Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Introduction Rev1

Caricato da

ice_PLTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Introduction Rev1

Caricato da

ice_PLCopyright:

Formati disponibili

1 1

Introduction to Advanced Casing

Introduction to Advanced Casing

Design Course

Design Course

Welcome!

Welcome!

2 2

Time Contract

Time Contract

X

X

AM

AM

10:15 AM: Morning session 1

10:15 AM: Morning session 1

Quiz every morning from day 2 Quiz every morning from day 2- -5 5

10:15 AM

10:15 AM

10:30 AM: Coffee Break

10:30 AM: Coffee Break

10:30 AM

10:30 AM

11:45 AM: Morning Session 2

11:45 AM: Morning Session 2

11:45 AM

11:45 AM

1:00 PM: Lunch

1:00 PM: Lunch

1:00 PM

1:00 PM

2:45 PM: Afternoon session 1

2:45 PM: Afternoon session 1

2:45 PM

2:45 PM

3:00 PM: Break

3:00 PM: Break

3:00 PM

3:00 PM

Y

Y

PM: Afternoon session 2

PM: Afternoon session 2

3 3

Week

Week

s Agenda

s Agenda

Day 1 Day 1

Introduction to Advanced Tubular Introduction to Advanced Tubular

Design Design

Theories of Strength Theories of Strength

Exercise 1 Exercise 1

Casing Loads Casing Loads

Exercise 2 Exercise 2 Parts 1 Parts 1- -6 6

Day 3 Day 3

Quiz Quiz

Materials Materials

Design Exercise Design Exercise Exercise Exercise 4 4

Special Problems Special Problems

Day 5 Day 5

Quiz Quiz

Tubing Design Tubing Design

Exercise 7, Tubing Exercise Exercise 7, Tubing Exercise

Closing Remarks Closing Remarks

Day 2 Day 2

Quiz Quiz

Design Approaches Design Approaches

Connections Connections

Connection Exercise Connection Exercise

Materials Materials

Day 4 Day 4

Quiz Quiz

Special Problems Special Problems

4 4

Course Objectives

Course Objectives

Introduce students to the fundamentals of

Introduce students to the fundamentals of

tubular design

tubular design

Introduce students to advanced design concepts

Introduce students to advanced design concepts

(Limit states, Reliability

(Limit states, Reliability

-

-

based design) in

based design) in

tubulars and structures

tubulars and structures

Familiarize students to changing standards

Familiarize students to changing standards

Introduce students to special problems and

Introduce students to special problems and

challenges arising in extreme situations

challenges arising in extreme situations

Share our knowledge and experience

Share our knowledge and experience

Learn from students

Learn from students

knowledge and experience

knowledge and experience

5 5

Course Contents

Course Contents

Failure Criteria and Theories of Strength (Ch 2)

Failure Criteria and Theories of Strength (Ch 2)

Loads and Estimation of Design Loads (Ch 3)

Loads and Estimation of Design Loads (Ch 3)

Design Approaches (Ch 4)

Design Approaches (Ch 4)

Connections (Ch 5)

Connections (Ch 5)

Materials Selection (Ch 6)

Materials Selection (Ch 6)

Special Problems (Ch 7)

Special Problems (Ch 7)

Tubing Design

Tubing Design

-

-

Introductory Level (Ch 8)

Introductory Level (Ch 8)

Exercises (Ch 9)

Exercises (Ch 9)

Appendices

Appendices

6 6

Not Covered in Detail

Not Covered in Detail

in This Course

in This Course

Casing and Hole Size Selection

Casing and Hole Size Selection

Casing Seat Selection

Casing Seat Selection

Integrated Wellbore Design

Integrated Wellbore Design

Design that combines borehole stability, risk

Design that combines borehole stability, risk

of differential sticking, well controllability, hole

of differential sticking, well controllability, hole

cleaning, and optimized ROP with standard

cleaning, and optimized ROP with standard

tubular design

tubular design

We will provide an introduction to this

We will provide an introduction to this

7 7

About Us

About Us

Blade Energy Partners, founded 2000 Blade Energy Partners, founded 2000

High High- -end engineering, research, training and project end engineering, research, training and project

management in upstream oil and gas management in upstream oil and gas

Critical well design (deep water, HPHT) Critical well design (deep water, HPHT)

Underbalanced Drilling Underbalanced Drilling

CT technology CT technology

Marine Drilling / Production Risers Marine Drilling / Production Risers

Pipelines Pipelines

Special Engineering Problems Special Engineering Problems

Special Problems in Reservoir Engineering Special Problems in Reservoir Engineering

65 engineering employees plus 15 engineering 65 engineering employees plus 15 engineering

consultants averaging 20+ years experience in consultants averaging 20+ years experience in

development and application of innovative well development and application of innovative well

construction and design technologies (1,600 years of construction and design technologies (1,600 years of

experience) experience)

8 8

Instructors

Instructors

Suri Suryanarayana

Suri Suryanarayana

Dave Lewis

Dave Lewis

9 9

About you

About you

Brief intro of

Brief intro of

Who you are, work location, and background

Who you are, work location, and background

in drilling and casing design

in drilling and casing design

Expectations from course

Expectations from course

10 10

Goals of Design

Goals of Design

A tubular is a load A tubular is a load- -bearing structure bearing structure- - load placed on it load placed on it

has an effect has an effect- - it creates stress it creates stress

Structure responds with its strength (or resistance) Structure responds with its strength (or resistance)

Goal is to ensure Tubular Capacity Exceeds Load Goal is to ensure Tubular Capacity Exceeds Load

Demands During the Service Life Demands During the Service Life

Load < Resistance Load < Resistance

Size Constraints Size Constraints

Diameter of First String Diameter of First String

Diameter of Last String (hole or completion) Diameter of Last String (hole or completion)

Casing seat point Casing seat point

OD of Next String (clearance to pass the next string) OD of Next String (clearance to pass the next string)

11 11

Design End Result

Design End Result

Size, Weight and Grade

Size, Weight and Grade

Connection Type

Connection Type

Material Requirements

Material Requirements

Inspection Requirements

Inspection Requirements

Operational Procedures and Precautions

Operational Procedures and Precautions

12 12

Purpose of Tubulars

Purpose of Tubulars

Structural Support for Wellhead and Other

Structural Support for Wellhead and Other

Tubulars

Tubulars

Wellbore Stability

Wellbore Stability

Isolate Formations

Isolate Formations

Control Well Pressures During Drilling,

Control Well Pressures During Drilling,

Production, and Intervention

Production, and Intervention

13 13

Types of Casing

Types of Casing

Conductor Isolation, shallow gas protection, structural support.

Surface Isolation of ground water, pressure control, build section coverage.

Intermediate Borehole stability, isolation of low pressure or producing zones.

Production Isolate producing zone, tubing leak protection, injection, gas lift.

Liners Local isolation and protection.

Tiebacks Convert liners to full strings to the wellhead.

Not all strings see loads during entire service life Not all strings see loads during entire service life- -

drilling and intermediate strings drilling and intermediate strings

Production strings are primary pressure vessels Production strings are primary pressure vessels

14 14

Principal Load Types

Principal Load Types

Load Type Cause

Axial tension

/ compression

Running, changes in temperature, slack off or pickup after cementing.

Pressure Burst or collapse due to kick, pressure test, shut in, cementing, injection,

circulation, evacuation, etc.

Bending Axial load due to buckling or doglegs.

Torsion and

shear

Normally not considered in casing design unless the liner will be rotated

while cementing, for example.

Loads always occur in combination!

Loads always occur in combination!

15 15

Design Process

Design Process

Identify Loads and Estimate Load

Identify Loads and Estimate Load

Magnitude.

Magnitude.

Calculate Principal Loads vs. Depth.

Calculate Principal Loads vs. Depth.

Axial, Internal and External Pressure, etc.

Axial, Internal and External Pressure, etc.

Calculate Strength of Pipe to Resist the

Calculate Strength of Pipe to Resist the

Loads (resistance is specific to load

Loads (resistance is specific to load

-

-

effect)

effect)

Check the Design and Select Pipe

Check the Design and Select Pipe

16 16

Load Parameters

Load Parameters

Casing Weight.

Casing Weight.

Pressure; pore and fracture.

Pressure; pore and fracture.

Fluid Density; affects pressure and weight.

Fluid Density; affects pressure and weight.

Temperature and Change in Temperature.

Temperature and Change in Temperature.

Top of Cement.

Top of Cement.

Drag.

Drag.

Doglegs and Buckling.

Doglegs and Buckling.

17 17

Strength Parameters

Strength Parameters

Size, OD

Size, OD

Yield Strength

Yield Strength

Wall Thickness

Wall Thickness

Material Properties that affect strength

Material Properties that affect strength

Young

Young

s Modulus, Poisson

s Modulus, Poisson

s Ratio, thermal

s Ratio, thermal

expansion coefficient

expansion coefficient

composition (metallurgy), hardness, impact

composition (metallurgy), hardness, impact

strength, toughness, etc.

strength, toughness, etc.

18 18

Uncertainty in Design

Uncertainty in Design

Loads and Load Parameters

Loads and Load Parameters

Strength

Strength

Failure Mode

Failure Mode

Design is a game of predicting future events

Design is a game of predicting future events

Every design process should provide a

Every design process should provide a

safe, reliable, cost

safe, reliable, cost

-

-

effective design.

effective design.

19 19

Data Requirements

Data Requirements

Pore and Fracture

Pore and Fracture

Pressure

Pressure

Temperature

Temperature

H

H

2 2

S and CO

S and CO

2 2

Directional Survey

Directional Survey

Casing OD and

Casing OD and

Minimum ID

Minimum ID

Casing Setting Depth

Casing Setting Depth

Casing Type

Casing Type

Mud Density

Mud Density

Cement Density

Cement Density

20 20

Units

Units

Mixed Units

Mixed Units

Local units where possible

Local units where possible

21 21

References

References

Connection Papers

Connection Papers

Standards List

Standards List

API bulletins, specs and standards API bulletins, specs and standards

5C3, 5CT, 5B5 5C3, 5CT, 5B5

ISO TR 10400, ISO 11960, ISO 13679, ISO TR 10400, ISO 11960, ISO 13679,

NACE MR0175, TM0177 NACE MR0175, TM0177

ISO 15156 Parts 1 ISO 15156 Parts 1 - - 3 3

Text Books

Text Books

Craig, B. D., Craig, B. D., Oilfield Metallurgy and Corrosion Oilfield Metallurgy and Corrosion, ,

PennWell PennWell Books Books

22 22

Last Slide

Last Slide

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Physics - Mechanical Properties of SolidsDocumento6 paginePhysics - Mechanical Properties of SolidsSai raniNessuna valutazione finora

- History of OCTGDocumento7 pagineHistory of OCTGice_PLNessuna valutazione finora

- Well CommanderDocumento8 pagineWell Commanderice_PLNessuna valutazione finora

- Ton MilesDocumento4 pagineTon Milesice_PLNessuna valutazione finora

- Circular Steel Tank Design CalculationDocumento9 pagineCircular Steel Tank Design CalculationNitesh SinghNessuna valutazione finora

- Powerpak HandbookDocumento0 paginePowerpak HandbookPehr HedströmNessuna valutazione finora

- Powerdrive x6Documento7 paginePowerdrive x6ice_PLNessuna valutazione finora

- SLB PosterDocumento3 pagineSLB Posterice_PL100% (2)

- Piping Stress Handbook - by Victor Helguero - Part 2 PDFDocumento121 paginePiping Stress Handbook - by Victor Helguero - Part 2 PDFCESAR100% (2)

- Hydra Jar ProceduresDocumento3 pagineHydra Jar Proceduresice_PLNessuna valutazione finora

- Bolted JointsDocumento20 pagineBolted JointsNurcahyo Djati WNessuna valutazione finora

- Jib Crane Design SellDocumento13 pagineJib Crane Design Selljafary100% (3)

- MINE5008 Responsible Mining Semester 1 2023 Kalgoorlie CampusDocumento13 pagineMINE5008 Responsible Mining Semester 1 2023 Kalgoorlie Campusice_PLNessuna valutazione finora

- Doris: Dropped Objects Register of Incidents & StatisticsDocumento15 pagineDoris: Dropped Objects Register of Incidents & Statisticsice_PLNessuna valutazione finora

- ASME Paper by Sparks - The Influence of Tension, Pressure & WeightDocumento9 pagineASME Paper by Sparks - The Influence of Tension, Pressure & Weightice_PLNessuna valutazione finora

- Deformation of Drill Pipe Held in Rotary SlipsDocumento20 pagineDeformation of Drill Pipe Held in Rotary Slipsice_PL100% (1)

- Holliday Steam Well DesignDocumento8 pagineHolliday Steam Well Designice_PLNessuna valutazione finora

- Hydra Jar Accelerator AP CsDocumento1 paginaHydra Jar Accelerator AP Csice_PLNessuna valutazione finora

- Hooke's Law Spring ConstantDocumento4 pagineHooke's Law Spring Constantice_PLNessuna valutazione finora

- Spe 165931 Pa P PDFDocumento0 pagineSpe 165931 Pa P PDFice_PLNessuna valutazione finora

- Spe 165931 Pa P PDFDocumento0 pagineSpe 165931 Pa P PDFice_PLNessuna valutazione finora

- Spe 159894 Pa P PDFDocumento0 pagineSpe 159894 Pa P PDFice_PLNessuna valutazione finora

- Hooke's Law Spring ConstantDocumento4 pagineHooke's Law Spring Constantice_PLNessuna valutazione finora

- Measuring Guide For New CoverallsDocumento1 paginaMeasuring Guide For New Coverallsice_PLNessuna valutazione finora

- H2008 PDFDocumento55 pagineH2008 PDFIvan G. MarroquinNessuna valutazione finora

- 2-7-Totally Gel-Free Fiber Optical Cables Manufactured With PBTDocumento6 pagine2-7-Totally Gel-Free Fiber Optical Cables Manufactured With PBTDursunNessuna valutazione finora

- A Space Tribology Handbook: ESTL, AEA Technology, Warrington, UKDocumento5 pagineA Space Tribology Handbook: ESTL, AEA Technology, Warrington, UKDamy ManesiNessuna valutazione finora

- Herimite Shape Function For BeamDocumento29 pagineHerimite Shape Function For BeamPisey KeoNessuna valutazione finora

- SprueDocumento26 pagineSpruetapobarna100% (1)

- Olympic CabeDocumento8 pagineOlympic CabeMuhammad darwisNessuna valutazione finora

- Norma E143.18713Documento4 pagineNorma E143.18713Fabian BarajasNessuna valutazione finora

- Lecture 13Documento80 pagineLecture 13kkeoadghNessuna valutazione finora

- Clarification I - Liming + Juice Heating PDFDocumento44 pagineClarification I - Liming + Juice Heating PDFPranetr R.Nessuna valutazione finora

- Thermal Decomposition Study by DTA-TG-MS of III Acetylacetonate Used As Ceria Thin Film PrecursorDocumento5 pagineThermal Decomposition Study by DTA-TG-MS of III Acetylacetonate Used As Ceria Thin Film PrecursorpicuriciNessuna valutazione finora

- Test Name: Determination of Tensile Properties of Geotextile Using Wide Strip ScopeDocumento3 pagineTest Name: Determination of Tensile Properties of Geotextile Using Wide Strip ScopeSwapan PaulNessuna valutazione finora

- Albodur 1055 HandoutDocumento1 paginaAlbodur 1055 HandoutВиктор ИсакNessuna valutazione finora

- Wire Wound ResistorDocumento4 pagineWire Wound ResistorZhori DuberryNessuna valutazione finora

- Hybrid Welding Possibilities of Thick Sections For Arctic ApplicationsDocumento10 pagineHybrid Welding Possibilities of Thick Sections For Arctic ApplicationsKaushik SenguptaNessuna valutazione finora

- M924 Application Guide - Speed & Feed (Inch) : Common Machining FormulasDocumento1 paginaM924 Application Guide - Speed & Feed (Inch) : Common Machining FormulasRobotNessuna valutazione finora

- Ugsemstersyllabus Physics 6sem 61802 Physics English PhysicsofnanomaterialsDocumento204 pagineUgsemstersyllabus Physics 6sem 61802 Physics English Physicsofnanomaterialsmallikamandapati93Nessuna valutazione finora

- Exciton Comsol Yao - PresentationDocumento13 pagineExciton Comsol Yao - Presentationhhakim32Nessuna valutazione finora

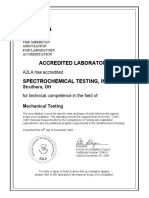

- Accredited Laboratory: A2LA Has AccreditedDocumento2 pagineAccredited Laboratory: A2LA Has AccreditedRene Alfonso BeltranNessuna valutazione finora

- ESHF RSHF GSHF For Different SystemsDocumento2 pagineESHF RSHF GSHF For Different Systemsgowtham gNessuna valutazione finora

- ShaliCure AcrylateDocumento2 pagineShaliCure AcrylateSunil Kumar GiriNessuna valutazione finora

- The 4th International Conference On Advanced Materials Science and TechnologyDocumento2 pagineThe 4th International Conference On Advanced Materials Science and TechnologyMas TrisNessuna valutazione finora

- Chapter11 PDFDocumento73 pagineChapter11 PDFMuhammad UsamaNessuna valutazione finora

- قوانين مادة الهيت كورس ٢Documento7 pagineقوانين مادة الهيت كورس ٢Abdoo YasserNessuna valutazione finora

- Chapter 12Documento5 pagineChapter 12ramcharanneeli4Nessuna valutazione finora

- Burr Grinding-Fatigue ImprovementDocumento11 pagineBurr Grinding-Fatigue ImprovementAnonymous I8nZsDqlmhNessuna valutazione finora