Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Merichem Process Technologies Brochure (English)

Caricato da

Walid FattahCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Merichem Process Technologies Brochure (English)

Caricato da

Walid FattahCopyright:

Formati disponibili

Sweet Solutions.

www.merichem.com

MERICHEM PROCESS TECHNOLOGIES

Products and Services Offering

Industrial Group Generation

Exclusive Russia / CIS Sales Representative

Industrial Group Generation is Merichems exclusive sales representative for

Russia and CIS countries. IG Generation is a leading manufacturer and

supplier of a wide range of oil and gas, petrochemical, drilling, and heat and

power engineering equipment in Russia and abroad. IG Generation offers

highly effective solutions and innovative technologies covering the spheres of

industrial drilling, oil production, oil and gas treatment, oil and gas

transportation, and heat and energy supply to the production

fields/enterprises. IG Generation consists of the following enterprises

leading manufacturer of reliable, high-quality products for the oil and gas and

heat-and-power engineering industries, scientific-research institutes,

engineering centers and a service drilling company.

RESTRICTIVE NOTICE

The technical information, data and ideas contained in the material to follow are the property of Merichem

Company and shall not be disclosed, duplicated, or used in whole or in part for any purposes other than to

evaluate the applicability of the information for the clients own considerations.

Industrial Group Generation

Mr. Alexey Desyatkin

Tel: +7-343-699-71-09

Fax: +7-343-699-71-91

E-mail: aad@generation.ru

INTRODUCTION 4-8

FIBER FILM

CONTACTOR TECHNOLOGIES 9-15

MERICHEM TECHNOLOGIES

TECHNOLOGY APPLICATIONS 16-17

AMINEX and AMINEX COS 18

AQUAFINING 19

NAPFINING and NAPFINING HiTAN 20

THIOLEX 21

THIOLEX COS 22

MERICAT and MERICAT C 23

ECOMERICAT 24

MERICAT II 25

MERICON 26

REGEN

27

FIBER FILM

PROCESSES 28-30

Merichem Company (Merichem) is a global partner serving the oil and gas

industries with focused technology, chemical, and service solutions. Merichem

provides the Oil and Gas industry with critical proprietary impurity removal

processes to increase the quality of Refinery Products and Gas streams.

Merichem beneficially re-uses spent caustics and other byproducts produced

by oil refining and petrochemical plants around the globe. We are also one

of the leading suppliers of naphthenic acid and its derivatives in the world.

A Tradition of Excellence

Merichem Process Technologies

has been providing key proprietary

refinery product improvement

technologies, many based on the

FIBER FILMtechnology for over 35

years. Merichem Gas Technologies

provides proprietary solutions for

the removal of H2S and other

impurities from a wide range of gas

applications. Merichem Caustic Services is the group that provides the

beneficial reuse option for Refinery Caustics including the production of

naphthenic acids. Merichem Company has been involved with refinery

caustics for over 65 years.

Merichem Company

Finding the right treating solution to remove impurities from hydrocarbon

streams is a challenging task for any refiner but thanks to Merichems extensive

experience and commitment to innovation, treating gaseous and liquid

hydrocarbons can be efficient, economical, and clean. Merichem combines

superior engineering know-how and outstanding technical service to provide

solutions that help refiners worldwide produce high quality products more

efficiently. With more than 35 years licensing experience, Merichem is the

industry leader due to its unparalleled focus, timeliness, performance flexibility,

and ability to provide an economical single-source solution. To date,

Merichem has granted over 900 licenses across the globe to operate various

technology offerings.

Introduced in 1974, the FIBER FILM

Contactor is Merichems proprietary

foundation for a variety of caustic, amine, and acid treating processes.

Merichem Processes using FIBER FILM Contactors have been licensed

worldwide and successfully applied to treating problems throughout the

hydrocarbon processing industries.

Commitment to Innovation

One of the most common applications

of FIBER FILM Contactor technology is

in caustic treatment, an essential part

of hydrocarbon processing for impurity

removal. Merichems FIBER FILM

Contactor technology achieves

non-dispersive phase contact without

the problems inherent in conventional

dispersive mixing devices.

Merichem Process Technologies

Customer Value Proposition

The Merichem Difference

Merichem is the worldwide leading licensor of technologies and supplier of

engineering and modularized equipment solutions for caustic treating light

and middle distillate hydrocarbons to remove H2S, CO2, COS, RSH and/or

naphthenic acids.

These technologies and processes are proprietary and are licensed to our

end-users. Engineering and equipment are provided to meet the customer's

project implementation needs. This is done in a professional project

environment that meets the end-users specifications.

Merichem Process Technologies

A single source treating solution which combines the process license

with process and mechanical guarantees on all designs and

equipment.

Solutions for spent caustic management services (Merichem Caustic

Services).

Fully dedicated Sales, Technical Services, and R&D support staff

whose expertise is focused on caustic and amine treating and

spent caustic management. This yields more personalized service

since Merichems expertise is not diverted into a host of other

technologies as offered by other licensors.

The Merichem Difference

Single Source

Focused Commitment

The J ohn T. Files Technical Center, Merichem's

Houston research center, supports the development

of new applications of FIBER FILM Contactor

technology and other technologies for the refining

and petrochemical industries. Our research staff

welcomes the challenge of creating an innovative

application that meets your needs. FIBER FILM

Contactor technology is backed by the engineering

know-how of our technical services department.

Merichem engineers and technicians take pride in

their record of long-term customer satisfaction.

Customer Value Proposition

Responsive to clients timing needs during the project conceptual

development.

Responsive to clients needs whether it is for fast project delivery

schedules or short notice technical services visits.

The ability and willingness to fabricate and supply equipment from

many countries around the world.

Modularization expertise that is based on being in the fabrication

business since 1981 (including shop ownership since 1991).

Minimal investments by using existing equipment and retrofitting with

the FIBER FILM Contactor to update and expand existing treating

systems.

Willingness and experience to design and fabricate to customer's

specific design and construction standards.

The Merichem Difference

Timely Response

Flexibility of Platform

Merichem Process Technologies

Each treating system is custom-designed to meet customer requirements,

then engineered and fabricated to the customer's specifications. Whether

your need is for a completely new facility or a minimum retrofit to upgrade

existing equipment, Merichem has the solution.

Merichems minimum scope of supply includes:

Complete basic engineering design

Fabrication of FIBER FILM Contactors and other proprietary and

special equipment

Operating and maintenance manuals

Process licensing

In-plant technical services and engineering support prior to start-up

and during operation

Additional services available at the client's option include:

Detailed engineering design

Fabrication of modularized systems

Installation supervision

Operator training

Scope of Work and Services

Dispersion Problem

Untreated

Hydrocarbon In

Treating

Solution In

Dispersive

Contacting

Devices

Separation

of Phases

(Additional Vessel)

Residual

Carryover

Removal

Treated Clear

Hydrocarbon

Out

Treating

Solution Out

Packed Bed

Trayed Tower

Mix Valve

Static Mixer

Bubble-Through

Rotating Discs

Spray Nozzle

Venturi Mixer

Eductor

Sand Fiber

Coalescer

Water Wash

Centrifuge

Knockout Vessel

Conventional System = Conventional Problems

FIBER FILM versus Conventional Technologies

Caustic treating processes with dispersive mixing devices were once

the only option available to the industry. Yet conventional dispersion

and phase separation methods are subject to numerous

shortcomings lack of turndown capability, pluggage, flooding,

channeling, unpredictable treating results, long settling times,

aqueous phase carryover, generation of dilute aqueous wastes,

lower service factor, hydrocarbon losses, larger plot space, product

contamination, and additional processing steps and equipment

needed to separate phases.

Dispersion Problem

Even when the dispersion-based system provides adequate

treatment, separating the two phases is usually extremely inefficient.

The mixture must remain in the phase separator until the caustic

droplets settle out by gravity, a process that may take hours. As the

treating requirement becomes more difficult, mixing energy is

increased to maximize interfacial surface area leading to a greater

dispersion of the aqueous phase causing the separation time to

become exponentially longer.

Stable emulsions can form in the mixing device resulting in massive

carryover out of the separator vessel. Due to excessive carryover,

expensive equipment such as knockout vessels, sand filters, and

water wash units must be installed downstream to remove the

dispersed aqueous phase from the treated product. Treatment is

often interrupted if an emulsion develops.

The conventional method of contacting two immiscible liquids such

as hydrocarbon and caustic or amine is to disperse one liquid

thoroughly into the other as small droplets. Impurities pass between

the two phases at the surface of the droplet. Mass transfer can only

be improved by creating more numerous and smaller droplets in

order to increase surface area.

Conventional Systems = Conventional Problems

The FIBER FILM

Contactor Basics

Intimate Contact Without Dispersion

In a FIBER FILM Contactor, the aqueous phase adheres to (wets) the metal

fibers and is continually renewed as it flows down the length of the fiber via a

combination of gravity and interfacial drag between the two immiscible

phases. Hydrocarbon also flows through the cylinder cocurrently and in

between the aqueous-wetted fibers. The large surface area and tight pack-

ing of the metal fibers bring ultra-thin falling films of the aqueous phase into

intimate contact with the hydrocarbon phase. The interfacial surface area

produced is orders of magnitude larger than in conventional devices allow-

ing impurities to easily diffuse between phases.

Additionally, emulsions and aqueous carryover are negligible occur since

surface tension causes the aqueous phase to adhere to the metal fibers while

the hydrocarbon phase flows freely between the wetted fibers. The result is a

highly efficient mass transfer of impurities from one phase to the other with

little to no emulsification, carryover, or high pressure drop.

FIBER FILM

Contactor

Treating

Solution Out

Treated Clear

Hydrocarbon Out

Untreated

Hydrocarbon In

Treating

Solution In

The FIBER FILM

Contactor

Effective treating results

Achieves maximum removal of

impurities from the hydrocarbon

to meet customers standards.

High mass transfer efficiency

The large interfacial surface

area, the microscopic diffusion

distance, and the continuous

renewal of the aqueous phase

combine to yield mass transfer

efficiencies far greater than

possible with conventional

treatment.

Technology Advantages

ULTRA-THIN FALLING FILMS

Elimination of carryover

Because the aqueous phase adheres to the fibers in the FIBER FILM Contactor

rather than being dispersed into the hydrocarbon phase, carryover is virtually

eliminated.

Elimination of emulsion formation

Since effective phase contact occurs without dispersion, stable emulsions will

not form in the FIBER FILM Contactor unit.

The FIBER FILM

Contactor

Technology Advantages

Reduced equipment size and cost

Since the FIBER FILM Contactor system does not depend on gravity settling or

emulsion coalescence, processing vessels can be much smaller. In most cases,

expensive downstream coalescers and other cleanup equipment are not

required. With fewer pieces of smaller equipment, plant space is more

efficiently utilized.

Lower operating costs

High caustic strength and recycle capability reduces use of fresh caustic as

well as providing excellent turndown capability.

TYPICAL SEPARATION TIMES

Conventional

Dispersive System

60-90 minutes

Fiber-Film

Contactor

10-15 minutes

Simplified, easily operated equipment

By eliminating the clean-up stages,

FIBER FILM Contactor systems are much

simpler to operate and maintain than

conventional treating equipment. In

addition, Merichems straightforward

designs make automation and control

easy.

The FIBER FILM

Contactor

Adaptable to Client needs

Merichems FIBER FILM Contactor units are custom-designed to integrate with

existing equipment to cost-effectively increase treating capacity and

significantly reduce project schedules. These revamps typically increase

capacity by 50300%.

Future expansion capability

To meet projected expansion needs, FIBER FILM Contactor systems can be

designed for economical capacity increase.

Modularized system availability

FIBER FILM Contactor systems can be modularized to reduce field fabrication

and installation costs. This option also offers quicker implementation of

grassroots systems, while Merichems pre-shipment checkout significantly

reduces start-up problems.

Flexible and Adaptable System Design

Technology Applications

Downstream Applications

Crude Distillation Unit

Overhead Ofgas (H

2

S, RSH, COS, CO)

Saturated LPG (H

2

S, RSH, COS)

LSR/HSR Naptha (H

2

S, RSH)

Jet Fuel / Kerosene (RCOOH, RSH)

Diesel (RCOOH)

AMINEX, THIOLEX, REGEN, LO-CAT,

SULFUR-RITE, ELIMINATOR

AMINEX, THIOLEX, REGEN

THIOLEX, REGEN, MERICAT

NAPFINING HiTAN, MERICAT II,

AQUAFINING

NAPFINING HiTAN, AQUAFINING

Source Stream (Impurities) Applicable Technologies

Catalytic Reformer

Overhead Ofgas (H

2

S)

Unstabilized Reformate (H

2

S, NH

4

CL)

FCCU or RCCU

Overhead Ofgas (H

2

S)

Unsaturated LPG (H

2

S, RSH, COS)

Light FCC Gasoline (H

2

S, RSH)

Heavy or Full Range FCC Gasoline (H

2

S, RSH)

LO-CAT, SULFUR-RITE, ELIMINATOR

CHLOREX

LO-CAT, SULFUR-RITE, ELIMINATOR

AMINEX, THIOLEX, REGEN

THIOLEX, REGEN, MERICAT, EXOMER

MERICAT, MERICAT II, EXOMER

Unstabilized Alkylate (Esters) Alkylation ESTEREX

Overhead Ofgas (H

2

S)

LPG and Naptha (H

2

S, RSH, COS)

Coker, Visbreaker

or Hydrocracker

LO-CAT, SULFUR-RITE, ELIMINATOR

AMINEX, THIOLEX, REGEN, MERICAT

Technology Applications

Midstream Applications

Natural Gas (H

2

S, RSH, COS, CO

2

)

Propane (H

2

S, RSH, COS)

Butane (H

2

S, RSH)

Natural Gasoline (H

2

S, RSH)

AMINEX,

THIOLEX, REGEN

THIOLEX, REGEN

THIOLEX, REGEN, MERICAT II

Source Stream (Impurities) Applicable Technologies

NGL Fractionation AMINEX,

THIOLEX, REGEN, LO-CAT,

SULFUR-RITE, ELIMINATOR

Upstream Applications

Natural Gas (H

2

S, RSH, COS, CO

2

)

LPG (H

2

S, RSH, COS)

Condensate (H

2

S, RSH)

AMINEX,

THIOLEX, REGEN

NAPFINING, THIOLEX, REGEN,

MERICAT II, MERICAT C

Stream (Impurities)

Gas Production Field AMINEX,

THIOLEX, REGEN, LO-CAT,

SULFUR-RITE, ELIMINATOR

Source Applicable Technologies

Associated Gas (H

2

S, RSH, COS, CO

2,

HCl, NH

4

, NH

4

Cl)

Crude Oil (H

2

S, CO

2,

RCOOH, RSH) NAPFINING, MERICAT C

Oil Production Field AMINEX,

THIOLEX, REGEN, LO-CAT,

SULFUR-RITE, ELIMINATOR

Oil Sands Heavy Oil

Upgrader

AMINEX,

THIOLEX, REGEN, LO-CAT,

SULFUR-RITE, ELIMINATOR

Fuel Gas (H

2

S, RSH, COS, CO

2

)

AMINEX,

THIOLEX, REGEN LPG (H

2

S, RSH, COS)

AMINEX and AMINEX COS

Rich amine

to regenerator

Treated

hydrocarbon

Untreated

hydrocarbon

Lean amine

from regenerator

AMINEX and AMINEX COS technologies employ the FIBER FILM Contactor

as the mass transfer device and utilize an appropriate amine as the treating

reagent to remove acid gas and carbonyl sulfide compounds from LPG-type

and gas streams.

AMINEX technologies were first licensed in 1998 and to date Merichem has

granted 27 unit operating licenses world-wide. The non-dispersive FIBER FILM

Contactor reduces capital expenditure and plant space requirements com-

pared to most treating alternatives, making AMINEX and AMINEX COS the

technologies-of-choice.

Rich amine

to regenerator

Treated

hydrocarbon

Untreated

hydrocarbon

Lean amine

from regenerator

AMINEX and AMINEX COS technologies employ the FIBER FILM Contactor

as the mass transfer device and utilize an appropriate amine as the treating

reagent to remove acid gas and carbonyl sulfide compounds from LPG-type

and gas streams.

AMINEX technologies were first licensed in 1998 and to date Merichem has

granted 27 unit operating licenses world-wide. The non-dispersive FIBER FILM

Contactor reduces capital expenditure and plant space requirements com-

pared to most treating alternatives, making AMINEX and AMINEX COS the

technologies-of-choice.

AQUAFINING

Spent water

Treated

hydrocarbon

Fresh water

Untreated

hydrocarbon

AQUAFINING technology employs the FIBER FILM Contactor as the mass

transfer device and utilizes water as the treating reagent to remove soluble

organic and inorganic impurities from liquid and gas hydrocarbon streams.

AQUAFINING technology was first licensed in 1978 and to date Merichem

has granted 90 unit operating licenses world-wide. The non-dispersive FIBER

FILM Contactor reduces capital expenditure and plant space requirements

compared to most treating alternatives, making AQUAFINING the

technology-of-choice.

NAPFINING and NAPFINING HiTAN

Spent caustic

Treated

hydrocarbon

Fresh caustic

Untreated

hydrocarbon

NAPFINING and NAPFINING HiTAN technologies employ the FIBER FILM

Contactor as the mass transfer device and utilize caustic as the treating

reagent to remove naphthenic acid compounds mainly from jet fuel, kero-

sene, diesel, condensate and crude oil streams.

NAPFINING technologies were first licensed in 1977 and to date Merichem

has granted 75 unit operating licenses world-wide. The non-dispersive FIBER

FILM Contactor reduces capital expenditure and plant space requirements

compared to most treating alternatives, making NAPFINING and NAPFIN-

ING HiTAN the technologies-of-choice.

In addition, on-stream factor between routine turnarounds is 100% whereas

electrostatic precipitators (ESPs) are much less reliable and incapable of pro-

cessing high TAN (>0.1 mg KOH/g) feeds.

THIOLEX

Spent caustic

or rich caustic

to REGEN

Treated

hydrocarbon

Fresh caustic or

lean caustic

from REGIN

Untreated

hydrocarbon

THIOLEX technology employs the FIBER FILM Contactor as the mass transfer

device and utilizes caustic as the treating reagent to remove acid gas and

mercaptan compounds from liquid and gas hydrocarbon streams.

THIOLEX technology was first licensed in 1980 and to date Merichem has

granted 220 unit operating licenses world-wide. The non-dispersive FIBER FILM

Contactor reduces capital expenditure and plant space requirements com-

pared to most treating alternatives, making THIOLEX the technology-of-

choice.

THIOLEX COS

Spent caustic/

catalyst

Treated

hydrocarbon

Fresh caustic/

catalyst

Untreated

hydrocarbon

THIOLEX COS technology employs the FIBER FILM Contactor as the mass

transfer device and utilizes caustic/catalyst mixture as the treating reagent to

remove acid gas and carbonyl sulfide compounds from liquid and gas hydro-

carbon streams.

The non-dispersive FIBER FILM Contactor reduces capital expenditure and

plant space requirements compared to most treating alternatives, making

THIOLEX COS the technology-of-choice.

MERICAT and MERICAT C

Air

Spent caustic

Treated

hydrocarbon

Fresh/

cascaded

caustic

Catalyst

Untreated

hydrocarbon

MERICAT & MERICAT C technologies employ the FIBER FILM Contactor as

the mass transfer device and utilize a caustic/catalyst/air mixture as the treat-

ing reagent to remove hydrogen sulfide and sweeten mercaptan compounds

in gasoline/naphtha, condensate and crude oil streams.

MERICAT technologies were first licensed in 1977 and to date Merichem has

granted 148 unit operating licenses world-wide. The non-dispersive FIBER FILM

Contactor reduces capital expenditure and plant space requirements com-

pared to most treating alternatives, making MERICAT and MERICAT C the

technologies-of-choice.

ECOMERICAT

Batch neutralized

brine to storage

Treated

hydrocarbon

Oxidation air

Fresh

caustic

(batch)

Catalyst

in

Untreated

hydrocarbon

Batch

Phenolic

caustic

CO

2

MERICAT ECOMERICAT

ECOMERICAT technology employs the FIBER FILM Contactor as the mass

transfer device to effectively sweeten mercaptans in gasoline/naphtha and

subsequently neutralize phenolic caustic using carbon dioxide to recover

phenols to maintain product yield. If gasoline/naphtha sweetening is the only

treating objective, then a stand-alone MERICAT design would be the

appropriate technology solution.

ECOMERICAT technology was first licensed in 2000 and to date Merichem

has granted two unit operating licenses world-wide. The non-dispersive FIBER

FILM Contactor reduces capital expenditure and plant space requirements

compared to most treating alternatives, making ECOMERICAT the

technology-of-choice.

MERICAT II

MERICAT II technology employs the FIBER FILM Contactor as the mass transfer

device and utilizes a caustic/catalyst/air mixture as the treating reagent to

remove hydrogen sulfide and sweeten mercaptan compounds in jet fuel,

kerosene and gasoline/naphtha streams.

MERICAT II technology was first licensed in 1986 and to date Merichem has

granted 43 unit operating licenses world-wide. The non-dispersive FIBER FILM

Contactor reduces capital expenditure and plant space requirements com-

pared to most treating alternatives, making MERICAT II the technology-of-

choice. In addition, the FIBER FILM Contactor is a built-in pre-wash which pro-

tects and extends the life of the carbon bed and, in many cases, negates the

need for a separate upstream pre-wash stage altogether.

Air

Spent caustic

Treated

hydrocarbon

Fresh

caustic

Catalyst

Untreated

hydrocarbon

Carbon

bed

MERICON

MERICON technologies are on-site solutions for processing spent caustics for

BOD/COD reduction, odor control, and/or pH adjustment. It employs neutral-

ization and/or oxidation steps to produce a neutral brine effluent stream

acceptable for routing to wastewater treating facilities, evaporation ponds, or

waterways.

MERICON technology was first licensed in 1988 and to date Merichem has

granted 27 unit operating licenses world-wide. The design of the system is

based on more than 75 years of first-hand operating knowledge gained from

Merichem-owned plants. This when coupled with Merichems extensive licens-

ing experience, makes MERICON the technology-of-choice.

M

r

e

z

i

d

i

x

O

DSO Gravity

Separator

coal

LP Steam

Solvent

Wash

Catalyst

Treated

Hydrocarbon

Offgas

Fresh

Solvent

Spent

Caustic

Fresh

Caustic

Sand

Filter

Condensate

THIOLEX

SM

REGEN

REGENtechnology processes regenerable rich caustic streams produced in the refinery allowing it to

be recycled thereby significantly improving caustic utilization. Typically REGENis coupled with extrac-

tive THIOLEX technology to regenerate the mercaptide-rich caustic purged from the THIOLEX

system and returns a lean caustic stream for additional mercaptan removal. Depending on the

stringency of the treated product specifications, the REGENdesign will employ disulfide oil (DSO)

gravity separation and/or solvent washing step(s) to minimize the impact of DSO back-extraction. In

addition, REGENtechnology is equally effective at reviving rich/spent caustic streams emanating

from conventional refinery treating units.

REGENtechnology was first licensed in 1980 and to date Merichem has granted 151 unit operating

licenses world-wide. Moderate levels of sodium sulfide (salt of hydrogen sulfide/H2S) can be accommo-

dated in the rich caustic and many times negates the need for a H2S pre-wash stage in the hydrocar-

bon extraction section of the treating unit resulting in less capital expenditure.

The design of the system is based on more than 75 years of first-hand operating knowledge gained from

Merichem-owned plants. This factor, when coupled with Merichems extensive licensing experience,

makes REGENthe technology-of-choice.

FIBER FILM

Processes

MERCAPTAN EXTRACTION

THIOLEX (typically coupled with REGEN

) Caustic extraction of

hydrogen sulfide, carbonyl sulfide, carbon dioxide and mercaptans

from gases, LPG and naphthas.

MERCAPTAN OXIDATION

MERICAT Liquid-liquid contact incorporating caustic, air, and

catalyst to oxidize mercaptans in light, heavy, and full-range cracked

naphthas.

MERICAT II Combination of liquid-liquid and solid-bed contact

using caustic, air, catalyst, and carbon to oxidize heavy mercaptans in

jet fuel and middle distillate streams.

MERICAT C Liquid-liquid contact incorporating caustic, air, and

catalyst to oxidize mercaptans in crude oil and condensate.

HYDROGEN SULFIDE EXTRACTION

AMINEX Amine extraction of acid gases from gases and LPG.

THIOLEX Caustic extraction of hydrogen sulfide, carbon dioxide,

and mercaptans from gases, LPG, and naphthas.

FIBER FILM

Processes

CARBON DIOXIDE EXTRACTION

AMINEX Amine extraction of acid gases from gases and LPG.

THIOLEX Caustic extraction of hydrogen sulfide, carbon dioxide,

and mercaptans from gases, LPG, and naphthas.

CARBONYL SULFIDE EXTRACTION

AMINEX COS Amine extraction of carbonyl sulfide from gases

and LPG.

THIOLEX COS Amine-catalyzed caustic extraction of carbonyl

sulfide gases and LPG.

NAPHTHENIC ACID EXTRACTION

NAPFINING Caustic extraction of naphthenic acids from jet fuel,

kerosene, and virgin middle distillates.

NAPFINING HiTAN Caustic extraction of naphthenic acids from

high TAN (>0.1 mg KOH/g) jet fuel, kerosene, and virgin middle

distillates.

IMPURITY EXTRACTION

AQUAFINING Water extraction of soluble organic and inorganic

impurities from gases, LPG, naphthas, and middle distillates.

FIBER FILM

Processes

SPENT CAUSTIC PROCESSES

REGENwith Gravity Separation Catalytic oxidation of mercaptide

caustic followed by gravity separation of disulfide oil to permit reuse

of the caustic in mercaptan extraction stages without significant DSO

back extraction.

REGENwith Solvent Wash Catalytic oxidation of mercaptide

caustic followed by solvent washing in a FIBER FILM Contactor for

complete disulfide oil removal in order to reuse the caustic in total

sulfur reduction stages without significant DSO back extraction.

MERICON Onsite oxidation or neutralization of sulfidic and

organic spent caustics to reduce BOD, COD and organics before

transfer to waste water treating facilities.

ECOMERICAT Oxidation of mercaptans in gasoline/naphtha and

subsequent neutralization of phenolic caustic using carbon dioxide to

reduce phenolic compounds in the neutralized brine.

Merichem Process Technologies

5450 Old Spanish Trail

Houston, Texas 77023

Tel: +1 713-428-5000

Fax: +1 713-921-4604

mptsales@merichem.com

Potrebbero piacerti anche

- Wet Air Oxidation of Refinery Spent Caustic Sept 2000Documento13 pagineWet Air Oxidation of Refinery Spent Caustic Sept 2000DAN IN-MARNessuna valutazione finora

- Wet Air OxidationDocumento42 pagineWet Air OxidationSiddharth ChoksiNessuna valutazione finora

- Air Treatment WaterleauDocumento28 pagineAir Treatment WaterleauSankar CdmNessuna valutazione finora

- Uop Polybed Psa For Gas Extraction Purification DatasheetDocumento2 pagineUop Polybed Psa For Gas Extraction Purification DatasheetRaji RauofNessuna valutazione finora

- Design of Caustic Wash System For Light HydrocarboDocumento5 pagineDesign of Caustic Wash System For Light HydrocarboWayne MonneryNessuna valutazione finora

- Spent Acid OverviewDocumento2 pagineSpent Acid OverviewacckypenrynNessuna valutazione finora

- 08 HydroprocessingDocumento38 pagine08 HydroprocessingrciographyNessuna valutazione finora

- Hydroprocessing Reactor and Process Design To Optimize Performance (Topsoe - 1998)Documento18 pagineHydroprocessing Reactor and Process Design To Optimize Performance (Topsoe - 1998)yliangcaNessuna valutazione finora

- Vapour Pressure DataDocumento44 pagineVapour Pressure Dataramsrivatsan50% (2)

- Refinery PDFDocumento22 pagineRefinery PDFromulussikalitNessuna valutazione finora

- Wet Air OxidationDocumento18 pagineWet Air OxidationUtkarsh PatilNessuna valutazione finora

- Gbhe Ammonia Co2 Removal Systems WSV PDFDocumento20 pagineGbhe Ammonia Co2 Removal Systems WSV PDFAaserElkenanyNessuna valutazione finora

- Filtration and Separation in RefineriesDocumento30 pagineFiltration and Separation in RefineriesprogerNessuna valutazione finora

- 2.3 Medical Waste Incineration: (Reformatted 1/95)Documento30 pagine2.3 Medical Waste Incineration: (Reformatted 1/95)drop shipNessuna valutazione finora

- Penex Process PDFDocumento49 paginePenex Process PDFAhmed Mohamed KhalilNessuna valutazione finora

- Hydro ProcessingDocumento24 pagineHydro Processingjeygar12Nessuna valutazione finora

- Bubble Column ReactorDocumento21 pagineBubble Column ReactorMuhammad Hamzah SyahrirNessuna valutazione finora

- Random PackingDocumento4 pagineRandom PackingAadam AryanNessuna valutazione finora

- Catalytic Reforming - 2Documento30 pagineCatalytic Reforming - 2Alekhya Bandaru0% (1)

- Maximise Ethylene Gain PDFDocumento4 pagineMaximise Ethylene Gain PDFRaj KumarNessuna valutazione finora

- Amine Expert Company PDFDocumento2 pagineAmine Expert Company PDFWajid NizamiNessuna valutazione finora

- Chapter 3. Acid Gas RemovalDocumento88 pagineChapter 3. Acid Gas RemovalTu Dang TrongNessuna valutazione finora

- Introduction To Merichem TechnologyDocumento16 pagineIntroduction To Merichem TechnologyNgoVietCuongNessuna valutazione finora

- Hydrotreating & Hydrocracking Process Technology Training Course - PetroKnowledgeDocumento3 pagineHydrotreating & Hydrocracking Process Technology Training Course - PetroKnowledgenishilgeorgeNessuna valutazione finora

- Merox & HydrotreatmentDocumento18 pagineMerox & HydrotreatmentLuis Acid100% (1)

- Schoepentoeter SEPARADORDocumento4 pagineSchoepentoeter SEPARADOREsau EstebanNessuna valutazione finora

- SC General Catalogue 2007 (3MB)Documento146 pagineSC General Catalogue 2007 (3MB)yeknom100% (1)

- C CC CC: CCCCCCCCCCCCCCCCDocumento27 pagineC CC CC: CCCCCCCCCCCCCCCCMuhammadTanzeeLUsmanNessuna valutazione finora

- UOP MeroxfixedbedDocumento2 pagineUOP MeroxfixedbednebulakersNessuna valutazione finora

- Pluses and Minuses of Caustic TreatingDocumento7 paginePluses and Minuses of Caustic Treatingargacho100% (1)

- WelChem BubbleCapTray 2020-2Documento6 pagineWelChem BubbleCapTray 2020-2Joel OkohNessuna valutazione finora

- Methyldiethanolamine As A Solvent For Gas DesulfurizationDocumento66 pagineMethyldiethanolamine As A Solvent For Gas DesulfurizationAnime MtNessuna valutazione finora

- 04 - Maximize Benefit From Your PRIME-G+ Proceedings PDFDocumento40 pagine04 - Maximize Benefit From Your PRIME-G+ Proceedings PDFmujeebtalibNessuna valutazione finora

- Diglycolamine Agent BrochureDocumento60 pagineDiglycolamine Agent Brochurebakhtyar21Nessuna valutazione finora

- SAS Engineering Process PackagesDocumento54 pagineSAS Engineering Process PackagesDewa Yuniardi FullNessuna valutazione finora

- Wet Air Oxidation Pre Treatment of Spent Caustic For Discharge To Biological Wastewater Treatment Allowing For Water Recovery and ReuseDocumento22 pagineWet Air Oxidation Pre Treatment of Spent Caustic For Discharge To Biological Wastewater Treatment Allowing For Water Recovery and ReuseAzam Khan100% (1)

- BrinkSA Bro-1112 PDFDocumento12 pagineBrinkSA Bro-1112 PDFSamir GanguliNessuna valutazione finora

- Sulfuric Acid - Wikipedia PDFDocumento94 pagineSulfuric Acid - Wikipedia PDFrajesh indukuriNessuna valutazione finora

- Waste ReductionDocumento108 pagineWaste ReductionJust Semsem100% (1)

- Documents - Pub - Front End Selective Hydrogenation Catalysts Enhance 2 1200 DR Wolffront EndDocumento28 pagineDocuments - Pub - Front End Selective Hydrogenation Catalysts Enhance 2 1200 DR Wolffront Endnafees ahmadNessuna valutazione finora

- Technical - Data - Sheet - Catalyst - HR 538Documento1 paginaTechnical - Data - Sheet - Catalyst - HR 538mohsen ranjbarNessuna valutazione finora

- Oxygen Enrichment FundamentalsDocumento15 pagineOxygen Enrichment FundamentalsahmadNessuna valutazione finora

- Slop Oil 1197 ENDocumento6 pagineSlop Oil 1197 ENsasankar_yhNessuna valutazione finora

- AlkyDocumento37 pagineAlkyMỹ PhanNessuna valutazione finora

- Spent Acid From Chlorine DryingDocumento2 pagineSpent Acid From Chlorine DryingacckypenrynNessuna valutazione finora

- MAHLE IF PremiumSelectElements ENDocumento6 pagineMAHLE IF PremiumSelectElements ENJamin SmtpngNessuna valutazione finora

- Process Simulation of Solvent Deasphalting Plants With PROIIDocumento29 pagineProcess Simulation of Solvent Deasphalting Plants With PROIIstudyendless100% (2)

- 02 - Wet Air Oxidation Catalogue - tcm524-465851Documento4 pagine02 - Wet Air Oxidation Catalogue - tcm524-465851PTIL ProcessNessuna valutazione finora

- Kinetics of The Catalytic Oxidation of Phthalic AnhydrideDocumento214 pagineKinetics of The Catalytic Oxidation of Phthalic Anhydrideannisa plNessuna valutazione finora

- Packinox Catalytic ReformingDocumento2 paginePackinox Catalytic Reformingzohaib_farooqNessuna valutazione finora

- Debottlenecking Refineries Through Comprehensive Feedstock PretreatmentDocumento20 pagineDebottlenecking Refineries Through Comprehensive Feedstock PretreatmentAnonymous msVFzaNessuna valutazione finora

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsDa EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNessuna valutazione finora

- Statistics for Process Control Engineers: A Practical ApproachDa EverandStatistics for Process Control Engineers: A Practical ApproachNessuna valutazione finora

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationDa EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNessuna valutazione finora

- PFT Overview BrochureDocumento25 paginePFT Overview BrochureMohamed GuezguezNessuna valutazione finora

- Brosjyre ChemineerDocumento14 pagineBrosjyre ChemineerRaul DiazNessuna valutazione finora

- Reliable: Pipeline Coating SolutionsDocumento9 pagineReliable: Pipeline Coating Solutionsshoaib1985Nessuna valutazione finora

- AdorDocumento280 pagineAdorDinesh KumarNessuna valutazione finora

- Fisher FB and FBG Control Valves Bulletin PDFDocumento24 pagineFisher FB and FBG Control Valves Bulletin PDFWalid FattahNessuna valutazione finora

- Guide To RegulatorsDocumento20 pagineGuide To RegulatorsWalid FattahNessuna valutazione finora

- Fisher 2625 Volume Booster SIS Safety ManualDocumento4 pagineFisher 2625 Volume Booster SIS Safety ManualWalid FattahNessuna valutazione finora

- Gas Turbine Combustion Temperature Spread Management: Presented By: Jonathan GriffithDocumento38 pagineGas Turbine Combustion Temperature Spread Management: Presented By: Jonathan GriffithWalid FattahNessuna valutazione finora

- Assets - SENSOR+TEST Konferenzen 2011 - SENSOR 2011 - C7.2 SENSOR2011Documento6 pagineAssets - SENSOR+TEST Konferenzen 2011 - SENSOR 2011 - C7.2 SENSOR2011Walid FattahNessuna valutazione finora

- Dinel CLM 36 Kapasitiivinen Lhetin EsiteDocumento7 pagineDinel CLM 36 Kapasitiivinen Lhetin EsiteWalid FattahNessuna valutazione finora

- Wobbe Index General Information Rev.1Documento4 pagineWobbe Index General Information Rev.1Walid FattahNessuna valutazione finora

- White Paper - ConductivityDocumento10 pagineWhite Paper - ConductivityWalid FattahNessuna valutazione finora

- Functional Safety Assessment AbbDocumento16 pagineFunctional Safety Assessment AbbWalid FattahNessuna valutazione finora

- EMX UVX Handbook PDFDocumento16 pagineEMX UVX Handbook PDFWalid FattahNessuna valutazione finora

- 4 Guidance On Valve Type SelectionDocumento86 pagine4 Guidance On Valve Type SelectionKrista OneillNessuna valutazione finora

- Principles of The LVDTDocumento3 paginePrinciples of The LVDTWalid FattahNessuna valutazione finora

- Exsilentia 3 Brochure FinalDocumento8 pagineExsilentia 3 Brochure FinalWalid FattahNessuna valutazione finora

- 6500 MembraneDocumento1 pagina6500 MembraneWalid FattahNessuna valutazione finora

- 9 5 - 358 362 PDFDocumento5 pagine9 5 - 358 362 PDFمالك مناصرةNessuna valutazione finora

- Elements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesDocumento8 pagineElements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesSadman Shaid SaadNessuna valutazione finora

- Purpose in LifeDocumento1 paginaPurpose in Lifeaashish95100% (1)

- The Passion For Cacti and Other Succulents: June 2017Documento140 pagineThe Passion For Cacti and Other Succulents: June 2017golf2010Nessuna valutazione finora

- S TR GEN ID (Component Marking) (Rev 3 2009) - AN Marked UpDocumento6 pagineS TR GEN ID (Component Marking) (Rev 3 2009) - AN Marked UpsnclgsraoNessuna valutazione finora

- Managing Diabetic Foot Ulcers ReadingDocumento21 pagineManaging Diabetic Foot Ulcers Readinghimanshugupta811997Nessuna valutazione finora

- LG250CDocumento2 pagineLG250CCarlosNessuna valutazione finora

- G.S 5Documento2 pagineG.S 5Jamsher BalochNessuna valutazione finora

- NF en Iso 5167-6-2019Documento22 pagineNF en Iso 5167-6-2019Rem FgtNessuna valutazione finora

- 1970 - Transformer FMEA PDFDocumento7 pagine1970 - Transformer FMEA PDFSing Yew Lam0% (1)

- Owner'S Manual: 2023 Chassis CabDocumento444 pagineOwner'S Manual: 2023 Chassis CabDmitry DimasNessuna valutazione finora

- From Input To Affordance: Social-Interactive Learning From An Ecological Perspective Leo Van Lier Monterey Institute Oflntemational StudiesDocumento15 pagineFrom Input To Affordance: Social-Interactive Learning From An Ecological Perspective Leo Van Lier Monterey Institute Oflntemational StudiesKayra MoslemNessuna valutazione finora

- Provision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field DevelopmentDocumento7 pagineProvision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field Developmentriandi100% (1)

- Someone Who Believes in YouDocumento1 paginaSomeone Who Believes in YouMANOLO C. LUCENECIONessuna valutazione finora

- Surface TensionDocumento13 pagineSurface TensionElizebeth GNessuna valutazione finora

- Fully Automatic Coffee Machine - Slimissimo - IB - SCOTT UK - 2019Documento20 pagineFully Automatic Coffee Machine - Slimissimo - IB - SCOTT UK - 2019lazareviciNessuna valutazione finora

- Nasopharyngeal Angiofibroma - PPTX Essam SrourDocumento10 pagineNasopharyngeal Angiofibroma - PPTX Essam SrourSimina ÎntunericNessuna valutazione finora

- Circle The Best Answer A, B, C, D or EDocumento4 pagineCircle The Best Answer A, B, C, D or Ewilder jackNessuna valutazione finora

- Irina Maleeva - Ariel Snowflake x6 - ENG - FreeDocumento4 pagineIrina Maleeva - Ariel Snowflake x6 - ENG - FreeMarinaKorzinaNessuna valutazione finora

- Malvinas Gas Plant Operator Training: Paragon Engineering Services, Inc. Houston, TexasDocumento71 pagineMalvinas Gas Plant Operator Training: Paragon Engineering Services, Inc. Houston, TexasMary Cruz Meza CahuanaNessuna valutazione finora

- Tugas 2-TRK Lanjut Kelompok 3 Andre-Arief-IstiaDocumento18 pagineTugas 2-TRK Lanjut Kelompok 3 Andre-Arief-IstiaAndre Fahriz Perdana HarahapNessuna valutazione finora

- Comparing Exponential NumbersDocumento5 pagineComparing Exponential NumbersMaya RahayuNessuna valutazione finora

- Ad149 Manual RDocumento69 pagineAd149 Manual RCharityNessuna valutazione finora

- The Broadband ForumDocumento21 pagineThe Broadband ForumAnouar AleyaNessuna valutazione finora

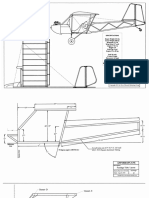

- Plans PDFDocumento49 paginePlans PDFEstevam Gomes de Azevedo85% (34)

- GCSE AstronomyDocumento30 pagineGCSE Astronomyharris123mc100% (1)

- Learning Activity Sheets Introduction To World Religions and Belief SystemDocumento56 pagineLearning Activity Sheets Introduction To World Religions and Belief SystemAngelica Caranzo LatosaNessuna valutazione finora

- Liver: Anatomy & FunctionsDocumento18 pagineLiver: Anatomy & FunctionsDR NARENDRANessuna valutazione finora

- Shandong Baoshida Cable Co, LTD.: Technical ParameterDocumento3 pagineShandong Baoshida Cable Co, LTD.: Technical ParameterkmiqdNessuna valutazione finora

- Lab Report Marketing Mansi 4Documento39 pagineLab Report Marketing Mansi 4Mansi SharmaNessuna valutazione finora