilot circuit using the air screw.

1997 to 2001 KDX220

Stock run a 42 pilot jet,the stock R1173L jet needle in the

second from the top clip position, a 142/145 main jet and fine

tune the pilot circuit using the air screw.

With a performance pipe/expansion chamber, air box mods ,

the factory or after-market silencer and the stock 33mm

carburetor run a 42 pilot, the stock R1173L jet needle in the

second from the top clip position, a 145/148 main jet and fine

tune the pilot circuit using the air screw.

Same as above but with your carburetor bored between 35 and

36mm or running a 1988 to 2000 KDX200 35mm carb jet

according to 95 to 2000 KDX200 requirements.

Addition of Boyesen reeds or a Boyesen RAD Valve will require

you to lean the pilot and main jet one size and readjust your air

screw.

1989 to 1994 KDX200

Stock -Run the stock R1172N jet needle in the second from the

top clip position, 48 pilot jet, 155 main jet and fine-tune the pilot

circuit using the air screw.

With a performance pipe/expansion chamber, the air box lid

removed and the stock or a performance silencer run a 45/48

pilot, R1173N jet needle in the mid clip position, a 152/155

main jet fine tune the pilot circuit using the air screw.

Addition of Boyesen reeds or a Boyesen RAD Valve will require

you to lean the pilot and main jet one size and readjust your air

screw.

For jetting recommendations on remaining models ( 1982 to 1988 KDX200s ) check

out Jeff Fredette's engine performance recommendations here.

If you require addition jetting help fire your question off to the JustKDX Forum. Youll

need to include the following information; year, model, modifications ( things like after-

market reeds, pipe, air box lid mods, silencer, ported cylinder etc etc. average riding

conditions, air temperature ( dont submit a range between 5 and 85 degrees F you

need to beak it down into your present condition within 10 degrees C or about 15

degrees F. ) altitude and average humidity.

If you would like to use or link to this material please contact me.

If you have any comments or suggestions smack the email

icon and send them my way.

David

Potrebbero piacerti anche

- Motorcycle Carburator Theory and TuningDocumento5 pagineMotorcycle Carburator Theory and TuningRubisel Guillen EsparzaNessuna valutazione finora

- Basic Two Stroke Tuning by Eric Gorr (I Think)Documento7 pagineBasic Two Stroke Tuning by Eric Gorr (I Think)Dr DNessuna valutazione finora

- Care & Feeding of The Keihin CarbDocumento13 pagineCare & Feeding of The Keihin CarbSean Osborne100% (1)

- Mikuni Motorcycle Carburetor Theory 101Documento8 pagineMikuni Motorcycle Carburetor Theory 101Riski HartonoNessuna valutazione finora

- Carburetor Theory Carburetor Theory: Paul Crovella Paul Crovella AGEN 220 AGEN 220Documento34 pagineCarburetor Theory Carburetor Theory: Paul Crovella Paul Crovella AGEN 220 AGEN 220Noer Wahyudi100% (1)

- Carburetor TuningDocumento4 pagineCarburetor Tuningviks505100% (1)

- 2 Stroke TuningDocumento6 pagine2 Stroke TuningRahul NakheNessuna valutazione finora

- 3368441308-PZ Carb Tuning ManualDocumento8 pagine3368441308-PZ Carb Tuning Manualelektroz100% (1)

- Two Cycle Carburetor and the Back Alley MechanicDa EverandTwo Cycle Carburetor and the Back Alley MechanicValutazione: 4.5 su 5 stelle4.5/5 (2)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionDa EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionValutazione: 4 su 5 stelle4/5 (1)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDa EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesValutazione: 5 su 5 stelle5/5 (1)

- High Performance Chevy Small Block Cams & ValvetrainsDa EverandHigh Performance Chevy Small Block Cams & ValvetrainsNessuna valutazione finora

- Mikuni Tuningmanual - 021003Documento20 pagineMikuni Tuningmanual - 021003Faqih GoetiaNessuna valutazione finora

- Advanced Carb TuningDocumento2 pagineAdvanced Carb TuningMurat Kaykun75% (8)

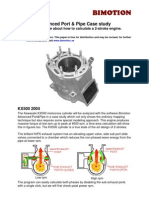

- Bimotion 2-Stroke Case StudyDocumento11 pagineBimotion 2-Stroke Case Studytfour200080% (5)

- Mikuni TuningDocumento22 pagineMikuni TuningStathis Ventouris89% (9)

- Basic 2 Stroke T UnningDocumento6 pagineBasic 2 Stroke T UnningCodaNorm S DevNessuna valutazione finora

- Port Timing Diagram of Two Stroke Cycle Pertrol EngineDocumento4 paginePort Timing Diagram of Two Stroke Cycle Pertrol Enginemechanical-engg50% (4)

- PJ PDFDocumento23 paginePJ PDFCarlos Diaz100% (5)

- CV Carb TuningDocumento7 pagineCV Carb Tuningmark_dayNessuna valutazione finora

- Crankcase Volume 2 StrokesDocumento19 pagineCrankcase Volume 2 Strokespistonbreaker100% (4)

- Higher - Compression - Two - Stroke PDFDocumento8 pagineHigher - Compression - Two - Stroke PDFImung Pernah SehatNessuna valutazione finora

- Porting Relations 2 StrokesDocumento10 paginePorting Relations 2 Strokespistonbreaker100% (8)

- Mikuni Tuning Manual For HSR42 - 45 CarbsDocumento12 pagineMikuni Tuning Manual For HSR42 - 45 Carbscarlos_hitech100% (1)

- Basic Porting - What To CutDocumento5 pagineBasic Porting - What To CutPratik Bajracharya Nepali100% (4)

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualDa EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualValutazione: 4.5 su 5 stelle4.5/5 (2)

- Jennings 2stroke GuideDocumento166 pagineJennings 2stroke GuidePaolo Di Marco100% (2)

- Scooter Tuning GuideDocumento22 pagineScooter Tuning GuideCarlos Simões100% (5)

- 2 Stroke Top End and PerformanceDocumento41 pagine2 Stroke Top End and PerformancePaul Martin0% (1)

- Keihin Carb JettingDocumento10 pagineKeihin Carb Jettinggjid04441450% (2)

- 2 Stroke ExhaustDocumento4 pagine2 Stroke ExhaustAniket Das100% (1)

- 2003 ExhaustDocumento47 pagine2003 ExhaustThip ZazaNessuna valutazione finora

- 2 Stroke Top End and PerformanceDocumento41 pagine2 Stroke Top End and PerformanceAndre Ruesl0% (1)

- 2 Stroke Guide r2Documento177 pagine2 Stroke Guide r2Larry Terrell100% (1)

- 2 Stroke Tuners HandbookDocumento78 pagine2 Stroke Tuners HandbookAnthony Van Hamond100% (2)

- Ch7-2stroke 1Documento24 pagineCh7-2stroke 1suresh_gs9999Nessuna valutazione finora

- Gordon Jenning Two Stroke Tunning Hand BookDocumento165 pagineGordon Jenning Two Stroke Tunning Hand BookChris IselinNessuna valutazione finora

- Tuning Suzuki GT250A MDocumento2 pagineTuning Suzuki GT250A Mgorlan50% (2)

- 2 Stroke GuideDocumento161 pagine2 Stroke Guide2hard100% (1)

- 2 Stroke Guide r2Documento178 pagine2 Stroke Guide r2Jan Crombez100% (1)

- Two Stroke Tuning GuideDocumento171 pagineTwo Stroke Tuning Guideavista123100% (1)

- How to Rebuild VW Air-Cooled Engines: 1961-2003Da EverandHow to Rebuild VW Air-Cooled Engines: 1961-2003Valutazione: 5 su 5 stelle5/5 (6)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Vi: the Ironhead Sportster: 1957 to 1985Da EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Vi: the Ironhead Sportster: 1957 to 1985Nessuna valutazione finora

- David Vizard's How to Port & Flow Test Cylinder HeadsDa EverandDavid Vizard's How to Port & Flow Test Cylinder HeadsValutazione: 4 su 5 stelle4/5 (9)

- High-Performance Cams & Valvetrains: Theory, Technology, and Selection: Theory, Technology, and SelectionDa EverandHigh-Performance Cams & Valvetrains: Theory, Technology, and Selection: Theory, Technology, and SelectionNessuna valutazione finora

- Building Honda K-Series Engine PerformanceDa EverandBuilding Honda K-Series Engine PerformanceValutazione: 5 su 5 stelle5/5 (2)

- How to Hook & Launch: Traction Mods for Street & StripDa EverandHow to Hook & Launch: Traction Mods for Street & StripNessuna valutazione finora

- Project Street Rod: The Step-by-step Restoration of a Popular Vintage CarDa EverandProject Street Rod: The Step-by-step Restoration of a Popular Vintage CarNessuna valutazione finora

- How to Make Your Muscle Car Handle: Revised EditionDa EverandHow to Make Your Muscle Car Handle: Revised EditionNessuna valutazione finora

- Ford Flathead Engines: How to Rebuild & ModifyDa EverandFord Flathead Engines: How to Rebuild & ModifyValutazione: 5 su 5 stelle5/5 (5)

- How to Build Max-Performance Mitsubishi 4G63t EnginesDa EverandHow to Build Max-Performance Mitsubishi 4G63t EnginesValutazione: 4.5 su 5 stelle4.5/5 (4)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume V: Part I of Ii—The Shovelhead: 1966 to 1985Da EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume V: Part I of Ii—The Shovelhead: 1966 to 1985Valutazione: 1 su 5 stelle1/5 (1)

- 02 - Screening AnalysisDocumento45 pagine02 - Screening AnalysisLEIAH MARIE JOY RIONessuna valutazione finora

- Garlock Klozure® High Performance Dynamic SealsDocumento2 pagineGarlock Klozure® High Performance Dynamic SealsCruzCarrizalesNessuna valutazione finora

- Principles of Geochemistry. G Ottonello 0231099843Documento938 paginePrinciples of Geochemistry. G Ottonello 0231099843Indra Gunawan100% (2)

- Battery Room Ventilation CalculationDocumento17 pagineBattery Room Ventilation Calculationzicus2010100% (1)

- 2ND Ia QP 2022Documento6 pagine2ND Ia QP 2022chandrashekar hiregoudarNessuna valutazione finora

- How To Inspect A GearboxDocumento13 pagineHow To Inspect A Gearboxkamal arabNessuna valutazione finora

- Theory of Plasticity: December 2018Documento28 pagineTheory of Plasticity: December 2018Angga Fajar SetiawanNessuna valutazione finora

- Oteva PDFDocumento29 pagineOteva PDFFABRICIONessuna valutazione finora

- Surfactants For Use As CodispersantsDocumento10 pagineSurfactants For Use As Codispersantsramitkatyal21881Nessuna valutazione finora

- Dunman High School Preliminary Exam Year 6: Paper 4 PracticalDocumento6 pagineDunman High School Preliminary Exam Year 6: Paper 4 PracticaloooNessuna valutazione finora

- Newton's Second Law On Rotational MotionDocumento3 pagineNewton's Second Law On Rotational MotionSanNessuna valutazione finora

- Dresser-Rand GFC Databook - Gas Field Policies-2Documento29 pagineDresser-Rand GFC Databook - Gas Field Policies-2kistaiNessuna valutazione finora

- Corrosion - Electrochemical MethodsDocumento1 paginaCorrosion - Electrochemical MethodsjuegyiNessuna valutazione finora

- ST-1 ITB NewDocumento19 pagineST-1 ITB NewES RouzaNessuna valutazione finora

- CHP 2 StaticsDocumento57 pagineCHP 2 StaticsApril Catherine ZafraNessuna valutazione finora

- Co-Ordination CompoundsDocumento11 pagineCo-Ordination CompoundsShashank AgarwalNessuna valutazione finora

- 10 Ultrasonic Testing Rev - 0 21.06.2019Documento8 pagine10 Ultrasonic Testing Rev - 0 21.06.2019Priya Kumari100% (1)

- Introduction To Phased Array Ultrasonic Technology Applications 336-340Documento5 pagineIntroduction To Phased Array Ultrasonic Technology Applications 336-340Kevin HuangNessuna valutazione finora

- Chapter 5 - Properties and Structure of MatterDocumento52 pagineChapter 5 - Properties and Structure of MattermishtinilNessuna valutazione finora

- Electronic Room Thermostat SRE06: Description FeaturesDocumento3 pagineElectronic Room Thermostat SRE06: Description FeaturesDaniel NogueiraNessuna valutazione finora

- Philippine Society of Mechanical EngineersDocumento27 paginePhilippine Society of Mechanical EngineersrollramsNessuna valutazione finora

- CFD Analysis of Ejector Using Different Refrigerant FinalDocumento6 pagineCFD Analysis of Ejector Using Different Refrigerant FinalAdarsh pratap Singh baisNessuna valutazione finora

- Paper - Harbison-Fischer - Common Problems and SolutionsDocumento3 paginePaper - Harbison-Fischer - Common Problems and SolutionsMohamed ElabbasyNessuna valutazione finora

- Mixtures Notes PDFDocumento5 pagineMixtures Notes PDFKhaled ElsayedNessuna valutazione finora

- Burkert Type 2000 Threaded BSPDocumento9 pagineBurkert Type 2000 Threaded BSPKuni KazeNessuna valutazione finora

- External Forced Convection: Heat and Mass Transfer: Fundamentals & ApplicationsDocumento16 pagineExternal Forced Convection: Heat and Mass Transfer: Fundamentals & ApplicationsAhmad AlbabNessuna valutazione finora

- Montevecchi2018heat Accumulation Prevention in Wire-Arc-Additive-Manufacturing Using Air JetDocumento9 pagineMontevecchi2018heat Accumulation Prevention in Wire-Arc-Additive-Manufacturing Using Air JetGustavo de CastroNessuna valutazione finora

- FBD, Forces and EquillibriumDocumento39 pagineFBD, Forces and EquillibriumMiguel LeonardoNessuna valutazione finora

- BioMEMS Chapter 1Documento85 pagineBioMEMS Chapter 1Mohanarajan Mohan KumarNessuna valutazione finora

- Cooling Tower DiscussionDocumento10 pagineCooling Tower Discussiondhanu_lagwankar100% (1)