Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Course Outline Jf6081

Caricato da

Firdaus Zakaria0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

49 visualizzazioni4 pagineQuality Control, JF608, Course Outline, Politeknik

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoQuality Control, JF608, Course Outline, Politeknik

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

49 visualizzazioni4 pagineCourse Outline Jf6081

Caricato da

Firdaus ZakariaQuality Control, JF608, Course Outline, Politeknik

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

COURSE OUTLINE

Department of Mechanical Engineering (JKM)

Programme Diploma In Mechanical Engineering

Page 1 of 4

File No : JKM/DEM/FK/47

Code & Course Name JF608 Quality Control Session : Jun 2013

Pre Requisite(s) None Semester : 06 Class :

DEM6A

Lecture Hours 30 hours ( 30 LECTURE : 0 TUTORIAL) Credit(s) : 02

No Lecturer Location Contact Number

1 Aspalila Awang Tingkat 4, Bangunan

Pentadbiran

0129509579

SYNOPSIS:

QUALITY CONTROL provides knowledge on basic principle and concept of quality including statistical method in

controlling products quality or services. This course also emphasize on the application of Control Chart and Quality

Control tools. In addition, this course also explains the importance of International Standard of Quality Assurance

Standard, ISO 9000 for an organization.

LEARNING OUTCOMES: At the end of the course the students will be able to:

No. Course Learning Outcome(CLO)

Programme Learning

Outcome(s) (PLO)

Addressed

Assessment Methods

1

Express the relation of statistics and quality

management system in understanding the

principles and concept of quality control and their

application tools.

PLO1

End of Chapter, Quiz,

Tests and Final Exam.

2

Measure the quality of products and services by

using control charts, Statistical Process Control and

Acceptance Sampling methods.

PLO4

Quiz, Tests and Final

Exam.

3

Propose the tools and techniques that can be used

to improve quality including cost associated in

controlling quality of products and services based

on quality system ISO 9000 Series.

PLO6

End of Chapter, Quiz,Case

Study and Final Exam

STUDENT LEARNING TIME:

No Teaching and Learning Activities

Student

Learning

Time(hours)

Face to Face

1.0

Delivery Method

a. Lecture 30

b. Tutorial 0

2.0

Coursework Assessment(CA)

a. Lecture hour assessment 3

Non face to face

3.0

Coursework Assessment (CA)

a. Case Study 6

4.0

Preparation and Review

a. Lecture 30

b. Practical 0

c. Tutorial 0

d. Assessment 8

e. Final Exam 0

Total 77

COURSE OUTLINE

Department of Mechanical Engineering (JKM)

Programme Diploma In Mechanical Engineering

Page 2 of 4

File No : JKM/DEM/FK/47

Code & Course Name JF608 Quality Control Session : Jun 2013

Pre Requisite(s) None Semester : 06 Class :

DEM6A

Lecture Hours 30 hours ( 30 LECTURE : 0 TUTORIAL) Credit(s) : 02

TEACHING METHODOLOGY:

This course is taught through Interactive Lecture, Discussion and Presentation.

WEEKLY SCHEDULE:

Week Topic/Sub Topic CLO/PLO

Week 1

Week 2 Week 3

1.0 BASIC STATISTICS

Mean, mode, range, standard system, histogram,

normal curve and problem solutions regarding quality

control.

CLO1

Week 4

2.0 BASIC QUALITY CONCEPT

The definition of quality,

The importance of quality, defects, quality assurance,

Total Quality Management (TQM) and continuous

improvement. the purposes of samples, inspection

methods and statistical

Quality control.

Week 6 Week 8

3.0 CONTROL CHART FOR VARIABLES

The variation, process in control, mean, range and

sigma chart.

The steps to collect data and preparing chart.

The method to determine center line value, upper and

lower control limit, chart construction, distribution/

scattering pattern criterion, analysis, relationship

between information and population

Process Capability Index.

CLO2

Week 9 Week 11

4.0 CONTROL CHART FOR ATTRIBUTE

The condition that is used to control attribute chart

The difference between attribute control chart and

variable,

The non-conforming term,

The advantages and disadvantages of attribute

control chart, construction of p, 100p, np, c and u

chart.

COURSE OUTLINE

Department of Mechanical Engineering (JKM)

Programme Diploma In Mechanical Engineering

Page 3 of 4

File No : JKM/DEM/FK/47

Code & Course Name JF608 Quality Control Session : Jun 2013

Pre Requisite(s) None Semester : 06 Class :

DEM6A

Lecture Hours 30 hours ( 30 LECTURE : 0 TUTORIAL) Credit(s) : 02

Week Topic/Sub Topic CLO/PLO

Week 12 Week 13

5.0 ACCEPTANCE SAMPLING

The use, advantages and disadvantages of

acceptance sampling.

The sampling planning method, lots, choosing

samples and non-conformities lots.

The customers risk, AQL (Acceptable Quality Level),

LTPD (Lot tolerance percent defective), Operating

Characteristic Curve and table MIL-STD-105D in

planning single sampling in normal, tightened and

reduced condition

Week 14

6.0 QUALITY COST

the relationship between cost and quality.

the types and categories of cost as such as preventive

cost, appraisal cost, internal failure cost and external

failure cost.

CLO3

Week 15 week 16

7.0 QUALITY IMPROVEMENT TECHNIQUE

the importance of quality,

the techniques to improve quality as such as

brainstorming, check sheet, Pareto Analysis, Matrix

Analysis, Cause-And-Effect Diagram, Scatter diagram

and Quality Circle Group.

Week 17

8.0 ISO 9000 SERIES

This topic explains the needs of quality system, basic

concepts, main terms in ISO 9000 and the advantages

and disadvantages of ISO 9000, including quality

managements systems for ISO 9001:2008.

CLO1

REFERENCES:

1. Dale H. Besterfield, (2001). Quality Control, 6th edition.Prentice Hall.

2. Eugene L. Grant, Richard S. Leavenworth, (1996). Statistical Quality Control,7th edition. McGraw Hill

3. Jay Heizer& Barry Render, (2006). Production and Operation Management, 8th edition.Prentice Hall.

4. Wayne C. Turner, Joe H. Mize, Kenneth E. Case, John W. Nazemetz, (1993). Introduction to industrial

and systems engineering. Prentice Hall

5. William J. Stevenson, (2007).Operations Management, 9th edition. McGraw Hill, United State

COURSE OUTLINE

Department of Mechanical Engineering (JKM)

Programme Diploma In Mechanical Engineering

Page 4 of 4

File No : JKM/DEM/FK/47

Code & Course Name JF608 Quality Control Session : Jun 2013

Pre Requisite(s) None Semester : 06 Class :

DEM6A

Lecture Hours 30 hours ( 30 LECTURE : 0 TUTORIAL) Credit(s) : 02

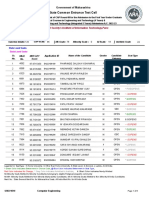

ASSESSMENT:

The course assessment is carried out in two sections:

i. Coursework (CA)

Coursework is continuous assessment that measures knowledge, technical skills and soft skills.

ii. Final Examination (FE)

Final examination is carried out at the end of the semester.

The percentage ratio of FE to CA shall follow the guideline stated in the Arahan-Arahan Peperiksaan dan Kaedah

Penilaian which is approved by the Lembaga Peperiksaan dan Penganugerahan Sijil/ Diploma Politeknik.

ASSESSMENT METHODS FOR COURSEWORK (CA)

No Assessment Quantity % Each % Total Week/Dates

1 Test 2 20 40 Week 12,week 17

2 Quiz 2 10 20 Week 11 , week 15

3 End of Chapter 2 10 20 Week 5,week 17

4 Case Study 1 20 20 Week 16

Total 7 Total 100

Prepared by Lecturer :

Signature : .

Cop & Name:

Date:

Certified by Head of Programme:

Signature : .

Cop & Name:

Date:

Potrebbero piacerti anche

- Quality Engineering Course OverviewDocumento2 pagineQuality Engineering Course OverviewVikash KumarNessuna valutazione finora

- BA9203 TQM Lesson PlanDocumento12 pagineBA9203 TQM Lesson PlanvasanthasenanNessuna valutazione finora

- Eastern Mediterranean University Department of Industrial Engineering IENG484/MANE484 Quality Engineering Spring 2019-2020 Course OutlineDocumento3 pagineEastern Mediterranean University Department of Industrial Engineering IENG484/MANE484 Quality Engineering Spring 2019-2020 Course OutlineIlkin JafarovNessuna valutazione finora

- GE2022Documento7 pagineGE2022Senthil RajkumarNessuna valutazione finora

- Sample MipDocumento5 pagineSample MipChelliah SelvavishnuNessuna valutazione finora

- Rajalakshmi Engineering College, Thandalam, Chennai - 602 105 Department of Mechanical EngineeringDocumento3 pagineRajalakshmi Engineering College, Thandalam, Chennai - 602 105 Department of Mechanical EngineeringvsanthanamNessuna valutazione finora

- Baccalaureus Technologiae: Quality: Qualification Code: BTQU02 - NQF Level 7Documento3 pagineBaccalaureus Technologiae: Quality: Qualification Code: BTQU02 - NQF Level 7Noah MigealNessuna valutazione finora

- Gujarat Technological University: Page 1 of 3Documento3 pagineGujarat Technological University: Page 1 of 3Fa CaNessuna valutazione finora

- Quality ControlDocumento3 pagineQuality ControlBaluontheline_001Nessuna valutazione finora

- Quality Management and Six Sigma ModuleDocumento5 pagineQuality Management and Six Sigma ModulesigmasundarNessuna valutazione finora

- INDU372/4T: Quality Control and Reliability (Credits: 3.0) : Mychen@encs - Concordia.caDocumento2 pagineINDU372/4T: Quality Control and Reliability (Credits: 3.0) : Mychen@encs - Concordia.caNguyễn Hữu PhấnNessuna valutazione finora

- GTU B.Voc 2nd Semester TQM SyllabusDocumento2 pagineGTU B.Voc 2nd Semester TQM SyllabusJigneshkumar PatelNessuna valutazione finora

- TQM Question BankDocumento20 pagineTQM Question BankbhuvansparksNessuna valutazione finora

- 1 MQC SyllabusDocumento5 pagine1 MQC SyllabusAnilChauvanNessuna valutazione finora

- Course Syllabus: Instructor InformationDocumento8 pagineCourse Syllabus: Instructor InformationGlicerio RufinoNessuna valutazione finora

- Mechanical Engineering Course Outlines Workshop Service ManagementDocumento2 pagineMechanical Engineering Course Outlines Workshop Service ManagementNareesh RajNessuna valutazione finora

- INE3012 Quality Management SyllabusDocumento1 paginaINE3012 Quality Management SyllabusbasriNessuna valutazione finora

- Quality Management and Industrial Engineering CoursesDocumento3 pagineQuality Management and Industrial Engineering CoursesShubham MahajanNessuna valutazione finora

- Course Code. Course Name L-T-P - Credits Year of IE308 Quality Engineering 3-0-0-3 2016 Prerequisite: Nil Course ObjectivesDocumento3 pagineCourse Code. Course Name L-T-P - Credits Year of IE308 Quality Engineering 3-0-0-3 2016 Prerequisite: Nil Course ObjectivesloshidhNessuna valutazione finora

- RPP BPC 32603 Sem 2 2013-2014Documento9 pagineRPP BPC 32603 Sem 2 2013-2014Raveverma PeriyasamyNessuna valutazione finora

- MM ZG522Documento5 pagineMM ZG522Krishna VamsiNessuna valutazione finora

- Business Process SyllableDocumento4 pagineBusiness Process SyllableanonymousnameNessuna valutazione finora

- RSTBSRDocumento3 pagineRSTBSRTiongJingYinNessuna valutazione finora

- GTU Quality Control and Reliability CourseDocumento3 pagineGTU Quality Control and Reliability CourseN NandiniNessuna valutazione finora

- QA Course Code L3T0Documento2 pagineQA Course Code L3T0garry1234Nessuna valutazione finora

- TQM Syllabus.Documento3 pagineTQM Syllabus.RITIK RISHUNessuna valutazione finora

- Sppu Be Computer 2015 StqaDocumento2 pagineSppu Be Computer 2015 StqaSwapnil Shinde0% (1)

- Course Outline MEM678 March - July 2020 PDFDocumento5 pagineCourse Outline MEM678 March - July 2020 PDFAmirul HarisNessuna valutazione finora

- GSU Robinson College MBA Operations Management Course SyllabusDocumento5 pagineGSU Robinson College MBA Operations Management Course SyllabusLee JNessuna valutazione finora

- Total Quality ManagementDocumento5 pagineTotal Quality Managementshweta15marNessuna valutazione finora

- EPGP-13-Quality Managment - Course Outline - Sec A, B, CDDocumento4 pagineEPGP-13-Quality Managment - Course Outline - Sec A, B, CDreva_radhakrish1834Nessuna valutazione finora

- QualityDocumento39 pagineQualitysudharshankyNessuna valutazione finora

- Anna University ME Quality Engineering CurriculumDocumento39 pagineAnna University ME Quality Engineering CurriculumJoswa CaxtonNessuna valutazione finora

- Industrial Statistics & Quality ControlDocumento4 pagineIndustrial Statistics & Quality ControlSalmane Benjelloun0% (1)

- Total Quality ManagementDocumento3 pagineTotal Quality Managementraghav dhamaniNessuna valutazione finora

- International Academy of Management and EconomicsDocumento6 pagineInternational Academy of Management and EconomicsPed SalvadorNessuna valutazione finora

- Certified Quality Engineer (Cqe) Body of KnowledgeDocumento12 pagineCertified Quality Engineer (Cqe) Body of Knowledgemehdi810Nessuna valutazione finora

- ME403 Production & Operation Management SyllabusDocumento6 pagineME403 Production & Operation Management SyllabusGajanan Shankarrao PatangeNessuna valutazione finora

- Quality, Reliability and Maintenance ModuleDocumento5 pagineQuality, Reliability and Maintenance Modulelaap85Nessuna valutazione finora

- IE488 Total Quality ManagementDocumento2 pagineIE488 Total Quality ManagementPraveen H Praveen H100% (1)

- TQM-CSE-2020-21 SYLLABUSDocumento2 pagineTQM-CSE-2020-21 SYLLABUSapakkiNessuna valutazione finora

- Cqe BokDocumento12 pagineCqe BokANessuna valutazione finora

- Lecture List: Indian Institute of Information and Technology, Allahabad (Deemed University)Documento4 pagineLecture List: Indian Institute of Information and Technology, Allahabad (Deemed University)Vansh Raj YadavNessuna valutazione finora

- Introduction of Project Quality Management: in Oil and Gas IndustryDocumento20 pagineIntroduction of Project Quality Management: in Oil and Gas IndustrySufira WahyuniNessuna valutazione finora

- IM ECEN 3463 Total Quality ManagementDocumento127 pagineIM ECEN 3463 Total Quality ManagementEm ReyesNessuna valutazione finora

- Mem575 Industrial Management Course Outline PM IsmailDocumento8 pagineMem575 Industrial Management Course Outline PM IsmailFaez FeakryNessuna valutazione finora

- GJK - PSOC Course Sheet - 21!9!12Documento8 pagineGJK - PSOC Course Sheet - 21!9!12gjk1236596Nessuna valutazione finora

- PGDM OM 4.3 Quality Management and Six SigmaDocumento1 paginaPGDM OM 4.3 Quality Management and Six SigmaAlok SinghNessuna valutazione finora

- Measuring The Dimensions of Quality in Higher EducationDocumento10 pagineMeasuring The Dimensions of Quality in Higher EducationGermán ChisakaNessuna valutazione finora

- TQM Instant SolutionDocumento21 pagineTQM Instant SolutionAiDLo0% (2)

- Southern University Bangladesh TQM CourseDocumento4 pagineSouthern University Bangladesh TQM CourseMazumder SumanNessuna valutazione finora

- Optimization TechniquesDocumento3 pagineOptimization Techniques2020001873.gcetNessuna valutazione finora

- Course DetailsDocumento11 pagineCourse DetailsDasun NirmalaNessuna valutazione finora

- CPQMDocumento2 pagineCPQMOlayinkaAweNessuna valutazione finora

- QMS Implementation in Construction24042240422404224042240422404224042240420.8220.260FSig.3.1580.0520.9560.5311.8020.1760.9950.3982.5010.0920.3090.4250.7280.4882.2330.894Documento40 pagineQMS Implementation in Construction24042240422404224042240422404224042240420.8220.260FSig.3.1580.0520.9560.5311.8020.1760.9950.3982.5010.0920.3090.4250.7280.4882.2330.894Shruthi IyengarNessuna valutazione finora

- Exam Cram Essentials Last-Minute Guide to Ace the PMP Exam: First EditionDa EverandExam Cram Essentials Last-Minute Guide to Ace the PMP Exam: First EditionNessuna valutazione finora

- Managing the Testing Process: Practical Tools and Techniques for Managing Hardware and Software TestingDa EverandManaging the Testing Process: Practical Tools and Techniques for Managing Hardware and Software TestingValutazione: 4 su 5 stelle4/5 (8)

- Home 168 Manila OJT Partnership ProposalDocumento18 pagineHome 168 Manila OJT Partnership Proposal168 HomeNessuna valutazione finora

- Full Sample English Tr7Documento257 pagineFull Sample English Tr7Lorainne Navarette87% (15)

- San Rafael, Zaragoza, Nueva Ecija Junior High SchoolDocumento55 pagineSan Rafael, Zaragoza, Nueva Ecija Junior High SchoolNica Mae SiblagNessuna valutazione finora

- Karam Katnaji: Work ExperienceDocumento1 paginaKaram Katnaji: Work ExperienceAhmad AhmadNessuna valutazione finora

- Lesson Plan - EmTech - 12 - Q3L5 - Manipulating Text, Graphics, and Images To Create ICT Content Intended For An Online EnvironmentDocumento4 pagineLesson Plan - EmTech - 12 - Q3L5 - Manipulating Text, Graphics, and Images To Create ICT Content Intended For An Online EnvironmentjfmefrannzNessuna valutazione finora

- CCISD School Calendar - 07!19!11Documento3 pagineCCISD School Calendar - 07!19!11modernsnobNessuna valutazione finora

- Marder Materialsanalysis1Documento11 pagineMarder Materialsanalysis1api-454914624Nessuna valutazione finora

- 10 1108 - Jeim 02 2017 0035Documento18 pagine10 1108 - Jeim 02 2017 0035andrianioktafNessuna valutazione finora

- ReconstructionismDocumento32 pagineReconstructionismKristine Vergara Masola100% (1)

- Paper 2Documento1.530 paginePaper 2Ali AshrafNessuna valutazione finora

- TH THDocumento24 pagineTH THSama Lex alexisNessuna valutazione finora

- MH 2018Documento24 pagineMH 2018Shilps PNessuna valutazione finora

- Math Essentials 3eDocumento212 pagineMath Essentials 3eDr. Momin SohilNessuna valutazione finora

- Administration ManualDocumento9 pagineAdministration ManualYna CapaNessuna valutazione finora

- Case Study 4 - Mergers Dont Lead Always To Culture ClashesDocumento3 pagineCase Study 4 - Mergers Dont Lead Always To Culture ClashesMahmoud NassefNessuna valutazione finora

- Rachel Turner - Technology Professional InterviewDocumento8 pagineRachel Turner - Technology Professional Interviewapi-314514319100% (1)

- Physical Education and Health Flexible Instruction Delivery PlanDocumento4 paginePhysical Education and Health Flexible Instruction Delivery PlanAngelyn Lingatong67% (3)

- Leadership EnhancementDocumento41 pagineLeadership EnhancementVivian Rabang BuduanNessuna valutazione finora

- Advantages of ProbabilityDocumento3 pagineAdvantages of Probabilityravindran85Nessuna valutazione finora

- Appreciation of PoetryDocumento10 pagineAppreciation of PoetryNur Sinta WindiaNessuna valutazione finora

- Abuse Shows Up in An InfantDocumento4 pagineAbuse Shows Up in An InfantCarmen Costea BarlutiuNessuna valutazione finora

- Banking CourseDocumento134 pagineBanking CourseFred Raphael IlomoNessuna valutazione finora

- 1987 Philippine ConstitutionDocumento3 pagine1987 Philippine ConstitutionJoya Sugue AlforqueNessuna valutazione finora

- Carrington - The Great Beyond PDFDocumento19 pagineCarrington - The Great Beyond PDFNick El NinoNessuna valutazione finora

- SteynDocumento11 pagineSteynskippy16Nessuna valutazione finora

- Grade 8 Science Focus and EpicenterDocumento2 pagineGrade 8 Science Focus and EpicenterRe BornNessuna valutazione finora

- Capr-Iii 6282Documento52 pagineCapr-Iii 6282yashrajdhamaleNessuna valutazione finora

- Job Advertisment 31082022638290828893059775Documento2 pagineJob Advertisment 31082022638290828893059775ZAIN SAJJAD AWANNessuna valutazione finora

- MT5001 Desc - Assignm & Syllabus (201617)Documento8 pagineMT5001 Desc - Assignm & Syllabus (201617)LiuZetongNessuna valutazione finora

- Consent Format For ResearchDocumento1 paginaConsent Format For ResearchSanta Nina SantosNessuna valutazione finora