Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AutoZine Technical School - Engine Smoothness

Caricato da

AshokCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AutoZine Technical School - Engine Smoothness

Caricato da

AshokCopyright:

Formati disponibili

Introduction

A refined engine should be smooth, free of vibration and quiet. These qualities also help the engine to spin freer at

high rpm, raising red line, hence power.

Engine smoothness depends very much on the basic configuration of the engine design - no. of cylinders, how the

cylinders are arranged (in-line, V-shape or horizontally opposed) and the V-angle for V-shape engines. In case a

less favourable configuration is chosen, probably due to packaging or cost reasons, counter weights or balancer

shafts may be used to counter the vibration generated in the price of a little bit energy loss.

Strengthening of the engine block, crankshaft etc. can absorb certain level of vibration and noise. Lastly, the use

of lower friction parts can further enhance smoothness and quietness.

Smooth power delivery

A cylinder takes 720crankshaft angle (i.e., 2 revolutions) to complete 1 cycle of 4-stroke operation. In other

words, it fires once every 2 crankshaft revolutions. Only the power stroke (expansion stroke) generates positive

power, while intake stroke, exhaust stroke and compression stroke consume power, especially the latter.

Therefore a single-cylinder engine generates power in the form of periodic pulse. The below picture shows how

the power be delivered:

To smooth the power delivery, all engines must employ a heavy flywheel, using its inertia to keep the engine

running roughly at constant speed. Of course, the heavier the flywheel, the smoother the power delivery

becomes, but it also makes the engine less responsive. Therefore the pulsation manner of the engine cannot be

completely eliminated by a reasonably large flywheel.

Therefore we need multi-cylinder engines. While single-cylinder engine fires once every 2 revolutions, twin-cylinder

engine fires once every revolution, 3-cylinder fires once every 720 / 3 = 240crank angle, 4-cylinder fires once

every 180(half a revolution) .... 12-cylinder engine fires once every just 60crank angle. Obviously, the more

cylinders the engine has, the smoother the power delivery becomes.

This explain why we prefer V12 engines than in-line 6, although both of them achieve near perfect internal

balance.

AutoZine Technical School - Engine http://www.autozine.org/technical_school/engine/smooth1.htm

1 of 3 1/11/2012 10:18 AM

Cause of vibration

Vibration is caused by the movement of the internal parts, especially are pistons and connecting rods. The piston

and con-rod move up and down periodically without counter balanced by other means. If the engine is a single-

cylinder engine, it will jump up and down periodically as well.

In reality, the direction of vibration is not just vertical. Because the connecting rod is not just travelling upward and

downward, but also left and right, there is also some vibration in transverse direction; However, compare with

piston, connecting rod is much lighter, thus the vibration generated by the left / right movement of con-rod is also

much smaller than the up / down vibration by the piston.

What about multi-cylinder engines? That's much more complicated than imagined. We'd better to discuss case by

case.

Inline 2-cylinder engines

As the engine fires once every revolution (or 720/ 2 = 360crankshaft angle), the two pistons run exactly in the

same direction as well as position. That means the total vibration will be twice the magnitude of that generated by

one cylinder. The direction of vibration is mostly upward / downward.

This is the worse engine configuration for refinement, therefore only the cheapest mini cars in the past employed

it, such as Fiat 128, entry-level Fiat Cinquecento and Honda Today etc. Today, I'm afraid there is probably no

mass production car still use twin-cylinder engines, not even the smallest Japanese K-cars. Although the

displacement of K-cars is 660 c.c. and is theoretically more suitable to twin-cylinder, they employs 3-cylinder or

even four-pot to avoid the severe vibration problem of twin-cylinder.

Inline 3-cylinder engines

As the engine fires once every 240crankshaft angle (720/ 3 = 240), the crankshaft design is as shown in the

below picture. (Firing order is: 1-3-2)

It seems that no matter how the crankshaft rotate, the combined

center of gravity of all 3 pistons and con-rods will remain at the

same location, hence no vibration generated. By mathematical

analysis, you can also find there is no forces generated in vertical

direction as well as transverse direction. (actually, I really

performed such calculations) So why did we hear that 3-cylinder

engine need balancer shaft ?

In fact, the calculation is wrong because it assumes the engine is

one point, thus the forces of all 3 cylinders act on this single point and result in complete cancellation. In reality,

the forces act on 3 different locations on the crankshaft, thus instead of canceling one another, they make the

crankshaft vibrating end to end.

Dont understand ? look at the above picture, the side view of the engine. Piston 1 is at the top now and is going

downward, thus generates an upward force to the left end of the crankshaft. Piston 2 is also going downward,

thus generates an upward force to the middle of the crankshaft. Piston 3 is going upward, thus generate a

downward force to the right end of crankshaft. As the engines center of gravity locates in cylinder 2, you can see

forces from piston 1 push the left end of the engine upward while forces from piston 3 push the right end of the

engine downward; After 180rotation, the situation will be completely reversed - downward force at left and

upward force at the right. In other words, this is an end-to-end vibration with respect to the center in cylinder 2.

AutoZine Technical School - Engine http://www.autozine.org/technical_school/engine/smooth1.htm

2 of 3 1/11/2012 10:18 AM

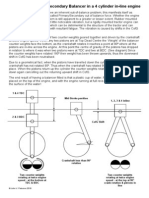

End-to-end vibration (shown here is a V6)

Solution - single balancer shaft

Therefore inline-3 engine is better to be equipped with a balancer shaft, driven by crankshaft. There is a weight at

each end of the balancer shaft. The weights move in direction opposite to the direction of the end pistons. When

the piston goes up, the weight goes down. When the piston goes down, the weight goes up. Therefore the

end-to-end vibration can be counter balanced by the balancer shaft which is driven at the same speed as the

crankshaft.

Continue ...

Copyright 1998-2000 by Mark Wan

AutoZine Technical School

Return to AutoZine home page

AutoZine Technical School - Engine http://www.autozine.org/technical_school/engine/smooth1.htm

3 of 3 1/11/2012 10:18 AM

Potrebbero piacerti anche

- THEORY: Reciprocating Engine Vibration: Lloyd JohnsonDocumento3 pagineTHEORY: Reciprocating Engine Vibration: Lloyd JohnsonJameel KhanNessuna valutazione finora

- Lecture 1 MC 377Documento15 pagineLecture 1 MC 377Joses AlornyoNessuna valutazione finora

- Operation of Multicylinder EnginesDocumento3 pagineOperation of Multicylinder EnginesSujith BobbaNessuna valutazione finora

- Essential features of a dumper vehicleDocumento20 pagineEssential features of a dumper vehicleDileep Kumar Manjhi100% (1)

- Balancing of Radial and V-Shape Engine by Ijaz AliDocumento20 pagineBalancing of Radial and V-Shape Engine by Ijaz AliMuhammad QasimNessuna valutazione finora

- Crank Shaft: Software Used-Catia V5R20 Submitted To Submitted byDocumento47 pagineCrank Shaft: Software Used-Catia V5R20 Submitted To Submitted byYaman Saluja0% (1)

- Sliding Mesh Miki FinalDocumento93 pagineSliding Mesh Miki FinalalebiegashityNessuna valutazione finora

- Engine balance fundamentalsDocumento14 pagineEngine balance fundamentalsTHYAGARAJAN KSNessuna valutazione finora

- Engine Dynamic Properties - 6Documento5 pagineEngine Dynamic Properties - 6Gthulasi78Nessuna valutazione finora

- Package Price ForDocumento32 paginePackage Price ForaryakushalNessuna valutazione finora

- Theory of A Primary/Secondary Balancer in A 4 Cylinder In-Line EngineDocumento1 paginaTheory of A Primary/Secondary Balancer in A 4 Cylinder In-Line EnginenithinvNessuna valutazione finora

- Chapter 28Documento11 pagineChapter 28biopoweredNessuna valutazione finora

- Abstract PDFDocumento70 pagineAbstract PDFDevulapally Venkata Anirudh AnirudhNessuna valutazione finora

- Engine BalanceDocumento6 pagineEngine BalancekspetsnazNessuna valutazione finora

- Dieselengine FundamentalDocumento29 pagineDieselengine FundamentalrahulNessuna valutazione finora

- Engine Construction 2Documento30 pagineEngine Construction 2collins arogoNessuna valutazione finora

- Marine Diesel Engine Parts and FunctionsDocumento29 pagineMarine Diesel Engine Parts and FunctionsArtemy KhotenovNessuna valutazione finora

- Contemporary Crankshaft DesignDocumento14 pagineContemporary Crankshaft DesignAbdulrahman AlkhowaiterNessuna valutazione finora

- WM80 WM90Documento29 pagineWM80 WM90Paola KeyNessuna valutazione finora

- GEARBOXES IN AUTOMOBILES: HOW THEY WORK AND TYPESDocumento71 pagineGEARBOXES IN AUTOMOBILES: HOW THEY WORK AND TYPESrijorijorijo100% (1)

- Experiment 3 ThermoDocumento11 pagineExperiment 3 ThermoMuneeb NaveedNessuna valutazione finora

- How A Four-Stroke Cycle Diesel Engine Works Marine Diesel Engine GuidelineDocumento8 pagineHow A Four-Stroke Cycle Diesel Engine Works Marine Diesel Engine GuidelineKarim Sowley DelgadoNessuna valutazione finora

- Study of Working Mechanisms of Important Components of Automobile EngineDocumento5 pagineStudy of Working Mechanisms of Important Components of Automobile EngineNiranjana KarandikarNessuna valutazione finora

- How Cars Turn - Rack-and-Pinion, Recirculating-Ball Steering Systems ExplainedDocumento9 pagineHow Cars Turn - Rack-and-Pinion, Recirculating-Ball Steering Systems ExplainedJanak AnandNessuna valutazione finora

- MCE 4780: Mechanical Engineering Lab 1: Fahim Shahrier, 160011052, MCE 16, Group B 2nd February 2020Documento19 pagineMCE 4780: Mechanical Engineering Lab 1: Fahim Shahrier, 160011052, MCE 16, Group B 2nd February 2020Fahim ShahrierNessuna valutazione finora

- GearboxesDocumento70 pagineGearboxesanand007krishnan0% (1)

- Recumbent Trike SteeringDocumento6 pagineRecumbent Trike SteeringAlifantis100% (2)

- Crankshaft InfoDocumento4 pagineCrankshaft InfoerickNessuna valutazione finora

- Quasi Turbine: By-Shivam Agarwal Roll No - 12 Section-D 130909058 Dept. of Mechanical and Manufacturing EngineeringDocumento37 pagineQuasi Turbine: By-Shivam Agarwal Roll No - 12 Section-D 130909058 Dept. of Mechanical and Manufacturing EngineeringShivam AgarwalNessuna valutazione finora

- Firing Order of CylindersDocumento17 pagineFiring Order of CylindersSaurav KumarNessuna valutazione finora

- Aen QBDocumento7 pagineAen QBKundan PednekarNessuna valutazione finora

- Wankel EngineDocumento16 pagineWankel Engineoscarlouis90Nessuna valutazione finora

- Engine Balancing GuideDocumento6 pagineEngine Balancing GuideOrlie Regla GallosNessuna valutazione finora

- TOM - Understanding Flywheel Function and Turning Moment DiagramsDocumento62 pagineTOM - Understanding Flywheel Function and Turning Moment DiagramsSudarson KarthikeyanNessuna valutazione finora

- Theory of Engine OperationDocumento19 pagineTheory of Engine OperationGabriel Dela Cruz LagmanNessuna valutazione finora

- Automobile Engineering Unit 2: ClutchesDocumento9 pagineAutomobile Engineering Unit 2: ClutchesPrince SethiNessuna valutazione finora

- Operation of Four Stroke EngineDocumento4 pagineOperation of Four Stroke EngineDaniel S. SantosNessuna valutazione finora

- Explain The Working of A 4 Stroke IC Engine?: Internal Combustion Engine PistonDocumento8 pagineExplain The Working of A 4 Stroke IC Engine?: Internal Combustion Engine PistonsanjayNessuna valutazione finora

- Gear Boxes in Automobiles PresentationDocumento24 pagineGear Boxes in Automobiles PresentationHada NanuNessuna valutazione finora

- Automotive Engine BasicsDocumento136 pagineAutomotive Engine Basicspreethu02Nessuna valutazione finora

- Tfe Module 3Documento14 pagineTfe Module 3Anandhu ANessuna valutazione finora

- Engine Types and ClassificationsDocumento16 pagineEngine Types and ClassificationsVõ Thanh Liêm100% (1)

- Reciprocating Engine Parts Design: G.T.U. B.E. (Mech) Sem-Viii 2011-12Documento61 pagineReciprocating Engine Parts Design: G.T.U. B.E. (Mech) Sem-Viii 2011-12Divyraj JadejaNessuna valutazione finora

- Mechanics RyanDocumento10 pagineMechanics RyanOrlie Regla GallosNessuna valutazione finora

- Vishal Singh 2nd Year TransmissionDocumento5 pagineVishal Singh 2nd Year TransmissionVishal SinghNessuna valutazione finora

- Universal Joint Alignment Proc 111606Documento5 pagineUniversal Joint Alignment Proc 111606Slobodan GaricNessuna valutazione finora

- FC01 UpdatedDocumento13 pagineFC01 UpdatedSOLAIMANNessuna valutazione finora

- Drive Shaft PDFDocumento14 pagineDrive Shaft PDFnamduong368Nessuna valutazione finora

- LP-4 Crankshaft Balance DoneDocumento3 pagineLP-4 Crankshaft Balance DoneKashif UsmanNessuna valutazione finora

- 2-stroke petrol engine seminar reportDocumento13 pagine2-stroke petrol engine seminar reportEr Raghvendra SinghNessuna valutazione finora

- U 1 P 1 Automobile IntroDocumento49 pagineU 1 P 1 Automobile Introshivam ruhelaNessuna valutazione finora

- starting systemDocumento31 paginestarting systemabhirajsinhvala76Nessuna valutazione finora

- Seven-Speed Dual-Clutch Gearbox 0B5/S TronicDocumento11 pagineSeven-Speed Dual-Clutch Gearbox 0B5/S TronicChristian Pach100% (1)

- Ae LabDocumento53 pagineAe LabAnkit DahiyaNessuna valutazione finora

- Aircraft Engine QuizDocumento30 pagineAircraft Engine Quizismael gonzalezNessuna valutazione finora

- Q: How Do Stirling Engines Work?: A: Stirling Engines Can Be Hard To Understand. Here Are The Key Points. EveryDocumento35 pagineQ: How Do Stirling Engines Work?: A: Stirling Engines Can Be Hard To Understand. Here Are The Key Points. EveryNavneet SharmaNessuna valutazione finora

- Southern Marine Engineering Desk Reference: Second Edition Volume IiDa EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNessuna valutazione finora

- A Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionDa EverandA Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionNessuna valutazione finora

- Moral Stories IllustratedDocumento74 pagineMoral Stories IllustratedAshok100% (1)

- Geometry PuzzlesDocumento14 pagineGeometry PuzzlesAshokNessuna valutazione finora

- Touch and See Your Solution: Finding Solutions For Your Problems in Bhagvad GitaDocumento1 paginaTouch and See Your Solution: Finding Solutions For Your Problems in Bhagvad Gitaanu50% (2)

- Fatigue CrankshaftDocumento31 pagineFatigue CrankshaftAngel Zanotti100% (1)

- 24 Generator SelectionDocumento45 pagine24 Generator SelectionAshokNessuna valutazione finora

- 25 Best Short Animal Stories For Kids With MoralsDocumento23 pagine25 Best Short Animal Stories For Kids With MoralsAshok80% (5)

- Air Bearing Fundamentals-Rev ADocumento13 pagineAir Bearing Fundamentals-Rev AAshokNessuna valutazione finora

- Selection of GeneratorDocumento11 pagineSelection of GeneratorsbpathiNessuna valutazione finora

- Engine Troubleshooting GuideDocumento16 pagineEngine Troubleshooting GuideAshokNessuna valutazione finora

- Basic Tools 1Documento13 pagineBasic Tools 1Kannan Nehru100% (1)

- Crankshaft Design GuideDocumento16 pagineCrankshaft Design GuideAshokNessuna valutazione finora

- Ed 7002 Efm NotesDocumento58 pagineEd 7002 Efm NotesAshokNessuna valutazione finora

- Backlash MitraDocumento8 pagineBacklash MitraAshokNessuna valutazione finora

- Design & Analysis of Crankshaft Bending Test Rig For Actual Engine Condition PDFDocumento8 pagineDesign & Analysis of Crankshaft Bending Test Rig For Actual Engine Condition PDFAshokNessuna valutazione finora

- NASA Fastener Design ManualDocumento100 pagineNASA Fastener Design ManualAaron D. MillerNessuna valutazione finora

- Transfer CaseDocumento41 pagineTransfer CaseAshok67% (3)

- Synchro RingDocumento9 pagineSynchro RingAshokNessuna valutazione finora

- Development of A Program For Calculating Gearbox SynchronizationDocumento86 pagineDevelopment of A Program For Calculating Gearbox SynchronizationAshok50% (2)

- Time ManagementDocumento30 pagineTime ManagementAshokNessuna valutazione finora

- Combustion Chamber Sae-Ref PaperDocumento9 pagineCombustion Chamber Sae-Ref PaperAshokNessuna valutazione finora

- General Tolerances DIN ISO 2768Documento2 pagineGeneral Tolerances DIN ISO 2768Vasil Gospodinov83% (23)

- Automotive Transmissions - Fundamentals Selection Design and Application by AshokDocumento470 pagineAutomotive Transmissions - Fundamentals Selection Design and Application by AshokAshokNessuna valutazione finora

- Basic Hydro Dynamic DriveDocumento68 pagineBasic Hydro Dynamic DriveAshokNessuna valutazione finora

- Chapter10 Design of GearsDocumento16 pagineChapter10 Design of GearsAshokNessuna valutazione finora

- Effect of Injection Rate and Split Injections On Diesel EngineDocumento14 pagineEffect of Injection Rate and Split Injections On Diesel EngineAshokNessuna valutazione finora

- Synchroniser 2Documento9 pagineSynchroniser 2AshokNessuna valutazione finora

- Basics of SynchronizersDocumento78 pagineBasics of SynchronizersAnish PaiNessuna valutazione finora

- Multi-Cone Synchronizer SystemsDocumento30 pagineMulti-Cone Synchronizer Systemsgrnflash100% (1)

- Synchroniser Ring 1Documento6 pagineSynchroniser Ring 1AshokNessuna valutazione finora

- Mechanical Behavior Simulation For SynchromechDocumento27 pagineMechanical Behavior Simulation For SynchromechAshokNessuna valutazione finora

- Gas Turbine Control & Protection: Presentation ONDocumento46 pagineGas Turbine Control & Protection: Presentation ONrahulNrana100% (2)

- Piston Engine TroubleshootingDocumento30 paginePiston Engine Troubleshootingkp subedi100% (1)

- Fuel Injection Pumps, In-LineDocumento24 pagineFuel Injection Pumps, In-LineJose Luis CristanchoNessuna valutazione finora

- Engine Systems 1Documento5 pagineEngine Systems 1anuradhaNessuna valutazione finora

- Руководство По Ремонту Двигателя Yale mazda FE/F2 524158742-0600yrm0496- (01-2011) -Uk-EnDocumento38 pagineРуководство По Ремонту Двигателя Yale mazda FE/F2 524158742-0600yrm0496- (01-2011) -Uk-EnПетр100% (1)

- Design & Analysis of Camshaft: S.G.Thorat, Nitesh Dubey, Arvind Shinde, Pushkar Fulpagare, Manish SuryavanshiDocumento5 pagineDesign & Analysis of Camshaft: S.G.Thorat, Nitesh Dubey, Arvind Shinde, Pushkar Fulpagare, Manish SuryavanshibebiNessuna valutazione finora

- Gears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocumento20 pagineGears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNessuna valutazione finora

- Training Report: Share Your ThoughtsDocumento1 paginaTraining Report: Share Your Thoughtsadeel jamilNessuna valutazione finora

- Timing Drive ComponentsDocumento3 pagineTiming Drive Componentsau7usa100% (1)

- B.E (Iv/Iv) - Mechanical - B: Rotary EngineDocumento25 pagineB.E (Iv/Iv) - Mechanical - B: Rotary EngineFaiz Naeem Sait100% (1)

- Design and Fabrication of Magnetic Engine: Ganesh Bairavan.P, Anojan.TDocumento5 pagineDesign and Fabrication of Magnetic Engine: Ganesh Bairavan.P, Anojan.Tarnika33Nessuna valutazione finora

- 2008 2010 Rhino 700fi Manual PDFDocumento503 pagine2008 2010 Rhino 700fi Manual PDFBaciu NicolaeNessuna valutazione finora

- YB100Documento46 pagineYB100Ingrid Garcia de Jauregui67% (3)

- Manual de Partes QSK 23 (PALA 207) PDFDocumento121 pagineManual de Partes QSK 23 (PALA 207) PDFKionss Kions100% (4)

- Plant Layout-CompressorsDocumento19 paginePlant Layout-Compressorshalder_kalyan9216Nessuna valutazione finora

- F1GB 2006Documento0 pagineF1GB 2006Ray Cepeda MenaNessuna valutazione finora

- Manual Book PC300-8 PBDocumento824 pagineManual Book PC300-8 PBNafrizal Suhendrik100% (1)

- NEW SO# Draft Parts ListDocumento5 pagineNEW SO# Draft Parts ListLayth S. ChalloobNessuna valutazione finora

- PDF 2Documento4 paginePDF 2Service MMINessuna valutazione finora

- 1103-1104 SpecsDocumento42 pagine1103-1104 Specsedukrl87% (46)

- Engine Awp Aww Awd Generic Scan Tool EngDocumento201 pagineEngine Awp Aww Awd Generic Scan Tool EngmafejoNessuna valutazione finora

- Electronic EngineDocumento4 pagineElectronic EngineSoumyadeep BhattacharyyaNessuna valutazione finora

- TM 9-1750F Power Unit For Medium Tanks M3A4 and M4A4 1943Documento309 pagineTM 9-1750F Power Unit For Medium Tanks M3A4 and M4A4 1943beppefranz100% (1)

- K20 Engine Control Module (LC5, LCP, or LMT)Documento5 pagineK20 Engine Control Module (LC5, LCP, or LMT)Alex Checa67% (3)

- Engine brake design and functionDocumento7 pagineEngine brake design and functionHamilton Miranda0% (1)

- Car HistoryDocumento7 pagineCar HistoryAhmad FikriNessuna valutazione finora

- Codes List Cummins - TIER4fDocumento137 pagineCodes List Cummins - TIER4fM V BHASKARARAONessuna valutazione finora

- Kirloskar Oil Engines Limited MRP List July 2017Documento205 pagineKirloskar Oil Engines Limited MRP List July 2017Sudhir KumarNessuna valutazione finora

- Job Profile Chart & Competency UnitDocumento13 pagineJob Profile Chart & Competency UnitEn BongNessuna valutazione finora

- Manifold CatalogDocumento124 pagineManifold CatalogVitor FronzaNessuna valutazione finora