Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

توابت حسابات الحريق وجداولها

Caricato da

safety86Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

توابت حسابات الحريق وجداولها

Caricato da

safety86Copyright:

Formati disponibili

Light Hazard Occupancies.

Group 1

Churches Automobile parking

Clubs Bakeries

Eaves and overhangs, Beverage manufacturing

Educational Canneries

Hospitals Dairy products

Institutional Electronic plants

Libraries, glass products manufacturing

Museums Laundries

Nursing or accomodation Restaurant service areas

Offices, showrooms

Residential

Restaurant seating areas

Theaters and auditoriums,

Unused attics

Table 14.5.2.2.1 Light Hazard Pipe Schedules

1 in. 2 sprinklers

1 in. 3 sprinklers

1 in. 5 sprinklers

2 in. 10 sprinklers

2 in. 30 sprinklers

3 in. 60 sprinklers

3 in. 100 sprinklers

4 in. See Section 8.2

Table 14.5.2.4 Number of Sprinklers Above and Below a Ceiling

1 in. 2 sprinklers

1 in. 4 sprinklers

Classification of Occupancies.

Ordinary Hazard Occupancies

Steel

Steel

1 in. 7 sprinklers

2 in. 15 sprinklers

2 in. 50 sprinklers

Table 14.5.3.4 Ordinary Hazard Pipe Schedule

1 in. 2 sprinklers

1 in. 3 sprinklers

1 in. 5 sprinklers

2 in. 10 sprinklers

2 in.. 20 sprinklers

3 in. 40 sprinklers

3 in. 65 sprinklers

4 in. 100 sprinklers

5 in. 160 sprinklers

6 in. 275 sprinklers

8 in. See Section 8.2

Table 14.5.3.5 Number of Sprinklers Greater than 12-ft (3.7-m) Separations

2 in. 15 sprinklers

3 in. 30 sprinklers

3 in. 60 sprinklers

Table 14.5.3.7 Number of Sprinklers Above and Below a Ceiling

1 in. 2 sprinklers

1 in. 4 sprinklers

1 in. 7 sprinklers

2 in. 15 sprinklers

2 in. 30 sprinklers

3 in. 60 sprinklers

Table 10.10.2.1.3 Flow Required to Produce a Velocity of 10 ft/sec (3 m/sec) in Pipes

IN mm

4 102

6 152

8 203

10 254

12 305

Steel

PIPE SIZE

Steel

Steel

Table 11.2.2.1 Water Supply Requirements for Pipe Schedule Sprinkler Systems

Occupancy Classification Minimum Residual Pressure Required (psi)

Light hazard 15

Ordinary hazard 20

Note: For SI units, 1 gpm = 3.785 L/min; 1 psi = 0.0689 bar.

Table 11.2.3.1.1 Hose Stream Demand and Water Supply Duration Requirements for Hydraulically Calculated Systems

Occupancy

Light hazard 0.50 -100

Ordinary hazard 0.50 -100

Extra hazard 0.50 -100

For SI units, 1 gpm = 3.785 L/min.

Inside Hose (gpm)

Table 11.2.3.9.1 Dry System Water Delivery

Hazard Number of Most Remote Sprinklers Initially Open

Residential 1

Light 1

Ordinary I 2

Ordinary II 2

Extra I 4

Extra II 4

High piled 4

Hazen-wiliams C values

Pipe or Tube

Multiplyin Factor

Plastic (listed) All

Cement lined or Cast or Ductile iron

Copper Tupe or Stainless Steel

C value Multiplier Table

Unlind Cast or Ductile Iron

Black Steel (dry system including Preaction

Value of C

Black Steel Wet system including Deluge

Gulvanized All

Sprinkler Inlet (inch k

1l2 5.6 - 5.7

3l4 8

Group 2

Cereal mills

Chemical plants ordinary

Confectionery products

Distilleries

Dry cleaners

Feed mills

Horse stables

Leather goods manufacturing

Libraries large stack room areas

Machine shops

Metal working

Mercantile

Paper and pulp mills

Paper process plants

Piers and wharves

Post offices

Printing and publishing

Repair garages

Resin application area

Stages

Textile manufacturing

Tire manufacturing

Tobacco products manufacturing

Wood machining

Wood product assembly

1 in.

1 in.

1 in.

2 in.

2 in.

3 in.

3 in.

4 in.

1 in.

1 in.

Classification of Occupancies.

Ordinary Hazard Occupancies

Copper

Copper

1 in.

2 in.

2 in.

1 in.

1 in.

1 in.

2 in.

2 in.

3 in.

3 in.

4 in.

5 in.

6 in.

8 in.

Table 14.5.3.5 Number of Sprinklers Greater than 12-ft (3.7-m) Separations

2 in.

3 in.

3 in.

1 in.

1 in.

1 in.

2 in.

2 in.

3 in.

Table 10.10.2.1.3 Flow Required to Produce a Velocity of 10 ft/sec (3 m/sec) in Pipes

gpm

390

880

1,560

2,440

3,520

Copper

Copper

FLOW RATE

Copper

Table 11.2.2.1 Water Supply Requirements for Pipe Schedule Sprinkler Systems

Acceptable Flow at Base of Riser

(Including Hose Stream Allowance) (gpm)

500750

8501500

Table 11.2.3.1.1 Hose Stream Demand and Water Supply Duration Requirements for Hydraulically Calculated Systems

Total Combined Inside and Outside

Hose (gpm)

100

250

500

FIGURE 11.2.3.1.5 Density/Area Curves.

Maximum Time of Water Delivery

15 seconds

60 seconds

50 seconds

50 seconds

45 seconds

45 seconds

40 seconds

100

0.713

Hazen-wiliams C values

Pipe or Tube

Plastic (listed) All

Cement lined or Cast or Ductile iron

Copper Tupe or Stainless Steel

C value Multiplier Table

Unlind Cast or Ductile Iron

Black Steel (dry system including Preaction

Black Steel Wet system including Deluge

Gulvanized All

Group 1 Group 2

Aircraft hangars Asphalt saturating

Combustible hydraulic fluid use areas Flammable liquids spraying

Die casting Flow coating

Metal extruding Manufactured home

Plywood and particles Open oil quenching

Printing Plastics processing

Rubber Solvent cleaning

Saw mills Varnish and paint dipping

Textile All kind

Upholstering with plastic foams

2 sprinklers

3 sprinklers

5 sprinklers

12 sprinklers

40 sprinklers

65 sprinklers

115 sprinklers

See Section 8.2

2 sprinklers

4 sprinklers

Extra Hazard Occupancies

Copper

Copper

7 sprinklers

18 sprinklers

65 sprinklers

2 sprinklers

3 sprinklers

5 sprinklers

12 sprinklers

25 sprinklers

45 sprinklers

75 sprinklers

115 sprinklers

180 sprinklers

300 sprinklers

See Section 8.2

20 sprinklers

35 sprinklers

65 sprinklers

2 sprinklers

4 sprinklers

7 sprinklers

18 sprinklers

40 sprinklers

65 sprinklers

L\S

1,476

3,331

5,905

9,235

13,323

Copper

Copper

FLOW RATE

Copper

Duration (minutes

3060

6090

30

60-90

90-120

Duration (minutes)

C Value

100

100

120

120

150

140

150

130 140 150

1.16 1.33 1.51

Hazen-wiliams C values

Pipe or Tube

Plastic (listed) All

Cement lined or Cast or Ductile iron

Copper Tupe or Stainless Steel

C value Multiplier Table

Unlind Cast or Ductile Iron

Black Steel (dry system including Preaction

Black Steel Wet system including Deluge

Gulvanized All

100 130

0.713 1.16

Value of C

Multiplyin Factor

C

C value Multiplier Table

140 150

1.33 1.51

C

C value Multiplier Table

Minimum Pipe Sizes (Nominal)

Suction1, 2 Discharge1 Relief Valve Relief Valve

gpm L/min (in.) (in.) (in.) Discharge

(in.)

25 95 1 1 0.75 1

50 189 1.5 1.25 1.25 1.5

100 379 2 2 1.5 2

150 568 2.5 2.5 2 2.5

200 757 3 3 2 2.5

250 946 3.5 3 2 2.5

300 1136 4 4 2.5 3.5

400 1514 4 4 3 5

450 1703 5 5 3 5

500 1892 5 5 3 5

750 2839 6 6 4 6

1000 3785 8 6 4 8

1250 4731 8 8 6 8

1500 5677 8 8 6 8

2000 7570 10 10 6 10

2500 9462 10 10 6 10

3000 11355 12 12 8 12

3500 13247 12 12 8 12

4000 15140 14 12 8 14

4500 17032 16 14 8 14

5000 18925 16 14 8 14

1 Actual diameter of pump flange is permitted to be different from pipe diameter.

Pump Rating

Meter Device Number and Hose Header Supply

(in.) Size of (in.)

Hose Valves (in.)

1.25 1 11/2 1

2 1 11/2 2.5

2.5 1 21/2 2.5

3 1 21/2 2.5

3 1 21/2 2.5

3.5 1 21/2 3

3.5 1 21/2 3

4 2 21/2 4

4 2 21/2 4

5 2 21/2 4

5 3 21/2 6

6 4 21/2 6

6 6 21/2 8

8 6 21/2 8

8 6 21/2 8

8 8 21/2 10

8 12 21/2 10

10 12 21/2 12

10 16 21/2 12

10 16 21/2 12

10 20 21/2 12

Potrebbero piacerti anche

- All NFPA TablesDocumento24 pagineAll NFPA TablesKhyle Laurenz DuroNessuna valutazione finora

- Fire Fighting Part - 1Documento218 pagineFire Fighting Part - 1Crypto IndiaNessuna valutazione finora

- PP Push-Fit Drainage Solutions Catalogue: "Superior German Quality"Documento31 paginePP Push-Fit Drainage Solutions Catalogue: "Superior German Quality"holoNessuna valutazione finora

- Foam SubmittalDocumento325 pagineFoam SubmittalKiran Al HajiryNessuna valutazione finora

- Hygienic Air Handling Unit Technical SpecificationsDocumento7 pagineHygienic Air Handling Unit Technical SpecificationsMuhammad IlyasNessuna valutazione finora

- The Good Ventilation of Switchgear and Transformer RoomsDocumento8 pagineThe Good Ventilation of Switchgear and Transformer RoomsjayamenggalaNessuna valutazione finora

- Fire DetectionDocumento10 pagineFire DetectionGautam LohiaNessuna valutazione finora

- FM-200™ Fire Suppression System: Product OverviewDocumento6 pagineFM-200™ Fire Suppression System: Product OverviewMAHMUD0% (1)

- SprinkCALC III ReportDocumento17 pagineSprinkCALC III ReportKhronos TempusNessuna valutazione finora

- Analysis of Performance-Based Smoke Management System Design in A Shopping MallDocumento12 pagineAnalysis of Performance-Based Smoke Management System Design in A Shopping MallShiva CivilenggNessuna valutazione finora

- Cla-Val: Fire Protection Pressure Relief ValveDocumento2 pagineCla-Val: Fire Protection Pressure Relief ValveShoaib AhmedNessuna valutazione finora

- UP04We 03 Water Spray SystemsDocumento4 pagineUP04We 03 Water Spray SystemsDucVikingNessuna valutazione finora

- HVWS SystemDocumento1 paginaHVWS Systemabhinay02meNessuna valutazione finora

- Tyco Water Curtain NozzleDocumento2 pagineTyco Water Curtain NozzlejonejackrousseauNessuna valutazione finora

- Product Manual DCP Trolley Mounted 25-50-75 KGDocumento6 pagineProduct Manual DCP Trolley Mounted 25-50-75 KGm4l4ysiaNessuna valutazione finora

- Greensol Aerosol Fire Suppression Systems Model A50: Features & BenefitsDocumento1 paginaGreensol Aerosol Fire Suppression Systems Model A50: Features & BenefitsPedro LacerdaNessuna valutazione finora

- 2 FM200 ComponentsDocumento40 pagine2 FM200 ComponentsJose Antonio Lara0% (1)

- FM DS 8-9Documento79 pagineFM DS 8-9edin64Nessuna valutazione finora

- GW SprinklersDocumento18 pagineGW SprinklersmajdirossrossNessuna valutazione finora

- SprinkCAD 3D 101 Study Guide USDocumento198 pagineSprinkCAD 3D 101 Study Guide USHenry M. Hurtado100% (1)

- Asd 640Documento2 pagineAsd 640RICHI100% (1)

- System Design: Total Flooding Extinguishing SystemDocumento45 pagineSystem Design: Total Flooding Extinguishing SystemsureshkanuboyinaNessuna valutazione finora

- Water Mist Nozzle GW M5 PDFDocumento6 pagineWater Mist Nozzle GW M5 PDFZulfi Andrie ZulkiarNessuna valutazione finora

- Ahu Iom Carrier 39hqDocumento41 pagineAhu Iom Carrier 39hqgenas7265Nessuna valutazione finora

- Heat Load Calculation ExampleDocumento5 pagineHeat Load Calculation ExampleJoshua RanjithNessuna valutazione finora

- Wise CatalogDocumento177 pagineWise CatalogHatim IshakNessuna valutazione finora

- 04-Sprinkler SystemDocumento32 pagine04-Sprinkler SystemRavi100% (1)

- Rxco2 DatasheetDocumento15 pagineRxco2 DatasheetBadr groupNessuna valutazione finora

- Ansul R-102Documento4 pagineAnsul R-102heliopintoNessuna valutazione finora

- BAFSA Technical Guidance No 1, November 2012Documento30 pagineBAFSA Technical Guidance No 1, November 2012flegheton100% (1)

- GreenEX - Cataloge - DSPA CompetitorDocumento4 pagineGreenEX - Cataloge - DSPA CompetitorJai GosarNessuna valutazione finora

- Unit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Documento21 pagineUnit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Navya chowdaryNessuna valutazione finora

- Water Spray SystemDocumento5 pagineWater Spray SystemNguyenThanhdungNessuna valutazione finora

- Prince Rupert Natural Gas Transmission Compressor Station Basics Factsheet TranscanadaDocumento2 paginePrince Rupert Natural Gas Transmission Compressor Station Basics Factsheet TranscanadaShaho Abdulqader MohamedaliNessuna valutazione finora

- Tyco Fire Protection Products: The Sprinkcad Installation Instruction PamphletDocumento11 pagineTyco Fire Protection Products: The Sprinkcad Installation Instruction PamphletYairton Vargas MuñozNessuna valutazione finora

- Types of Fire:: Type DescriptionDocumento9 pagineTypes of Fire:: Type DescriptionMuStafaAbbasNessuna valutazione finora

- Waterspray MistextinguishingsystemDocumento10 pagineWaterspray MistextinguishingsystemSalley BukhariNessuna valutazione finora

- Nfs2-8 Instal Manual WebDocumento0 pagineNfs2-8 Instal Manual WebDota NgNessuna valutazione finora

- Ahri Standard 410-2023 Si I-PDocumento93 pagineAhri Standard 410-2023 Si I-PDalaPaulaNessuna valutazione finora

- Nordtest Method NT Fire 049Documento16 pagineNordtest Method NT Fire 049mail2021Nessuna valutazione finora

- Fts034 Hi-Fog 2000 Us Light Hazard (FM)Documento3 pagineFts034 Hi-Fog 2000 Us Light Hazard (FM)Wissam Jarmak100% (1)

- Article - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFDocumento8 pagineArticle - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFphilipyongNessuna valutazione finora

- PyroSim User Manual - Thunderhead Support PDFDocumento138 paginePyroSim User Manual - Thunderhead Support PDFJohnson ChuaNessuna valutazione finora

- 01 - Chemetics Anotrol 2000 InfoSheetDocumento2 pagine01 - Chemetics Anotrol 2000 InfoSheetWeb Logueando100% (1)

- Access Door 2010Documento4 pagineAccess Door 2010Roy Anthone LaysonNessuna valutazione finora

- Hydraulic Calculation For FFDocumento2 pagineHydraulic Calculation For FFtowiwaNessuna valutazione finora

- Fire ProDocumento104 pagineFire ProMaiger100% (2)

- Fire MistDocumento93 pagineFire Mistgambin888Nessuna valutazione finora

- 03 - INTERPIPE Catalogue - Seamless PipesDocumento20 pagine03 - INTERPIPE Catalogue - Seamless PipesClarkFedele27Nessuna valutazione finora

- Water Cooled Fcu Piping DetailsDocumento14 pagineWater Cooled Fcu Piping Detailsfernandoreyes893Nessuna valutazione finora

- Pipe NetDocumento4 paginePipe NetasbuasbuNessuna valutazione finora

- QCDD BP GuidelinesDocumento6 pagineQCDD BP Guidelines남광연0% (1)

- Net Positive Suction HeadDocumento7 pagineNet Positive Suction HeadNenad MutavdzicNessuna valutazione finora

- Ventilation in Hospital ProjectsDocumento18 pagineVentilation in Hospital ProjectsMAGDY KAMELNessuna valutazione finora

- Fire Resisting Construction 1996-AllDocumento39 pagineFire Resisting Construction 1996-AlliyhkNessuna valutazione finora

- NAFFCO - Associated CompaniesDocumento1 paginaNAFFCO - Associated CompaniesTerrence Gil Pamienta BuenaflorNessuna valutazione finora

- B5-Sprinkler Pumps With VDS Approval - 2009Documento64 pagineB5-Sprinkler Pumps With VDS Approval - 2009eimrehNessuna valutazione finora

- General Plumbing KnowledgeDocumento6 pagineGeneral Plumbing KnowledgeobNessuna valutazione finora

- Gas AnalyzerDocumento40 pagineGas Analyzercranker117Nessuna valutazione finora

- 200t Normal Pressure Oil Rotocel ExtractionDocumento3 pagine200t Normal Pressure Oil Rotocel ExtractionWanda OilpressNessuna valutazione finora

- Unsafe Acts Safety TalkDocumento1 paginaUnsafe Acts Safety Talksafety86Nessuna valutazione finora

- Safety MomentsDocumento1 paginaSafety Momentssafety86100% (1)

- Fire Crisis - PPSXDocumento17 pagineFire Crisis - PPSXsafety86Nessuna valutazione finora

- 04 Flame TemperatureDocumento38 pagine04 Flame TemperatureGnanasambandan SwaminathanNessuna valutazione finora

- HSE Tool Box TalkDocumento47 pagineHSE Tool Box TalkAbdulKather100% (10)

- Unsafe Acts Safety TalkDocumento1 paginaUnsafe Acts Safety Talksafety86Nessuna valutazione finora

- Fire Fighting Course - PPSXDocumento58 pagineFire Fighting Course - PPSXsafety86Nessuna valutazione finora

- Fire Fighting: Shabbir ChannaDocumento20 pagineFire Fighting: Shabbir Channasafety86Nessuna valutazione finora

- Accident Reporting Procedure 1Documento2 pagineAccident Reporting Procedure 1safety86Nessuna valutazione finora

- Accident Report FormDocumento1 paginaAccident Report Formsafety86Nessuna valutazione finora

- 3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5Documento2 pagine3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5safety86Nessuna valutazione finora

- Accident Report FormDocumento1 paginaAccident Report Formsafety86Nessuna valutazione finora

- 3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5Documento2 pagine3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5safety86Nessuna valutazione finora

- 3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5Documento2 pagine3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5safety86Nessuna valutazione finora

- Bauer Hse Policy enDocumento1 paginaBauer Hse Policy ensafety86Nessuna valutazione finora

- 27k Crane Lifting PermitDocumento1 pagina27k Crane Lifting Permitsafety86Nessuna valutazione finora

- Safety at Work AwardsDocumento37 pagineSafety at Work Awardssafety86Nessuna valutazione finora

- Human Factors in Accident Investigation: David BirkbeckDocumento30 pagineHuman Factors in Accident Investigation: David Birkbecksafety86Nessuna valutazione finora

- Foot ProtectDocumento29 pagineFoot Protectjinyuan74100% (1)

- Safety at Work: and Here Are The Winners of The CompetitionDocumento23 pagineSafety at Work: and Here Are The Winners of The Competitionsafety86Nessuna valutazione finora

- Topic One: An Introduction To Health & Safety in IndustryDocumento19 pagineTopic One: An Introduction To Health & Safety in IndustrysrkamNessuna valutazione finora

- Testing of Lifts: Simple Guidance For Lift Owners (INDG339) )Documento2 pagineTesting of Lifts: Simple Guidance For Lift Owners (INDG339) )safety86Nessuna valutazione finora

- IMS PolicyDocumento2 pagineIMS Policysafety86Nessuna valutazione finora

- Generic PpeDocumento32 pagineGeneric Ppesafety86Nessuna valutazione finora

- Welding, Cutting and Brazing ChecklistDocumento11 pagineWelding, Cutting and Brazing ChecklistokamoNessuna valutazione finora

- Sample Written Program For Fall Protection: Provided As A Public Service byDocumento25 pagineSample Written Program For Fall Protection: Provided As A Public Service bysafety86Nessuna valutazione finora

- Editable Health and Safety FormsDocumento32 pagineEditable Health and Safety FormsFlavia Rodrigo Guedes100% (1)

- 2fse Hierarchy of ControlDocumento17 pagine2fse Hierarchy of ControlredbireNessuna valutazione finora

- China Hydrotest FailureDocumento7 pagineChina Hydrotest FailureaatkhoNessuna valutazione finora

- Thomas HardyDocumento11 pagineThomas HardyShan Sumalani100% (3)

- Regent BrochureDocumento81 pagineRegent BrochurekasunNessuna valutazione finora

- Zero Conditional - (Type Zero) - Situación Siempre VerdaderaDocumento4 pagineZero Conditional - (Type Zero) - Situación Siempre VerdaderaFernanda SabaNessuna valutazione finora

- The New World Order: in Their Own Words & in The Bible (HISTORY OF FREEMASONS EXPOSED)Documento16 pagineThe New World Order: in Their Own Words & in The Bible (HISTORY OF FREEMASONS EXPOSED)treadingserpents100% (2)

- Reflection 1Documento2 pagineReflection 1api-302897695Nessuna valutazione finora

- How To Build A Network Intrusion Detection System: Step by Step InstructionsDocumento35 pagineHow To Build A Network Intrusion Detection System: Step by Step InstructionsMuh SoimNessuna valutazione finora

- Hill ArchitectureDocumento5 pagineHill ArchitectureShubamGargNessuna valutazione finora

- Vcop Pyramids 1Documento6 pagineVcop Pyramids 1Haslina ZakariaNessuna valutazione finora

- Balaji Telefilms IsDocumento14 pagineBalaji Telefilms IsdhanvaniNessuna valutazione finora

- Beowulf Extension ActivitiesDocumento2 pagineBeowulf Extension Activitiesapi-259906929Nessuna valutazione finora

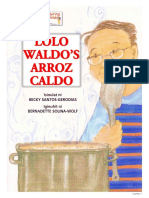

- Lolo Waldo S ArrozcaldoDocumento25 pagineLolo Waldo S ArrozcaldoLyn Romero81% (16)

- Name: - Gr. & Sec.: - ScoreDocumento2 pagineName: - Gr. & Sec.: - ScoreCriza Bill LauNessuna valutazione finora

- Vizio E701i-A3 CNET Review Calibration ResultsDocumento7 pagineVizio E701i-A3 CNET Review Calibration ResultsDavid KatzmaierNessuna valutazione finora

- Project-Orpheus A Research Study Into 360 Cinematic VRDocumento6 pagineProject-Orpheus A Research Study Into 360 Cinematic VRjuan acuñaNessuna valutazione finora

- Introduct. To Linguistics Paso 4Documento5 pagineIntroduct. To Linguistics Paso 4DanielaNessuna valutazione finora

- Pidicrete URPDocumento4 paginePidicrete URPsaaz adilNessuna valutazione finora

- Svitlana Matviyenko The Imaginary App 1Documento328 pagineSvitlana Matviyenko The Imaginary App 1Mariano Carrasco MaldonadoNessuna valutazione finora

- Grammar Revision ExercisesDocumento4 pagineGrammar Revision ExercisesNicoletaNessuna valutazione finora

- Om SemDocumento89 pagineOm SemRezki AshidiqiNessuna valutazione finora

- Unit 2 StaircaseDocumento75 pagineUnit 2 StaircaseArsh ChaudharyNessuna valutazione finora

- Hero and Leander QuotesDocumento2 pagineHero and Leander QuotesCharlie JasperNessuna valutazione finora

- Inertia Design Studio: Republic Act 9266 Section 33Documento1 paginaInertia Design Studio: Republic Act 9266 Section 33kalix Dela CruzNessuna valutazione finora

- Knitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1Documento25 pagineKnitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1shahinrezaNessuna valutazione finora

- The American Tabacco CompanyDocumento5 pagineThe American Tabacco CompanyMarkiesha StuartNessuna valutazione finora

- Dosage Forms Module 1Documento2 pagineDosage Forms Module 1Lyka TamarayNessuna valutazione finora

- Vishniac's Photo Archive Lands at Magnes, Including Unseen Israel Images - Jweekly 2018.11.20Documento4 pagineVishniac's Photo Archive Lands at Magnes, Including Unseen Israel Images - Jweekly 2018.11.20spagnoloachtNessuna valutazione finora

- CollectionDocumento10 pagineCollectionqafewghtrhgfNessuna valutazione finora

- David Bordwell - The Poetics of Cinema - IntroDocumento9 pagineDavid Bordwell - The Poetics of Cinema - IntroSudipto BasuNessuna valutazione finora

- Name: Sarah Quinlan Class: W20 EDUC1321-02 Plan/Direct, Per. Due Date: Jan 31, 2020Documento10 pagineName: Sarah Quinlan Class: W20 EDUC1321-02 Plan/Direct, Per. Due Date: Jan 31, 2020api-526505312Nessuna valutazione finora

- World Travel Agency: GermanyDocumento8 pagineWorld Travel Agency: GermanyAnonymous 27EhWKmhsaNessuna valutazione finora