Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cheaper Alternatives to Conventional Solar Water Heaters

Caricato da

ErickMartinSDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cheaper Alternatives to Conventional Solar Water Heaters

Caricato da

ErickMartinSCopyright:

Formati disponibili

366 Renewable energy engineering and technology

Cheaper alternatives to conventional solar water heaters

As conventional solar water heaters have higher initial costs as compared to

commercial fuel-based water heaters (for example, electric geysers), several

attempts have been made to design cheaper systems. Some of these are

discussed below.

Collector-cum-storage water heater

This is a rectangular or cylindrical metal box (usually galvanized iron or mild

steel to keep the cost low), one side of which is painted black. The metal box is

kept inside a wooden enclosure (or a similar low-cost enclosure) with one side

open for fixing a cover glass (Figure 6.25).

If the height of the metal box is 50 mm, it can hold 50 litres/m

2

of

collector area. On the basis of a rough calculation for a 24-hour average

radiation level of 200 W/m

2

and an average collector efficiency of 25%, a

temperature rise of about 20 C can be obtained for such a box-type col-

lector. If the initial temperature of water is 30 C, the final water

temperature would be 50 C, which is quite adequate for bathing, etc. Such

Figure 6.25 Simple collector-cum-storage solar water heater

Solar thermal engineering 367

box-type water heaters have been investigated in India at CAZRI (Central

Arid Zone Research Institute), Jodhpur, and at TERI.

Shallow solar ponds

SSPs (shallow solar ponds) have long been considered potential alternatives for

conventional flat plate collectors. One of the earlier applications of SSPs was

in desalination (Hodge, Thompson, Groh, et al. 1966). An SSP prototype

facility was built and operated to supply hot water to the Sohio Uranium Mill

near Grants, New Mexico (Dickinson, Clark, and Iantuore 1976). A compact

SSP for hot water preparation for military and recreation purposes was

reported by Kudish and Wolf (1979).

SSP consists of a shallow bed of water contained within two plastic layers

black plastic layer at the bottom and transparent layer at the top with

suitable insulation and container box, and another glazing to reduce heat

losses (Figure 6.26).

The temperature build-up over the day can be obtained by solving the

equation

( ) ( ) MC

dT

dt

A G A U T T

p

p

c c L p a

=

( ) ...(6.84)

where (MC)

p

is the mass-specific heat product of water in the pond, T

p

is the

temperature of water at a given time t, A

c

is the area of the pond exposed to

sunlight, and () and U

L

are same as those in flat plate collectors. As fins and

Figure 6.26 Sectional view of shallow solar pond

368 Renewable energy engineering and technology

fluid flow are not involved, F and F

R

are unity. A theoretical and experimental

investigation of SSPs with continuous heat extraction has been proposed

(Kishore, Gandhi, and Rao 1986). A domestic solar water heater based on SSP

with a heat pipe heat exchanger, shown in Figure 6.27, has been studied experi-

mentally (Gandhi and Kishore 1983).

A portable SSP water heater has also been proposed (Kishore, Ranga

Rao, and Raman 1987). Temperature increments of up to 30 C over the day

have been reported. An SSP-DHW (shallow solar pond based domestic hot

water) system, where the hot water can be drained down into an insulated stor-

age tank, has been tested for long-term performance in Delhi (Raman and

Kishore 1992) (Figures 6.28 and 6.29).

Salinity gradient solar ponds

When sunlight falls on a water body such as a pond or a lake, part of the en-

ergy is reflected from the surface and the rest is transmitted. For a given

wavelength of light, the transmission (, l) of a ray through a distance l in

water can be represented as

, exp l

l

( )

( )

=

...(6.85)

where () is the characteristic wavelength-dependent attenuation length.

Attenuation of light results from absorption, molecular scattering, and scatter-

Figure 6.27 Shallow solar pond based domestic solar water heater

Solar thermal engineering 369

ing from suspended particles. The higher the magnitude of (), the lower is

the penetration of radiation. Experimental values for distilled water show that

water is relatively transparent to the visible wavelength (0.40.7 m), which

includes much of the solar spectrum (Hull, Nielsen, and Golding 1989).

Figure 6.28 Schematic diagram of a shallow solar pond based domestic solar water heater

Source Raman and Kishore (1992)

Figure 6.29 Storage tank temperatures of the SSPDHW system

370 Renewable energy engineering and technology

Due to the absorption of radiation, the temperature of a given layer of

water increases and the heated water tends to rise to the surface through

convection. For a layer of thickness l and temperature difference between the

top and bottom layer temperatures T, Rayleigh showed that convection does

not set in until T reaches a critical value given by the following equation

R

g Tl

k

T

T

= = =

3 4

27

4

657 5 .

...(6.86)

where R

T

is the thermal Rayleigh number, g is the acceleration due to gravity,

is the thermal expansion coefficient, is the kinematic viscosity, and k

T

is the

thermal diffusivity.

In normal circumstances, convection would set in depending on the

magnitude of the Rayleigh number, but if one can create a density gradient,

in which the bottom portion of the layer has higher density than the top,

convection can be suppressed even if T is higher than the critical value. If

convection is suppressed, the solar energy entering the pond is trapped,

resulting in higher temperatures of the lower layers of water in the pond, from

which heat can be extracted for useful purposes. This is the principle of

operation of a solar pond. The pond thus becomes a solar collector with

built-in storage, and as no expensive metals are used, it is potentially cheaper.

Practical solar ponds are based on the fact that saline water has higher density

as compared to pure water. The density of a salt solution can be represented as

=

0

[1 C

T

(T T

0

) + C

s

(S S

0

)] ...(6.87)

where

0

corresponds to a reference state; C

S

and C

T

are coefficients; and S is

the salinity expressed as concentration or percentage of salt in the saline solu-

tion. The change in density can be calculated as follows.

T

C

T

=

0 ...(6.88)

S

C

s

=

0 ...(6.89)

and

x S

S

x T

T

x

= +

...(6.90)

where x is the vertical co-ordinate increasing downward. For densities to

remain stable, it is necessary that

Solar thermal engineering 371

>

x

0

...(6.91)

Substituting from Equations 6.88 and 6.89 and re-arranging, we get

R

C

S

x

C

T

x

s

T

( )

( )

> 1

...(6.92)

This is the criterion for static stability and provides the salinity gradient

values for a given temperature gradient. In real ponds, there is another

criterion called dynamic stability criteria, in which both thermal and mass

diffusivity are considered in the double-diffusive system (Hull, Nielsen, and

Golding 1989).

In real solar ponds, there are three distinct zones: UCZ (upper

convective zone) or the surface zone, NCZ (non-convective zone) or the

gradient zone, and LCZ (lower convective zone) or the storage zone. A sche-

matic diagram of the solar pond is shown in Figure 6.30 (a).

The UCZ is formed due to wind effects, evaporation, etc., and can be

maintained at a thickness of about 3050 cm. The NCZ has a thickness of

11.5 m and the LCZ has a thickness of about 1.5 m. The density gradient

can be created artificially using a diffuser method (Kishore and Kumar

1996). Temperatures in LCZ and NCZ build up rapidly once the salinity gra-

dient is established in a clear pond. The rise of temperature in the LCZ for

the 6000 m

2

solar pond of Bhuj is shown in Figure 6.30 (b).

With convection suppressed, NCZ can be treated as a transparent con-

ducting solid with a heat generating source (solar radiation absorbed).

Figure 6.30a Schematic diagram of the solar pond

372 Renewable energy engineering and technology

Choosing a co-ordinate system with x = 0, corresponding to the surface of the

pond, the solar radiation at depth x is given by

G(x) = G

s

g(x) ...(6.93)

where G

s

is the radiation immediately below the surface and is given by

G

s

= G

0

(1 a) ...(6.94)

where G

o

is the global radiation on a horizontal surface and a is the albedo of

the surface, which depends on the incident angle.

The one-dimensional unsteady heat conduction equation for the NCZ is

C

T

t

k

T

x

G

x

p

=

2

2

...(6.95)

The initial condition can be taken as T = T

o

at the start-up of the pond.

The two boundary conditions required to solve the above equation are

obtained by heat balance on UCZ and NCZ. With a suitable functional form

Figure 6.30(b) Temperature history of the storage zone for the 6000 m

2

solar pond in Bhuj

Source Kishore and Kumar (1996)

Month/Day

Solar thermal engineering 373

for G(x), Equation 6.95 can be solved using numerical techniques. One general

method of solving it is by applying the CrankNicolson method (Joshi and

Kishore 1985a; Joshi, Kishore, and Rao 1984).

A useful expression for obtaining the efficiency of the solar pond can

be derived by assuming pseudo-steady state conditions in which T/t = 0.

Equation 6.95 can then be written as

k

d T

dx

d

dx

G x

2

2

= ( ) ( ) ...(6.96)

An energy balance for UCZ gives

Q G g x k

dT

dx

s s

x x

= [ ( )] 1

1

1

+

=

...(6.97)

where Q

s

is the sum of heat losses (convective, radiative, and evaporative)

from the surface and x

1

is the depth of UCZ. A similar equation for LCZ can

be written as

Q G g x k

dT

dx

Q

u s

x x

b

= ( )

2

2

=

...(6.98)

where Q

u

is the useful heat extracted, Q

b

is the bottom loss to the ground, and

x

2

corresponds to the interface between NCZ and LCZ. Equation 6.96 can be

solved using the boundary conditions of Equations 6.96 and 6.98 (Kishore and

Joshi 1984; Kooi 1979).

Q

u

= G

s

() U

t

(T

b

T

s

) Q

b

...(6.99)

where

( )

=

g x dx

x x

x

x

( )

1

2

2 1

...(6.100)

and

U

k

x x

t

=

2 1

...(6.101)

Q

s

and Q

b

can be related to the ambient and ground conditions, respec-

tively. Taking assumed or measured profiles for g(x), thermal efficiencies of

solar ponds can be obtained. However, such results are applicable only for

yearly average performance (Joshi and Kishore 1986).

374 Renewable energy engineering and technology

The attenuation function g(x) had been fitted to various functional

forms. The RablNielsen model is expressed as

g x r x

i i r

i

( ) exp sec =

( )

=

1

4

...(6.102)

where r

i

and

i

are the constants for a particular seawater and

r

is the angle of

refraction.

Bryant and Colbeck proposed a simple two-parameter model

g(x) = ab ln (x sec

r

) ...(6.103)

The one-parameter model proposed by Hawlader and Brinkworth is

expressed as

g(x) = (1F)exp[(x)sec

r

] ...(6.104)

where F is taken as 0.4 and as 0.06 m. The effect of using different attenua-

tion models on performance predictions has been studied by Joshi and

Kishore (1985b).

Considerable work on solar ponds has been done worldwide, including

India (Rao, Kishore, and Vaja 1990). The largest solar pond in Asia, the

6000 m

2

solar pond at Bhuj, India, operated in an industrial environment and

supplied process hot water to the Kuchch dairy for more than two years

(Kishore and Kumar 1996). The solar pond at Pondicherry is producing

electricity since 2004. A very large number of applications, including

desalination, bromine recovery, manufacture of magnesium chloride,

improved salt production, and so on have been identified for coastal areas in

India.

Evacuated tube collectors

Evacuated or vacuum tube collectors are fast becoming popular in the world

market. Emmett first proposed the concept of an evacuated tube collector

in 1909. With recent advances in vacuum and sealing technology and the

development of selective coating on glass surfaces, the evacuated tube

collectors are now mass-produced in various countries.

Essentially, these are based on the Dewar vacuum flask concept, wherein

the convective losses from the collector surface are reduced by providing

vacuum around the absorber. There are two major design configurations in

evacuated tube collectors

Single-glass tube

Double-glass tube

Solar thermal engineering 375

Figure 6.31 Evacuated tube collector designs

Source Goswami, Kreith, and Kreider (2000)

Single-glass tube evacuated collectors

In single-glass tube collectors, either a heat pipe is used to extract heat from

the collector or a simple U-tube with fin is provided to circulate the fluid

(Figure 6.31 a, b). The metal tube or heat pipe tube and the glass tube covering

it are hermetically sealed to form a vacuum tight joint. The air between

the gap is extracted from the other end using a vacuum pump and then the

end is sealed. Activated barium getter is provided to absorb the gases, which

can diffuse through the glass tube. Sometimes a small ripple reflector is pro-

vided below the collector to improve the concentration of the solar

radiation from below. The sealing of the glass to metal joint is the most

important area in these collectors. These types of collectors have a few advan-

tages as listed below.

Higher heat transfer efficiencies.

No fluid present inside the glass collectors.

Easy to use as an indirect heating element, especially when the outside

conditions are freezing or hard water is to be heated.

Double-glass tube evacuated collectors

Double-glass tube collectors (Figure 6.31c) are easy to manufacture but are

less efficient than single-glass tube collectors. They have two glass tubes

376 Renewable energy engineering and technology

attached to each other at one end while the other end of both the tubes is

closed. The space between them is evacuated and a selective absorbing coating

is applied on the outer surface of the inner tube. They can be used directly to

heat water stored in the inner tube and are commonly used in domestic water

heating systems. Domestic solar water heating systems based on double-glass

tube collectors are now commonly available in the Indian market.

Evacuated tube collector thermal analysis

Conductive heat transfer between two surfaces having low-pressure gas in the

interim space is given by the following equation (Goswami 2006).

q

l

= kt/(g + 2p) ...(6.105)

where q

l

is the heat loss, k is the constant, t is the temperature gradient, g is

the gap between surfaces, and p is the mean free path of molecules.

For air, the mean free path at atmospheric temperature and pressure is

about 70 m. If 99% air is removed from a tubular collector, the mean free

path increases to 7 mm, and conduction heat transfer is almost unaffected.

However, the mean free path increases to 7 cm at 10

7

torr, which is

substantially greater than the heat transfer path length (gap between the glass

tubes), which is of the order of 20 mm. This reduces the conductive heat

transfer substantially.

The relative reduction in heat transfer as a function of the mean free

path can be derived from Equation 6.105

q

q p g

vac

l

=

1

1 2 + /

...(6.106)

where q

l

is the conductive heat transfer if convection is suppressed and q

vac

is

the conductive heat transfer under vacuum.

The effective heat gain of the evacuated tubular collector based on

the aperture area can be expressed as follows (Goswami, Kreith, and Kreider

2000b).

q G

A

A

U T T

A

A

u eff

tb

c

L abs a

abs

c

= ()

1 1

( )

...(6.107)

where q

u

is the useful heat gain (W/m

2

) and G

eff

is the effective solar radiation,

both intercepted directly and after reflection from the back reflector

(reflected radiation is typically 10%) (W/m

2

); A

tb

is the projected tube

area (m

2

), A

c1

is the total collector area (m

2

), U

L

is the overall heat loss

Solar thermal engineering 377

coefficient (W/m

2

K), T

abs

is the absorber temperature (C), T

a

is the ambient

temperature (C), and A

abs

is the projected area of the absorber (m

2

).

Bekey and Mather have shown that a tube spacing of one diameter apart

maximizes the energy output (Goswami, Kreith, and Kreider 2000).

392 Renewable energy engineering and technology

Nomenclature

a Albedo of the surface

A Aperture area of the cooker (m

2

)

A

c

Area of the collector (m

2

)

A

r

Receiver area (m

2

)

A

c1

Total collector area (m

2

)

A

tb

Projected tube area (m

2

)

A

abs

Projected area of the absorber (m

2

)

A

1

/A

2

Area ratio

b Width (m)

b

o

Incident angle modifier coefficient

B Radiance (W)

C Concentration ratio

C

b

Bond conductance (W/m)

C

r

Ratio of (MC)

w

/(MC)

w

d Diameter (m)

D

e

Equivalent diameter (m)

D

i

Inside tube diameter (m)

E

2

/E

1

Flux concentration ratio

f Factor

F Fin efficiency

F Collector efficiency factor

g Gravitational acceleration (m/s

2

)

G

o

Global radiation on a horizontal surface (W/m

2

)

G

s

Radiation immediately below the surface (W/m

2

)

G

s,c

Solar constant

G

eff

Effective solar radiation (W/m

2

)

G

sun

Radiosity

h

1

, h

2

Convective heat transfer coefficient (W/m

2

K)

h

bf

Convective heat transfer coefficient from the bottom plate to the air

(W/m

2

K)

h

fi

Fluid heat transfer coefficient (W/m

2

K)

h

pf

Convective heat transfer coefficient between the plate and the fluid

(W/m

2

K)

h

r,pb

Radiative heat transfer coefficient between the collector plate and the

bottom plate (W/m

2

K) in air heater

I Irradiance, W/m

2

k Equivalent number of velocity heads lost by the flow in passing through

bends, thermal conductivity (W/mK)

Solar thermal engineering 393

k

T

Thermal diffusivity (m

2

/s)

K Extinction coefficient of the medium

K

a

Incident angle modifier

l Thickness of water layer (m), length, m

L Length of the collector plate (m)

L Cover plate thickness (m)

m Fluid flow rate for a single tube (kg/s)

MC Mass-specific heat product of water in the pond (J/K)

n

1

, n

2

Refractive indices of the media

Nu Nusselt number

p Mean free path molecule (m)

q

1

Conductive heat transfer if convection is suppressed (W)

q

u

Useful heat gain (W)

q

pc

Heat loss, W

q

load

Useful energy supplied to the load from the storage (W)

q

vac

Conductive heat transfer under vacuum (W)

Q

b

Bottom loss to the ground (W)

Q

L

Heat lost (W)

Q

s

Sum of heat losses (W)

Q

u

Useful heat (W)

r Reflectance of unpolarized light

r

pa

Parallel component of the unpolarized light

r

pp

Perpendicular component of the unpolarized light

Re Reynolds number

R

T

Thermal Rayleigh number

S Salinity (kg/m

3

)

S Solar radiation absorbed by the fin (W/m

2

)

t Time (s)

T Temperature

u Velocity (m/s)

U

b

Heat loss coefficient from the bottom of the collector (W/m

2

K)

U

L

Overall heat loss coefficient (W/m

2

K)

U

t

Top loss coefficient (W/m

2

K)

(UA)

tank

Product of the overall heat transfer coefficient and the surface area of

the tank (W/K)

x x-coordinate

y y-coordinate

Radiant flux (W)

Angle

.

.

.

394 Renewable energy engineering and technology

Transmittance

pa

Transmittance for the parallel component

pp

Transmittance for the perpendicular component

Reflectance

d

Diffuse reflectance

Absorptance, thermal expansion coefficient

Wavelength (m)

Collector tilt

Fin thickness (m)

i

Thickness of the insulating material (m)

c

Thickness of a copper plate (m)

Efficiency

o

Optical efficiency

Kinematic viscosity (m

2

/s)

() Characteristic wavelength-dependent attenuation length (m)

Solid angle

References

Brandemuehl M J and Beckman W A. 1980

Transmission of diffuse radiation through CPC and flat plate collector glazing

Solar Energy 24(511)

Close D J. 1962

The performance of solar water heaters with natural circulation

Solar Energy 6(33)

Dickinson W C, Clark A F, and Iantuore A. 1976

in Proceedings of the International Solar Energy Society

Solar Energy Conference 5(117)

Duffie J and Beckman W A. 1991

Solar Engineering of Thermal Processes

New York: John Wiley and Sons, Inc.

Gandhi M R and Kishore V V N. 1983

Experimental performance of shallow solar pond of novel design

In Proceedings of the Sixth Miami International Conference on Alternative Energy Sources [Sixth

Miami International Conference on Alternative Energy Sources, Florida]

Garg H P, Mullick S C, and Bhargava A K. 1985

Solar Thermal Energy Storage

Reidel Publishing Company

Solar thermal engineering 395

Goswami Y D, Kreith F, and Kreider J N. 2000

Principles of Solar Thermal Engineering, Second edition

Philadelphia: Taylor and Francis

Grossman G, Shitzer A, and Zvirin Y. 1977

Heat transfer analysis of a flat-plate solar energy collector

Solar Energy 19: 493502

Gupta C L and Garg H P. 1967

Performance studies of solar air heaters

Solar Energy II(25)

Gupta C L and Garg H P. 1968

System design in solar water heaters with natural circulation

Solar Energy 12(163)

Hodge C N, Thompson T L, Groh J E, Frieling D H. 1966

Progress Report 194

USA: Office of Saline Water Research and Development

Hull J R, Nielsen C E, and Golding P. 1989

Salinity-gradient Solar Ponds

Boca Raton, Florida: CRC Press

IS 12933. 2003

Solar flat plate collector-specifications

New Delhi: Bureau of Indian Standards

Joshi V and Kishore V V N. 1985a

Computer simulation of the performance of the solar pond

Reg. J Energy Heat Mass Transfer 7(2): 97106

Joshi V and Kishore V V N. 1985b

A numerical study of the effects of solar attenuation modelling on the

performance of solar ponds

Solar Energy 35(4): 377380

Joshi V and Kishore V V N. 1986

Applicability of steady state equations for solar pond thermal performance

predictions

Energy II(8): 821827

Joshi V, Kishore V V N, and Rao K S. 1984

A digital simulation of non-convecting solar pond for Indian conditions

Renewable Energy Sources: International Progress edited by T. Nejat Veziroglu

Elsevier, pp. 207220

Kaushika N D and Sumathy K. 2003

Solar transparent insulation materials: a review

Renewable and Sustainable Energy Reviews 7: 317351

396 Renewable energy engineering and technology

Kishore V V N and Joshi V. 1984

A practical collector efficiency equation for non-convecting solar ponds

Solar Energy 33(5): 391395

Kishore V V N and Katam S. 1987

Flat Plate Collector Testingan overview

SESI Journal 1: 1117

Kishore V V N and Kumar A. 1996

Solar pond: an exercise in development of indigenous technology at Kutch

Energy for Sustainable Development III (1)

Kishore V V N, Gandhi M R, and Rao K S. 1984

Analysis of flat-plate collectors charged with phase-changing fluids

Applied Energy 17: 133149

Kishore V V N, Gandhi M R, and Rao K S. 1986

Experimental and analytical studies of shallow solar pond system with

continuous heat extraction

Solar Energy 36(3): 245256

Kishore V V N, Ranga Rao V V, and Raman P. 1987

A portable shallow solar pond water heater

Solar and Wind Technology 4(2): 201204

Kishore V V N, Gandhi M R, Marquis Ch, Rao K S. 1984

Testing flat plate collectors charged with phase-changing fluids

Applied Energy 17: 155168

Kishore V V N, et al. 1986

Development of solar (thermal) water pump prototype an Indo Swiss

experience

Solar Energy 36(3): 257265

Kooi C F. 1979

The steady state salt gradient solar pond

Solar Energy 23: 3745

Kudish A I and Wolf D. 1979

A compact shallow solar pond hot water heater

Solar Energy 21(317)

Maru L V, Kishore V V N, and Gomkale S D. 1986

A roof collector for industrial hot water production

Energy II(7): 651657

Mullick S C, Kandpal T C, and Saxena A K. 1987

Thermal test procedure for box-type solar cooker

Solar Energy 39: 353360

Solar thermal engineering 397

Ong K S. 1974

A finite-difference method to evaluate the thermal performance of a solar water

heater

Solar Energy 16: 137147

Pytlinski J T. 1978

Solar energy installations for pumping irrigation water

Solar Energy 21: 255262

Raman P and Kishore V V N. 1992

Performance of a shallow solar pond based domestic hot water system (100 LPD), in

North Indian Climate

[Paper presented in the National Seminar on UrbanRural Alternative Energy

Management, Pondicherry University, 78 February 1992]

Rao D P and Rao K S. 1976

A solar water pump for lift irrigation

Solar Energy 18: 405411

Rao K S, Kishore V V N, and Vaja D (eds). 1990

Solar pond: scope and utilisation

Vadodara: Gujarat Energy Development Agency

Sukhatme S P. 1984

Thermal Energy Storage. Solar Energy principles of thermal collection and storage

New Delhi: Tata McGraw-Hill Publishing Company Ltd

Whillier A. 1963

Black painted solar air heaters of conventional design

Solar Energy 8(31)

Whillier A and Saluja G. 1965

Effects of materials and of construction details on the thermal performance of solar

water heaters

Solar Energy 9(21)

Winter C J, Sizmann R L, and Vant-Hull L L (eds.). 1991

Solar Power Plants: fundamentals, technology, systems, economics

New York: Springer-Verlag

Zakhidov R A, Umarov G Y A, and Weiner A A. 1992

Theory and calculation of applied solar energy concentrating systems

Vadodara: Gujarat Energy Development Agency

Potrebbero piacerti anche

- Predicted Performances of A Proposed Coffered Solar PondDocumento24 paginePredicted Performances of A Proposed Coffered Solar PondResearcherzNessuna valutazione finora

- Numerical Model For The Behaviour of A Salt-Gradient Solar-Pond Greenhouse-Heating SystemDocumento16 pagineNumerical Model For The Behaviour of A Salt-Gradient Solar-Pond Greenhouse-Heating SystemResearcherzNessuna valutazione finora

- Solar Heating and Cooling Systems Utilizing Evacuated Tube Solar CollectorsDocumento6 pagineSolar Heating and Cooling Systems Utilizing Evacuated Tube Solar Collectorshassan zohairNessuna valutazione finora

- Applied Energy: R. R. Isaac and C. L. GuptaDocumento15 pagineApplied Energy: R. R. Isaac and C. L. GuptaResearcherzNessuna valutazione finora

- Accepted Manuscript: 10.1016/j.energy.2017.09.110Documento42 pagineAccepted Manuscript: 10.1016/j.energy.2017.09.110Mustansir KarimNessuna valutazione finora

- The Effect of Ground Conditions Under A Solar Pond On The Performance of A Solar Air-Conditioning SystemDocumento8 pagineThe Effect of Ground Conditions Under A Solar Pond On The Performance of A Solar Air-Conditioning SystemIT MalurNessuna valutazione finora

- Partitioned Solar Pond Collector/Storage System: Applied Energ)Documento22 paginePartitioned Solar Pond Collector/Storage System: Applied Energ)ResearcherzNessuna valutazione finora

- M.M. Rahman, M.M. Billah, N.A. Rahim, N. Amin, R. Saidur and M. HasanuzzamanDocumento5 pagineM.M. Rahman, M.M. Billah, N.A. Rahim, N. Amin, R. Saidur and M. HasanuzzamanSourav SahaNessuna valutazione finora

- Heat Mass Transfer and Thermophysical Analysis For Pyramid Type Solar StillDocumento4 pagineHeat Mass Transfer and Thermophysical Analysis For Pyramid Type Solar StillIjsrnet EditorialNessuna valutazione finora

- Collector Efficiency Improvement of Recyclic Double-Pass Sheet-And-Tube Solar Water Heaters With Internal Fins AttachedDocumento10 pagineCollector Efficiency Improvement of Recyclic Double-Pass Sheet-And-Tube Solar Water Heaters With Internal Fins AttachedResearcherzNessuna valutazione finora

- Relationship To Thermodynamics: Chapter One Section 1.3Documento18 pagineRelationship To Thermodynamics: Chapter One Section 1.3Ahmed M TNessuna valutazione finora

- Paper Tubos Al VacioDocumento8 paginePaper Tubos Al VaciomarkeduardNessuna valutazione finora

- Zima DziewaDocumento19 pagineZima Dziewa11751175Nessuna valutazione finora

- Heat Extraction From Salinity-Gradient Solar Ponds Using Heat PipeDocumento11 pagineHeat Extraction From Salinity-Gradient Solar Ponds Using Heat Pipeedy_iasiNessuna valutazione finora

- Physics 222 - Test 4 - Spring 2010Documento1 paginaPhysics 222 - Test 4 - Spring 2010eltytanNessuna valutazione finora

- BASIC HYDRODYNAMIC ASPECTS OF A SOLAR ENERGY BASED DESALINATION PROCESSDocumento10 pagineBASIC HYDRODYNAMIC ASPECTS OF A SOLAR ENERGY BASED DESALINATION PROCESSagmibrahim5055Nessuna valutazione finora

- Heat Transfer Homework 3 Solutions ME 335Documento10 pagineHeat Transfer Homework 3 Solutions ME 335David SebulskyNessuna valutazione finora

- Thermal Analysis and Modeling of A Swimming Pool Heating SystemDocumento12 pagineThermal Analysis and Modeling of A Swimming Pool Heating Systemthermosol5416100% (1)

- Thermal Analysis and Modeling of A Swimming Pool Heating System by Utilizing Waste Energy Rejected From A Chiller Unit of An Ice RinkDocumento13 pagineThermal Analysis and Modeling of A Swimming Pool Heating System by Utilizing Waste Energy Rejected From A Chiller Unit of An Ice RinksqfadfafqefNessuna valutazione finora

- 2019 CFD Modeling of Operating Processes of A Solar Air Heater in ANSYS FluentDocumento7 pagine2019 CFD Modeling of Operating Processes of A Solar Air Heater in ANSYS FluentaliNessuna valutazione finora

- Wei 2013Documento7 pagineWei 2013PRADEEP SNessuna valutazione finora

- Centre of Energy Studies, Indian Institute of Technology, Hauz Khas, New Delhi - Llo 016 (India)Documento16 pagineCentre of Energy Studies, Indian Institute of Technology, Hauz Khas, New Delhi - Llo 016 (India)ResearcherzNessuna valutazione finora

- Research Article: The Vertical-Tube Solar Collector: A Low-Cost Design Suitable For Temperate High-Latitude LocationsDocumento8 pagineResearch Article: The Vertical-Tube Solar Collector: A Low-Cost Design Suitable For Temperate High-Latitude LocationsMusrady MulyadiNessuna valutazione finora

- V Grooved Solar CollectorDocumento7 pagineV Grooved Solar CollectoridriszulkifleNessuna valutazione finora

- Thermal Performance of Rock Bed StorageDocumento9 pagineThermal Performance of Rock Bed StorageAnonymous oUoJ4A8xNessuna valutazione finora

- We M5Documento14 pagineWe M5knyogishNessuna valutazione finora

- Transient Conduction - Lumped Cap MTD - S1 2013-2014Documento40 pagineTransient Conduction - Lumped Cap MTD - S1 2013-2014Elroy LeeNessuna valutazione finora

- Effect of The Tilt Angle of Natural Convection in A Solar Collector With Internal Longitudinal FinsDocumento5 pagineEffect of The Tilt Angle of Natural Convection in A Solar Collector With Internal Longitudinal FinsInternational Journal of Science and Engineering InvestigationsNessuna valutazione finora

- SolarsDocumento11 pagineSolars11751175Nessuna valutazione finora

- Research EvolutionDocumento21 pagineResearch EvolutionMatthew NelsonNessuna valutazione finora

- Optimal Performance of An Endo-Reversible Solar Driven Sorption Refrigeration SystemDocumento7 pagineOptimal Performance of An Endo-Reversible Solar Driven Sorption Refrigeration SystemvampiroNessuna valutazione finora

- Sls Case StudyDocumento4 pagineSls Case Studyapi-567341485Nessuna valutazione finora

- Heat Loses From Parabolic Trough Solar CollectorsDocumento9 pagineHeat Loses From Parabolic Trough Solar CollectorsSaúl García HernándezNessuna valutazione finora

- Zhu WangDocumento17 pagineZhu WangpietjansenNessuna valutazione finora

- Performance of A Portable Mini Solar-Pond: M.A. Tahat, Z.H. Kodah, S.D. Probert, H. Al-TahainehDocumento12 paginePerformance of A Portable Mini Solar-Pond: M.A. Tahat, Z.H. Kodah, S.D. Probert, H. Al-TahainehResearcherzNessuna valutazione finora

- Mathematical Modeling of Heat Transfer Processes in Energy-Saving Solar Energy SystemsDocumento4 pagineMathematical Modeling of Heat Transfer Processes in Energy-Saving Solar Energy SystemserpublicationNessuna valutazione finora

- 48 Ragab 1-s2.0-S2352152X23004528-main - CompressedDocumento14 pagine48 Ragab 1-s2.0-S2352152X23004528-main - CompressedAbo AmroNessuna valutazione finora

- Solar Pond TechnologyDocumento18 pagineSolar Pond TechnologyAdanNessuna valutazione finora

- Investigation of A Flow Coefficient For Predicting A Natural Circulation of Water in A Built-In-Storage Solar Water HeaterDocumento5 pagineInvestigation of A Flow Coefficient For Predicting A Natural Circulation of Water in A Built-In-Storage Solar Water HeaterchrissbansNessuna valutazione finora

- Energy Conversion and Management: Monia Chaabane, Hatem Mhiri, Philippe BournotDocumento7 pagineEnergy Conversion and Management: Monia Chaabane, Hatem Mhiri, Philippe Bournotrahul rawatNessuna valutazione finora

- Experimental and Theoretical Temperature Distributions in A Solar PondDocumento11 pagineExperimental and Theoretical Temperature Distributions in A Solar Pondebrahimkarimi12Nessuna valutazione finora

- Thermodynamics of A Shallow Solar StillDocumento21 pagineThermodynamics of A Shallow Solar StillsepehrNessuna valutazione finora

- An Electrical Analog of A Flat-Plate Solar Water Heating SystemDocumento4 pagineAn Electrical Analog of A Flat-Plate Solar Water Heating SystemChih-yuan WengNessuna valutazione finora

- Solar Swimming Pool HeatingDocumento9 pagineSolar Swimming Pool HeatingAtmesh PoudyalNessuna valutazione finora

- CFD Presentation Final2Documento16 pagineCFD Presentation Final2Taha KhanNessuna valutazione finora

- Low Mass Flow Rate in Flat-Plate Liquid Heating Solar CollectorsDocumento17 pagineLow Mass Flow Rate in Flat-Plate Liquid Heating Solar CollectorsMarjan IvanovskiNessuna valutazione finora

- Two-Dimensional Analysis of Parallel Flow Flat-Plate Solar CollectorDocumento15 pagineTwo-Dimensional Analysis of Parallel Flow Flat-Plate Solar CollectorAncelmo Queiroz JúniorNessuna valutazione finora

- Jiarong Li 2020Documento11 pagineJiarong Li 2020Fábio A. BodnarNessuna valutazione finora

- A Case Study On Solar Vapour Absorption Refrigeration SystemDocumento7 pagineA Case Study On Solar Vapour Absorption Refrigeration SystemShivam MaheraNessuna valutazione finora

- Pergamon: ChemicalDocumento6 paginePergamon: ChemicalAzharuddin_kfupmNessuna valutazione finora

- Modeling of Counter Current Moving Bed Gas-Solid Reactor Used in Direct Reduction of Iron Ore - PlusDocumento10 pagineModeling of Counter Current Moving Bed Gas-Solid Reactor Used in Direct Reduction of Iron Ore - PlusJavier GómezNessuna valutazione finora

- An Energy Efficient Hybrid System of Solar Powered Water Heater and Adsorption Ice MakerDocumento7 pagineAn Energy Efficient Hybrid System of Solar Powered Water Heater and Adsorption Ice MakerAjith KrishnanNessuna valutazione finora

- Chapter 7 Solar Collector Design For Solar Assisted Desiccant CoolingDocumento31 pagineChapter 7 Solar Collector Design For Solar Assisted Desiccant CoolingEngr Muhammad SohailNessuna valutazione finora

- Mms Assignment No. 1 Session 16171Documento7 pagineMms Assignment No. 1 Session 16171Gurjeet SinghNessuna valutazione finora

- Fowler GRC 2021 Feasibility Analysis 2Documento19 pagineFowler GRC 2021 Feasibility Analysis 2khaledNessuna valutazione finora

- Time Travel: An Approximate Mathematical SolutionDa EverandTime Travel: An Approximate Mathematical SolutionNessuna valutazione finora

- Mini Dozer Info 1967Documento13 pagineMini Dozer Info 1967Jim100% (2)

- Boiler InspectionsDocumento4 pagineBoiler InspectionsErickMartinSNessuna valutazione finora

- The S-90 Go-Kart Optimal Design ReportDocumento70 pagineThe S-90 Go-Kart Optimal Design ReportshauuuuuuuuuuuuuuuuNessuna valutazione finora

- Development of A Chest Freezer - Optimum DesignDocumento15 pagineDevelopment of A Chest Freezer - Optimum DesignErickMartinSNessuna valutazione finora

- Boiler Basics: Design, Operation, Components & SystemsDocumento5 pagineBoiler Basics: Design, Operation, Components & SystemsEng Waleed MouhammedNessuna valutazione finora

- Pengering GambirDocumento14 paginePengering GambirErickMartinSNessuna valutazione finora

- Collectors Innovation To Increase Performance SolarDocumento7 pagineCollectors Innovation To Increase Performance SolarErickMartinSNessuna valutazione finora

- Monthly Boiler Maintenance ChecklistDocumento2 pagineMonthly Boiler Maintenance ChecklistErickMartinSNessuna valutazione finora

- Balancing of Rotating and Reciprocating Systems in EngineDocumento12 pagineBalancing of Rotating and Reciprocating Systems in EngineNeacsu EugenNessuna valutazione finora

- Fluidized Bed IntroductionDocumento19 pagineFluidized Bed IntroductionErickMartinSNessuna valutazione finora

- Quick Freezing Using Liquid NitrogenDocumento5 pagineQuick Freezing Using Liquid NitrogenErickMartinSNessuna valutazione finora

- Food Freezing Heat Transfer CoefficientsDocumento24 pagineFood Freezing Heat Transfer CoefficientsErickMartinSNessuna valutazione finora

- Development of A Chest Freezer - Optimum DesignDocumento15 pagineDevelopment of A Chest Freezer - Optimum DesignErickMartinSNessuna valutazione finora

- Heat Transfer in Freeze-Drying ApparatusDocumento25 pagineHeat Transfer in Freeze-Drying ApparatusErickMartinS100% (1)

- Design BladeDocumento7 pagineDesign BladeErickMartinSNessuna valutazione finora

- The DoublehelixDocumento46 pagineThe DoublehelixErickMartinSNessuna valutazione finora

- FE FluidMechanicsDocumento12 pagineFE FluidMechanicsErickMartinSNessuna valutazione finora

- Mesin Pencacah Rumput GajahDocumento8 pagineMesin Pencacah Rumput GajahErickMartinSNessuna valutazione finora

- Chm580 Experiment 3Documento9 pagineChm580 Experiment 3ohhiNessuna valutazione finora

- I. 8-Bit Microprocessors Architecture, Instruction Set and Their ProgrammingDocumento4 pagineI. 8-Bit Microprocessors Architecture, Instruction Set and Their ProgrammingSaorabh KumarNessuna valutazione finora

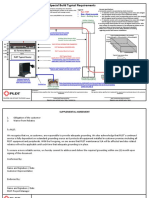

- Special Build Typical Requirements (Rev1) PDFDocumento2 pagineSpecial Build Typical Requirements (Rev1) PDFToper CdjNessuna valutazione finora

- Unit2.SP - Mill.setting and ImbibitionDocumento15 pagineUnit2.SP - Mill.setting and ImbibitionHari kantNessuna valutazione finora

- Signal and Telecommunication - 1Documento83 pagineSignal and Telecommunication - 1srinathNessuna valutazione finora

- Projectile LoomDocumento23 pagineProjectile Loommehedi111560% (5)

- The Use and Misuse of SEMDocumento30 pagineThe Use and Misuse of SEMPPDTBM renNessuna valutazione finora

- Performance comparison of bored and excavated pilesDocumento10 paginePerformance comparison of bored and excavated pilesDavid Aponte RojasNessuna valutazione finora

- TIMO Mock 2019 卷P3fDocumento9 pagineTIMO Mock 2019 卷P3fDo Yun100% (1)

- TC 1800 QI 1 1 0 (User Manual)Documento25 pagineTC 1800 QI 1 1 0 (User Manual)Emman JimenezNessuna valutazione finora

- Suunto Core UserguideDocumento58 pagineSuunto Core UserguidePriyo AkuntomoNessuna valutazione finora

- Computer Science Project On Management SystemDocumento26 pagineComputer Science Project On Management Systemsajid aliNessuna valutazione finora

- JavaDocumento20 pagineJavaSivasakthi MarimuthuNessuna valutazione finora

- Analysis of Excessive Hydrogen Generation in TransformersDocumento8 pagineAnalysis of Excessive Hydrogen Generation in TransformersandikaubhNessuna valutazione finora

- How To Solve AssignmentsDocumento4 pagineHow To Solve AssignmentsHarisNessuna valutazione finora

- Operations Management 1St Edition Cachon Test Bank Full Chapter PDFDocumento36 pagineOperations Management 1St Edition Cachon Test Bank Full Chapter PDFwayne.martin885100% (11)

- Periodic TableDocumento1 paginaPeriodic TableChemist MookaNessuna valutazione finora

- Operation Manual Zoomlion QY40Documento133 pagineOperation Manual Zoomlion QY40Hải Tiến100% (1)

- Surface Roughness Conversion Chart Tables - Engineers EdgeDocumento10 pagineSurface Roughness Conversion Chart Tables - Engineers Edgejames.anitNessuna valutazione finora

- Mechanical Technology Concepts: Applied ThermodynamicsDocumento45 pagineMechanical Technology Concepts: Applied ThermodynamicsLe0 GamingNessuna valutazione finora

- Ray OpticsDocumento41 pagineRay OpticsHannah VsNessuna valutazione finora

- Measuring Propeller Drop With The Help of Poker GaugeDocumento2 pagineMeasuring Propeller Drop With The Help of Poker Gaugeas100% (1)

- METAL CLUSTER COMPLEXESDocumento13 pagineMETAL CLUSTER COMPLEXESKeybateNessuna valutazione finora

- Smart AntennasDocumento40 pagineSmart AntennasMeeraNessuna valutazione finora

- Training Seminar ON GSM Held at BSNL: Presented By: Charli Bagga Kriti Rastogi (AEI-08)Documento51 pagineTraining Seminar ON GSM Held at BSNL: Presented By: Charli Bagga Kriti Rastogi (AEI-08)Ankita BharadwajNessuna valutazione finora

- May June 2019 P02Documento40 pagineMay June 2019 P02Rongrui ZhouNessuna valutazione finora

- Dispersing AgentsDocumento6 pagineDispersing AgentsEdward MenezesNessuna valutazione finora

- Measure Runoff and Soil Loss at Erosion Plots in TanzaniaDocumento19 pagineMeasure Runoff and Soil Loss at Erosion Plots in TanzaniaMohd Sofiyan Bin SulaimanNessuna valutazione finora

- Unisonic Technologies Co., LTD: 8-Channel Analog Multiplexers/DemultiplexersDocumento7 pagineUnisonic Technologies Co., LTD: 8-Channel Analog Multiplexers/DemultiplexersNaresh KsNessuna valutazione finora

- Bombers and SeagullsDocumento8 pagineBombers and SeagullshpgeraldNessuna valutazione finora