Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

KKS Guidelines - 1AHA062168 - Rev. B PDF

Caricato da

sbiliristhod0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

652 visualizzazioni26 pagineTitolo originale

KKS Guidelines_1AHA062168_Rev. B.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

652 visualizzazioni26 pagineKKS Guidelines - 1AHA062168 - Rev. B PDF

Caricato da

sbiliristhodCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 26

Cross checked

Department Name Date Signature

Main Contractor

ALSTOM (SWITZERLAND) LTD. , Brown Boveri Strasse 7, CH 5401-Baden

Replaces

Scale

ALSTOM Document Code

ALI/00/M/01-----001/IS/001

Responsible dept.

PEP3

Created by

Burzynski W.

Checked by

Koutras E.

Approved by

Koutras E.

Format

A4

Document Type

Work Instruction (WI)

Document Status

Electronically released

Identification number

1AHA062168

Originator

POWER SYSTEMS

PLANT BUSINESS

Title, Subtitle

KKS Guidelines and Keys

ALIVERI V, 1 x KA26-1 ICC TP

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

1-1/12

Template No.: GGG/00/-/EQA---/FT/302F (released with Work Instruction GGG/00/-/EQA---/WI/306)

ALSTOM 2007. All rights reserved. Please consider the environment before printing this document.

KKS Guidelines and Keys

ALIVERI V, 1 x KA26-1 ICC TPRH

Projects and Customers Information:

Space for Stamping (Review and Validation status - if needed)

Remark:

This document is intended to be an identification aid only.

It contains no binding information about scope of supply.

Additional Project Information

Project Name:

Aliveri

Country GR

Revision History

Rev. Revision Date Created by Checked by Approved by Description

B 10.08.2007 Burzynski Koutras Koutras

Section 2.2.1, 2.2.2

Description latest Revision:

Plant and unit code changed from 1 to 5

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-2

1. Chapter 1 - KKS-Introduction .........................................................................................................................1-4

1.1. Purpose and Area of application 1-4

1.2. Requirements 1-4

1.3. Structure and application 1-4

1.3.1. Identification and type of data characters.....................................................................................................1-5

1.3.2. Process-Related Identification.......................................................................................................................1-5

1.3.3. Point of Installation Identification...................................................................................................................1-5

1.3.4. Location identification ....................................................................................................................................1-6

1.4. Structure and contents of the breakdown levels 1-7

1.4.1. General...........................................................................................................................................................1-7

1.4.2. Breakdown level Function...........................................................................................................................1-8

1.4.3. Breakdown level Component....................................................................................................................1-10

1.5. KKS relevant symbols in P&ID's and principle sketches 1-12

2. Chapter 2 - PROJECT RELATED RULES, AGREEMENTS AND PROCEDURES...................................2-1

2.1. Project-related rules, agreements and procedures 2-1

2.2. Agreement on breakdown level "G" and prefix number for system code "F

0

" numbering. 2-1

2.2.1. G and F0 for process related and point of installation identification (example). ...................................2-1

2.2.2. G and F0 for location identification (example). .......................................................................................2-1

2.3. General rules on numbering code elements (F

N

, A

N

, B

N

). 2-1

2.4. General rules regarding direction of numbering 2-2

2.5. Rules on modifications and cancellations of KKS numbers. 2-2

2.6. Writing modus of KKS code 2-2

2.7. General rules on process-related identification 2-2

2.8. Rules on A

n

numbering for piping and in-pipe-components 2-3

2.9. Responsibilities 2-4

2.9.1. KKS Project Guidelines & Keys ....................................................................................................................2-4

2.9.2. Responsibility for KKS Identification of Systems and Equipment Units......................................................2-4

2.10. Explanation of abbreviations 2-4

3. Chapter 3 - KKS EQUIPMENT UNIT KEY.....................................................................................................3-1

3.1. A Mechanical equipment 3-1

3.2. B Mechanical equipment 3-1

3.3. C Direct measuring circuits 3-2

3.4. D Closed loop control circuits 3-2

3.5. E Analog and binary signal conditioning 3-3

3.6. F Indirect measuring circuits 3-3

3.7. G Electrical equipment 3-4

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-3

3.8. H Subassemblies of main and heavy machinery 3-4

4. Chapter 4 - KKS COMPONENT KEY.............................................................................................................4-0

4.1. - Electrical components 4-0

4.2. A -blocked- 4-1

4.3. B -blocked- 4-1

4.4. C -blocked- 4-1

4.5. D -blocked- 4-1

4.6. E -blocked- 4-1

4.7. F -blocked- 4-1

4.8. G -blocked- 4-1

4.9. H -blocked- 4-1

4.10. J -blocked- 4-1

4.11. K Mechanical components 4-1

4.12. L -blocked- 4-1

4.13. M Mechanical components 4-1

4.14. N -blocked- 4-2

4.15. P -blocked- 4-2

4.16. Q Instrumentation and control components (non-electrical) 4-2

4.17. R -blocked- 4-3

4.18. S -blocked- 4-3

4.19. T -blocked- 4-3

4.20. U -blocked- 4-3

4.21. V -blocked- 4-3

4.22. W -blocked- 4-3

4.23. X Signal origins 4-3

4.24. Y Signal applications 4-3

4.25. Z Gated signals 4-4

5. Chapter 5 - KKS FUNKTION KEY...................................................................................................................5-1

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-4

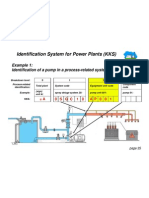

1. CHAPTER 1 - KKS-INTRODUCTION

(Identification System for Power Stations

1.1. Purpose and Area of application

The power plant identification system is applied to clearly identify plants, systems, parts and

components to their purpose, type and location.

The contents are in accordance with "KKS identification systems for Power Stations" issued by

VGB Kraftwerkstechnik GmbH Essen.

This document is intended to be an identification aid only. It contains no binding information

about scope of supply

1.2. Requirements

In order to perform the set tasks the identification system must be capable of satisfying

the following requirements:

Uniform identification for all types of power stations and any connected processes

Sufficient capacity and detail for identification of all systems, components and structures

Sufficient capacity for extension to accommodate new technologies

Consistent identification for planning, licensing, construction, operation, maintenance and

waste management

Interdisciplinary applicability to mechanical engineering, civil engineering, electrical and

instrument & control engineering combined with ability to identify according to process

functions, points of installation and locations

Consideration of national and international standards,

Non-language-based coding to ensure international usability,

Application in computer data processing

1.3. Structure and application

The KKS consists of three types of identification:

The process-related code identifies installations and equipment according to their assigned task

in the power plant process,

The point of installation code identifies the points of installation within an installation unit (e.g.

cubicles, consoles, panels),

The location code identifies the rooms and floors, or other installation sites, for installations and

equipment in building structures.

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-5

A uniform identification structure, with a maximum of four breakdown levels, was created for all

three types; the units referred to becoming smaller from left to right.

Serial number of breakdown level 0 1 2 3

Name of breakdown level Total plant Function Equipment unit Component

Example Unit 1 Feedwater system Pump unit Pump

Breakdown levels, referring to Process-Related Identification.

1.3.1. Identification and type of data characters

Table 1 summarizes the identification and type of data characters of the breakdown levels for all

three different types of identification appearing in the KKS.

Serial number

of breakdown level

0 1 2 3

Name of break-down level Total

Plant

Function Equipment

Unit

component

Designation of data character G F

0

F

1

F

2

F

3

F

N

A

1

A

2

A

N

A

3

B

1

B

2

B

N

Type of data character (A) or (N) (N) A A A NN A A NNN (A) A A NN

A = Alphabetical symbols (letters, special symbols)

N = Numerical symbols (digits)

( ) = These data characters may be omitted

1.3.2. Process-Related Identification

In this type of identification the entire system is subdivided according to the function or process,

since, whether for mechanical, electrical, control or civil engineering, the equipment units and

components must be identifiable in relation to the process.

The process-related identification is for many applications the most important identification, since

it permits, for example, locations of electrical and controls equipment, rooms, signals, and the

identification in circuit diagrams related to particular functions.

In the electrical and instrumentation control engineering sectors, the equipment for auxiliary

services, power supply, open-loop-control, instrumentation, protection, etc., is treated as a

process engineering function. The same applies to structures in civil engineering work.

The process-related identification corresponds to the identification block "Plant" in DIN 40719,

part 2. This block has the prefix sign "=". According to the standard, the prefix sign can be omitted

provided that the identification remains unambiguous.

1.3.3. Point of Installation Identification

As with the Process-Related Identification, the KKS is also used to identify locations, principally of

electrical and instrumentation and control equipment, but also of mechanical equipment.

M

PI

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-6

Locations -for example, coordinates, racks and positions in cubicles etc. - are identified in the

breakdown level EQUIPMENT UNIT.

The identification letters now used for the Point of installation identification in the breakdown level

FUNCTION are the same as those for the process-related identification. This improves

recognition of the identification in the overall system. In order to prevent possible confusion

between Process-Related Identification and Point of Installation Identification the prefix sign +

must be added to the Point of Installation Code (according to DIN 40719, part 2). Resp. the

breakdown symbols "full stop" between breakdown Level 1 and 2 must be added. This prefix sign

is omitted when there is absolutely no ambiguity - for example, in layout documents.

1.3.4. Location identification

In order to clearly identify the position of plant, sub-systems and equipment in the power station,

the building structure and floor is entered at the breakdown level FUNCTION, and the rooms on

the various floors of the building structure at the breakdown level EQUIPMENT UNIT. The

breakdown level COMPONENT is omitted in such cases. Fire protection sections are identified

according to the room identification.

Title and Contents of the breakdown levels

Breakdown levels 0

Total plant

1

Function

2

Equipment unit

3

component

Process-related

Code

Total plant System

code

Equipment

unit code

Component

code

Mechanical engineering Unit System Pump unit (Pump)

Civil engineering Unit

Unit

Structure, floor

Structure, floor

Rolling door

Fan unit

(Motor)

(Fan)

Control and

instrumentation (for

mechanical and civil

engineering)

Unit

Unit

Unit

Unit

System

Structure, floor

System

Unit coordinate level

Measuring circuit

Measuring circuit

Open-loop-control

Closed-loop-control

Transducer

Temp. sensor

Push-button

Controller

Electrical and control

and instrumentation

engineering

Unit

Unit

Unit

Unit

Unit

Unit

Switchgear

Transformer

Transformer

Transformer

Elect. Equipment cab.

Structure, floor

Switchgear assembly

Fan unit

Measuring circuit

Terminal box

Measuring circuit

Junction box

Fuse

Motor

Indicator

Terminal block

Smoke detector

Telephone jack

Point of

Installation

Total plant Installation

unit code

Installation

space code

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-7

Electrical and control

and instrumentation

engineering

Unit

Unit

Unit

Switchgear

Elect. Equipment cab.

Control console

Tier/Space

Tier/Space

Coordinate

Location code

Total plant Structure-code Room-code

Civil engineering Unit

Unit

Structure, floor

Outdoor area

Room/coordinates

Coordinates

1.4. Structure and contents of the breakdown levels

1.4.1. General

The KKS is divided into different BREAKDOWN LEVELS and codes from left to right in diminishing order

of the units of a complete power plant:

0 1 2 3

Total Plant Function Equipment Unit Component

G F

0

F

1

F

2

F

3

F

n

A

1

A

2

A

n

A

3

B

1

B

2

B

n

A or N N A A A N N A A N N N A A A N N

Overall plant prefix No.

(Chapter 2.1)

Function level prefix No.

(Chapter 2.1)

Function code

(Chapter 5)

Equipment unit code

(Chapter 3)

Component code

(Chapter 4)

Systems and sub-systems limit descriptions in the breakdown level Function are part of the

function code list. Where they are not defined, the beginning of a new system is at branch-off or

outlet of other system or at a point where unequivocal allocation of a component to a system is

possible.

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-8

Legend for the limits:

from

i ncl.

from excl.

to excl.

to

i ncl .

"from incl." means "including" the mentioned component

"from excl." means "excluding" the mentioned component

"to excl." means "excluding" the mentioned component

"to incl." means "including" the mentioned component

1.4.2. Breakdown level Function

Function identification:

Serial No. of breakdown level 1

Name of the breakdown level Function

Identification of data character F

0

F

1

F

2

F

3

F

n

Type of data character N A A A N N

Main groups F

1

Groups F

1

/F

2

Subgroups F

1/

F

2

/F

3

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-9

Function Key, main groups F

1

:

Code Identification

A GRID AND DISTRIBUTION SYSTEMS

B POWER TRANSMISSION AND AUXILIARY POWER SUPPLY

C INSTRUMENTATION AND CONTROL EQUIPMENT

(Identification on a priority basis according to main, instrumentation and control function

also acceptable in composite structure hardware packaging systems.)

E CONVENTIONAL FUEL SUPPLY AND RESIDUES DISPOSAL

G WATER SUPPLY AND DISPOSAL

H CONVENTIONAL HEAT GENERATION

L STEAM, WATER, GAS CYCLES

M MAIN MACHINE SETS

P COOLING WATER SYSTEMS

Q AUXILIARY SYSTEMS

S ANCILLARY SYSTEMS

T - blocked -

U STRUCTURES

Z WORKSHOP AND OFFICE EQUIPMENT

For complete function code list including system limits of function groups F

1

F

2

and function

subgroups F

1

F

2

F

3

see Function code key (chapter 5).

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-10

Breakdown level Equipment unit

Equipment unit identification:

Serial No. of breakdown level 2

Name of the breakdown level Equipment Unit

Identification of data character A

1

A

2

A

n

A

3

Type of data character A A N N N N N

Main groups A

1

Sub-groups A

1

A

2

Equipment Unit Key, groups A

1

:

Code Identification

A MECHANICAL EQUIPMENT

B MECHANICAL EQUIPMENT

C DIRECT MEASURING CIRCUITS

D CLOSED-LOOP-CONTROL CIRCUITS

E ANALOG AND BINARY SIGNAL CONDITIONING

F INDIRECT MEASURING CIRCUITS

G ELECTRICAL EQUIPMENT

H SUB-ASSEMBLIES OF MAIN AND HEAVY MACHINERY

For complete Equipment Units of sub-groups A1A2 see Equipment Unit code Key (chapter 3)

1.4.3. Breakdown level Component

Component identification:

Serial No. of breakdown level 3

Name of the breakdown level Component

Identification of data character B

1

B

2

B

n

Type of data character A A N N

Main groups B

1

Sub-groups B

1

B

2

Component code main groups B

1

:

Code Identification

K MECHANICAL COMPONENTS

M MECHANICAL COMPONENTS

Q INSTRUMENTATION AND CONTROL COMPONENTS (Non electrical)

- ELECTRICAL COMPONENTS

X SIGNAL ORIGIN

Y SIGNAL APPLICATION

Z GATED SIGNALS

For complete Components of the sub-groups B

1

B

2

see Component Code Key (chapter 4). In P&I

diagrams breakdown level 3 is NOT used. In other documents it may be used according to

separate agreements.

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-11

Overview

Serial No. of breakdown level 0 1 2 3

Name of breakdown level Total

Plant

Function Equipment

Unit

Compo-

nent

Identification of data character G F

0

F

1

F

2

F

3

F

n

A

1

A

2

A

n

A

3

B

1

B

2

B

n

Type of data character = A or N (N) A A A N N A A N N N (A) A A N N

Prefix sign of process

related identification

Identification of

power station units and

non-unit specific plants

Prefix No. of the function code

Counting of similar systems and plants

System-classifying

Classifying sub-division of

systems and plants of a unit

System-counting

Counting sub-division of systems and plants

into system sections and sub-systems

Equipment-classifying

Classifying sub-division of mechanical equipment,

open loop-control

Equipment-counting

Counting of similar mechanical equipment,

electrical and control & instrumentation equipment

Additional identification of breakdown level 2

Identification of pilot valves, multiple drives/

el. loads, measuring points with multiple

output/operating points

Component-classifying

Classifying sub-division of components,

signals or signal-applications

Component-counting

Counting of components

or signals or signal-applications

The data character marked ( ) and the prefix sign can be omitted if the identification remains unequivocal.

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

1-12

1.5. KKS relevant symbols in P&ID's and principle sketches

In P&I diagrams the following symbols to indicate KKS code and limit functions and piping

sections are recommended

The symbol "pin with empty head" is used to

identify the limits of functions and sub-functions

The symbol "pin with full head" is used to identify

the limits of piping sections

DN600 DN800

Reducers are assigned to the piping with the larger diameter.

They need not be shown on P&ID`s.

(See KKS Application Commentaries Part B1, page 52)

NNAAANN

The symbol "flag" is used for the identification

of pipings,

AANNN

The direction of the flag shows the direction

of the medium flow.

NNAAANN

The extended "flag" symbol is used for the identification of a pipe where

medium flow direction alters according to the operating conditions

AANNN

The symbol pointer between connected systems represented on different P&IDs

NNAAANN

Breakdown level Function of the connected system as a minimum information.

The symbol "I & C - circuits" (DIN 19227, sheet 1)

is used to represent measuring circuits.

KKS-code for measuring circuits

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

2-1

2. CHAPTER 2 - PROJECT RELATED RULES, AGREEMENTS AND

PROCEDURES

2.1. Project-related rules, agreements and procedures

This KKS project related rules, agreements and procedures are based on the 2nd

English Edition 09/1992 by VGB-Kraftwerkstechnik GmbH, Essen, Germany.

2.2. Agreement on breakdown level "G" and prefix number for system code "F

0

"

numbering.

2.2.1. G and F

0

for process related and point of installation identification (example).

Total

plant

System code

prefix No.

Contents

"G" "F

0

"

5 1 Unit 1, Gas Turbine1, HRSG1, El. Generator1 and all related systems

5 8 Unit 1, Steam Turbine, Steam Water Cycle and all related systems

5 9 Unit 1 - related common equipment

9 0 Non-unit specific plants and systems*)

2.2.2. G and F

0

for location identification (example).

Total

plant

System code

prefix No.

Contents

"G" "F

0

"

5 0 Structure appears only once in unit 1

5 1 - 9 Counting more than one structures with the same structure code (F

1

,

F

2

, F

3

) in unit 1

9 0, 1 - 9 Non-unit specific structures*)

Z 0, 1 - 9 Temporary structures

*) Also plants, systems, structures and equipment considered to occur only once when

extension to 6 or 7 or more (e.g. to existing) units takes place.

2.3. General rules on numbering code elements (F

N

, A

N

, B

N

).

Numbering starts anew when one of the preceding code elements changes.

Numbering may be consecutive or grouping.

Numbering need not be continuous.

Numbering conventions, once established, may not be altered, not even in the event of

changes made in the progress of planning.

Redundant zeros must be written.

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

2-2

An application-specific scheme of numbering may be established. However, it has to be valid

throughout all project disciplines in order of an unequivocal understanding of the code.

Management systems (e.g. computer checking programs, allocation sheets) have to assure,

that no double KKS numbers occur in the project and that no multiple KKS numbers are

assigned to one item.

If necessary, subdivisions of number ranges in F

N

and A

N

according to the division of work

could be made. They have to be written down directly in the Function key code and must be

respected by the partners.

2.4. General rules regarding direction of numbering

Standard identifications have priority in all cases.

Numbers are increasing in media or process flow direction.

Project counting directives referred to local layouts are related to breakdown level "G", prefix

number for system code "F

0

" and structures (F

1

= U) only.

The counting is not related to any geographical direction (e.g. not from west to east, not

from north to south).

2.5. Rules on modifications and cancellations of KKS numbers.

It is not allowed to change allocated KKS numbers for a project, if these numbers have been

released for the project.

The original KKS number is still kept, even when another kind of equipment is used providing

that the function according to the KKS equipment unit code is not changed (e.g. substitution

of a gate valve by a globe valve).

If in a project a hardware component is no longer used, it is not allowed to re-allocate its

KKS number for another component in the same project.

2.6. Writing modus of KKS code

Following structures of the KKS code are allowed:

- in one line with space between Function Level, Equipment Unit Level (and Component

Level).

e.g. 19PAB10 AP001 (-M01)

- in two (three) lines

e.g. 19PAB10

AP001

(-M01)

2.7. General rules on process-related identification

Piping & Instrument Diagrams (P&ID) are the basic documents (origins) for a process -

related KKS coding.

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

2-3

Single line diagrams are the basic documents (origins) for a process-related KKS coding in

electrical engineering. However, KKS codes for electrical consumers, measuring loops and

items of I & C represented in Function Diagrams are originated in P&IDs.

For other engineering activities (e.g. component engineering), KKS code must always be

taken from the above mentioned basic documents.

In basic KKS documents (P&IDs, single line diagrams and site layouts) the breakdown level

3 (component code) is never used.

The detailed KKS coding in process-related identification has to be made according to the

KKS-Application Commentaries, Part B1, B3 and B4 by VGB Kraftwerkstechnik GmbH.

2.8. Rules on A

n

numbering for piping and in-pipe-components

Serial No. Application for

NNN

001-199 Piping and in-pipe-components incl. instruments for main media/systems*)

201-299 Piping and in-pipe-components incl. instruments in discharge, drains and venting

301-399 1st isolation valves in instrument lines

401-499 Piping and isolation valves between technological and sampling & dosing systems

501-599 Piping and in-pipe-components incl. instruments for testing functions

601-699 Piping and in-pipe-components incl. instruments for heating and maintaining heat

701-719

720-749

750-779

780-789

790-799

Piping and in-pipe-components incl. instruments for special purposes

-N

2

purging / conservation connections

-Water / Steam purging (e.g. temporary blow-out)

-Compensators

-Hydro tests

-Free for project-specific allocations; documented agreement necessary

801-819

820-829

830-899

Piping and in-pipe-components incl. instruments for special purposes

-Hydraulic control piping and in-pipe-components

-Temporary flushing piping

-Free for project-specific allocations; documented agreement necessary

901-999 Indirect measuring circuits (according to Application Commentaries B4, Chpt. 2.1.2.2)

*) Main media / system = in F

1

, F

2

, F

3

(F

N

) identified system with its media; e.g. LAB(95) = High pressure

feedwater piping system

Note: Special rules on point of installation identification and location identification have to be

established within the relevant engineering disciplines (electrical, I&C and civil engineering)

according to the KKS-Application Commentaries, Part B2, B3 and B4 by VGB Kraftwerkstechnik

GmbH.

The KKS basic documents for these types of KKS code have to be identified as well.

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

2-4

2.9. Responsibilities

2.9.1. KKS Project Guidelines & Keys

Responsible for publishing, updating and for co-ordination of KKS identification between project

partners (external and internal):

Mr Waldemar Burzynski, dept. PIA1 tel. +41 56 20 59832

fax +41 56 20 52962

e-mail: waldemar.burzynski@power.alstom.com

2.9.2. Responsibility for KKS Identification of Systems and Equipment Units

Engineering teams responsible for development of basic KKS documents (see chapter 2.1)

are the creators of the KKS identification and, therefore, responsible for a correct

detailed identification according to this document. They should allocate KKS numbers only

in the number range they have been allowed (see chapter 5 - KKS Function code, column

<<Workflow>>).

2.10. Explanation of abbreviations

In chapter 5 KKS Function Key following abbreviations are used in the column

<<Rev>>:

A means Revision A (B,C etc)

A# means Revision A Text deleted

A@ means Revision A Text inserted new.

In chapter 5 KKS Function Key following abbreviations are used in the column

<<Workflow>>:

ARR_PL Arrangement planning

WSC Steam water cycle (SWC)

WSC_Supl Subsuppliers SWC (HRSG, TWP)

BOP Balance of Plant systems (BOP)

BOP_Supl Subsuppliers of BOP

CIVIL Civil engineering constructions (concrete, steel a.s.o.)

BLDG_FAC Ancillary systems (HVAC, Fire extinguishing a.s.o.)

EL Electrical engineering

IC Instrumentation & Control

GT_A_SYS Gas Turbine Gas Turbine Auxiliary System

GT_CMBST Gas Turbine Combuster

GT_T_BLK Gas Turbine Thermal Block

GEN El. Generator Plant

ST Steam Turbine Plant

NOTDEFINED More than one system owner

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

3-1

3. CHAPTER 3 - KKS EQUIPMENT UNIT KEY

3.1. A Mechanical equipment

AA Valves, dampers, etc., incl. actuators, also manual; rupturedisk equipment

AB Isolating elements, air locks

AC Heat exchangers, heat transfer surfaces

AD -blocked-

AE Turning, driving, lifting and slewing gear (also manipulators)

AF Continuous conveyors, feeders (escalators)

AG Generator units

AH Heating, cooling and air conditioning units

AJ Size reduction equipment, only as part of process

AK Compacting and packaging equipment, only as part of process

AL -blocked-

AM Mixers, agitators

AN Compressor units, fans

AP Pump units

AQ -blocked-

AR -blocked-

AS Adjusting and tensioning equipment for non-electrical variables (to be applied only, if the

actuator forms itself a constructive unit with another equipment unit)

AT Cleaning, drying, filtering and separating equipment, excl. *BT*

AU Braking, gearbox, coupling equipment, non-electrical converters

AV Combustion equipment

AW Stationary tooling, treatment equipment

AX Test and monitoring equipment for plant maintenance

AY -blocked-

AZ -blocked-

3.2. B Mechanical equipment

BA -blocked-

BB Storage equipment (tanks)

BC -blocked-

BD -blocked-

BE Shafts (for erection and maintenance only)

BF Foundations

BG -blocked-

BH -blocked-

BJ -blocked-

BK -blocked-

BL -blocked-

BM -blocked-

BN Jet pumps, ejectors, injectors

BP Flow restrictors, limiters, orifices (not metering orifices)

BQ Hangers, supports, racks, piping penetrations

BR Piping, ductwork, chutes, compensators

BS Silencers

BT Flue gas catalytic converter modules

BU Insulation, sheathing

BV -blocked-

BW -blocked-

BX -blocked-

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

3-2

BY -blocked-

BZ -blocked-

3.3. C Direct measuring circuits

(Data character A2 following DIN 19227, part 1, Sept. 1973 edition, table 1, initial letter)

CA -blocked-

CB -blocked-

CC -blocked-

CD Density

CE Electrical variables (e.g. current, voltage, power, electr. frequency)

CF Flow, rate

CG Distance, length, position, direction of rotation

CH Manual input as manually operated sensor (e.g. fire detector)

CJ -blocked-

CK Time

CL Level (also for dividing line)

CM Moisture, humidity

CN -blocked-

CP Pressure

CQ Quality variables (analysis, material properties), other than *CD*, *CM*, *CV*

CR Radiation variables

CS Velocity, speed, frequency (mechanical), acceleration

CT Temperature

CU Combined and other variables

CV Viscosity

CW Weight, mass

CX Neutron flux

CY Vibration, expansion

CZ -blocked-

3.4. D Closed loop control circuits

(Data character A2 following DIN 19227, part 1, Sept. 1973 edition, table 1, initial letter)

DA -blocked-

DB -blocked-

DC -blocked-

DD Density

DE Electrical variables (e.g. current, voltage, power, electr. frequency)

DF Flow, rate

DG Distance, length, position, direction of rotation

DH -blocked-

DJ -blocked-

DK Time

DL Level (also for dividing line)

DM Moisture, humidity

DN -blocked-

DP Pressure

DQ Quality variables (analysis, material properties), other than *DD*, *DM*, *DV*

DR Radiation variables

DS Velocity, speed, frequency (mechanical), acceleration

DT Temperature

DU Combined and other variables

DV Viscosity

DW Weight, mass

DX Neutron flux

DY Vibration, expansion

DZ -blocked-

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

3-3

3.5. E Analog and binary signal conditioning

EA Open loop control (free for use)

EB Open loop control (free for use)

EC Open loop control (free for use)

ED Open loop control (free for use)

EE Open loop control (free for use)

EF -blocked-

EG Alarm, annunciation (free for use)

EH Alarm, annunciation (free for use)

EJ Alarm, annunciation (free for use)

EK Alarm, annunciation (free for use)

EL -blocked-

EM Process computer (free for use)

EN Process computer (free for use)

EP Process computer (free for use)

EQ Process computer (free for use)

ER Reactor protection

ES -blocked-

ET -blocked-

EU Combined analog and binary signal conditioning

EV -blocked-

EW Protection (free for use)

EX Protection (free for use)

EY Protection (free for use)

EZ Protection (free for use)

3.6. F Indirect measuring circuits

(Data character A2 following DIN 19227, part 1, September 1973 edition, table 1, initial

letter)

FA -blocked-

FB -blocked-

FC -blocked-

FD Density

FE Electrical variables (e.g. electr. efficiency, power)

FF Flow, rate

FG Distance, length, position, direction of rotation

FH -blocked-

FJ -blocked-

FK Time

FL Level (also for dividing line)

FM Moisture, humidity

FN -blocked-

FP Pressure

FQ Quality variables (analysis, material properties), other than *FD*, *FM*, *FV*

FR Radiation variables

FS Velocity, speed, frequency (mechanical), acceleration

FT Temperature

FU Combined and other variables

FV Viscosity

FW Weight, mass

FX Neutron flux

FY Vibration, expansion

FZ -blocked-

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

3-4

3.7. G Electrical equipment

GA Junction boxes and cable/bus bar penetrations (free for use)

GB Junction boxes and cable/bus bar penetrations (free for use)

GC Junction boxes and cable/bus bar penetrations (free for use)

GD Junction boxes and cable/bus bar penetrations (free for use)

GE Junction boxes and cable/bus bar penetrations (free for use)

GF Junction boxes and cable/bus bar penetrations (free for use)

GG Junction boxes and cable/bus bar penetrations (free for use)

GH Electrical and instrumentation and control installation units identified as per process

system (e.g. cubicles, boxes)

GJ -blocked-

GK Information display and operator control equipment for process computers and

automation systems

GL -blocked-

GM Junction boxes for light-current systems of national telecommunication services

GN -blocked-

GP Subdistribution/junction boxes for lighting

GQ Subdistribution/junction boxes for power sockets

GR DC generating equipment, batteries

GS Switchgear equipment if not identified under process equipment

GT Transformer equipment

GU Converter equipment

GV Structure-related earthing and lightning protection equipment, surge arrestors

GW Cabinet power supply equipment

GX Actuating equipment for electrical variables

GY Junction boxes for light-current systems (not of national telecommunication services)

GZ Hangers, supports and racks for electrical and instrumentation and control equipment

3.8. H Subassemblies of main and heavy machinery

(only to be used in conjunction with *M* = Main machine sets and *X* = Heavy machinery)

HA Machine stationary assembly

HB Machine rotating assembly

HC -blocked-

HD Bearing assembly

HE -blocked-

HF -blocked-

HG -blocked-

HH -blocked-

HJ -blocked-

HK -blocked-

HL -blocked-

HM -blocked-

HN -blocked-

HP -blocked-

HQ -blocked-

HR -blocked-

HS -blocked-

HT -blocked-

HU -blocked-

HV -blocked-

HW -blocked-

HX -blocked-

HY -blocked-

HZ -blocked-

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

4-0

4. CHAPTER 4 - KKS COMPONENT KEY

4.1. - Electrical components

(To DIN 40719, part 2, September 1978 edition)

-A Assemblies and subassemblies

-B Transducers for non-electrical to electrical variables and vice-versa

-C Capacitors

-D Binary elements, delay devices, memory devices

-E Special components

-F Protective devices

-G Generators, power supplies

-H Signalling devices

-K Relays, contactors

-L Inductors

-M Motors

-N Amplifiers, controllers

-P Measuring instruments, testing equipment

-Q Power switchgear

-R Resistors

-S Switches, selectors

-T Transformers

-U Modulators, converters from electrical to other electrical variables

-V Tubes, semiconductors

-W Transmission paths, waveguides, aerials

-X Terminals, plugs, sockets

-Y Electrical positioners, e.g. solenoids (not motors)

-Z Terminations, balancing equipment, filters, limiters, cable terminations

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

4-1

4.2. A -blocked-

4.3. B -blocked-

4.4. C -blocked-

4.5. D -blocked-

4.6. E -blocked-

4.7. F -blocked-

4.8. G -blocked-

4.9. H -blocked-

4.10. J -blocked-

4.11. K Mechanical components

KA Gate valves, globe valves, dampers, cocks, rupture disks, orifices

KB Gates, doors, dam boards

KC Heat exchangers, coolers

KD Vessels/tanks, pools, surge tanks (fluid systems)

KE Turning, driving, lifting and slewing gear

KF Continuous conveyors, feeders

KG -blocked-

KH -blocked-

KJ Size reduction machines

KK Compacting, packaging machines

KL -blocked-

KM Mixers, agitators

KN Compressors, blowers, fans

KP Pumps

KQ -blocked-

KR -blocked-

KS -blocked-

KT Cleaning machines, dryers, separators, filters

KU -blocked-

KV Burners, grates

KW Stationary tooling and treatment machines for maintenance

KX -blocked-

KY -blocked-

KZ -blocked-

4.12. L -blocked-

4.13. M Mechanical components

MA -blocked-

MB Brakes

MC -blocked-

MD -blocked-

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

4-2

ME -blocked-

MF Foundations

MG Gearboxes

MH -blocked-

MJ -blocked-

MK Clutches, couplings

ML -blocked-

MM Engines, not electrical

MN -blocked-

MP -blocked-

MQ -blocked-

MR Piping components, ductwork components

MS Positioners, not electrical

MT Turbines

MU Transmission gear, non electrical, converters and boosters other than couplings and

gearboxes

MV -blocked-

MW -blocked-

MX -blocked-

MY -blocked-

MZ -blocked-

4.14. N -blocked-

4.15. P -blocked-

4.16. Q Instrumentation and control components (non-electrical)

QA -blocked-

QB Sensors if not structurally integral with *QP*, metering orifices

QC -blocked-

QD -blocked-

QE -blocked-

QF -blocked-

QG -blocked-

QH Signalling devices

QJ -blocked-

QK -blocked-

QL -blocked-

QM -blocked-

QN Controllers, flybolt governor

QP Measuring instruments, testing equipment

QQ -blocked-

QR Instrument piping

QS Condensation chambers (datum reservoir) in measuring circuits

QT Thermowells and pockets for protection of sensors

QU -blocked-

QV -blocked-

QW -blocked-

QX -blocked-

QY -blocked-

QZ -blocked-

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

4-3

4.17. R -blocked-

4.18. S -blocked-

4.19. T -blocked-

4.20. U -blocked-

4.21. V -blocked-

4.22. W -blocked-

4.23. X Signal origins

(Subgroups are established as appropriate to the type of instrumentation and control

system and are therefore subject to agreement between the parties to the project.)

X Signal origins (free for use)

XB Signal origins (free for use)

XC Signal origins (free for use)

XD Signal origins (free for use)

XE Signal origins (free for use)

XF Signal origins (free for use)

XG Signal origins (free for use)

XH Signal origins (free for use)

XJ Signal origins (free for use)

XK Signal origins (free for use)

XL Signal origins (free for use)

XM Signal origins (free for use)

XN Signal origins (free for use)

XP Signal origins (free for use)

XQ Signal origins (free for use)

XR Signal origins (free for use)

XS Signal origins (free for use)

XT Signal origins (free for use)

XU Signal origins (free for use)

XV Signal origins (free for use)

XW Signal origins (free for use)

XX Signal origins (free for use)

XY Signal origins (free for use)

XZ Signal origins (free for use)

4.24. Y Signal applications

(Subgroups are established as appropriate to the type of instrumentation and control

system and are therefore subject to agreement between the parties to the project.)

YA Signal applications (free for use)

YB Signal applications (free for use)

YC Signal applications (free for use)

YD Signal applications (free for use)

YE Signal applications (free for use)

YF Signal applications (free for use)

YG Signal applications (free for use)

YH Signal applications (free for use)

YJ Signal applications (free for use)

YK Signal applications (free for use)

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

4-4

YL Signal applications (free for use)

YM Signal applications (free for use)

YN Signal applications (free for use)

YP Signal applications (free for use)

YQ Signal applications (free for use)

YR Signal applications (free for use)

YS Signal applications (free for use)

YT Signal applications (free for use)

YU Signal applications (free for use)

YV Signal applications (free for use)

YW Signal applications (free for use)

YX Signal applications (free for use)

YY Signal applications (free for use)

YZ Signal applications (free for use)

4.25. Z Gated signals

(Subgroups are established as appropriate to the type of instrumentation and control

system and are therefore subject to agreement between the parties to the project.)

ZA Gated signals (free for use)

ZB Gated signals (free for use)

ZC Gated signals (free for use)

ZD Gated signals (free for use)

ZE Gated signals (free for use)

ZF Gated signals (free for use)

ZG Gated signals (free for use)

ZH Gated signals (free for use)

ZJ Gated signals (free for use)

ZK Gated signals (free for use)

ZL Gated signals (free for use)

ZM Gated signals (free for use)

ZN Gated signals (free for use)

ZP Gated signals (free for use)

ZQ Gated signals (free for use)

ZR Gated signals (free for use)

ZS Gated signals (free for use)

ZT Gated signals (free for use)

ZU Gated signals (free for use)

ZV Gated signals (free for use)

ZW Gated signals (free for use)

ZX Gated signals (free for use)

ZY Gated signals (free for use)

ZZ Gated signals (free for use)

Electronically released Rev.

Originator

ALSTOM POWER SYSTEMS

Identification number

1AHA062168

Rev.

B

Date

27.08.2007

Lang.

en

Sheet

ALSTOM 2007. All rights reserved.

5-1

5. CHAPTER 5 - KKS FUNKTION KEY

Refer to enclosure 1

Potrebbero piacerti anche

- Kks AlstomDocumento135 pagineKks Alstomcabral1205100% (5)

- Att.1 QT1-L-G-020-05-00003, KKS Numbering SystemDocumento85 pagineAtt.1 QT1-L-G-020-05-00003, KKS Numbering SystemDoan Ngoc DucNessuna valutazione finora

- Procedure For Plant Identification (KKS Numbering System)Documento82 pagineProcedure For Plant Identification (KKS Numbering System)zerocool86100% (8)

- KKS Identification - Mong Duong 1 PowerPlant PDFDocumento82 pagineKKS Identification - Mong Duong 1 PowerPlant PDFTran HoangNessuna valutazione finora

- Article Transition KKS To RDS-PP Rev2011-EnGDocumento10 pagineArticle Transition KKS To RDS-PP Rev2011-EnGsdiamanNessuna valutazione finora

- KKS Application Explanations For Hydro Power Plants: VGB-B106 D1Documento6 pagineKKS Application Explanations For Hydro Power Plants: VGB-B106 D1LHYT NTUANessuna valutazione finora

- Kks Key Book AlstomDocumento136 pagineKks Key Book AlstomGentelmanOnly100% (3)

- Enelpower: Project Procedure - PP03Documento50 pagineEnelpower: Project Procedure - PP03Shaik Nizam Uddin0% (1)

- KKS General View SDocumento56 pagineKKS General View SArslan Abbas Malik100% (4)

- 71 OFFSHORE2011presentationDocumento19 pagine71 OFFSHORE2011presentationJACKNessuna valutazione finora

- Kks Handbook Edition 08Documento113 pagineKks Handbook Edition 08David BenderNessuna valutazione finora

- Kraftwerk Kennezeichen SystemDocumento78 pagineKraftwerk Kennezeichen SystemGopinathan Bipin50% (2)

- KksDocumento78 pagineKksgopi_dey8649Nessuna valutazione finora

- VGB-S-002-05-2015-10-EN (Public License)Documento52 pagineVGB-S-002-05-2015-10-EN (Public License)Mohamed Zaghloul100% (1)

- KKS For BeginnersDocumento21 pagineKKS For Beginnersy_kadir100% (1)

- 1VPN000000S0001 - BESS E-House SpecificationsDocumento25 pagine1VPN000000S0001 - BESS E-House SpecificationsJeniffer Sta. Maria100% (2)

- KKS Designation SystemDocumento19 pagineKKS Designation SystemTamer Ahmed SalemNessuna valutazione finora

- Define Your PetrochemicalProject Execution PlanDocumento9 pagineDefine Your PetrochemicalProject Execution PlanLiu Yangtze100% (1)

- CMI Energy Reference ListDocumento23 pagineCMI Energy Reference ListMochamad BhadawiNessuna valutazione finora

- KKS HandbookDocumento93 pagineKKS HandbookJose Aguilos BotanaNessuna valutazione finora

- Referensi FEED PDFDocumento46 pagineReferensi FEED PDFMuhammad Fadhil Imansyah100% (1)

- TMS16482 Electrical Instrumentation and Control SystemDocumento96 pagineTMS16482 Electrical Instrumentation and Control SystemTuesou MachereNessuna valutazione finora

- Kks CodeDocumento1 paginaKks Coderokorio0% (1)

- S 821 91 2020 10 ENeBookupdate21Documento76 pagineS 821 91 2020 10 ENeBookupdate21mohdfirdausNessuna valutazione finora

- Pip Elcgl01 Electrical Design CriteriaDocumento7 paginePip Elcgl01 Electrical Design CriteriaRichard TorrivillaNessuna valutazione finora

- Aku Aeb0001enDocumento101 pagineAku Aeb0001enManuel Enrique Coto ReyesNessuna valutazione finora

- TM - Intro & KKS GeschDocumento33 pagineTM - Intro & KKS GeschTemitope Vic100% (1)

- KKS RDS-PPDocumento26 pagineKKS RDS-PPwilst001100% (4)

- Guideline: Letter Code For Power Plant SystemsDocumento244 pagineGuideline: Letter Code For Power Plant SystemsLuis Felipe Cortes Pacheco100% (3)

- VGB-B 106e VGB-Guideline KKS Identification System For Power Stations - Application ExplanationsDocumento9 pagineVGB-B 106e VGB-Guideline KKS Identification System For Power Stations - Application ExplanationsChris WebelmanNessuna valutazione finora

- Fantastic Power Plant AuditDocumento168 pagineFantastic Power Plant Audithussainjk100% (1)

- Equpment NumberingDocumento16 pagineEqupment NumberingSabilal ArifNessuna valutazione finora

- VGB-S-821-00-2016-06-EN RDS-PP® Reference Designation System For Power Plants (System Key)Documento17 pagineVGB-S-821-00-2016-06-EN RDS-PP® Reference Designation System For Power Plants (System Key)Chris Webelman25% (4)

- VGB KKS CodeDocumento48 pagineVGB KKS CodeEymenNessuna valutazione finora

- Cable Block DiagramDocumento1 paginaCable Block DiagramgormankungNessuna valutazione finora

- CCPPDocumento34 pagineCCPPphanindra100% (1)

- VOL 2 SEC 3 1 - SCOPE OF WORKS Rev 2 PDFDocumento189 pagineVOL 2 SEC 3 1 - SCOPE OF WORKS Rev 2 PDFsivaguruk250% (2)

- EP FA EL 02 PH - Philosophy - Earthing - and - Bonding - ProtectionDocumento24 pagineEP FA EL 02 PH - Philosophy - Earthing - and - Bonding - Protectionmarin cristianNessuna valutazione finora

- Job Description - Project Engineer (TRI000A)Documento5 pagineJob Description - Project Engineer (TRI000A)abguyNessuna valutazione finora

- Guide For RDS-PSDocumento9 pagineGuide For RDS-PSyoonghmNessuna valutazione finora

- Full Documentation of Resume Builder ProjectDocumento130 pagineFull Documentation of Resume Builder Projectshaheryar xhahNessuna valutazione finora

- 000-Performance Test Procedure (General)Documento10 pagine000-Performance Test Procedure (General)K R Kumar RanjanNessuna valutazione finora

- TOR Wind Farm - Technical Due Diligencev1 - 0Documento9 pagineTOR Wind Farm - Technical Due Diligencev1 - 0Alexandru IonescuNessuna valutazione finora

- KKS Tagging Philosophy For Power Generating StationDocumento61 pagineKKS Tagging Philosophy For Power Generating Stationchandakbera100% (1)

- 63M0002-D Project General Technical Specification PDFDocumento69 pagine63M0002-D Project General Technical Specification PDFVasiljka Đordan Jelaca100% (1)

- Megajana - Company ProfileDocumento14 pagineMegajana - Company ProfileM Rizal B AzmiNessuna valutazione finora

- Work Breakdown Structure and Plant-Equipment Designation System Numbering Scheme For The Hight Temperature Gas Reactor PDFDocumento22 pagineWork Breakdown Structure and Plant-Equipment Designation System Numbering Scheme For The Hight Temperature Gas Reactor PDFArini RizalNessuna valutazione finora

- FEED Deliverable List (Sample) - The Project Definition PDFDocumento5 pagineFEED Deliverable List (Sample) - The Project Definition PDFPeter BridgeNessuna valutazione finora

- 446RDP Ge WPR 000 SPC in 0010 - 1 (2o541wpukzm)Documento31 pagine446RDP Ge WPR 000 SPC in 0010 - 1 (2o541wpukzm)RVELEZNessuna valutazione finora

- International Standard Kks Codification PDFDocumento53 pagineInternational Standard Kks Codification PDFjulian_morales_24Nessuna valutazione finora

- NIOEc SP 00 62Documento28 pagineNIOEc SP 00 62amin100% (1)

- Control System Configuration PDFDocumento2 pagineControl System Configuration PDFjuliunNessuna valutazione finora

- Kks Ama00m Pmfna252 A Kks GuidelinesDocumento102 pagineKks Ama00m Pmfna252 A Kks GuidelinesRafil Alani100% (1)

- TII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsDocumento11 pagineTII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsBorn ToSinNessuna valutazione finora

- KKS Component Coding Manual 40-0000294 - D - 002 PDFDocumento18 pagineKKS Component Coding Manual 40-0000294 - D - 002 PDFsvnaik14100% (1)

- Kks Code SystempdfDocumento95 pagineKks Code SystempdfAnurakshan EngineersNessuna valutazione finora

- KKS Handbook Rev BDocumento63 pagineKKS Handbook Rev BlrpatraNessuna valutazione finora

- 45-45 - R2 KKS Keypart Fossil PDFDocumento84 pagine45-45 - R2 KKS Keypart Fossil PDFbacuoc.nguyen356Nessuna valutazione finora

- Equipment Numbering Code - 16 Jun 13Documento136 pagineEquipment Numbering Code - 16 Jun 13krishnsgkNessuna valutazione finora

- Plant Identification (KKS)Documento75 paginePlant Identification (KKS)Taladron LekNessuna valutazione finora

- IATA Report PDFDocumento14 pagineIATA Report PDFsbiliristhodNessuna valutazione finora

- Check-In PartiesDocumento1 paginaCheck-In PartiessbiliristhodNessuna valutazione finora

- IATA Report PDFDocumento14 pagineIATA Report PDFsbiliristhodNessuna valutazione finora

- Gekterna Fs Notes 31-12-2018 en PDFDocumento232 pagineGekterna Fs Notes 31-12-2018 en PDFsbiliristhodNessuna valutazione finora

- Athens International Airport: Developing Airport Business: The Key Role of Pavements in Airfield InvestmentsDocumento47 pagineAthens International Airport: Developing Airport Business: The Key Role of Pavements in Airfield InvestmentssbiliristhodNessuna valutazione finora

- HER Traffic Forecast Study - Final Report - en - v3Documento117 pagineHER Traffic Forecast Study - Final Report - en - v3sbiliristhodNessuna valutazione finora

- E1 83 PDFDocumento7 pagineE1 83 PDFsbiliristhodNessuna valutazione finora

- Ti 166Documento1 paginaTi 166MAI_QualityNessuna valutazione finora

- Oregen Wasted Heat Recovery CycleDocumento6 pagineOregen Wasted Heat Recovery CyclesbiliristhodNessuna valutazione finora

- Bds en 15273 3 2009Documento188 pagineBds en 15273 3 2009milan_popovic_2Nessuna valutazione finora

- Ti 166Documento1 paginaTi 166MAI_QualityNessuna valutazione finora

- 26 Selected Items - PubMed - NCBIDocumento4 pagine26 Selected Items - PubMed - NCBIsbiliristhodNessuna valutazione finora

- Power Plants Programme 2014Documento138 paginePower Plants Programme 2014sbiliristhodNessuna valutazione finora

- Manual de Pararrayos SiemensDocumento120 pagineManual de Pararrayos SiemensfvicunaeNessuna valutazione finora

- S 39Documento37 pagineS 39sbiliristhodNessuna valutazione finora

- Materials Recommended For Pump FluidsDocumento4 pagineMaterials Recommended For Pump FluidssbiliristhodNessuna valutazione finora

- Lifecycle Cost Knowledge Impact Investment DecisionsDocumento5 pagineLifecycle Cost Knowledge Impact Investment DecisionssbiliristhodNessuna valutazione finora

- Control Valves Tuning PDFDocumento13 pagineControl Valves Tuning PDFsteam100deg1658Nessuna valutazione finora

- Pump Curves Rev 0Documento2 paginePump Curves Rev 0sbiliristhodNessuna valutazione finora

- S 39Documento37 pagineS 39sbiliristhodNessuna valutazione finora

- MQCDocumento8 pagineMQCnavneetkpatil8409Nessuna valutazione finora

- Calibration ValidationDocumento12 pagineCalibration Validationelmira100% (2)

- Scientific Instruments ListDocumento4 pagineScientific Instruments ListSuneelNessuna valutazione finora

- Questions and AnswersDocumento2 pagineQuestions and AnswersDevarakonda KondayyaNessuna valutazione finora

- Classification and Selection of Instruments: Instrumentation and Control EngineeringDocumento8 pagineClassification and Selection of Instruments: Instrumentation and Control EngineeringCOCO TVNessuna valutazione finora

- Unit 1Documento20 pagineUnit 1S APNessuna valutazione finora

- Mpmy PM PRC 0002 - 1.0 Equipment and Tag Numbering ProcedureDocumento21 pagineMpmy PM PRC 0002 - 1.0 Equipment and Tag Numbering ProcedureAnonymous 1ykzuaxWgYNessuna valutazione finora

- Socomec Catálogo Equipos Medida Monitorización Gestión EnergéticaDocumento148 pagineSocomec Catálogo Equipos Medida Monitorización Gestión EnergéticaVEMATEL100% (1)

- (I) Direct Method of MeasurementDocumento7 pagine(I) Direct Method of MeasurementAakib alamNessuna valutazione finora

- Integrated Science CurriculumDocumento63 pagineIntegrated Science CurriculumPatrice GrantNessuna valutazione finora

- Dresser PDFDocumento28 pagineDresser PDFalexrm12Nessuna valutazione finora

- Engineering Me Trology MeasurementsDocumento51 pagineEngineering Me Trology MeasurementsShe DilNessuna valutazione finora

- Measuring InstrumentsDocumento8 pagineMeasuring Instrumentsatul206Nessuna valutazione finora

- Welding Inspector: Calibration Section 24Documento9 pagineWelding Inspector: Calibration Section 24AliNessuna valutazione finora

- 4 SemDocumento2 pagine4 Semvino1393Nessuna valutazione finora

- Introduction To MetrologyDocumento55 pagineIntroduction To MetrologyVishnuPSVichuNessuna valutazione finora

- TCB Role Measurement CalibarationDocumento68 pagineTCB Role Measurement CalibarationRidhWanNessuna valutazione finora

- Is Iso 8041 2005Documento98 pagineIs Iso 8041 2005Donaldo Garcia Mendieta100% (1)

- Instuments Types With ExamplesDocumento9 pagineInstuments Types With ExamplesAmmar KhalidNessuna valutazione finora

- Airflow CatalogueDocumento16 pagineAirflow Catalogueسامح الجاسم100% (1)

- Mechanical Measurement and Metrology PDFDocumento2 pagineMechanical Measurement and Metrology PDFsuhas_SCEM0% (1)

- Exp 4 InstrumentationDocumento14 pagineExp 4 Instrumentationizzat ezmanNessuna valutazione finora

- Instrumentation and ControlDocumento53 pagineInstrumentation and ControlDaniel D Danso100% (1)

- A en 01221 00Documento56 pagineA en 01221 00prihartono_diasNessuna valutazione finora

- Scientific InstrumentsDocumento5 pagineScientific InstrumentsSanjeev ChaudharyNessuna valutazione finora

- Ryan International School SESSION 2015-16 Holidays Home Work Class-Vi Subject-EnglishDocumento3 pagineRyan International School SESSION 2015-16 Holidays Home Work Class-Vi Subject-EnglishUmang DhawanNessuna valutazione finora

- Iec62056 61header PDFDocumento8 pagineIec62056 61header PDFprajith5550% (1)

- MC602 DataSheetDocumento20 pagineMC602 DataSheetCostel CostescuNessuna valutazione finora

- Partner Juli EngineeringDocumento3 paginePartner Juli EngineeringsaidNessuna valutazione finora

- The Positioning in Uence of Dial Gauges On Their Calibration ResultsDocumento10 pagineThe Positioning in Uence of Dial Gauges On Their Calibration ResultsDwi Achmad SatrioNessuna valutazione finora