Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Combined loading analysis of structures

Caricato da

Daniel Laurence Salazar ItableTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Combined loading analysis of structures

Caricato da

Daniel Laurence Salazar ItableCopyright:

Formati disponibili

Inmanystructuresthemembersarerequiredtoresistmorethanonekindofloading

(combinedloading).Thesecanoftenbeanalyzedbysuperimposingthestressesand

strainscausebyeachloadactingseparately.

Superpositionofstressesandstrainsispermissibleonlyunderthefollowing

conditions:

a.Thestressesandthestrainsmustbealinearfunctionoftheappliedloads(Hookes

lawmustbeobeyedandthedisplacementsmustbesmall).

b.Theremustbenointeractionbetweenthevariousloads.

COMBINED LOADS

Examples:wideflangebeamsupportedbyacable(combinedbendingandaxial

load),cylindricalpressurevesselsupportedasabeam,andshaftincombinedtorsion

andbending.

1.Selectthepointonthestructurewherethestressesandthestrainsaretobedetermined.

2.Foreachloadonthestructure,determinethestressresultantatthecrosssection

containingtheselectedpoint..

3.Calculatethenormalandshearstressesattheselectedpointduetoeachofthestress

resultant.

4.Combinetheindividualstressestoobtaintheresultantstresses attheselectedpoint.

5.Determinetheprincipalstressesandmaximumshearstressesattheselectedpoint.

6.DeterminethestrainsatthepointwiththeaidofHookeslawforplanestress.

7.Selectadditionalpointsandrepeattheprocess.

t

pr

Ib

VQ

I

My

A

P

= =

=

= =

Method of Analysis:

Thebarshownissubjectedtotwotypesofloads:a

torqueT andaverticalloadP.

Letusselectarbitrarilytwopoints.PointA (topof

thebar)andpointB (sideofthebar inthesame

crosssection).

Theresultingstressesactingacrossthesectionare

thefollowing:

AtwistingmomentequaltothetorqueT.

AbendingmomentM equaltotheloadP times

thedistanceb.

Ashearforce V equalstotheloadP.

Illustration of the Method:

Thetwistingmoment producesatorsional shearstresses

Thestress

1

actshorizontallytotheleftatpointA and

verticallydownwardsatpointB.

ThebendingmomentM producesatensilestressatpointA

However,thebendingmomentproducesnostressatpointB,becauseB is

locatedontheneutralaxis.

3

2

r

T

I

Tr

Polar

torsion

= =

3

4

r

M

I

Mr

bending

= =

TheshearforceV producesnoshearstressatthetopofthe

bar(pointA),butatpointB theshearstressisasfollows:

A

and

1

areactinginpointA,whilethe

1

and

2

areacting

inpointB.

A

V

Ib

VQ

shear

3

4

= =

Notethattheelementisinplanestresswith

x

=

A

,

y

= 0 , and

xy

= -

1

.

AstresselementinpointB isalsoinplanestressandthe

onlystressesactingonthiselementaretheshear

stresses

1

and

2

. Therefore

x

=

y

= 0 and

xy

= - (

1

+

2

).

At point A:

x

=

A

,

y

= 0 , and

xy

= -

1

At point B

x

=

y

= 0 and

xy

= - (

1

+

2

).

Ofinterestarethepointswherethestressescalculatedfromtheflexureandshear

formulashavemaximumorminimumvalues,calledcriticalpoints.

Iftheobjectiveoftheanalysisistodeterminethelargeststressesanywhereinthe

structure,thenthecriticalpointsshouldbeselectedatcrosssectionswherethe

stressresultantshavetheirlargestvalues.

Furthermore,withinthosecrosssections,thepointsshouldbeselectedwhere

eitherthenormalstressesortheshearstresseshavetheirlargestvalues.

SelectionofCriticalAreasandPoints

Forinstance,thenormalstressesduetobending

arelargestatthecrosssectionofmaximum

bendingmoment,whichisatthesupport.

Therefore,pointsC andD atthetopandbottom

ofthebeamatthefixedendsarecriticalpoints

wherethestressesshouldbecalculated.

Stress at which point?

The rotor shaft of an helicopter drives the rotor blades that provide the lifting

force to support the helicopter in the air. As a consequence, the shaft is

subjected to a combination of torsion and axial loading.

For a 50mm diameter shaft transmitting a torque = 2.4kN.m and

a tensile force P = 125kN, determine the maximum tensile stress,

maximum compressive stress, and maximum shear stress in the

shaft.

Solution

The stresses in the rotor shaft are produced by the combined

action of the axial force P and the torque . Therefore the

stresses at any point on the surface of the shaft consist of a

tensile stress

o

and a shear stress

o

.

( )

MPa

m

kN

A

P

66 . 63

05 . 0

4

125

2

= = =

The tensile

stress

The shear stress to is obtained

from the torsion formula

( )

( )

MPa

m kN

I

Tr

P

Torsion

78 . 97

32

05 . 0

2

05 . 0

. 4 . 2

4

=

= =

( ) MPa

xy

y x

MAX

103

2

2

2

= +

33 . 2

103

2

480

= =

MPa

MPa

SF MSST

Knowing the stresses o and o, we can now obtain the principal

stresses and maximum shear stresses . The principal stresses are

obtained from

( )

2

2

2 , 1

2 2

xy

y x y x

+

=

The maximum in-plane shear

stresses are obtained using the

formula

Because the principal stresses

1

and

2

have opposite signs, the maximum in-plane

shear stresses are larger than the maximum out-of-plane shear stresses. Therefore,

the maximum shear stress in the shaft is 103MPa.

( )

MPa

MPa

71

135

78 . 97

2

66 . 63 0

2

66 . 63 0

2

1

2

2

2 , 1

=

=

+

+

=

Will it fail if

yield

=480MPa?

( ) ( )( ) ( )

65 . 2

2 . 181

480

2 . 181 71 71 135 135

2 2

= =

= + =

MPa

MPa

SF DET

MPa

VM

A thin wall cylindrical pressure vessel with a circular cross section is

subjected to internal gas pressure p and simultaneously compressed by an

axial load P = 12k. The cylinder has inner radius r = 2.1in. And wall thickness t

= 0.15in. Determine the maximum allowable internal pressure p

allow

based

upon an allowable shear stress of 6500psi in the wall of the vessel.

Solution

The stresses on the wall of the pressure vessel are caused by a combined action of

the internal pressure and the axial force. We can isolate a stress element in point A.

The x-axis is parallel to the longitudinal axis of the pressure vessel and the y-axis is

circumferential. Note that there are no shear stresses acting on the element.

The longitudinal stress

x

is equal to the tensile stress

produced by the internal pressure minus the

compressive stress produced by the axial force.

rt

P

t

pr

A

P

t

pr

x

2 2 2

= =

The circumferential stress

y

is equal to the tensile

stress produced by the internal pressure.

Note that

y

>

x

.

t

pr

y

=

Since no shear stresses act on the element the

above stresses are also the principal stresses

rt

P

t

pr

t

pr

x

y

2 2

2

1

= =

= =

( )

( )

( ) ( )( ) [ ]

psi p

in in

k

in .

in . p

rt

P

t

pr

p

in .

in . p

t

pr

6063 0 . 7

15 . 0 1 . 2 2

12

15 0 2

1 2

2 2

0 . 14

15 0

1 2

2

1

= = =

= = =

substituting numerical values

In-Plane Shear Stresses

The maximum in-plane shear stress is

( ) ( ) ( ) ( )

psi p

psi p p

Max

3032 5 . 3

2

6063 0 . 7 0 . 14

2

2 1

+ =

=

Since

max

is limited to 6500psi then

psi p psi p psi

allowed

990 3032 4 . 3 65000 = + =

Out-of-Plane Shear Stresses

The maximum out-of-plane shear stress is either

Comparing the three calculated values for the allowable pressure, we see

that (p

allow

)

3

= 928psi governs.

At this pressure, the principal stresses are

1

= 13000psi and

2

= 430psi.

These stresses have the same signs, thus confirming that one of the out-

of-plane shear stresses must be the largest shear stress.

2

2

2

1

=

=

Max

Max

From the first equation we get

From the second equation we

get:

psi p

psi p psi

allowed

2720

3032 5 . 3 65000

=

=

psi p p psi

allowed

928 0 . 7 65000 = =

Allowable internal pressure

A sign of dimensions 2.0mx1.2m is supported by a

hollow circular pole having outer diameter 220mm and

inner diameter 180mm (see figure). The sign offset

0.5m from the centerline of the pole and its lower edge

is 6.0m above the ground.

Determine the principal stresses and maximum shear

stresses at points A and B at the base of the pole due

to wind pressure of 2.0kPa against the sign.

Solution

Stress Resultant: The wind pressure against the sign

produces a resultant force Wthat acts at the midpoint

of the sign and it is equal to the pressure p times the

area A over which it acts:

( )( ) kN m m kPa pA W 8 . 4 2 . 1 0 . 2 0 . 2 = = =

The line of action of this force is at height h = 6.6m above the ground and at

distance b = 1.5m from the centerline of the pole.

The wind force acting on the sign is statically equivalent to a lateral force W

and a torque acting on the pole.

The torque is equal to the force W

times the distance b:

( )( )

m kN T

m kN Wb T

=

= =

2 . 7

5 . 1 8 . 4

The stress resultant at the base of the pole consists of a bending moment M, a

torque and a shear force V. Their magnitudes are:

M = Wh = (4.8kN)(6.6m) = 31.68kN.m

= 7.2kN.m

V = W = 4.8kN

Examination of these stress resultants shows that maximum bending stresses

occur at point A and maximum shear stresses at point B.

Therefore, A and B are critical points where the stresses should be determined.

Stresses at points A and B

The bending moment M produces a tensile stress

a

at point A, but no stress at

point B (which is located on the neutral axis)

( )

( )( )

( )

MPa

m kN

d d

d

M

a

91 . 54

64

18 . 0 22 . 0

11 . 0 68 . 31

64

2

4 4 4

1

4

2

2

=

The torque produces shear stresses

1

at points A and B.

Finally, we need to calculate the direct shear stresses at points A and B

due to the shear force V.

( )

( )( )

( )

MPa

m m kN

d d

d

T

Torsion

24 . 6

32

18 . 0 22 . 0

11 . 0 . 2 . 7

32

2

4 4 4

1

4

2

2

=

The shear stress at point A is zero, and the shear stress at

point B (

2

) is obtained from the shear formula for a circular

tube

The stresses acting on the cross section at points A and B

have now been calculated.

( )

( )

) ( 2

3

2

64

1 2

3

1

3

2

4

1

4

2

2

r r b

r r Q

d d

I

Ib

VQ

=

=

=

=

( )

MPa

m A

V

Max

7637 . 0

01257 . 0

4800 2 2

2

, 2

= = =

Stress Elements

For both elements the y-axis is parallel to the longitudinal

axis of the pole and the x-axis is horizontal.

Point A :

x

= 0

y

=

a

= 54.91MPa

xy

=

1

= 6.24MPa

( )

2

2

2 , 1

2 2

xy

y x y x

+

=

Principal stresses at Point A

Substituting

1,2

= 27.5MPa +/- 28.2MPa

1

= 55.7MPa and

2

= - 0.7MPa

The maximum in-plane shear

stresses can be obtained from

the equation

( ) MPa

xy

y x

MAX

2 . 28

2

2

2

= +

Because the principal stresses have opposite signs, the maximum in-plane

shear stresses are larger than the maximum out-of-plane shear stresses.

Then,

max

= 28.2MPa.

Point B :

x

=

y

= 0

xy

=

1

+

2

xy

= 6.24MPa + 0.76MPa = 7.0MPa

Principal stresses at point B are

1

= 7.0MPa

2

= - 7.0 MPa

And the maximum in-plane shear stress is

max

= 7.0MPa

The maximum out-of-plane shear stresses are half of

this value.

Note

If the largest stresses anywhere in the pole are needed, then we must also

determine the stresses at the critical point diametrically opposite point A,

because at that point the compressive stress due to bending has its largest

value.

The principal stresses at that point are

1

= 0.7MPa and

2

= - 55.7MPa

The maximum shear stress is 28.2MPa.

(In this analysis only the effects of wind pressure are considered. Other loads, such as

weight of the structure, also produce stresses at the base of the pole).

A tubular post of square cross section supports a

horizontal platform (see figure).

The tube has outer dimension b = 6in.

And wall thickness t = 0.5in.

The platform has dimensions 6.75in x 24.0in and

supports an uniformly distributed load of 20psi acting

over its upper surface.

The resultant of this distributed load is a vertical

force

P

1

= (20psi)(6.75in x 24.0in) = 3240lb

This force acts at the midpoint of the platform, which

is at distance

d = 9in. from the longitudinal axis of the post.

A second load P

2

= 800lb acts horizontally on the

post at height h = 52in above the base.

Determine the principal stresses and maximum

shear stresses at points A and B at the base of the

post due to the loads P

1

and P

2

.

Stress Resultants

The force P

1

acting on the platform is statically

equivalent to a force P

1

and a moment

M

1

= P

1

d acting on the centroid of the cross section

of the post.

The load P

2

is also shown.

Solution

The stress resultant at the base of the post due to the

loads P

1

and P

2

and the moment M

1

are as follows:

(A) An axial compressive force P

1

= 3240lb

(B) A bending moment M

1

produced by the force P

1

:

M

1

= P

1

d = (3240lb)(9in) = 29160lb-in

(C) A shear force P

2

= 800lb

(D) A bending moment M

2

produced by the force P

2

:

M

2

= P

2

h = (800lb)(52in) = 41600lb.in

Examinations of these stress resultants shows that both M

1

and M

2

produce

maximum compressive stresses at point A and the shear force produces

maximum shear stresses at point B. Therefore, A and B are the critical points

where the stresses should be determined.

Stresses at points A and B

(A) The axial force P

1

produces uniform compressive stresses throughout the

post. These stresses are

P1

= P

1

/ A where A is the cross section area of the

post

A = b

2

(b 2t)

2

= 4t(b-t) = 4 (0.5in)(6in 0.5in) = 11.0in

2

P1

= P

1

/ A = 3240lb / 11.00in

2

= 295psi

(B) The bending moment M

1

produces compressive stresses

M1

at points A

and B. These stresses are obtained from the flexure formula

M1

= M

1

(b / 2) /

where is the moment of inertia of the cross section. The moment of inertia is

= [b

4

- (b -2t)

4

] / 12 = [(6in)

4

(5in)

4

] / 12 = 55.92in

4

Thus,

M1

= M

1

b / 2 = (29160lb.in)(6in) / (2)(55.92in

4

) = 1564psi

(C) The shear force P

2

produces a shear stress at point B but not at point A.

We know that an approximate value of the shear stress can be obtained by

dividing the shear force by the web area.

P2

= P

2

/ A

web

=P

2

/(2t(b 2t)) =800lb / (2)(0.5in)(6in1in)= 160psi

The stress

p2

acts at point B in the direction shown in the above figure.

We can calculate the shear stress

P2

from the more accurate formula. The

result of this calculation is

P2

= 163psi, which shows that the shear stress

obtained from the approximate formula is satisfactory.

D) The bending moment M

2

produces a compressive stress at point A but no

stress at point B. The stress at A is

M2

= M

2

b / 2 = (41600lb.in)(6in) / (2)(55.92in

4

) = 2232psi.

This stress is also shown in the above figure.

Stress Elements

Each element is oriented so that the y-axis is

vertical (i.e. parallel to the longitudinal axis of the

post) and the x-axis is horizontal axis

Point A : The only stress in point A is a

compressive stress

a

in the y direction

A

=

P1

+

M1

+

M2

A

= 295psi + 1564psi + 2232psi = 4090psi

(compression)

Thus, this element is in uniaxial stress.

Principal Stresses and Maximum Shear Stress

x

= 0

y

= -

a

= - 4090psi

xy

= 0

Since the element is in uniaxial stress,

1

=

x

and

2

=

y

= - 4090psi

And the maximum in-plane shear stress is

max

= (

1

-

2

) / 2 = (4090psi) = 2050psi

The maximum out-of-plane shear stress has the same magnitude.

Point B:

Here the compressive stress in the y direction is

B

=

P1

+

M1

B

= 295psi + 1564psi = 1860psi (compression)

And the shear stress is

B

=

P2

= 160psi

The shear stress acts leftward on the top face and

downward on the x face of the element.

Principal Stresses and Maximum Shear Stress

x

=0

y

= -

B

= - 1860psi

xy

= -

P2

= - 160psi

Substituting

1,2

= - 930psi +/- 944psi

1

= 14psi and

2

= - 1870psi

( )

2

2

2 , 1

2 2

xy

y x y x

+

=

The maximum in-plane shear stresses can be obtained from the equation

Because the principal stresses have opposite signs, the maximum in-plane

shear stresses are larger than the maximum out-of-plane shear stresses.

Then,

max

= 944psi.

( ) psi

xy

x

MAX

944

2

2

2

= +

Three forces are applied to a short steel post as

shown. Determine the principle stresses,

principal planes and maximum shearing stress

at point H.

Determine internal forces in Section EFG.

Solution

( )( ) ( )( )

( )( ) m kN 3 m 100 . 0 kN 30 0

m kN 5 . 8

m 200 . 0 kN 75 m 130 . 0 kN 50

kN 75 kN 50 kN 30

= = =

=

=

= = =

z y

x

x

z x

M M

M

M

V P V

Note: Section properties,

( )( )

( )( )

( )( )

4 6 3

12

1

4 6 3

12

1

2 3

m 10 747 . 0 m 040 . 0 m 140 . 0

m 10 15 . 9 m 140 . 0 m 040 . 0

m 10 6 . 5 m 140 . 0 m 040 . 0

= =

= =

= =

z

x

I

I

A

( )( )

( )( )

( ) MPa 66.0 MPa 2 . 23 3 . 80 93 . 8

m 10 15 . 9

m 025 . 0 m kN 5 . 8

m 10 747 . 0

m 020 . 0 m kN 3

m 10 5.6

kN 50

4 6

4 6 2 3 -

= + =

=

+ + =

x

x

z

z

y

I

b M

I

a M

A

P

Evaluate the stresses at H.

Shear stress at H.

( )( ) [ ]( )

( )( )

( )( )

MPa 52 . 17

m 040 . 0 m 10 15 . 9

m 10 5 . 85 kN 75

m 10 5 . 85

m 0475 . 0 m 045 . 0 m 040 . 0

4 6

3 6

3 6

1 1

=

= =

=

= =

t I

Q V

y A Q

x

z

yz

Normal stress at H.

Calculate principal stresses and maximum shearing stress.

=

= = =

= = =

= + = + =

= + = =

98 . 13

96 . 27 2

0 . 33

52 . 17

2 tan

MPa 4 . 7 4 . 37 0 . 33

MPa 4 . 70 4 . 37 0 . 33

MPa 4 . 37 52 . 17 0 . 33

p p

min

max

2 2

max

p

CD

CY

R OC

R OC

R

=

=

=

=

98 . 13

MPa 4 . 7

MPa 4 . 70

MPa 4 . 37

min

max

max

p

The cantilever tube shown is to be

made of 2014 aluminum alloy

treated to obtain a specified

minimum yield strength of

276MPa. We wish to select a stock

size tube (according to the table

below). Using a design factor of

n=4.

The bending load is F=1.75kN, the axial tension is P=9.0kN and the

torsion is T=72N.m. What is the realized factor of safety?

Consider the critical area ( top surface).

I

Mc

A

P

x

+ =

Maximum bending moment = 120F

I

d

kNx mm

A

kN

x

+ =

2

75 . 1 120

9

J

d

J

d

J

Tr

zx

36

2

72

=

= =

( )

2

1

2 2

3

zx x VM

+ =

GPa GPa

n

S

y

VM

0690 . 0

4

276 . 0

= =

For the dimensions of that tube

57 . 4

06043 . 0

276 . 0

= = =

VM

y

S

n

A certain force F is applied at D near the end of the 15-in lever,

which is similar to a socket wrench. The bar OABC is made of AISI

1035 steel, forged and heat treated so that it has a minimum (ASTM)

yield strength of 81kpsi. Find the force (F) required to initiate

yielding. Assume that the lever DC will not yield and that there is no

stress concentration at A.

Solution:

1) Find the critical section

The critical sections will be

either point A or Point O. As the

moment of inertia varies with r

4

then point A in the 1in diameter

is the weakest section.

F

d

in F

d

d

M

I

My

x

6 . 142

14 32

64

2

3 4

=

=

= =

2) Determine the stresses at the

critical section

F

in

in F

d

d

T

J

Tr

zx

4 . 76

) 1 (

15 16

32

2

3 4

=

=

= =

3) Chose the failure

criteria.

The AISI 1035 is a

ductile material. Hence,

we need to employ the

distortion-energy

theory.

lbf

S

F

F

VM

y

zx x xy y x y x VM

416

5 . 194

81000

5 . 194 3 3

2

2

2

2 2

= = =

= + = + + =

Apply the MSS theory. For a point undergoing plane stress with

only one non-zero normal stress and one shear stress, the two non-

zero principal stresses (

A

and

B

) will have opposite signs (Case 2).

( ) ( ) ( )

lbf F

F F

S

S

zx x zx

x

y B A

zx

x

y

B A

388

4 . 76 4 6 . 142 81000

4

2

2

2 2 2

2

1

2 2

2

2

2

2

2

2

max

=

+ =

+ = +

=

+

= =

A round cantilever bar is subjected to torsion plus a transverseload at

the free end. The bar is made of a ductile material having a yield

strength of 50000psi. The transverse force (P) is 500lb and the torque

is 1000lb-in applied to the free end. The bar is 5in long (L) and a

safety factor of 2 is assumed. Transverse shear can be neglected.

Determine the minimum diameter to avoid yielding using both MSS

and DET criteria.

Solution

1) Determine the critical section

The critical section occurs at the

wall.

3 4

32

64

2

d

PL

d

d

PL

I

Mc

x

=

= =

3 4

16

32

2

d

T

d

d

T

J

Tc

xy

=

= =

( ) ( )

( )

( )

+ =

+ =

=

+

= +

+

=

2

2

3

2 , 1

2

2

3

2

3

2

3 3

2 , 1

2

2

2

2

2 , 1

1000 5 500 5 500

16

16 16 16 16

2 2 2 2

d

T PL PL

d d

T

d

PL

d

PL

xy

x x

xy

y x y x

in d

n

S

d d

y

MAX

MAX

031 . 1

000 , 25

2

50000

2

4 . 13715

2

) 8 . 980 ( 26450

2

3 1

3 3

3 1

= = =

=

=

3

1

26450

d

=

3

2

8 . 980

d

=

The stresses are in the wrong

order.. Rearranged to

3

1

26450

d

=

3

3

8 . 980

d

=

MSS

in d

n

S

d

d d d d

y

VM

VM

025 . 1

2

50000 26950

8 . 980 26450 8 . 980 26450

3

3 3

2

3

2

3

3 1

2

3

2

1

= =

= + =

DET

The factor of safety for a machine

element depends on the particular

point selected for the analysis. Based

upon the DET theory, determine the

safety factor for points A and B.

This bar is made of AISI 1006 cold-drawn steel (S

y

=280MPa) and it is

loaded by the forces F=0.55kN, P=8.0kN and T=30N.m

Solution:

Point A

2 3 2 4

4 32

4 64

2

d

P

d

Fl

d

P

d

d

Fl

Area

P

I

Mc

x

+ = +

= + =

( )( )( )

( )

( )( )

( )

MPa

x

49 . 95

02 . 0

10 8 4

02 . 0

1 . 0 10 55 . 0 32

2

3

3

3

= + =

( )

( )

MPa

d

T

J

Tr

xy

10 . 19

020 . 0

30 16 16

3 3

= = = =

( ) ( ) [ ]

77 . 2

1 . 101

280

1 . 101 1 . 19 3 49 . 95 3

2

1

2

2 2 2

= = =

= + = + =

VM

y

xy x VM

S

n

MPa

Point B

( )( )

( )

( )

( )

( )( )

( )

( ) [ ]

22 . 6

02 . 45

280

02 . 45 43 . 21 3 47 . 25

43 . 21

02 . 0

4

3

10 55 . 0 4

02 . 0

30 16

3

4 16

47 . 25

02 . 0

10 8 4 4

2

1

2

2

2

3

3 3

2

3

2

= =

= + =

=

+ = + =

= = =

n

MPa

MPa

A

V

d

T

MPa

d

P

VM

xy

x

The shaft shown in the figure below is supported by two bearingsand carries two V-

belt sheaves. The tensions in the belts exert horizontal forces on the shaft, tending to

bend it in the x-z plane. Sheaves B exerts a clockwise torque on the shaft when

viewed towards the origin of the coordinate system along the x-axis. Sheaves C

exerts an equal but opposite torque on the shaft. For the loading conditions shown,

determine the principal stresses and the safety factor on the element K, located on the

surface of the shaft (on the positive z-side), just to the right of sheave B. Consider

that the shaft is made of a steel of a yield strength of 81ksi

Shearing force = 165lb

Bending Moment = -1540lb-in

( )

( )

ksi

r

r M

I

Mc

x

031 . 8

625 . 0

1540

4

4

3 4

=

= = =

( )

( )

ksi

r

T

J

Tr

xz

868 . 2

625 . 0

1100 2 2

3 3

= = = =

( ) ( )

( )

ksi ksi

xy

x x

xy

y x y x

92 . 0 95 . 8

868 . 2

2

03 . 8

2

03 . 8

2 2 2 2

2 1

2

2

2 , 1

2

2

2

2

2 , 1

= =

+

=

+

= +

+

=

( )

2 . 8

935 . 4

2

81

2

..

935 . 4

2

92 . 0 95 . 8

2

.....

3 1

= = = =

=

=

=

Max

Y

Max

S

n Factor Safety

ksi MSS

( ) ( ) ( )( )

58 . 8

44 . 9

81

..

44 . 9 92 . 0 95 . 8 92 . 0 95 . 8 ......

2 2

3 1

2

3

2

1

= = = =

= + = + =

VM

y

VM

S

n Factor Safety

ksi DET

A horizontal bracket ABC consists of two perpendicular arms AB and BC, of

1.2m and 0.4m in length respectively. The Arm AB has a solid circular cross

section with diameter equal to 60mm. At point C a load P

1

=2.02kN acts

vertically and a load P

2

=3.07kN acts horizontally and parallel to arm AB.

For the points p and q, located at support A, calculate:

(1)The principal stresses.

(2) the maximum in-plane shear stress.

1.2m

q

Potrebbero piacerti anche

- Chapter Problems (Ed 5)Documento167 pagineChapter Problems (Ed 5)ابو النمرNessuna valutazione finora

- Mechanics of Deformable Bodies PDFDocumento27 pagineMechanics of Deformable Bodies PDFEmmanuel Del Rosario82% (11)

- Machine Design Reviewer - Complete PDFDocumento104 pagineMachine Design Reviewer - Complete PDFRae Nikka May Pablo83% (24)

- Mechanics of Deformable Bodies Module 1Documento14 pagineMechanics of Deformable Bodies Module 1jhuascute06Nessuna valutazione finora

- Ex PDFDocumento4 pagineEx PDFFernandaFerreiraNessuna valutazione finora

- Numerical Examples of Stress AnalysisDocumento20 pagineNumerical Examples of Stress AnalysisHamid MasoodNessuna valutazione finora

- Principle Stress ExamplesDocumento36 paginePrinciple Stress ExamplesPaldexNessuna valutazione finora

- Geotubo GT-500Documento1 paginaGeotubo GT-500Juan AceitunoNessuna valutazione finora

- PEF 2309 Fundamentos de Mecânica Das Estruturas Timoshenko, S.P.,PWS Publishing Company, 1997, Boston, USA, p.408-410, 580-583. Example 8-4Documento6 paginePEF 2309 Fundamentos de Mecânica Das Estruturas Timoshenko, S.P.,PWS Publishing Company, 1997, Boston, USA, p.408-410, 580-583. Example 8-4Jc FortNessuna valutazione finora

- A NoteDocumento106 pagineA NoteKenneth SantiagoNessuna valutazione finora

- Exercises On Stress StateDocumento4 pagineExercises On Stress StatecusanhNessuna valutazione finora

- BFC 20903 (Mechanics of Materials) Chapter 2: Stress and Strain TransformationDocumento27 pagineBFC 20903 (Mechanics of Materials) Chapter 2: Stress and Strain Transformationhamierul mohamadNessuna valutazione finora

- Tensile Stress: AnswerDocumento22 pagineTensile Stress: Answeramiel_togleNessuna valutazione finora

- Final Exam - Report About StressDocumento25 pagineFinal Exam - Report About StressMashuNessuna valutazione finora

- Section III: Load and Stress AnalysisDocumento29 pagineSection III: Load and Stress Analysisrameshaarya99Nessuna valutazione finora

- STRESS THEORYDocumento31 pagineSTRESS THEORYajaykrishna_99Nessuna valutazione finora

- Static Equilibrium: M M M F F FDocumento41 pagineStatic Equilibrium: M M M F F FINMENessuna valutazione finora

- MD 5BDocumento73 pagineMD 5Bctvd93100% (1)

- Assignment Chapter 7Documento9 pagineAssignment Chapter 7Mujtaba RizviNessuna valutazione finora

- 1.mechanical Technology A Two Year Course 257 294 - Compressed 20 38Documento19 pagine1.mechanical Technology A Two Year Course 257 294 - Compressed 20 38josh harleedNessuna valutazione finora

- Static Failure AnalysisDocumento10 pagineStatic Failure AnalysisQ_TNessuna valutazione finora

- Lesson 1 and 2 PDFDocumento18 pagineLesson 1 and 2 PDFDenver NieverasNessuna valutazione finora

- Eccentric Loaded Bolted ConnectionsDocumento17 pagineEccentric Loaded Bolted ConnectionsRandieleo AsisNessuna valutazione finora

- MD 2Documento33 pagineMD 2Wilfredo Nieves OsoriaNessuna valutazione finora

- Numerical ExamplesDocumento20 pagineNumerical ExampleslitrakhanNessuna valutazione finora

- Σ = P A P Π R R Π Mm Τ = Tρ J Tρ Π D D Π Mm: = − = 168,000 N 140 − 125 = 13.5 MpaDocumento2 pagineΣ = P A P Π R R Π Mm Τ = Tρ J Tρ Π D D Π Mm: = − = 168,000 N 140 − 125 = 13.5 MpaEdmil Jhon AriquesNessuna valutazione finora

- Mechanic of Materials (Normal Stress)Documento44 pagineMechanic of Materials (Normal Stress)moj33Nessuna valutazione finora

- Mechanics of Deformable Bodies: Mechanical Engineering DepartmentDocumento11 pagineMechanics of Deformable Bodies: Mechanical Engineering DepartmentAngelo BendalNessuna valutazione finora

- Pressure VesselDocumento32 paginePressure VesselYonjon SubhaNessuna valutazione finora

- Tutorials 2Documento3 pagineTutorials 2Daemaro Liv Guud BremmerNessuna valutazione finora

- StressDocumento42 pagineStressNauman SuriaNessuna valutazione finora

- Mmems 2 UDocumento163 pagineMmems 2 UHardeshkumar KumarNessuna valutazione finora

- Chapter 1 Tension, Compression, and ShearDocumento27 pagineChapter 1 Tension, Compression, and ShearManolo L LandigNessuna valutazione finora

- HW09 - Angular Momentum Conservation and GravitationDocumento8 pagineHW09 - Angular Momentum Conservation and GravitationBradley NartowtNessuna valutazione finora

- Circular Shaft em 327: Mechanics of Materials Laboratory: ObjectivesDocumento4 pagineCircular Shaft em 327: Mechanics of Materials Laboratory: ObjectivesSumit SharmaNessuna valutazione finora

- 04 Practical Application WeldingDocumento6 pagine04 Practical Application Weldingenrico.michelatoNessuna valutazione finora

- Img X13115347 0001Documento6 pagineImg X13115347 0001Bob Van de VoortNessuna valutazione finora

- Van 2021 - Solid Mechanics 2: Unisymmetric Bending Transverse ShearDocumento59 pagineVan 2021 - Solid Mechanics 2: Unisymmetric Bending Transverse ShearHuseyn U. d'IslamNessuna valutazione finora

- Bending of BeamsDocumento26 pagineBending of BeamsJovelyn DayonNessuna valutazione finora

- CH 08Documento49 pagineCH 08LeonardoMadeira11Nessuna valutazione finora

- Theories of FailureDocumento77 pagineTheories of FailureAnonymous 6HADGUEXDNessuna valutazione finora

- Solution Tutorial - 1Documento2 pagineSolution Tutorial - 1Akash FuryNessuna valutazione finora

- Torsion of Circular Sections: Recitation #6 October 14, 2003Documento12 pagineTorsion of Circular Sections: Recitation #6 October 14, 2003Krm ChariNessuna valutazione finora

- Mechanics of Deformable Bodies Module 1Documento15 pagineMechanics of Deformable Bodies Module 1Christian Angelo ButacNessuna valutazione finora

- Bending of BeamsDocumento26 pagineBending of BeamsObito UchihaNessuna valutazione finora

- Session 11Documento25 pagineSession 11dhak shanNessuna valutazione finora

- Strength of MaterialsDocumento81 pagineStrength of MaterialsSenthil Kumar67% (3)

- Mechanics of Deformable Bodies1Documento47 pagineMechanics of Deformable Bodies1Nicole PerezNessuna valutazione finora

- O level Physics Questions And Answer Practice Papers 2Da EverandO level Physics Questions And Answer Practice Papers 2Valutazione: 5 su 5 stelle5/5 (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDa EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresValutazione: 4 su 5 stelle4/5 (1)

- Interactions between Electromagnetic Fields and Matter: Vieweg Tracts in Pure and Applied PhysicsDa EverandInteractions between Electromagnetic Fields and Matter: Vieweg Tracts in Pure and Applied PhysicsNessuna valutazione finora

- Constructed Layered Systems: Measurements and AnalysisDa EverandConstructed Layered Systems: Measurements and AnalysisNessuna valutazione finora

- Dce mc2Documento8 pagineDce mc2Daniel Laurence Salazar ItableNessuna valutazione finora

- BROCHURE TENSA MODULAR LR CH enDocumento8 pagineBROCHURE TENSA MODULAR LR CH enDem HasiNessuna valutazione finora

- Creep and Shrinkage Cable-Stayed Bridges Composite: S. Arzouman1N1S, Burg, and SchmidDocumento8 pagineCreep and Shrinkage Cable-Stayed Bridges Composite: S. Arzouman1N1S, Burg, and SchmidDaniel Laurence Salazar ItableNessuna valutazione finora

- Hol Concreep10 2015Documento21 pagineHol Concreep10 2015Daniel Laurence Salazar ItableNessuna valutazione finora

- Graduate Studies Enrollment GuideDocumento11 pagineGraduate Studies Enrollment GuideDaniel Laurence Salazar ItableNessuna valutazione finora

- Right: Macgrid Ar A - Asphalt ReinforcementDocumento2 pagineRight: Macgrid Ar A - Asphalt ReinforcementDaniel Laurence Salazar ItableNessuna valutazione finora

- Pages From IPIF1-BCIB-Environmental Impact Assessment Report Issue 3Documento1 paginaPages From IPIF1-BCIB-Environmental Impact Assessment Report Issue 3Daniel Laurence Salazar ItableNessuna valutazione finora

- Modification of Creep-Prediction Equation of Concrete Utilizing Short-Term Creep TestsDocumento7 pagineModification of Creep-Prediction Equation of Concrete Utilizing Short-Term Creep TestsDaniel Laurence Salazar ItableNessuna valutazione finora

- Compressive strength of steam cured concreteDocumento6 pagineCompressive strength of steam cured concreteDaniel Laurence Salazar ItableNessuna valutazione finora

- 048 Iee en - 3Documento130 pagine048 Iee en - 3Daniel Laurence Salazar ItableNessuna valutazione finora

- Dlsu Health and Safety GuideDocumento23 pagineDlsu Health and Safety GuideDaniel Laurence Salazar ItableNessuna valutazione finora

- Course Offerings AY 22 23 T1Documento4 pagineCourse Offerings AY 22 23 T1Daniel Laurence Salazar ItableNessuna valutazione finora

- Strategies For Reducing Math AnxietyDocumento2 pagineStrategies For Reducing Math AnxietyDaniel Laurence Salazar ItableNessuna valutazione finora

- IEE for Gutalac-Baliguian Road ProjectDocumento110 pagineIEE for Gutalac-Baliguian Road ProjectDaniel Laurence Salazar ItableNessuna valutazione finora

- Macgrid Eg S & Eb: Product Installation GuideDocumento2 pagineMacgrid Eg S & Eb: Product Installation GuideDaniel Laurence Salazar ItableNessuna valutazione finora

- Project title/IA/Fund Source Issue Details Actions Taken/actions To Be Taken/updatesDocumento117 pagineProject title/IA/Fund Source Issue Details Actions Taken/actions To Be Taken/updatesDaniel Laurence Salazar ItableNessuna valutazione finora

- Girder Own VersionDocumento35 pagineGirder Own VersionDaniel Laurence Salazar Itable100% (1)

- Overview of NCHRP Design Guideline For EPS-Block Geofoam in Slope Stabilization and RepairDocumento20 pagineOverview of NCHRP Design Guideline For EPS-Block Geofoam in Slope Stabilization and RepairDaniel Laurence Salazar ItableNessuna valutazione finora

- ALW Tensile Stress Calcs - Rev2Documento7 pagineALW Tensile Stress Calcs - Rev2Daniel Laurence Salazar ItableNessuna valutazione finora

- ALW Tensile Stress Calcs - Rev2Documento7 pagineALW Tensile Stress Calcs - Rev2Daniel Laurence Salazar ItableNessuna valutazione finora

- Separator PDFDocumento5 pagineSeparator PDFDaniel Laurence Salazar ItableNessuna valutazione finora

- Span Super T Ref No. Deck Drain Ref No. StatusDocumento1 paginaSpan Super T Ref No. Deck Drain Ref No. StatusDaniel Laurence Salazar ItableNessuna valutazione finora

- DLSI Attendance MonitoringDocumento2 pagineDLSI Attendance MonitoringDaniel Laurence Salazar ItableNessuna valutazione finora

- 21 Day Devotional PDFDocumento28 pagine21 Day Devotional PDFDaniel Laurence Salazar ItableNessuna valutazione finora

- Box ShapesDocumento40 pagineBox ShapesDaniel Laurence Salazar ItableNessuna valutazione finora

- 21 Day Devotional PDFDocumento28 pagine21 Day Devotional PDFDaniel Laurence Salazar ItableNessuna valutazione finora

- Span by Span PDFDocumento2 pagineSpan by Span PDFDaniel Laurence Salazar ItableNessuna valutazione finora

- 2Documento16 pagine2Daniel Laurence Salazar ItableNessuna valutazione finora

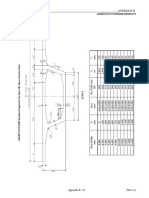

- Appendix B: Aashto/Pci Standard ProductsDocumento2 pagineAppendix B: Aashto/Pci Standard ProductsRodrigo LameirasNessuna valutazione finora

- Transurethral Resection of The Prostate (TURP)Documento4 pagineTransurethral Resection of The Prostate (TURP)Daniel Laurence Salazar ItableNessuna valutazione finora

- Lamara2018 PDFDocumento13 pagineLamara2018 PDFUmer HayatNessuna valutazione finora

- Pages From ASME - B31.3 - Ed.2018Documento10 paginePages From ASME - B31.3 - Ed.2018sarsan nedumkuzhiNessuna valutazione finora

- Solute Transport and Heat Transfer in Single-Phase Flow in Porous Medium With Generative/Destructive Chemical Reaction and Variable Viscosity ImpactsDocumento10 pagineSolute Transport and Heat Transfer in Single-Phase Flow in Porous Medium With Generative/Destructive Chemical Reaction and Variable Viscosity ImpactsAnonymous 5sBa2pNessuna valutazione finora

- Practice Set - 2 (B) Young's Modulus: ElasticityDocumento7 paginePractice Set - 2 (B) Young's Modulus: ElasticityWillis ChekovNessuna valutazione finora

- Large Commercial Split System RAUP-TTV Product CatalogDocumento44 pagineLarge Commercial Split System RAUP-TTV Product CataloghungstampNessuna valutazione finora

- General Duty Valves For Plumbing Piping PDFDocumento12 pagineGeneral Duty Valves For Plumbing Piping PDFfatima tanjutcoNessuna valutazione finora

- Steel TipsDocumento123 pagineSteel TipsEngr AxleNessuna valutazione finora

- Bolting Material Specifications - PIPING HANDBOOKDocumento1 paginaBolting Material Specifications - PIPING HANDBOOK최승원Nessuna valutazione finora

- Steam Consumption of Heat Exchangers - International Site For Spirax Sarco (Calorifier)Documento7 pagineSteam Consumption of Heat Exchangers - International Site For Spirax Sarco (Calorifier)Prak RemNessuna valutazione finora

- Open Ended Structure LabDocumento24 pagineOpen Ended Structure LabIzzatul Syahira Binti ZakariaNessuna valutazione finora

- Projek Solid Mechanics 1Documento3 pagineProjek Solid Mechanics 1Shaktivell Letchumanan0% (1)

- 155 - Supalux Water Resistant Shaftwall PDFDocumento0 pagine155 - Supalux Water Resistant Shaftwall PDFodemircioglu2Nessuna valutazione finora

- Supraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilDocumento2 pagineSupraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilHugo RodriguezNessuna valutazione finora

- Electric Discharge Machining (EDM)Documento34 pagineElectric Discharge Machining (EDM)Paras Malhotra0% (2)

- DAR 108 Rev 01 TC MS Flushing For CHW SystemDocumento65 pagineDAR 108 Rev 01 TC MS Flushing For CHW SystemMarwan NizarNessuna valutazione finora

- Drain 600x600Documento7 pagineDrain 600x600Himanshu ChaturvediNessuna valutazione finora

- Shalabny Buonocore - 2022 APSUSDocumento9 pagineShalabny Buonocore - 2022 APSUSFrankie GoodheartNessuna valutazione finora

- Decor DepoDocumento19 pagineDecor Depokh 9Nessuna valutazione finora

- Greenheck DGXDocumento72 pagineGreenheck DGXBrad GNessuna valutazione finora

- ANNEX I STANDARDSDocumento7 pagineANNEX I STANDARDSWilfrid Dutruel100% (1)

- R 4360c 36 Series Gas Valve Cross Reference en 5239824Documento28 pagineR 4360c 36 Series Gas Valve Cross Reference en 5239824pandahiuNessuna valutazione finora

- Introduction To Structural Analysis-Part 1Documento30 pagineIntroduction To Structural Analysis-Part 1Hiew Ching YongNessuna valutazione finora

- A-1 - Perspective, Vicinity Map and Location MapDocumento1 paginaA-1 - Perspective, Vicinity Map and Location MapOJ MatiasNessuna valutazione finora

- Indian Codes - Steel Design Per IS 800:2007Documento3 pagineIndian Codes - Steel Design Per IS 800:2007dineshNessuna valutazione finora

- Bioact EC-7 Defluxer: Technical Data SheetDocumento4 pagineBioact EC-7 Defluxer: Technical Data Sheetmadiahmad84Nessuna valutazione finora

- Roof Layout: General Notes For BuildersDocumento4 pagineRoof Layout: General Notes For Buildersivanstankovic4Nessuna valutazione finora

- Cooling and Dehumidification - High Latent Load ApplicationDocumento4 pagineCooling and Dehumidification - High Latent Load ApplicationNidas SameeraNessuna valutazione finora

- NDT Certificate Inspection ReportsDocumento9 pagineNDT Certificate Inspection ReportsikponmwonsaNessuna valutazione finora

- Experimental Investigation On Octagonal Concrete Filled Steel Stub Columns Under Uniaxial Compression, 2018 (Jiong-Yi Zhu) PDFDocumento11 pagineExperimental Investigation On Octagonal Concrete Filled Steel Stub Columns Under Uniaxial Compression, 2018 (Jiong-Yi Zhu) PDFPhan Đào Hoàng HiệpNessuna valutazione finora