Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DeltaInstructionsWG200 PDF

Caricato da

madgogx0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

76 visualizzazioni13 pagineThe Delta series of temperature control units combine ease of operation with sophisticated technology to give high comfort level and economical running cost of your central heating system. Automatically adjusting the heat output depending on outside temperature is known as weather compensation, and has major benefits. 1High comfort level is achieved as the heat input is continuously matched to the space heat requirement. 2Reduced running cost of the heating system - which usually designed to meet maximum heat, infrequently required - by running it at lower temperature and as required.

Descrizione originale:

Titolo originale

DeltaInstructionsWG200.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe Delta series of temperature control units combine ease of operation with sophisticated technology to give high comfort level and economical running cost of your central heating system. Automatically adjusting the heat output depending on outside temperature is known as weather compensation, and has major benefits. 1High comfort level is achieved as the heat input is continuously matched to the space heat requirement. 2Reduced running cost of the heating system - which usually designed to meet maximum heat, infrequently required - by running it at lower temperature and as required.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

76 visualizzazioni13 pagineDeltaInstructionsWG200 PDF

Caricato da

madgogxThe Delta series of temperature control units combine ease of operation with sophisticated technology to give high comfort level and economical running cost of your central heating system. Automatically adjusting the heat output depending on outside temperature is known as weather compensation, and has major benefits. 1High comfort level is achieved as the heat input is continuously matched to the space heat requirement. 2Reduced running cost of the heating system - which usually designed to meet maximum heat, infrequently required - by running it at lower temperature and as required.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 13

IPPEC Systems Ltd

Delta manual page 1

Delta

The Programmer Compensator Temperature Control System

Table of Contents :

Part I

Introduction

Table of Operating and Programming

The Delta Functions

The Display Panel

Daytime & Night Time Temperature Settings

The Heating Slope

Domestic Hot Water Operation

Other Adjustment Options

Additional Functions Of The Delta Controller

Part II

Installation of the Controller

Temperature Sensors

Remote Control and Room Temperature Sensors

Starting Procedures and Operational Presets

Troubleshooting, a guide to possible solutions

Technical Data

WG100 Enclosure

System layout

IPPEC Systems Ltd

Delta manual page 2

Part I

Introduction

The Delta series of temperature control units

combine ease of operation with sophisticated

technology to give high comfort level and

economical running cost of your central heating

system. Circular dials with easy to understand

symbols provide control over the main functions.

Several built timing programs means the unit is

ready to use once installed. Brief instructions are

supplied on one sheet of paper which is stored in

the facia slot.

Automatically adjusting the heat output depending

on outside temperature is known as weather

compensation, and has to major benefits.

1- High comfort level is achieved as the heat input

is continuously matched to the space heat

requirement. This avoids uncomfortable

temperature overshoot experienced with simple

controls.

2- Reduced running cost of the heating system -

which usually designed to meet maximum heat,

infrequently required - by running the it at lower

temperature and as required.

The Delta unit is supplied with the WG100 panel to

simplify further the installation procedure. This

panel avoids the need of extra junction boxes,

relays and switches that would be required

otherwise.

This Instruction Manual applies to the following

Controller types :

Delta 23 Weather responsive boiler control

with circulating heating pump and mixing valve

control.

Delta 23B Weather responsive boiler control

with circulating heating pump, mixing valve, and

domestic hot water control.

Delta Control Functions

Knobs and Dials

Program

Selector

Selects programmer mode of operation.

1- Standby Frost protection mode. All other functions are

disabled.

2- Automatic Day and night timing and temperatures including

the domestic hot water are operational.

3- Economy All day settings are operational. Night setting in

standby mode only.

4- Day Override Heating day settings are available continuously.

5- Night Override Heating night settings available continuously.

6- Manual

Override

Selected only during servicing of heating system.

Heating pump and boiler continuously running.

8- Sun Adjust temp. during the day or 'on' position.

9- Moon The temp. of day setting is reduced by this knob

during the night or 'off' setting.

11- Mixer Valve Adjusts compensation 'slope' between outside

and inside temp. Normal setting 0.8 for underfloor

heating.

12- Boiler Adjust compensation 'slope' between inside and

outside temp. for radiator heating. Normal setting

is 1.4.

Display

13- Red Neons Indicates active output signal, such as boiler

firing, pump running, mixer valve opening or

closing.

14- Digital Clock Displays time, marks week day and active

system.

Buttons

15- d h m Adjusts day, hour and minutes when pressed.

Time could be advanced or retarded by 1 hour

when d,h or d,m buttons pressed simultaneously.

Clock resets to 0.00 when all buttons pressed

together.

16- Clock,

Prog., Heating,

Hot Water

Clock mode button adjusts heating and hot water

programming along with above d,h,m buttons.

Prog. button activates preset programme (Heating

and hot water on from 6 to 22 daily).

Table of Operation and Programming Steps

The Delta functions

The controller is designed to regulate three separate

circuit functions in one compact unit.

A. Boiler weather compensation control. The boiler

temperature is smoothly regulated depending on

outside temperature, the heating curve slope, and the

selected normal operating temperature level.

Explanation : When outside temperatures are low the

boiler will operate at a proportionally higher

temperatures. When outside temperature increases

the boiler temperature will throttle down. The direct

regulation of radiators is possible without a mixing

valve control.

B. Mixing valve control circuit with weather responsive control for a floor panel heating system or a second

radiator heating circuit. The mixing control valve uses the relationship between the supply temperature and the

outside temperature to regulate this circuit.

IPPEC Systems Ltd

Delta manual page 3

Explanation : The mixing control valve regulation uses a modulating actuator to open and close the mixing valve.

The travel time for the control valve can be adjusted in the controller between 1 and 4 minutes. The regulating

curve may be corrected over a separate heating curve. Another option is to use a remote control or a room

temperature sensor to monitor a separate heating circuit.

C. Domestic hot water temperature control

is set using the hot water temperature adjustment knob.

When the hot water temperature falls below the set

temperature, the circulation pump switched off and the

domestic hot water loading pump is activated together with

the burner. When the selected temperature for the hot water

is redhead the burner shuts off, the hot water pump will

continue to run to remove excess heat from the boiler. The

length of time the hot water pump continues to operate is

variable from 30 seconds to 10 minutes. Boiler size will

determine the length of time necessary to remove excess

heat.

The Display Panel

1. Operating Temperature (Daytime) Adjustment Control Knob

This control knob is normally set in the middle position and suggest a room temperature of 20C if all heating

system installation measure are correct. Turn the knob left to decrease or to the right to increase the boiler

temperature as indicated by the thermometer symbols printed on the controller. The maximum temperature

adjustment amounts to 6K, and is relative to room temperature. This adjustment covers not only the boiler, but

makes equal adjustments to the mixing control valve circuit. After installation is completed, and the system is in

operation, changes should only be made in small steps (single graduations). Each mark on the scale is

approximately equal to 1C in room temperature difference. After making a change it is recommended to wait

one to two hours to see if the room temperature meets user expectations.

2. Night Time Temperature Reduction (Night Set-Back) Control Knob

This control knob is responsible for reducing the temperature in rooms which will not be occupied or for a

general reduction in temperature during times when the heating system is not needed at the 100% operating

level. If all heating installation measures are correct the counter clockwise setting suggests room temperature

of 20C (no reduction), and when turned fully clockwise attains a maximum reduction in room temperature of

8C. This adjustment, like normal day settings regulates the Mixing Control Valve, it can also be controlled

remotely with RFF 30S or FBR 30S.

3. Operation Mode Switch (6 Position Rotary Switch)

With this rotary switching knob, it is possible for the user to switch from six different modes of heating and hot

water operation.

Standby Operation

All controller functions are placed in stand-by, only frost protection and pump seizing protection remain in

operation. This digital clock remains operating. The Mixing Control Valve remains closed until frost protection

temperature ranges are reached. At this point the Mixer regulates the minimum boiler temperature. Operation

of off season pump cycling to prevent pump seizing remains in operation. This occurs each time the digital

clock switches from off to on, and it runs the circulation pump for approximately 10 seconds.

Automatic Operation

Automatic mode regulates the heating system in normal daytime and nigh set-back operation through the use of

the switching that is programmed in the digital clock. Room sensors and remote control operational functions

are also active. Domestic hot water supply will also be loaded as required by the programming of the clock. In

this mode it is permissible to change from Day operation to Night operation through the use of the FBR 30S.

Economy Operation

Automatic switching from Normal to Standby operation instead of to Night Set-Back, with the exception that hot

water preparation continues to function. During outside temperatures below the frost protection setting, Night

Set-Back settings become priority and minimum temperatures for the boiler will be maintained.

Continual Daytime Operation

Normal operation settings of Daytime operation will be priority and no night set-back will occur in this mode, any

IPPEC Systems Ltd

Delta manual page 4

switching activity of the digital clock will be ignored for the heating system, hot water preparation will not be

effected by this mode selection.

Continual Night Set-Back Operation

In this mode of operation the heating will operate at selected night reduction temperatures. Clock switching for

ON (daytime operation) will be ignored. Hot water operation is not effected in this mode.

The Heating Slope

The controller is equipped with two separate and individual

variable heating curves. Because they are separate it

possible to regulate two heating circuits using only three

sensors (outdoor temp. sensor, supply temp. sensor, and

boiler temp. sensor) Example: Radiator heating system and

underfloor heating system at the same time.

4. Boiler Heating Slope Control

The heating curve for the boiler circuit is adjustable from 0,25

to 3,5. It is factory preset to 1,5, this means that by an outside

temperature of 0C the boiler will be heated to a temperature

of 56C. Should the room temperature be too high or too low,

the heating slope can be adjusted to accommodate user

specific requirements. (See the Heating Curve chart for

detailed information).

5. Mixing Control Valve Heating Control

The heating curve for the mixing control valve is variable from 0,25 to 3,5. With this adjustment it is possible to

change the temperature at which the mixing control valve opens and closes. It is factory preset to 1,0,

corresponding to normal operation of the boiler circuit. Like the boiler heating curve the mixing control valve

curve is related to an outside temperature of 0C, but instead of relating to a boiler temperature it is related to a

supply temperature of 44C. Should this setting be too high or too low, it may be altered to user specific

requirements. After making adjustments to the mixing control valve slope the temperature should be observed

for several days before readjustment

Note : The adjustment of the mixing control valve curve may not be set higher than that of the boiler heating

curve, otherwise the mixing control valve will not regulate supply and/or return lines. (The supply temperature

would then require the valve to remain closed)

6. Hot Water Temperature Adjustment Knob

The controller posses a separately working electronically

controlled hot water supply regulation system. The

temperature regulation of an integrated or external hot water

tank is adjusted according to the scale around the adjustment

know. The temperature range if adjustable from 20C to 80C.

For example: The user desires a hot water temperature of

50C and sets the knob on 50C. After the hot water falls

under this setting, the boiler comes on along with the hot water

pump and heats the water to approximately 56C. This extra

6 is the switching difference.

7. Neon Display Lighting

The controller is equipped with a light display so the user van

clearly see which heating system functions are currently

operating. The symbols lit indicate their function.

=Boiler is in operation.

=Heating/Underfloor Circulating Pump is

running.

=Domestic Hot Water Pump is running.

=Mixer Valve opening (temp. increase)

=Mixer Valve is closing (temp.

decrease)

8. Domestic Hot Water Operation

The Delta controller is equipped with a hot water regulator which is used with a built-in or separate storage tank.

The hot water preparation is controlled by the digital clock according to the selected temperature on the hot

water temperature dial. When the hot water temperature in the storage tank falls below the selected

temperature the burner will fire, water in the boiler will heat and be pumped by the hot water pump through the

heating coil inside the storage tank, when the water is 6K above the selected temperature the burner will shut

off. The pump will continue running to remove excess heat from the boiler. The length of time the boiler runs is

adjustable from 30 seconds to 10 minutes, depending on the size of the boiler. This prevents any after heating

effects that may occur when the circulating pump returns to operation.

IPPEC Systems Ltd

Delta manual page 5

Digital Clock - See Appendix II for detailed instructions

Domestic Hot Water Operation Options

Domestic Hot Water Priority Option

When demand is placed on hot water operation the circulated pump is shut off so that quicker preparation can

be obtained. The disadvantage of this method is that during hot water heating the heating system is not in

service, and a slight cooling of room temperature may be noticed.

Domestic Hot Water alongside Heating Option

For heating systems with very high hot water demand, DHW heating can be simultaneously accomplished with

the central heating circuit to prevent any cooling of the rooms and/or heating system. The disadvantage to this

operation is that the heating up time for the hot water is longer.

Note : In order to perform parallel operation it is necessary to place a jumper wire from pin 1 to pin 13 on the

sensor side of the controller connector. (See connection of WG100 below)

Caution: This jumper is only to be used in systems which employ a mixing control valve. During DHW heating

boiler temperatures are higher than normal central operation. Therefore maximum high temperatures would be

allowed in the boiler and central circuit negating compensation functions for these circuits.

Domestic Hot Water Pump " Overrun"

Once the the domestic hot water temperature is reached, the boiler turns off as it is probable that the boiler has

excessive residual heat. The system would switch off (through the high limit setting or through boiler own

thermostat setting.).

To remove this excess heat the controller is equipped with an automatic overrun, which depending on the size

of the boiler, can be adjusted from 0,5 minutes to 10 minutes. It is important for the user to realise that this

should be adjusted merely long enough to remove the excess heat. Setting it to run for too long causes

unnecessary delays in reverting to central heating mode.

Temperature Differential Changeover

The difference between the temperature at which the

cylinder is heated and the point at which it shuts off is

adjustable from 1/+0,5K to -/+5K.

Other Adjustments Options

On the underside and backside of the controller there are several adjustable potentiometers which are factory

set. These should not be altered unless for special reasons which may be necessary for your the type of

heating system. Any modifications must be made after the system has been in operation for a while..

Adjustments must be made in small increments and over a period of time. DO NOT FORCE potentiometers

screws beyond limits, otherwise damage will occur. Please use the small yellow screwdriver provided with the

unit

Heating System Set Points

1 - Min.temperature of heating system (low limit)

2 - Max. boiler temperature setting (high limit)

3 - Max. outside temp. Setting

4 - Min. Outside temperature (frost protection)

5 - Boiler/DHW temperature diffrential changeover

6 - DHW pump overrun time in minutes

IPPEC Systems Ltd

Delta manual page 6

The controller is equipped with a variable boiler

minimum temperature limiter that allows the boiler to

cool down to a set minimum limit. This minimum limit

is adjustable from 10C to 60C.

Description : The boiler is switched on by the Delta

unit when minimum temperature is reached and

switched off at the minimum set level +5K (it is

feasible to operate under the lower limit if outside

temperature are higher than outside temperature high

limit. See outside temperature shut-off). In this

manner rooms will not be overheated especially

during vacation times, or when rooms are not

occupied. Lower limits prohibit boiler corrosion in oil

fired boiler units. The factory pre-set for the minimum

temperature is 38C.

Boiler

Burner

Heating

Pump

ON

OFF

ON

OFF

38

41

Time

Temp.

Boiler Low Limit

In addition to minimum temperature limiting, a boost heating is provided for the protection of the boiler. During

boost heating the mixing control valve is closed, and both heating and DHW circulating pumps are shut.

Description : Because the unit is weather responsive it is possible for the boiler to cool down below minimum

limits. Dependent on outside temperature. Outside temperature shut off. When the burner is fired, at first the

circulation pump, mixing control valve, and hot water pump are shut, allowing the boiler to come to operating

temperature. (Set temperature +5K). Once the minimum set temperature is reached the heating pump, and the

mixing control valve are activated..

Boiler Maximum Temperature Setting (High Limit)

The Delta is equipped with a boiler maximum temperature set point. When the boiler temperature reaches this

maximum temperature, the burner is turned off. The burner starts again when boiler temperature drops to 4K

under the set high limit. The adjustable the high limit range is from 70C to 90C and is factory pre-set to

approximately 80C.

Outside Temperature Shut-Off

The unit is equipped with an automatic shut-off, when outside temperatures rise above the selected high limit,

(automatic summer mode). The adjustable range for this function spans between 15 and 30C, and is related

directly to outside temperature conditions. When outside temperature shut-off occurs, the boiler and circulating

pump will go into stand-by operation, the operating difference is 1K. Outside temperature shut off is factory pre-

set to 22C

Frost Protection

During periods where the heating system is placed in stand-by operation the controller is equipped with a frost

protection monitoring system. When outside temperatures drop below the set limit the heating system

operation will reset itself as necessary to prevent the circuits from freezing. Under the set limit the circulation

pump continually pumps water through the system. The burner will warm the boiler to minimum limits. As soon

as outside temperatures rise above set frost protection level (+3K) the system returns automatically to the

stand-by mode. The adjustable temperature range is from -5C to 10C.

Mixing Valve Travel Time Adjustment - Situated at the back of unit

For Optimum performance it may be necessary to adjust the mixing valve travel. The

signal impulse rate at which the actuator drives the mixing valve. The travel time is

adjustable from 1 to 4 minutes. This calibration is only necessary if the low temperature

(undrefloor) circuit and the mixing control valve are unsynchronised. A 4 minute per 90

deg. travel mixer is provided. Refer to the manual of the mixer valve or servo-motor.

IPPEC Systems Ltd

Delta manual page 7

Additional Functions of the Delta Controller

Protection of Mixing Valve from Seizing

During periods where the heating system is not in operation, i.e. warm summer weather, vacation,

stand-by mode, the mixing control valve is not in operation. To prevent the control valve from seizure

by corrosion the Delta controller will open and close the mixing control valve for a few seconds

during programmed switching times. Each time the clock (channel 1, boiler circuit) switches from

OFF mode to ON mode, signals are sent to the actuator, moving the arm of the mixing control valve.

Protection of Circulation Pump from Seizing

The circulation pump is also protected from corrosion blockage. Each time the clock (channel 1,

boiler circuit) switches from OFF to ON the circulation pump is activated. The duration of this cycling

is approximately 10 seconds.

Pump " Overrun"

To prevent the boiler from "over heating" effects, the Delta unit is equipped with an "Overrun"

temperature reduction program. This function allows the circulation pump to continue to run until the

boiler temperature has cooled down to approximately 65C, afterwards the circulation pump

discontinues operation.

Selected Modes of Operation

Stand-By Function

In this mode of operation the heating system is completely shut off, but is protected against freezing.

The clock continues to function. When outside temperatures fall below the set frost protection level,

the boiler will operate at the given night set-back level, or at least until minimal boiler temperature

(low limit) is reached. This method of stand-by has the advantage of preventing condensation

damage to walls and wood framing. The mixing valve operates in the frost protection range but the

supply temperature to the heating circuit is restricted by the boiler temperature.

These precautionary measures provide optimum protection for the heating system at minimum

energy expenditures.

CAUTION : The selection of stand-by mode is recommended for long vacancies. Switching the

emergency or power off switch to off cause loss of battery life and eventually the loss of clock

programming.

Automatic Mode

1. Daytime Operation (Digital Clock Channel 1 ON.)

Boiler and supply temperatures in this mode of operation are governed by the settings of boiler

heating curve, mixing valve heating curve and the daytime temperature control knob. The use of a

room temperature remote control (RFF 30S) or remote control knob (FBR 30S) (Optional) will

additionally affect the settings of the boiler and supply circuit.

2. Night Reduction Operation (Set-Back) (Digital Clock Channel 1, OFF)

Boiler and supply temperature in this mode are governed by boiler heating curve, mixing valve

heating curve and night reduction temperature sensor (RFF 30S) or remote control (FBR 30S)

(Optional) will additionally affect boiler and supply temperatures. The circulation pump operates

continually so long as outside temperatures remain under the set outside temperature shut-down

level.

Economy Operation

1. Daytime operation (Digital Clock Channel 1, ON)

In economy mode the controller reacts exactly as operation in automatic mode. The difference is in

night set-back operation when the clock switches to OFF.

2. Economy Mode (Night Set-Back/Shut-Down) (Channel 1, OFF)

2a. Operation without Internal Sensor.

When outside temperature at the time of switch over (from ON to OFF) are below frost protection

range, the unit will not shut down, but merely drop into night reduction operation. The circulation

IPPEC Systems Ltd

Delta manual page 8

pump will continue to operate. The boiler temperature falls to night set-back temperatures and the

mixer continues to function along with the mixer heating curve. The heating system continues to

operate in a weather responsive manner, taking into account minimum boiler limits.

2b. Operation with Internal Temperature Sensor

Heating system operates as described in paragraph 2a with the following additional functions :

During economy operation (CH1, OFF) the boiler temperature will fall to presets made to night set-

back and the boiler heating curve. Additional corrections (+or -) made on the internal temperature

sensor control will then be integrated. When internal sensor correction levels are below night set-

back presets, further reductions will be made. The use of a weather responsive controlled minimum

limit ensures that boiler temperatures fall to internal sensor corrected levels. Corrected boiler levels

are not limited prior to achieving corrected reductions from the internal sensor. Naturally, areas with

good insulation factors will require less heating support, and therefore will have longer shut-down

periods.

2c. Hot Water Operation during Economy Shut-Down Operation

Hot water loading occurs as in automatic mode with the following differences :

When outside temperatures are above the frost protection range the boiler temperature reduction

discussed in 2a will reduce the boiler temperature down to 65C, then the circulating pump will

discontinue operation. When, however, the outside temperatures are above automatic shut-off range,

the remaining heat in the boiler will be reduced through the hot water pump "overrun" cycle. (See

Pump "Overrun").

Part II

Installation of the Delta Controller

Fixing requirements

The Delta controller is designed for panel installation, a cut-out for the Delta unit measure 138 mm x 92 mm. It

can be installed in any panel, or sheet material with a thickness ranging from 1 to 3 mm. mounting screw

fasteners under the protection dust cover, (on the left and right side of the unit face, in the middle) are used to fit

the controller using a small flat blade screwdriver, exerting minimal pressure, press the screw slot slightly

inwards until it stops, then turn the screw approximately 1/4 turn clockwise to set. To remove the controller

reverse the process. The screw fasteners are only plastic, do not use excessive force to press or turn the

screws, otherwise damage may result.

Installation Connections

Connection of the Delta controller is the most important part of installation read and understand all warnings

before attempting to supply power to the unit.

Attach all leads to the screw-connector strip in the WG10 panel provided with your Delta unit. Note that the blue

connector on the Delta unit itself are connected to the sensor connections strip running at 5 volt while the red

connectors are connected to the supply connection strip and for 220 volt AC

Warning: Incorrect connection can permanently damage the controller. Special attention must be taken that

220 V AC connections are only attached to the red connection strip.

Attaching external power sources to the sensor side of the controller will destroy electronic components.

Caution: Do not install sensor lines in or near 230v power lines, this will cause operational interference to

sensor inputs.

The Dust Cover

The dust cover is designed so that it may be installed to open from either side of the controller. With a little

pulling pressure the dust cover can be removed, rotated 180 and snapped into place on the other side.

General Information

The Delta controller should not be installed where ambient temperatures exceed +50C.

Possible breakage on sensor or sensor lines will automatically inhibit the burner from firing, this prevents

subsequent damage to the heating system by overheating.

IPPEC Systems Ltd

Delta manual page 9

To prevent damage of the Delta circuitry from a short circuit in the 230V AC lines, the power supply is fed via a

circuit breaker or fuse.

Temperature Sensors

Boiler Temperature Sensor KF

The boiler temperature sensor KVT 20 for the boiler and mixing heating curve, is an immersion cartridge type,

with a 2m long flexible, heat-resistant cable. If possible install it in the immersion pocket on the boiler, in which

the sensors for the safety thermostat, thermometer display. Alternatively strap to flow pipe and well insulate.

Power from 230 V AC (Red Marking)

WG 10 Delta Description Sensor System

14 Boiler - Relay controlled output auxiliary

15 Boiler - Relay input 230V AC Auxiliary

9 16 Mains Supply 230V AC - Neutral

17 No Connection

8 18 Power Input 230V AC - Phase

7 19 Output to Mixer Servo (closing)

6 20 Output to Mixer Servo (opening)

5 link to live 21 Boiler - Relay controlled output primary

4 via switch 22 Boiler - Relay input 230V AC Phase

3 link to live 23 Heating/Underfloor pump relay controlled output

2 via switch 24 Heating/Underfloor pump input 230V AC Phase

1 link to live 25 Domestic Hot water pump relay output

12 via switch 26 Domestic Hot water pump input 230V

Sensor Connector Plug (Blue Marking)

10 13 Common/ground for all sensor inputs

9 12 Outside sensor

11 No connection

8 10 Manifold flow/return sensor

7 9 Manifold flow/return sensor

6 8 Boiler temperature sensor

5 7 Remote control internal sensor position 2

4 6 Remote control internal sensor position 4

3 5 Remote control internal sensor position 3

2 4 Domestic Hot water cylinder sensor

1 3 Domestic Hot water cylinder sensor

2 No connection

1 No connection

Note :

While only one ground connection exist on the sensor connector, a separate

multiple connection plug is provided to attach additional ground.

Outside Temperature Sensor AF

The outside sensor supplied in a small white box AF 20 must be placed on a north facing wall under the eaves

but away from a window. A two core cable of 0.75 - 1.5 mm sq. is required (and preferably shielded) and is

attached to the bottom side of the sensor casing, and connected to the appropriate terminals on the control

panel (see diagram).

Cylinder Sensor SF

The domestic hot water temperature sensor KVT 20 supplied in a an immersion type and must be located either

in a pocket in the cylinder or strapped to the domestic hot water pipe output very close to the cylinder body. A

two core cable of 5 metres length is supplied with sensor and can be extended to a maximum length of 20

metres. The cable is then connected to the appropriate connectors at the control panel (see diagram). This

sensor is only available with Delta 23B.

Underfloor (Flow or Return) Sensor VF (KVT)

The flow sensor for the 3-port or 4-port mixer valve is housed in grey plastic box and must be strapped about

500 mm. downstream from the mixer valve on the pipe or manifold. A two core cable of 0.5mm sq. Is required to

connect it to control panel. The cable can be extended up to 30 metres.

Optional Remote Internal Sensor RFF 30 S

The RFF 30S Internal Sensor is an adaptive control unit and allows the user to raise or lower room

temperatures with the use of a control knob. This adjustment control knob has a range of +/- 5K. The toggle

switch allows change from Automatic, Continuous Daytime or Continuous Night-time operation. The addition of

IPPEC Systems Ltd

Delta manual page 10

a Internal Sensor will take into consideration internal air temperature changes to further improve temperatures

compensation by raising or lowering the Boiler Heating Curve.

Recommended Location of the RFF30S

It is recommended that the RFF 30S internal temperatures sensor with remote control be installed in a room

that is frequently occupied (for example the living room). Do not place the internal sensor near a source of heat

or in a cold draught. (E.g. Radiator or a frequently opened window.) Also do not place in room with other room

individual room thermostat and avoid blocking it by curtains or cupboard. All these will adversely affect the

Delta regulation.

Connections

Installation Diagram (RFF 30S)

When not using the optional RFF 30S the connection terminals on the Delta controller are left open.

Trouble Shooting

No functions when switch on WG100 is automatic mode

- Outside dependent temp. limiter is in operation

- Check outside sensor connections.

- Channel 1 of digital clock is in OFF state

- Check remote (internal) sensor (RFF 30/S)

Boiler doesnt fire.

- Outside dependent heat limiter is in.

- Check outside sensor

- Check high temp. (supply) sensor

- Channel 1 of digital clock is in OFF state

- Check internal sensor if installed (RFF 30/S)

- Boiler has tripped due to high temp. Or low water content.

- Unlock boiler by resting malfunction indicator button. Usually inside casing.)

- Check high limit thermostat for locked state and reset.

Boiler works continuously (shut off only at High Temperature Limit)

- Check outside and high temp.(supply) sensor for short circuit.

- Sensor lines are installed near and in parallel to main power supply cable and/or in common installation duct.

Mixing valve does not operate

- Check connection to servo-motor.

- Domestic water heating is on.

- Check outside sensor connections.

- Check mixing valve sensor (mounting and wiring): closed circuit lets valve run to increase temp.,

open circuit lets valve run to decrease temp.

- Measure value of mixing valve sensor and compare with resistance listed below. Remember to do

measurements. Only with blue marked terminal strip disconnected.

Heating Pump not working.

- Outside dependent temperature limit is reached.

IPPEC Systems Ltd

Delta manual page 11

- Domestic water heating is activated

- Channel 1 of digital clock is in OFF state

- Check connection to outside sensor

Delta doesnt change to heating

mode after domestic water loading

- Boiler Thermostat is set lower than adjusted domestic water temperature

- Domestic water temperature is adjusted to high or cylinder is not connected yet.

- Poor thermal contact between Domestic water temperature sensor and cylinder pipe pocket.

- Check domestic water sensor connections.

- Sensor line of domestic water sensor is installed close to DHW pump power supply cable. Separate lines!

Sensor Resistance Tables

Temp. Outside

Sensor

Temp. Boiler /

Cylinder

Sensor

- 10 1511 25 2002

- 8 1537 30 2078

- 6 1563 35 2155

- 4 1590 40 2234

- 2 1617 45 2314

0 1644 50 2395

2 1671 55 2478

4 1699 60 2563

6 1727 65 2648

8 1755 70 2735

10 1783 75 2824

12 1812 80 2914

14 1840 85 3005

16 1869 90 3098

18 1898 95 3192

20 1928 100 3287

Technical Data

Power Supply: 230 V ~+6 to -10 % Digital Clock Specifications

Mains Frequency: 50 - 60 Hz Battery reserve: 1 year

Test Voltage: 4 KV Accuracy: 1 sec./day

Power Consumption: 5 VA Clock: Quartz

Protective Voltage: 10 V D.C Programmable modes: 56, per day per Ch.

Operating temperature: 0-50 C Output: 2 channels

Maximum relay load: 8 Amp Display: LCD

IPPEC Systems Ltd

Delta manual page 12

Appendix I

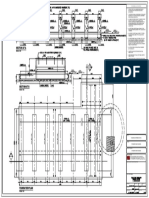

Delta Enclosure WG 100/200

This panel is designed to provide an enclosure and easy connection to Delta units and with extra

functions to simplify operation and maintenance. The connection strips are placed under separate

cover underneath the unit for easy access. The left bank connects to the sensors and the right bank to

the output of pumps boiler and valves and to power supply input 230V AC. The Delta plugs directly

into the WG 200/100 sockets. Make sure you do not use excessive force when connecting to avoid

invalidating the one year warranty.

The connections on the WG 100/200 are shown for separate DHW pump but can also be used instead

to control two motorised valves with one heating pump, usually situated in boiler. The boiler can be

connected from its room thermostat position using T1 and T2 or the live is bridged with T1 and output to

boiler is from T2 if the sole live to the boiler is from the Delta enclosure. See diagrams below.

WG 100/200 Switching functions

For servicing purposes the WG 100/200 has 2 switches:

Manual/Automatic switch

In the manual position the boiler will run continuously and is only turned off by its high limit thermostat.

This position is only used during boiler and flue service. It must be kept in the automatic position to

allow the Delta to function properly.

On / Off switch

The down position is the ON mode and the top position disconnect the mains power to the unit.

F S 2

RLF RGF

R S

MK2 PM

Room Sensor

3 1 2 4

5

6 7 8 9

10

12

13 1 2

3

4 11

AI

L

29 27 24

E N

AII

L E N L E N L E N Op Cl E N

Mixer I

T1 T2 T6 T8

Boiler

Op Cl E N

Mixer II

L N L E N

PM Mains

26

30 28 23 25

AI AII KP SLP

20

AUF

19

ZU

22

21

S2

14 15

AUF ZU

S1

18

F1

6,3

AT

K

V

T

2

0

A

F

V

F

1

K

V

T

2

0

RFF30S

M

K

V

T

2

0

A

F

V

F

K

V

T

2

0

M

I II

I

230V 50Hz

230V 50Hz

Mains Voltage Section

Low Voltage Section

FBR30S

3 1 2 4

*

S2 = Auto/Manual

S1 = Mains

Cylinder

Sensor

Outside

Sensor

Boiler

Sensor

Pipe

Sensor

Cylinder Heating

F S 2

RLF RGF

R S

MK2 PM

Room Sensor

3 1 2 4

AI

L E N

AII

L E N L E N L E N Op Cl E N

Mixer I

T1 T2 T6 T8

Boiler

Op Cl E N

Mixer II

L N L E N

PM Mains Cylinder

Sensor

Outside

Sensor

Boiler

Sensor

pipe

Sensor

Cylinder Heating

Delta 23B: 1 Boiler +1 cylinder

Delta 223B: 2 Boilers +1 cylinder

Pump via

cylinder

pump

or Valve

* Bridge for parallel

operation

Pump via

cylinder

pump

or Valve

Mixer Servo

Motor

Mixer Servo

Motor

Heating

Pump

Heating

Pump

Mains

Manual

Bridges 'stat in boiler

or live supply If L is

looped to T2

Bridges 'stat in boilers

or live supply If L is

looped to T2 and T8

Unused Unused Unused

Unused Unused Unused

Unused Delta 333

Unused Delta 333

Wiring to the connection panel of WG 100/200 enclosure

IPPEC Systems Ltd

Delta manual page 13

WG 100 Connection to heating system

Typical heating system layout with Delta programmer/compensator

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Construction of Toilet with Running WaterDocumento26 pagineConstruction of Toilet with Running WaterJanardhanReddyNessuna valutazione finora

- Celesta BrochureDocumento13 pagineCelesta BrochurePranavNessuna valutazione finora

- Austrian Standard B-1992!1!1Documento80 pagineAustrian Standard B-1992!1!1tth28288969Nessuna valutazione finora

- Filtrair Filter Media VNF M1 Series ENDocumento2 pagineFiltrair Filter Media VNF M1 Series ENThái Hòa GiangNessuna valutazione finora

- TWI Passivation Report July 2013Documento7 pagineTWI Passivation Report July 2013sakshi patilNessuna valutazione finora

- Water Tank FoundationDocumento1 paginaWater Tank FoundationKhurram Shahzad Amjad100% (1)

- SAP Manual HandbookDocumento21 pagineSAP Manual HandbookDennyzaNessuna valutazione finora

- Greenheck DGXDocumento72 pagineGreenheck DGXBrad GNessuna valutazione finora

- Neca 409-2009 - Installing and Maintaining Dry Type TransformersDocumento42 pagineNeca 409-2009 - Installing and Maintaining Dry Type TransformersJosé Luis FalconNessuna valutazione finora

- Havells LV and HT Aerial Bunched Cables OverviewDocumento23 pagineHavells LV and HT Aerial Bunched Cables OverviewJinto JacobNessuna valutazione finora

- Thesis On Structure DesignDocumento6 pagineThesis On Structure DesignHarshit NagarNessuna valutazione finora

- Astm A618Documento4 pagineAstm A618Mohamed Farouk100% (1)

- EIL Installation StandardsDocumento85 pagineEIL Installation StandardsMurli ramchandran0% (2)

- Boq Comparative ChartDocumento5 pagineBoq Comparative Chartmvs srikarNessuna valutazione finora

- - =-3.6 log ф ^ - J J (: 182 Chapter 6 Interphase Transport in Isothermal SystemsDocumento3 pagine- =-3.6 log ф ^ - J J (: 182 Chapter 6 Interphase Transport in Isothermal SystemsAndrianPratamaNessuna valutazione finora

- Vinyl Floor InstallDocumento10 pagineVinyl Floor InstallMoose112Nessuna valutazione finora

- Simply Supported Beam With Support Added at Midspan To Prevent Excessive DeflectionDocumento2 pagineSimply Supported Beam With Support Added at Midspan To Prevent Excessive DeflectionShiela GonzalesNessuna valutazione finora

- HVAC Consolidated Issues ListDocumento10 pagineHVAC Consolidated Issues ListSaid Massinissa Elhadj AliNessuna valutazione finora

- Heat Treatment GuideDocumento33 pagineHeat Treatment GuidefethiaktuncNessuna valutazione finora

- Transport Schedule of TopicsDocumento4 pagineTransport Schedule of TopicsHarshaNessuna valutazione finora

- ARCA SOUTH DYNAMIC DESIGNDocumento26 pagineARCA SOUTH DYNAMIC DESIGNJan LhesterNessuna valutazione finora

- Tanques Hidroneumaticos ProsourceDocumento4 pagineTanques Hidroneumaticos ProsourceHéctorNessuna valutazione finora

- Ruukki Load Bearing Sheet DrawingsDocumento56 pagineRuukki Load Bearing Sheet DrawingsРостислав ВасилевNessuna valutazione finora

- TRL144Documento59 pagineTRL144ONE SMART LRT3-2Nessuna valutazione finora

- Water's Edge BrochureDocumento15 pagineWater's Edge BrochureAndrew Ahmed50% (2)

- Huth Equation TateDocumento69 pagineHuth Equation TatewingsmithNessuna valutazione finora

- Reinforcing Details for Skewed and Angled Box CulvertsDocumento1 paginaReinforcing Details for Skewed and Angled Box Culvertsarif_rubin83% (6)

- CIVL 7132 Soil Mechanics HomeworkDocumento2 pagineCIVL 7132 Soil Mechanics HomeworkmrinmaiNessuna valutazione finora

- Amp Qb.Documento6 pagineAmp Qb.svkarthik83Nessuna valutazione finora

- Fracture MechanicsDocumento12 pagineFracture Mechanicsramachadra122Nessuna valutazione finora