Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Trailer Systems Troubleshooting Guide W7NPA Radio

Caricato da

Zeck0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

303 visualizzazioni2 pagineThis document provides guidance on troubleshooting air brake systems for trailers. It begins by explaining how to identify whether the issue is with the parking or service brake system. It then describes the various air brake systems used on trailers (labeled Systems A through H) and how to identify which system a specific trailer has. The document concludes by listing potential problems with the different systems and recommended solutions.

Descrizione originale:

Trailer Electrical Troubleshooting Guide

Titolo originale

Trailer Systems Troubleshooting Guide W7NPA Radio (1)

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document provides guidance on troubleshooting air brake systems for trailers. It begins by explaining how to identify whether the issue is with the parking or service brake system. It then describes the various air brake systems used on trailers (labeled Systems A through H) and how to identify which system a specific trailer has. The document concludes by listing potential problems with the different systems and recommended solutions.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

303 visualizzazioni2 pagineTrailer Systems Troubleshooting Guide W7NPA Radio

Caricato da

ZeckThis document provides guidance on troubleshooting air brake systems for trailers. It begins by explaining how to identify whether the issue is with the parking or service brake system. It then describes the various air brake systems used on trailers (labeled Systems A through H) and how to identify which system a specific trailer has. The document concludes by listing potential problems with the different systems and recommended solutions.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

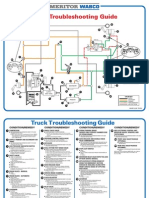

Trailer Systems Troubleshooting Guide

REV. 6/02 25M CUT L20305

HOW TO USE THIS CHART

The purpose of the chart is to help you solve a specific problem in the pneumatic portion of a trailer air brake system with the

assumption the foundation brake components and tractor pneumatics are in good repair.

Identify which system is malfunctioning. (Refer to how to check your system).

Identify your system from the schematics shown.

Identify the problem and select the solution recommended for that system.

CAUTION: WHEELS MUST BE BLOCKED.

CAUTION: SPRING BRAKE INSPECTION AND DISASSEMBLY MUST BE IN ACCORD WITH THE

MANUFACTURERS PROCEDURE.

HOW TO CHECK YOUR SYSTEM

The most important factor in trailer troubleshooting is to determine if the malfunction is in the vehicles parking brake system

or the service brake system. If the problem is Neither air system is working, the fault may be mechanical. All Pre-121 or

new 121 trailers have a parking/emergency system and a normally used service brake system. The parking system

works from the emergency (supply) line. The service system works from the service (control) line. You can determine if the

parking emergency brakes operate by charging and then disconnecting the tractor emergency (supply) line.

The service brakes will operate with apply and release air in the service (control) line by the tractor hand control or foot

control valve.

HOW TO IDENTIFY YOUR SYSTEM

All types of trailer air brake systems can be identified for troubleshooting purposes by starting from the brake chamber or

spring brake assembly. This procedure will work for older Pre-121 equipped trailers regardless of how many tanks and

valves, or types of valves that you see.

If your trailer is equipped with chambers only you are dealing with system A for a trailer and systems C and D for a

converter dolly. A four-wheel trailer may have chambers on the steerable axle identify axle as a dolly system C or D.

If the vehicle is equipped with spring brakes you must determine which hose is the parking/emergency and which is the

service.

Follow the service hose from the service portion of the spring brake assembly, the hose will be connected to the service relay

valve and it is responsible for the application and release of the service brake only.

Follow the parking/emergency hose from the spring brake assembly and you will end up at the spring brake control valve.

After you have identified your system, go directly to the Problem and Solution Sections on the reverse side to remedy your

situation.

SYSTEM J

TWO TANK ONE VALVE TANDEM AXLE SYSTEM

SYSTEM D

TYPICAL 121 DOLLY SYSTEM WITH

NON-CHARGING TYPE RELAY/EMERGENCY VALVE

SYSTEM E

TWO TANK TWO VALVE SINGLE AXLE SYSTEM WITH MIDLAND

RT4/RG2 VALVE OR SEALCO MULTI-FUNCTION & RELAY

SYSTEM A

PRE-121 RELAY/EMERGENCY VALVE SYSTEM

SYSTEM C

SINGLE AXLE DOLLY SYSTEM WITH CHARGING TYPE

RELAY/EMERGENCY VALVE

SYSTEM B

PRE-121 RELAY/EMERGENCY VALVE SYSTEM

WITH SPRING BRAKES

SYSTEM F

MOD-I FULL FUNCTION ABS 2S/1M

SYSTEM H

TWO TANK THREE VALVE TANDEM SYSTEM MIDLAND RT4/RG2 (RG5) VALVES

OR SEALCO MULTI-FUNCTION WITH SERVICE RELAY VALVE

SYSTEM G

MOD-II ABS 4S/2M

For ABS Troubleshooting, See ABS Diagnostic Troubleshooting Guide (L20293).

For ABS Troubleshooting, See ABS Diagnostic Troubleshooting Guide (L20293).

NOTE: Proc edures suggested on this c hart are merely suggested and should not be c onstrued to be all inc lusive nor should the sc hematic s be regarded as typic al of piping patterns on all vehic les.

EMERGENCY

RELAY VALVE

ASSEMBLY

GLADHAND

SERV./CONT.

GLADHAND

EMER./SUPPLY

BRAKE ADJUSTER

AIR CHAMBER

OPTIONAL

SPEED UP

RELAY

GLADHAND

SERV./CONT.

GLADHAND

EMER./SUPPLY

TO REAR SEMI

TRAILER

RT4 VALVE

GLADHAND

SERV./CONT.

GLADHAND

EMER./SUPPLY

OPTIONAL

ANTI-COMPOUNDING

RG2 VALVE

BRAKE

ADJUSTER

SPRING BRAKE

BRAKE ADJUSTER

GLADHAND

SERV./CONT.

GLADHAND

EMER./SUPPLY

RG2 OR RG5 VALVE (2)

RT4 VALVE

SPRING BRAKE

FULL FUNCTION

(FF2) VALVE

GLADHAND

SERV./CONT.

GLADHAND

EMER./SUPPLY

BRAKE ADJUSTER

SPRING

BRAKE

EMER./SUPPLY SER./CONT. SER./DEL. PARK/EMER. DEL.

FULL FUNCTION

ABS VALVE

GLADHAND

SERV./CONT.

GLADHAND

EMER./SUPPLY

ABS RELAY VALVE

WITH ECU

FULL FUNCTION

ABS VALVE

WITH ECU

GLADHAND

SERV./CONT.

GLADHAND

EMER./SUPPLY

EXCITER RING

AND SENSOR

EMERGENCY

RELAY VALVE

ASSEMBLY

GLADHAND

SERV./CONT.

GLADHAND

EMER./SUPPLY

BRAKE ADJUSTER

AIR CHAMBER

EMERGENCY

RELAY

GLADHAND

SERV./CONT.

GLADHAND

EMER./SUPPLY

BRAKE ADJUSTER

AIR CHAMBER

EXCITER RING

AND SENSOR

PROBLEM SYSTEM LETTER AND SOLUTION NUMBER SOLUTION

REV. 6/02 25M CUT L20305

1. Check service chamber at clamp housing, push rod

for damage.

2. Check service chamber diaphragm for rupture.

3. Check brake adjuster and chamber/spring brake

push rod alignment for interference.

4. Assure brake adjuster and chamber/spring brake

push rod angle 90 applied with proper adjustment.

5. Check all lines, valves, reservoirs, actuators for

leakage.

6. Check spring brake for damage or loose clamp.

7. Assure jumper hoses are not crossed.

8. Assure functional return spring in service chamber

or spring brake.

9. Assure air chamber size and brake adjuster arm

length to original spec.

10. Assure spring brake control port has exhausted.

11. Check for ruptured spring brake diaphragm (furthest

from brake adjuster).

12. Supply/emergency line must be at atmosphere.

13. Assure emergency line exceeds 100 psi pressure;

check and maintain governor at max cut-in.

14. Assure air delivery to service gladhand.

15. Assure air delivery to service relay valve control port.

16. Assure air delivery to air chamber or spring brake.

17. Assure air delivery to emergency gladhand exceeds

100 psi.

18. Assure air delivery to emergency relay valve

emergency port.

19. Assure air delivery to all reservoirs at system

working pressure.

20. Assure air delivery to spring brake control valve

control port.

21. Assure air delivery to control port on spring brake

(port furthest from brake adjuster).

22. Assure open lines no kinks, bends, closed shut-off

cocks, restrictions, excessive elbows.

23. Check for trapped service air pressure at trailer

service/delivery hoses. If air pressure is noted, check

for full release of all application valves (tractor/truck/

trailer).

24. Trailer brakes which have a spring brake control valve

can be compounded by the tractor air brake

system. The compounding occurs when service air

pressure is trapped in the trailer service line by the

tractor protection valve when the supply line is

released to atmosphere. Compounding is prevented

by connecting the trailer service line to the

appropriate port of the trailer spring brake control valve

through a tee. Early spring brake control valves are

equipped with a shuttle valve between the supply

and service connections at the cover. The RT-4 has

a one-way check valve which prevents supply

pressure from entering the service lines; but will allow

service pressure to vent at trailer supply coupling.

Systems A, B, C, D will not compound the trailer

brake system if connected as shown on this chart.

25. Check for ruptured service brake diaphragm in spring

brake (clamp nearest brake adjuster) after attention

to damage or loose clamps.

26. Proceed same as for service relay valve.

27. Assure spring brake is fully released with supply air

at system pressure above 100 psi on emergency side

of spring brake.

28. Excessive volume imposed in supply/emergency

lines ie: air pintle air chamber.

29. On a pre-121 exempt trailer utilizing an emergency

relay valve, the spring brake emergency port should

be plumbed directly to the tank.

30. Observe and determine which specific device,

fitting or hose is leaking and replace.

31. Assure a leak free system by applying service brake

and inspecting.

32. Note that some trailers may have the emergency/

supply line piped to a single check valve at both

tanks one could be leaking.

33. Check for failure in spring brake center seal.

A. Block wheels and release park brake.

B. Check for air pressure leakage at service port of

each spring brake until the leaking assembly is

located. Replace leaking unit.

C. If no spring brake leakage is found see #41.

34. Confirm and replace with Type 30 diaphragm, air

chamber Type 30.

35. Confirm and replace/use rubber grommets with

integral brackets.

36. Confirm and replace with appropriate spring brake

assembly; Type 30/30 or Type 24/30. Diaphragm

Type 24/30 PiggyBack.

37. Confirm and replace with Type 30/30 PiggyBack or

Type 24/30 PiggyBack.

38. Confirm and replace with service relay valve 1/2

supply or 3/8 supply.

39. Confirm and replace with task spring brake control

valve.

40. Confirm and replace with RT-4 spring brake control

valve (replaces Sealco ratio valves).

41. Assure adequate trailer brake function.

42. Confirm and replace with emergency relay valve,

1/4 Delivery or 3/8 Delivery.

43. Confirm and replace with FFV (Full Function Valve)

System.

44. Assure adequate tractor brake function.

45. Assure adequate pressure and timing balance

relative to tractor/trailer application.

46. Consider addition of FAB Valve to accelerate trailer

timing.

47. Consider use of jumper hose analyzer and

duplex gauge to pin-point brake imbalance.

48. Assure full mechanical release foundation brake.

49. Assure push-out pressure or initial brake adjuster

motion at 3 to 7 psi at all brakes.

50. Proceed per problem trailer brakes drag.

51. Confirm and replace with emergency relay valve

(non-charging).

52. Confirm and replace with pressure protection valve

with one-way check, 50 psi or 75 psi.

53. Confirm and replace with full function valve (FFV).

FFV has built-in anti-compounding feature.

54. Confirm and replace with spring brake priority or

service brake priority (FFABS) ABS full function

valve.

NOTE: FOR FURTHER TECHNICAL ASSISTANCE CONTACT YOUR HALDEX SERVICES

DISTRIBUTOR, DISTRICT MANAGER, A TECHNICAL SERVICE REPRESENTATIVE OR

CALL (800) 643-2374 AND ASK FOR A TECHNICAL ADVISOR.

AIR LEAK AT

Service Brake Chamber 1-2-34 1-2-34 1-2-34

Spring Brake with Service Brakes Released & Park Brake Applied 11-36-37

Spring Brake with Service Brakes Released & Park Brake Released 6-11-36 6-11-36 6-11-36 6-11-36 6-11-36 6-11-36

or 37 or 37 or 37 or 37 or 37 or 37

Spring Brake with Service Brakes Applied & Spring Brake Released 6-25-36 6-25-36 6-25-36 6-25-36 6-25-36 6-25-36

Emergency Relay Valve with Service Brake Applied or Released 42 33-36-37 42 51

or 42

Emergency Relay Valve with Emergency Brake Applied 42 42 42 51

Service Relay Valve with Service Brake Released & Spring Brake Applied 38 54 54 38 53

Service Relay Valve with Service Brake Released & Spring Brake Released 33-38 33-54 33-54 33-38 33-53

Service Relay Valve with Service Brake Applied & Spring Brake Released 38 54 54 38 53

Spring Brake Control Valve with Spring Brake Applied or Released 40 54 54 40 53

Trailer Service Gladhand on Disconnect (with Trailer Supply Pressurized) 42 42 42 51 24-40 54 54 24-40 53

Trailer Emergency Gladhand on Disconnect 42 42 42 51 or 52

Trailer System Leakage Exceeds 2 p.s.i., per min. with Service Brakes Applied 30 30 30 30 30 30 30 30 30

SERV Valve with Service Brake Released & Park Brake Applied

SERV Valve with Service Brake Released & Park Brake Released

SERV Valve with Service Brake Applied & Park Brake Released

SYSTEM OR COMPONENT FAILURE

Trailer Brakes Slow and Sluggish 3-4-22- 3-4-22 3-4-22 3-4-22 3-4-22 3-4-22 3-4-22 3-4-22 3-4-22

44-45- 44-45- 44-45- 44-45- 44-45- 44-45- 44-45- 44-45- 44-45-

46-47 46-47 46-47 46-47 46-47 46-47 46-47 46-47 46-47

Trailer Brakes Drag 3-4-13- 3-4-22- 3-4-22- 3-4-22- 3-4-13- 3-4-13- 3-4-13- 3-4-13- 3-4-13-

22-23- 23-27 23-42 23-51 22-23- 22-23- 22-23- 22-23- 22-23-

42 27-37 27-37 27-37 27-37 27-37

Trailer Brakes Wont Apply (Service) 3-4-14- 3-4-14- 3-4-14- 3-4-14- 3-4-14- 3-4-14- 3-4-14- 3-4-14- 3-4-14-

16-18-19 16-18-19 16-18-19 14-18-19 15-16-19 15-16-19 15-16-19 15-16-19 15-16-19

Trailer Emergency Application Too Slow 22-28 22-28 22-28 22-28 22-28 22-28 22-28 22-28 22-28

Park/Emergency Brakes Wont Release 7-17-18- 7-11-17- 7-17-18- 7-17-18 7-11-17- 7-11-13- 7-11-13- 7-11-17- 7-11-13-

19-22-42 18-19- 19-22- 19-22- 19-22- 17-19- 17-19-22- 19-22- 17-19-

22-42 42 51 40 22-54 54 40 53

Park/Emergency Brakes Wont Hold 3-4-19 3-4-36 19-32 19-32 3-4-36 3-4-36 3-4-36 3-4-36 3-4-36

or 37 or 37 or 37 or 37 or 37 or 37

Park/Emergency Brakes Wont Apply 4-12- 4-12- 4-12- 4-12- 4-10- 4-10- 4-10- 4-10- 4-10-

19-42 19-36 or 19-42 19-51 12-36 or 12-36 or 12-36 or 12-36 or 12-36 or

37-42 37-40 37-54 37-54 37-40 37-53

Air Reservoir Leaks or Loose Mounting 35 35 35 35 35 35 35 35 35

BRAKE BALANCE

Semi-Trailer RUNS-UP on Tractor 4-22-45- 4-22-45- 4-22-46- 4-22-46- 4-22-45- 4-22-45- 4-22-45- 4-22-45 4-22-45

46-47-49 46-47-49 47-49 47-49 46-47-49 46-47-49 46-47-49 46-47-49 46-47-49

Uneven Brakes 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22- 3-4-22

31-49 31-49 31-49 31-49 31-49 31-49 31-49 31-49 31-49

Trailer Brake Lining Wear Excessive 45-50 27-44-50 44-50 44 27-44-50 27-44-50 27-44-50 27-44-50 27-44-50

Trailer Brake Lining Wear Insufficient When Compared to Tractor 4-16-45- 4-16-45- 4-17-45- 4-16-45- 4-16-45- 4-16-45- 4-16-45- 4-16-45- 4-16-45-

46-47-49 46-47-49 46-47-49 46-47-49 46-47-49 46-47-49 46-47-49 46-47-49 46-47-49

Trailer Brakes Slow to Apply 4-19-22- 4-19-22- 4-19-22- 4-19-22- 4-19-22- 4-19-22- 4-19-22- 4-19-22- 4-19-22-

46-47 46-47 46-47 46-47 46-47 46-47 46-47 46-47 46-47

Trailer Brakes Slow to Release 8-22-42- 8-22-42- 8-22-42- 8-22-47- 8-22-38- 8-22-38- 8-22-38- 8-22-38- 8-22-38-

47-48 47-48 47-48 48-51 47-48 47-48 47-48 47-48 47-48

Damaged Foundation Components Due to Brake Compounding 29 24 24 54 54 24 53

A B C D E F G H J

HALDEX LIMITED

525 Southgate Drive, Unit 1

Guelph, Ontario Canada N1G 3W6

Phone: (519) 826-7723

Fax: (519) 826-9497

BRAKE SYSTEM DIVISION

North Americ an Sales & Svc . Org.

10707 N.W. Airworld Drive

Kansas City, Missouri 64153-1215

Phone: (816) 891-2470 Fax: (816) 880-9766

BRAKE SYSTEMS DIVISION

World Headquarters

10930 N. Pomona Avenue

Kansas City, Missouri 64153-1297

Phone: (816) 891-2470 Fax: (816) 891-9447

www.hbsna.com

Potrebbero piacerti anche

- Bendix Air Brake System Schematic PDFDocumento1 paginaBendix Air Brake System Schematic PDFraidhemed67% (3)

- Air Brake System DiagramDocumento2 pagineAir Brake System Diagramlostintroy100% (16)

- Air Brake Manual CompDocumento102 pagineAir Brake Manual Compshan4600100% (1)

- Bendix Air Brake HandbookDocumento67 pagineBendix Air Brake Handbookwmaresko100% (4)

- Service Manual: Failure Analysis June 2009Documento50 pagineService Manual: Failure Analysis June 2009ericNessuna valutazione finora

- Abs BendixDocumento72 pagineAbs BendixVeterano del CaminoNessuna valutazione finora

- Airbrake Manual EnglishDocumento58 pagineAirbrake Manual EnglishJennifer ParkerNessuna valutazione finora

- 72 Fuller RTLO 18918B As Transmission Service ManualDocumento130 pagine72 Fuller RTLO 18918B As Transmission Service Manualmaciasalan80Nessuna valutazione finora

- Air Brake BendixDocumento136 pagineAir Brake Bendixqwureyquwery100% (5)

- Trsm0940en Us PDFDocumento255 pagineTrsm0940en Us PDFSelvin Escobar RojasNessuna valutazione finora

- Freightliner Coronado SD: SectionDocumento23 pagineFreightliner Coronado SD: SectionhoangnhuphuocNessuna valutazione finora

- Isuzu Commercial Truck Forward Tiltmaster Service Manual Supplement 2003 PDFDocumento215 pagineIsuzu Commercial Truck Forward Tiltmaster Service Manual Supplement 2003 PDFArnel AlmenarioNessuna valutazione finora

- Catalogo Abs Meritor WabcoDocumento12 pagineCatalogo Abs Meritor Wabcosifuentes18100% (3)

- 2009 BodyBuilderGuideDocumento412 pagine2009 BodyBuilderGuideSixto CairaNessuna valutazione finora

- 014-013 Aftertreatment TestingDocumento9 pagine014-013 Aftertreatment TestingIan Woods0% (1)

- DAVIE Quick Ref Guide 2012 - ProgrammingDocumento2 pagineDAVIE Quick Ref Guide 2012 - ProgrammingCharly Ramos100% (1)

- Air Brake SystemDocumento81 pagineAir Brake SystemOdalis Caba100% (15)

- Wabco Wall Chart For Trailer and Truck AbsDocumento1 paginaWabco Wall Chart For Trailer and Truck AbsJay RitschardNessuna valutazione finora

- Wabco ABSDocumento20 pagineWabco ABSachampney679667% (6)

- Wabco Trailer AbsDocumento47 pagineWabco Trailer AbsMohd FairusNessuna valutazione finora

- 01air Elect Feb2015Documento27 pagine01air Elect Feb2015juanNessuna valutazione finora

- Climate SystemDocumento25 pagineClimate Systeminformer techNessuna valutazione finora

- Axsm 0042Documento144 pagineAxsm 0042aliNessuna valutazione finora

- DieselNet Technology GuideDocumento5 pagineDieselNet Technology Guidealoksemail2011Nessuna valutazione finora

- Road RangerDocumento466 pagineRoad RangerGiapy Phuc Tran0% (1)

- Instrument Panel ClusterDocumento36 pagineInstrument Panel Clusterkvp61327Nessuna valutazione finora

- Ajuste de Eaton EmbragueDocumento5 pagineAjuste de Eaton EmbragueHamilton Miranda100% (1)

- Pressure Testing The Intake & Exhaust Sys at One TimeDocumento2 paginePressure Testing The Intake & Exhaust Sys at One Timejaime roblesNessuna valutazione finora

- Frenos WabcoDocumento61 pagineFrenos WabcoFastcross HondaNessuna valutazione finora

- Bendix Partes Del SistemaDocumento1 paginaBendix Partes Del SistemaMiguel Valdivia Quesada100% (1)

- Air Brake SystemDocumento20 pagineAir Brake Systemmeseraabdi100% (2)

- Axsm 0046Documento114 pagineAxsm 0046igoraryskinNessuna valutazione finora

- Air Brake Manual CompleteDocumento95 pagineAir Brake Manual CompleteAnjum Ansh Khan100% (1)

- Air Over BrakeDocumento50 pagineAir Over Brakesidik purnomo100% (1)

- Bendix D-2 GovernorDocumento4 pagineBendix D-2 GovernormarcrunnerNessuna valutazione finora

- Meritor ABS TrainingDocumento108 pagineMeritor ABS Trainingford62b100% (3)

- Clutch PDFDocumento12 pagineClutch PDFIzz BaharNessuna valutazione finora

- Brake System - Exc Wed - PDFDocumento20 pagineBrake System - Exc Wed - PDFMAQUINARIAPESADA100% (1)

- CLSM0200 0512aDocumento68 pagineCLSM0200 0512amds9185Nessuna valutazione finora

- Bendix ® Gen 4 TM and Gen 5 TMDocumento48 pagineBendix ® Gen 4 TM and Gen 5 TMMarcialCastroLeonidasNessuna valutazione finora

- Fuel SystemDocumento7 pagineFuel SystemখালিদহাসানNessuna valutazione finora

- Isuzu Specs For NPR HD Crew DieselDocumento29 pagineIsuzu Specs For NPR HD Crew DieselDaniel Moya100% (1)

- Turbo ChargersDocumento8 pagineTurbo ChargersPhil B.Nessuna valutazione finora

- Bendix - AD-IP Sevice Data (SD-08-2414)Documento28 pagineBendix - AD-IP Sevice Data (SD-08-2414)Eduardo SanchezNessuna valutazione finora

- Ivtm - Tire Pressure Monitoring For Commercial Vehicles: System DescriptionDocumento48 pagineIvtm - Tire Pressure Monitoring For Commercial Vehicles: System DescriptionElmin SkuljNessuna valutazione finora

- Air Brake ManualDocumento92 pagineAir Brake ManualAbhishek Sase100% (1)

- 01A Air Elect Mar2017Documento28 pagine01A Air Elect Mar2017Oscar HernandezNessuna valutazione finora

- 2002 Electrical General PDFDocumento102 pagine2002 Electrical General PDFEduardo Barrios50% (2)

- Como Remover Un Iyector MackDocumento6 pagineComo Remover Un Iyector MackHamilton MirandaNessuna valutazione finora

- Abs Wabco Manutec2Documento47 pagineAbs Wabco Manutec2Bom_Jovi_681Nessuna valutazione finora

- AutoDocumento111 pagineAutomanuales1000100% (1)

- TechOne - Automatic Transmissions Chapter 23,28Documento21 pagineTechOne - Automatic Transmissions Chapter 23,28don krtek100% (1)

- 4208-26, S 2 1Documento34 pagine4208-26, S 2 1Robert RustenNessuna valutazione finora

- Chapter 28-BennetDocumento63 pagineChapter 28-BennetsengottaiyanNessuna valutazione finora

- Truck Brake Systems PDFDocumento63 pagineTruck Brake Systems PDFLazarusNessuna valutazione finora

- 26l Brake Valve KBPDFDocumento80 pagine26l Brake Valve KBPDFfernanguedes2071Nessuna valutazione finora

- Bendix TCS-9000 Control Brake Valve: HandleDocumento4 pagineBendix TCS-9000 Control Brake Valve: Handlejorge chavarriaNessuna valutazione finora

- Vacuum Air BrakeDocumento55 pagineVacuum Air BrakeAnshul Gupta100% (1)

- 1367482635621-Vacuum Air BrakeDocumento31 pagine1367482635621-Vacuum Air BrakeEr Rajesh BuraNessuna valutazione finora

- Multimatic Deluge Valve A4Documento6 pagineMultimatic Deluge Valve A4Lenin Rajaah AlaganNessuna valutazione finora

- Heli Forklift ModelsDocumento8 pagineHeli Forklift ModelsZeck100% (1)

- Romondes RD510 Battery Charger Repair ManualDocumento18 pagineRomondes RD510 Battery Charger Repair ManualZeckNessuna valutazione finora

- Midtronics EXP HD Instruction ManualDocumento52 pagineMidtronics EXP HD Instruction ManualZeckNessuna valutazione finora

- Air Line Filter: Operating Instructions & Parts ManualDocumento18 pagineAir Line Filter: Operating Instructions & Parts ManualZeckNessuna valutazione finora

- Zep Dyna Clean Installation and Operator's Manual: A. General InformationDocumento6 pagineZep Dyna Clean Installation and Operator's Manual: A. General InformationZeckNessuna valutazione finora

- Brochure Evx and VX Series RadiosDocumento9 pagineBrochure Evx and VX Series RadiosZeckNessuna valutazione finora

- MSD-V104 Oily Water Separator FiltersDocumento5 pagineMSD-V104 Oily Water Separator FiltersZeckNessuna valutazione finora

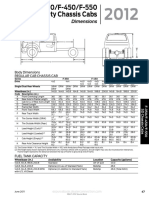

- Dimensions: Body Dimensions Regular Cab Chassis CabDocumento32 pagineDimensions: Body Dimensions Regular Cab Chassis CabZeckNessuna valutazione finora

- Fall Arrest Systems - Confined Space - Engineering - Rescue SystemsDocumento36 pagineFall Arrest Systems - Confined Space - Engineering - Rescue SystemsZeckNessuna valutazione finora

- HAZARD - Honda - Generator - Recall EU2000iDocumento1 paginaHAZARD - Honda - Generator - Recall EU2000iZeckNessuna valutazione finora

- MPS 350Documento1 paginaMPS 350ZeckNessuna valutazione finora

- Eu22i Safteyrecall Consumer 2020 v2Documento1 paginaEu22i Safteyrecall Consumer 2020 v2ZeckNessuna valutazione finora

- ZLS Series: Owner's ManualDocumento22 pagineZLS Series: Owner's ManualZeckNessuna valutazione finora

- Mdde FaqDocumento3 pagineMdde FaqZeckNessuna valutazione finora

- Service Bulletin: Exhaust Aftertreatment System Fault Tracing - Catalyzed DPFDocumento6 pagineService Bulletin: Exhaust Aftertreatment System Fault Tracing - Catalyzed DPFZeckNessuna valutazione finora

- Mercedes: Part Type Engine Mwfi # Oem Cross Reference Part BrandDocumento1 paginaMercedes: Part Type Engine Mwfi # Oem Cross Reference Part BrandZeckNessuna valutazione finora

- 595 BMW 3 SERIES 1.9ti 318i Ti Compact 3dr Long MOTDocumento2 pagine595 BMW 3 SERIES 1.9ti 318i Ti Compact 3dr Long MOTimranNessuna valutazione finora

- Alfa Romeo 159 2005 - 2011 Fuse Box DiagramDocumento9 pagineAlfa Romeo 159 2005 - 2011 Fuse Box Diagramxaver pan100% (1)

- 2011 Aftermarket Engine Price ListDocumento23 pagine2011 Aftermarket Engine Price ListMonojit MukherjeeNessuna valutazione finora

- EBS3.1 Repair GuideDocumento40 pagineEBS3.1 Repair GuidealeksandrNessuna valutazione finora

- 2008 Audi S4/S4 Avant Quick Reference GuideDocumento6 pagine2008 Audi S4/S4 Avant Quick Reference GuideAlnazer HaythamNessuna valutazione finora

- Husqvarna L 65 and L77 User Manual - 1978Documento11 pagineHusqvarna L 65 and L77 User Manual - 1978lupusnoirNessuna valutazione finora

- Jeep Wrangler JK (07) Spec SheetDocumento11 pagineJeep Wrangler JK (07) Spec Sheetipampu5353Nessuna valutazione finora

- Piaggio Beverly Sport Touring 350 ABS - ASR (EN)Documento357 paginePiaggio Beverly Sport Touring 350 ABS - ASR (EN)Manualles83% (6)

- Genuine Cummins Celect PX Injectors: Better Reliability. Every TimeDocumento2 pagineGenuine Cummins Celect PX Injectors: Better Reliability. Every TimeMassahiro Filho100% (1)

- Benelli Tornado 650 Owner's Manual PDFDocumento16 pagineBenelli Tornado 650 Owner's Manual PDFdcapito4017Nessuna valutazione finora

- Peugeot 207 ManualDocumento15 paginePeugeot 207 ManualJohn C Wesley-BarkerNessuna valutazione finora

- RIENG1Documento158 pagineRIENG1Petrus Kanisius WiratnoNessuna valutazione finora

- MZ TS 125 150 1983 Parts ListDocumento99 pagineMZ TS 125 150 1983 Parts Listuros zupancicNessuna valutazione finora

- 2023 Corolla CrossDocumento8 pagine2023 Corolla CrossHannah CanlasNessuna valutazione finora

- Dialnet LaRoboticaEducativaComoUnaInnovativaInterfazEducat 4227111Documento31 pagineDialnet LaRoboticaEducativaComoUnaInnovativaInterfazEducat 4227111Maximo ChavezNessuna valutazione finora

- Jeep Manual FSM Grand Cherokee WJ 2001 - Manual 01WJEDocumento3 pagineJeep Manual FSM Grand Cherokee WJ 2001 - Manual 01WJEAlbert TuykinNessuna valutazione finora

- Piaggio X9 Evolution 500 ABS (EN)Documento61 paginePiaggio X9 Evolution 500 ABS (EN)Manualles100% (1)

- Vat 45Documento2 pagineVat 45mehralsmenschNessuna valutazione finora

- Tesla Model S (Electric Motor Specifications)Documento3 pagineTesla Model S (Electric Motor Specifications)seyyidMubeen67% (3)

- GT Techinfo PDFDocumento58 pagineGT Techinfo PDFВадим ТертицаNessuna valutazione finora

- Specifications: 800D Industrial EngineDocumento28 pagineSpecifications: 800D Industrial EngineJacques Van NiekerkNessuna valutazione finora

- Walbro CarburetorsDocumento2 pagineWalbro CarburetorsfelreforditNessuna valutazione finora

- DPI - Dec 16Documento72 pagineDPI - Dec 16ratninp9368Nessuna valutazione finora

- Dynapac CA 250 Operations O250enDocumento28 pagineDynapac CA 250 Operations O250enkikoNessuna valutazione finora

- Tugas PneumaticDocumento14 pagineTugas PneumaticWayan WahyuNessuna valutazione finora

- Yanmar Type 4JH4-HTE: Right Side View Rear ViewDocumento2 pagineYanmar Type 4JH4-HTE: Right Side View Rear ViewAndrea BEtancurNessuna valutazione finora

- Caterpillar C15 ACERT Tier 4Documento4 pagineCaterpillar C15 ACERT Tier 4Alfred Hernandez MendozaNessuna valutazione finora

- Perkins Engine Number Guide English Issue 5Documento2 paginePerkins Engine Number Guide English Issue 5sfantu_29Nessuna valutazione finora

- Yamaha Gytr Acc 2023Documento20 pagineYamaha Gytr Acc 2023Galang Wira SatriadjieNessuna valutazione finora

- VacuumDocumento24 pagineVacuumDani-meganeboy100% (1)