Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Case Lockbourne

Caricato da

Briand DaydayTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Case Lockbourne

Caricato da

Briand DaydayCopyright:

Formati disponibili

THE LOCKBOURNE COMPANY

The company is a leading manufacturer and distributor of a line of packaged goods which it sells

nationally under the Burn-Loc Products trade name. The company operates three factories from which it

ships to regional warehouses or directly to large outlets. Last year, demand for Burn-Loc Products was

3.2 million e!ui"alent# cases, distributed as follows $in million cases% according to fi"e sales regions&

Atlanta Los Angeles Dallas Chicago New York Total

'.( '.) '.) *.* '.+ 3.2

,ne-shift production capacity in each of the three plants was as follows $in million cases%&

Hoe Cit! Branch No" # Branch No" $ Total

*.2 '.- *.( 3.)

.stimated freight costs $/0case% from each of the factories to each distribution center are as follows&

Hoe Cit! Branch No" # Branch No" $

Atlanta '.1( '.3( '.1'

Los Angeles *.'( *.+' *.+'

Dallas '.+' *.)' *.2'

Chicago '.3' '.+' '.-'

New York *.'' '.3' '.+(

3ot all shipments are routed through regional warehouses, but on a"erage the freight cost on direct

shipments to outlets was !uite close to the cost which would ha"e been incurred if the shipment had been

routed through the ser"icing warehouse.

Lockbourne followed a philosophy of decentrali4ed management. Top e5ecuti"es fa"ored this approach

for a number of reasons. 6irst, by enriching the e5perience of subordinate managers, it pro"ided better

training for ultimate top management responsibility. 7econd, it insured that operating decisions were

made by those persons most familiar with the detailed circumstances which would determine the success

or failure of the decisions. 8nder the decentrali4ed approach, subordinate managers were held

responsible for the profitability of operations under their control.

9onsistent with the policy of decentrali4ation, each of the fi"e regional warehouses was under the direct

super"ision of a regional sales manager. The warehouses were not assigned to a particular plant for

ser"icing, since demand shifts made a certain amount of fle5ibility necessary. :ather, the regional sales

manager decided upon which plant to place an order. The price paid by the warehouse was /2.2(0case

6,B the plant. This price was set to reco"er costs plus a reasonable return on in"estment for the

manufacturing di"ision. 7ince the regional warehouse was re!uired to absorb the freight costs, the

regional sales managers are e5pected to place their orders so as to minimi4e their own freight costs and

hence those of the company as a whole.

,"er a period of time, this procedure has led to increasing amounts of organi4ational friction, and early

this year some Lockbourne officials were beginning to !uestion whether the procedure was e"en

achie"ing the ob;ecti"e of minimi4ing freight costs. Because Branch 3o. 2 was not the closest plant to

any of the regional warehouses, it was ne"er deliberately selected as source by a regional sales

manager. :ather, the managers would initially order from the <ome 9ity or Branch 3o. *, whiche"er was

closer. 7ince those plants had inade!uate capacity to meet all sales demands, it was then necessary for

the plant managers to re;ect some orders. 3o consistent procedure was followed in determining which

order would be accepted, but it was largely a matter of first-come-first-ser"ed. The regional sales

managers whose orders were re;ected were then usually forced to take them to Branch 3o. 2, typically at

a considerable increase in freight cost. This aspect of the situation resulted in much grumbling by the

regional sales managers.

=oreo"er, since the orders placed with Branch 3o. 2 were not placed there in a conscious effort to

minimi4e freight costs, there appeared to be a strong possibility that the resulting o"er-all shipping

program was not optimal. 6or this reason, some e5ecuti"es felt that the practice of lea"ing shipping

decisions to the decentrali4ed ;udgments of regional sales managers should be discontinued. They

proposed instead that all orders be routed through a central office which could then determine an optimal

shipping program from an o"erall company point of "iew. The actual !uantities $in million cases% shipped

o"er each possible route last year are as follows with total shipping costs that year reaching /2,)*','''&

Hoe Cit! Branch No" # Branch No" $ Total

Atlanta '.3 '.2 %"&

Los Angeles '.* '.3 %"'

Dallas '.2 '.2 %"'

Chicago '.1 '.2 #"#

New York '.2 '.2 %"(

Total #"$ %") #"* *"$

,ther e5ecuti"es were concerned about the effect such a proposal would ha"e on the general

effecti"eness of decentrali4ed management. They also obser"ed that one result of the proposal would be

to saddle the regional sales managers with freight costs o"er which they could e5ercise no control.

Potrebbero piacerti anche

- Moparm Action - December 2014 USADocumento100 pagineMoparm Action - December 2014 USAenricoioNessuna valutazione finora

- Occupational Therapy in Mental HealthDocumento16 pagineOccupational Therapy in Mental HealthjethasNessuna valutazione finora

- Is 778 - Copper Alloy ValvesDocumento27 pagineIs 778 - Copper Alloy ValvesMuthu KumaranNessuna valutazione finora

- Use MoreDocumento5 pagineUse Moreg14032Nessuna valutazione finora

- Colibri - DEMSU P01 PDFDocumento15 pagineColibri - DEMSU P01 PDFRahul Solanki100% (4)

- Chicago GSB Casebook 2007Documento143 pagineChicago GSB Casebook 2007Archibald_Moore100% (1)

- Operational PlanDocumento13 pagineOperational PlanJacques EngelbrechtNessuna valutazione finora

- Assisted Living - Philippines Strategic PlanningDocumento21 pagineAssisted Living - Philippines Strategic PlanningBriand DaydayNessuna valutazione finora

- Instructor S ManualDocumento233 pagineInstructor S ManualDarwin Roberto Veloz Vaca100% (4)

- Midwest OfficeDocumento4 pagineMidwest OfficeSaurabh MalhanNessuna valutazione finora

- Service Delivery Profile PhilippinesDocumento13 pagineService Delivery Profile Philippines15-0001Nessuna valutazione finora

- SCA ALKO Case Study ReportDocumento4 pagineSCA ALKO Case Study ReportRavidas KRNessuna valutazione finora

- Case 7 W-G-P Chemical Company: ObjectivesDocumento3 pagineCase 7 W-G-P Chemical Company: Objectivesmohamed mohamedgalal0% (1)

- Case 1 - Ocean Carriers QuestionsDocumento2 pagineCase 1 - Ocean Carriers QuestionsOmar Al FarooqNessuna valutazione finora

- Planning Cement Terminal OperationsDocumento10 paginePlanning Cement Terminal Operationsasad55001Nessuna valutazione finora

- Merloni-Tranist Point ModelDocumento6 pagineMerloni-Tranist Point ModelUmair Chishti100% (1)

- Atom Medical Usa Model 103 Infa Warmer I - 2 PDFDocumento7 pagineAtom Medical Usa Model 103 Infa Warmer I - 2 PDFLuqman BhanuNessuna valutazione finora

- Team3 PDFDocumento5 pagineTeam3 PDFSamir Yaddua Torres OrjedaNessuna valutazione finora

- Cost-Effective: Apples To ApplesDocumento6 pagineCost-Effective: Apples To ApplesMl AgarwalNessuna valutazione finora

- Is Cross-Docking For You - ToyotaDocumento4 pagineIs Cross-Docking For You - Toyotanishikumarnishi8000Nessuna valutazione finora

- Protecting Finding Perfecting: ReprintDocumento4 pagineProtecting Finding Perfecting: ReprintFlorrNessuna valutazione finora

- Arctic InsulationDocumento5 pagineArctic InsulationjhonmarteNessuna valutazione finora

- Supply ChainIPMDocumento7 pagineSupply ChainIPMMAHIN CHAWLANessuna valutazione finora

- Cash Collection Systems: Professor of Financial Economics University of Nebraska Kearney, NEDocumento15 pagineCash Collection Systems: Professor of Financial Economics University of Nebraska Kearney, NEAbuBakarSiddiqueNessuna valutazione finora

- Fall 2006 Chemco Case Study Page 1 of 5Documento5 pagineFall 2006 Chemco Case Study Page 1 of 5Byron Galáctico RodríguezNessuna valutazione finora

- Case-Study Giles Tabandite Tuerker WotkeDocumento16 pagineCase-Study Giles Tabandite Tuerker WotkeAlfred Poleng0% (1)

- Logistics Strategy Improvement Case Studies Memorandum 708Documento10 pagineLogistics Strategy Improvement Case Studies Memorandum 708uroojishfaqNessuna valutazione finora

- Problems 7Documento1 paginaProblems 7Maria AngeliqueNessuna valutazione finora

- Chap003 - Network PlanningDocumento88 pagineChap003 - Network PlanningMukund KshirsagarNessuna valutazione finora

- The Grey Box ConceptDocumento6 pagineThe Grey Box ConceptRichard ButcherNessuna valutazione finora

- An Industrial Ocean-Cargo Shipping Problem: Administrative Sciences, G W e School Management, Kent, OH 44242-0001Documento29 pagineAn Industrial Ocean-Cargo Shipping Problem: Administrative Sciences, G W e School Management, Kent, OH 44242-0001IHZA RAMADHANNI FITRA IPBNessuna valutazione finora

- Supply Chain Management of Major Courier Companies in IndiaDocumento15 pagineSupply Chain Management of Major Courier Companies in IndiaNilabjo Kanti PaulNessuna valutazione finora

- Multinational Inventory ManagementDocumento2 pagineMultinational Inventory ManagementPiyush Chaturvedi75% (4)

- UPS World Port Forum Final.2.Documento15 pagineUPS World Port Forum Final.2.Julian NeiraNessuna valutazione finora

- Chapter 9 - Managing The Global PipelineDocumento9 pagineChapter 9 - Managing The Global PipelineJeffrey EugenioNessuna valutazione finora

- Case SCMDocumento9 pagineCase SCMbarkha_agarwal_4Nessuna valutazione finora

- 2958 Lastmilefreightstudy FinalDocumento312 pagine2958 Lastmilefreightstudy FinalSiva KumarNessuna valutazione finora

- An Inventory-Location ModelDocumento32 pagineAn Inventory-Location ModelEduardo GonzálezNessuna valutazione finora

- Logistics AssignmentDocumento14 pagineLogistics AssignmentHarsha GuptaNessuna valutazione finora

- Designing The Distribution Network in A Supply ChainDocumento18 pagineDesigning The Distribution Network in A Supply ChainMária Teresa CastroNessuna valutazione finora

- Brynn Grey Financial Impact StudyDocumento239 pagineBrynn Grey Financial Impact StudyScott FranzNessuna valutazione finora

- The Introduction of SIMON: UPB E BusinessDocumento3 pagineThe Introduction of SIMON: UPB E BusinessISABEL ARCHONDONessuna valutazione finora

- The Introduction of SIMON: UPB E BusinessDocumento3 pagineThe Introduction of SIMON: UPB E BusinessISABEL ARCHONDONessuna valutazione finora

- Dollar Tree Case StudyDocumento11 pagineDollar Tree Case StudyVarun Sharda100% (2)

- Management Science Unit 7Documento18 pagineManagement Science Unit 7Paula Ella BatasNessuna valutazione finora

- W3-Network OptimizationDocumento21 pagineW3-Network OptimizationEva RosaNessuna valutazione finora

- CSAVAssignment FinalDocumento4 pagineCSAVAssignment Finalst57143100% (1)

- The Capital Evaluation ProcessDocumento7 pagineThe Capital Evaluation ProcessUjjval PatelNessuna valutazione finora

- Ganesh Gowtham B (Assignment2) - 1911033Documento3 pagineGanesh Gowtham B (Assignment2) - 1911033ganesh gowthamNessuna valutazione finora

- FiNO Inventory User Guide by Abhishek Nayar PDFDocumento49 pagineFiNO Inventory User Guide by Abhishek Nayar PDFAbhishek KNessuna valutazione finora

- Principles of Business For CSEC®: 2nd EditionDocumento6 paginePrinciples of Business For CSEC®: 2nd EditionKerine Williams-FigaroNessuna valutazione finora

- Bưu kiện chuyển phátDocumento15 pagineBưu kiện chuyển phátRobert PiaNessuna valutazione finora

- Best Practices For Transportation Management PDFDocumento8 pagineBest Practices For Transportation Management PDFAbner LlenosNessuna valutazione finora

- NSW 571 (3) Logistics Network PDFDocumento34 pagineNSW 571 (3) Logistics Network PDFDeva Ardha NareswaraNessuna valutazione finora

- OPER312 Fall23 HW2Documento2 pagineOPER312 Fall23 HW2Berk AlbakerNessuna valutazione finora

- Lec 4 Log MGTDocumento20 pagineLec 4 Log MGTShahriat Sakib DhruboNessuna valutazione finora

- Merloni Elettrodomestici SpADocumento5 pagineMerloni Elettrodomestici SpAAmit ShiraliNessuna valutazione finora

- Management AccountingDocumento9 pagineManagement Accounting1t4Nessuna valutazione finora

- Advanced Operation Management: Name: Amar Verma Roll: 13P119 American Lighting ProductsDocumento7 pagineAdvanced Operation Management: Name: Amar Verma Roll: 13P119 American Lighting ProductsArchit AroraNessuna valutazione finora

- This Is A New Docutment That Lets Me DownloadDocumento4 pagineThis Is A New Docutment That Lets Me DownloadPoopboysNessuna valutazione finora

- Uncoordinated Supply Chain: by Prof. M. K. Tiwari Dept of IE&M IIT KharagpurDocumento125 pagineUncoordinated Supply Chain: by Prof. M. K. Tiwari Dept of IE&M IIT Kharagpurravi_radanNessuna valutazione finora

- Minimizing Late Deliveries in A Truck Loading Problem EjorDocumento10 pagineMinimizing Late Deliveries in A Truck Loading Problem EjorCESARPINEDANessuna valutazione finora

- Issues: Executive SummaryDocumento10 pagineIssues: Executive SummaryKartik KakriaNessuna valutazione finora

- Return-Loads Bureaus To Save Waste In TransportationDa EverandReturn-Loads Bureaus To Save Waste In TransportationNessuna valutazione finora

- THE DETERMINANTS OF PRICES OF NEWBUILDING IN THE VERY LARGE CRUDE CARRIERS (VLCC) SECTORDa EverandTHE DETERMINANTS OF PRICES OF NEWBUILDING IN THE VERY LARGE CRUDE CARRIERS (VLCC) SECTORNessuna valutazione finora

- InitialOrder 2017-005DRDocumento11 pagineInitialOrder 2017-005DRBriand DaydayNessuna valutazione finora

- Assisted Living - Feasibility Assisted Care.2005Documento24 pagineAssisted Living - Feasibility Assisted Care.2005Briand DaydayNessuna valutazione finora

- ETHICS - Reflection Paper 1Documento2 pagineETHICS - Reflection Paper 1Briand DaydayNessuna valutazione finora

- Assisted Living - Feasibility Assisted Care.2005Documento24 pagineAssisted Living - Feasibility Assisted Care.2005Briand DaydayNessuna valutazione finora

- Chap 7 Analyzing Business Markets DaydayDocumento40 pagineChap 7 Analyzing Business Markets DaydayBriand DaydayNessuna valutazione finora

- Introduction (Briand) : What Is Business Speaking?Documento12 pagineIntroduction (Briand) : What Is Business Speaking?Briand DaydayNessuna valutazione finora

- ETHICS - Reflection Paper 2.societyDocumento2 pagineETHICS - Reflection Paper 2.societyBriand Dayday100% (3)

- MARKMA - Session Summary 14Documento11 pagineMARKMA - Session Summary 14Briand DaydayNessuna valutazione finora

- Munication BarriersDocumento14 pagineMunication BarriersBriand DaydayNessuna valutazione finora

- Chap 7 Analyzing Business Markets DaydayDocumento40 pagineChap 7 Analyzing Business Markets DaydayBriand DaydayNessuna valutazione finora

- 7 S MckinseyDocumento3 pagine7 S MckinseyBriand DaydayNessuna valutazione finora

- Human Resource Management 4: Fundamentals ofDocumento56 pagineHuman Resource Management 4: Fundamentals ofBriand DaydayNessuna valutazione finora

- ETHICS - Romulo Bernas CaseDocumento2 pagineETHICS - Romulo Bernas CaseBriand Dayday100% (1)

- ETHICS - Reflection Paper 2.societyDocumento2 pagineETHICS - Reflection Paper 2.societyBriand Dayday100% (3)

- Profitability Ratios: Gross MarginDocumento3 pagineProfitability Ratios: Gross MarginBriand DaydayNessuna valutazione finora

- Venture Initiation PaperDocumento27 pagineVenture Initiation PaperBriand DaydayNessuna valutazione finora

- Management ThinkingDocumento29 pagineManagement ThinkingBriand DaydayNessuna valutazione finora

- 14 CE Chapter 14 - Developing Pricing StrategiesDocumento34 pagine14 CE Chapter 14 - Developing Pricing StrategiesAsha JaylalNessuna valutazione finora

- MOL Breaker 20 TonDocumento1 paginaMOL Breaker 20 Tonaprel jakNessuna valutazione finora

- Learner Guide HDB Resale Procedure and Financial Plan - V2Documento0 pagineLearner Guide HDB Resale Procedure and Financial Plan - V2wangks1980Nessuna valutazione finora

- S 101-01 - PDF - User Interface - Computer MonitorDocumento130 pagineS 101-01 - PDF - User Interface - Computer Monitormborghesi1Nessuna valutazione finora

- Brazilian Mineral Bottled WaterDocumento11 pagineBrazilian Mineral Bottled WaterEdison OchiengNessuna valutazione finora

- Qa-St User and Service ManualDocumento46 pagineQa-St User and Service ManualNelson Hurtado LopezNessuna valutazione finora

- Sikkim Manipal MBA 1 SEM MB0038-Management Process and Organization Behavior-MQPDocumento15 pagineSikkim Manipal MBA 1 SEM MB0038-Management Process and Organization Behavior-MQPHemant MeenaNessuna valutazione finora

- Hoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFDocumento2 pagineHoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFMarco Antonio Gutierrez PulchaNessuna valutazione finora

- CE5215-Theory and Applications of Cement CompositesDocumento10 pagineCE5215-Theory and Applications of Cement CompositesSivaramakrishnaNalluriNessuna valutazione finora

- Pharaoh TextDocumento143 paginePharaoh Textanon_31362848Nessuna valutazione finora

- Troubleshooting For Rb750Glr4: Poe Does Not WorkDocumento7 pagineTroubleshooting For Rb750Glr4: Poe Does Not Workjocimar1000Nessuna valutazione finora

- Crivit IAN 89192 FlashlightDocumento2 pagineCrivit IAN 89192 FlashlightmNessuna valutazione finora

- MDC PT ChartDocumento2 pagineMDC PT ChartKailas NimbalkarNessuna valutazione finora

- How To Unbrick Tp-Link Wifi Router Wr841Nd Using TFTP and WiresharkDocumento13 pagineHow To Unbrick Tp-Link Wifi Router Wr841Nd Using TFTP and WiresharkdanielNessuna valutazione finora

- National Senior Certificate: Grade 12Documento13 pagineNational Senior Certificate: Grade 12Marco Carminé SpidalieriNessuna valutazione finora

- Developments in Prepress Technology (PDFDrive)Documento62 pagineDevelopments in Prepress Technology (PDFDrive)Sur VelanNessuna valutazione finora

- Annisha Jain (Reporting Manager - Rudrakshi Kumar)Documento1 paginaAnnisha Jain (Reporting Manager - Rudrakshi Kumar)Ruchi AgarwallNessuna valutazione finora

- SEBI Circular Dated 22.08.2011 (Cirmirsd162011)Documento3 pagineSEBI Circular Dated 22.08.2011 (Cirmirsd162011)anantNessuna valutazione finora

- QP 4Documento4 pagineQP 4Yusra RaoufNessuna valutazione finora

- MMMDocumento6 pagineMMMReet KanjilalNessuna valutazione finora

- 7373 16038 1 PBDocumento11 pagine7373 16038 1 PBkedairekarl UNHASNessuna valutazione finora

- Grace Strux Beton PDFDocumento33 pagineGrace Strux Beton PDFmpilgirNessuna valutazione finora

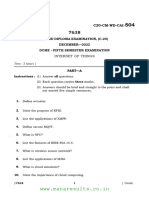

- WWW - Manaresults.co - In: Internet of ThingsDocumento3 pagineWWW - Manaresults.co - In: Internet of Thingsbabudurga700Nessuna valutazione finora

- TENDER DOSSIER - Odweyne Water PanDocumento15 pagineTENDER DOSSIER - Odweyne Water PanMukhtar Case2022Nessuna valutazione finora

- Industrial Management: Teaching Scheme: Examination SchemeDocumento2 pagineIndustrial Management: Teaching Scheme: Examination SchemeJeet AmarsedaNessuna valutazione finora