Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Blast Furnace Simulation Using DEM

Caricato da

Daniel Nasato0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

105 visualizzazioni18 pagineUsage of DEM numerical simulation to predict material flow in a Blast Furnace

Titolo originale

Blast Furnace Simulation using DEM

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoUsage of DEM numerical simulation to predict material flow in a Blast Furnace

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

105 visualizzazioni18 pagineBlast Furnace Simulation Using DEM

Caricato da

Daniel NasatoUsage of DEM numerical simulation to predict material flow in a Blast Furnace

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 18

Blast furnace load simulation using EDEM

Guilherme Defendi Vale

Anderson Baltazar Vale

Paulo de Freitas Nogueira - Vale

Daniel Schiochet Nasato - ESSS

SUMMARY

Overview - Vale

Introduction

Objectives

Conclusion

Objectives

Use EDEM to predict the material behavior when loading the

blast furnace;

Analyze the voidage distribution in the blast furnace;

Use EDEM to predict compressive forces;

Show potential of EDEM to simulate blast furnaces.

Geometry dynamics

Geometry dynamics:

3 opening (batches)

Linear translation z:

-75mm/s

Total opening time:

10 s per batch

Operating conditions

Informed by Vale:

Batch 1 (Coke):

Coke: 31.2 ton

Coke density (bulk): 500 kg/m

Batch 2 (Metal):

Sinter: 70.59 ton

Pellet: 26.91 ton

Batch 3 (Metal):

Sinter : 31.07 ton

Pellet: 20.93 ton

Metal density (bulk): 2300 kg/m

Calculated by ESSS

Material density (absolute):

Coke: 1250 kg/m

Considering a maximum

packing of 40%

500 kg/m /0.4 =1250 kg/m

Metal: 5750 kg/m

Plate Position

(displacement):

Batch 1: 300mm

Batch 2: 400mm

Batch 3: 200mm

Particle Size

Informed by Vale:

For pellet was used two fixed value from 8mm and 5mm

Pellet Size (mm) 18 8 5

Withheld (%) 0,0 97,96 2,04

Coke Size (mm) 40 37,5 30 25

Withheld (%) 69,2 12,47 14,87 3,46

Sinter Size (mm) 50 25 15 10 5

Withheld (%) 11,77 34,12 26,56 13,92 13,63

0

10

20

30

40

50

60

70

80

25 27 29 31 33 35 37 39

COKE

0,00

5,00

10,00

15,00

20,00

25,00

30,00

35,00

40,00

5 10 15 20 25 30 35 40 45 50

SINTER

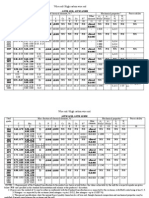

Data calibration Coeff. of Restitution

Experiments were performed at Vale, in order

to obtain correct materials data;

Coefficient of restitution, static and rolling friction

were calibrated at ESSS.

Restitution parameters calibrated based on

free fall test.

Initial Hight (cm) Return Hight (cm) Coeff of Restitution

40 0,400 0,100

40 1,270 0,178

40 1,200 0,173

40 1,000 0,158

40 1,140 0,169

40 1,300 0,180

pellet/pellet

sinter/pellet

sinter/coke

sinter/sinter

coke/pellet

coke/coke

Data calibration Static Friction

Parameters were calibrated based on normal/shear force

test.

y = 0,6574x + 8,4531

y = 0,2222x + 10,054

y = 0,6484x + 43,417

0,00

10,00

20,00

30,00

40,00

50,00

60,00

70,00

0,00 5,00 10,00 15,00 20,00 25,00 30,00 35,00

Shear Force(N)

Normal Force (N)

Sinter Pellet Coke Sinter Pellet Coke

Coke Sinter Pellet Sinter Pellet Coke

9,81 14,24 36,92 12,90 12,54 49,38 13,17

19,62 22,68 45,37 20,46 13,79 56,94 16,28

29,43 27,13 56,50 25,36 16,90 62,10 18,68

Shear Force (N)

Normal

Force (N)

Data calibration Rolling Friction

Based on repose angle, simulations were

performed to reproduce the same angle on

EDEM;

Friction coefficient were adjusted to

reproduce the repose angle.

Parameter coke/coke coke/pellet coke/sinter coke/steel pellet/pellet pellet/sinter pellet/steel sinter/sinter sinter/steel

Coeff. of Restitution 0.18 0.1 0.17 0.3 0.18 0.16 0.3 0.18 0.3

Coeff. of Static Friction 0.58 0.62 0.65 0.5 0.64 0.9 0.5 0.52 0.5

Coeff. of Rolling Friction 0.4 0.35 0.38 0.25 0.25 0.33 0.25 0.35 0.25

Material Repose angle (degree)

Coke 35 to 38

Sinter 29 to 33

Pellet 25 to 26

Simplifications

Due to real model size, it was simulated only a slice of the

real geometry;

Batch 1 (Coke):

Coke: 174.2 Kg

Batch 2 (Metal):

Sinter: 394 Kg

Pellet: 150.2 Kg

Batch 3 (Metal):

Sinter : 173.4 Kg

Pellet: 116.8 Kg

Initial conditions particle creation

It was defined a virtual area in the top of the blast furnace

to create particles.

Particles were created in a dynamic way.

Approximated 500 thousand particles simulated.

Results

Voidage Distribution

Sample points in the material bed voidage distribution

Material Distribution

Coke distribution Metal distribution

Material Distribution

Sinter distribution

Pellet distribution

Compressive Force

Compressive force can be seen in the particle bed

Compressive Force

Compressive force profile similar to coke distribution profile

Coke distribution profile Compressive force profile

Conclusions

EDEM has demonstrated the ability to reproduce real

phenomena from a large and complex model;

A furnace model was simulated in about 160 hours:

More than 500.000 Particles Simulated;

Physical results based on real Physics.

EDEM is able to generate quantitative results for blast

furnaces;

Particle size distribution, compressive force, total force, voidage.

Potrebbero piacerti anche

- Electrodynamic ShakersDocumento3 pagineElectrodynamic ShakersSathiya Moorthy100% (1)

- Unit ConversionDocumento2 pagineUnit ConversionBoy BangusNessuna valutazione finora

- Design of Sucker Rod Pumping SystemDocumento95 pagineDesign of Sucker Rod Pumping SystemAnandNessuna valutazione finora

- Bulk Density PDFDocumento15 pagineBulk Density PDFrudi rockerNessuna valutazione finora

- 40 KL DesignDocumento10 pagine40 KL DesignSung Woong MoonNessuna valutazione finora

- KilnDocumento17 pagineKilnprashant mishraNessuna valutazione finora

- FVT Fundamentals of Vacuum Technology EN58774555441f3Documento200 pagineFVT Fundamentals of Vacuum Technology EN58774555441f3velmuruganNessuna valutazione finora

- GOOD Gear Calculations Rev MEDocumento5 pagineGOOD Gear Calculations Rev MEAndi SumantriNessuna valutazione finora

- Biodiversity Assessment in PFLA 1, Mount Makiling Forest Reserve Using Various Biodiversity Assessment Methods and Monitoring TechniquesDocumento16 pagineBiodiversity Assessment in PFLA 1, Mount Makiling Forest Reserve Using Various Biodiversity Assessment Methods and Monitoring TechniquesPamela SorianoNessuna valutazione finora

- Lab ReportDocumento3 pagineLab ReportDonalyn Mae Eunice BeteNessuna valutazione finora

- Z M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Documento16 pagineZ M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Babu RajamanickamNessuna valutazione finora

- Steel Melt Shop 2 Process .Documento50 pagineSteel Melt Shop 2 Process .Rahul Pandey0% (2)

- CoreLok ManualDocumento41 pagineCoreLok ManualRafa Bernal Padilla100% (1)

- Structural Design and Erection: General RequirementsDocumento15 pagineStructural Design and Erection: General RequirementsMKPashaPashaNessuna valutazione finora

- Foundations For Auto Shredders : - Hammer / / / / / / / / / IDocumento6 pagineFoundations For Auto Shredders : - Hammer / / / / / / / / / ISandraNessuna valutazione finora

- TFE 731 Chap 77Documento12 pagineTFE 731 Chap 77Egor85Nessuna valutazione finora

- Calculation of The Torque Required To OperateDocumento3 pagineCalculation of The Torque Required To OperateOsama MohammedNessuna valutazione finora

- Charpy Impact Test: Experiment 2Documento5 pagineCharpy Impact Test: Experiment 2Utkarsh KumarNessuna valutazione finora

- Coal Quality and Its Impact On Performance: Dr. D. BanerjeeDocumento55 pagineCoal Quality and Its Impact On Performance: Dr. D. BanerjeeShubham PatelNessuna valutazione finora

- Soluble SilicatesDocumento311 pagineSoluble SilicatesSomboon BoonsomNessuna valutazione finora

- System Dynamics Simulation - RevisedDocumento63 pagineSystem Dynamics Simulation - RevisedSunny TrivediNessuna valutazione finora

- Mine Rescue Manual PDFDocumento159 pagineMine Rescue Manual PDFMariana StoenescuNessuna valutazione finora

- Flat Slide Valve With Pneumatic Actuation: Machine Manual En-23261.004-BDocumento29 pagineFlat Slide Valve With Pneumatic Actuation: Machine Manual En-23261.004-BRahmat HidayatNessuna valutazione finora

- Telescopic Chute Brochure enDocumento2 pagineTelescopic Chute Brochure enAbu Fathi Mifth Huda100% (1)

- Chapter 3Documento21 pagineChapter 3hailemebrahtuNessuna valutazione finora

- Mohs Hardness TestDocumento3 pagineMohs Hardness TestSelva KumarNessuna valutazione finora

- Comminution Ore TestingDocumento35 pagineComminution Ore TestingHarrison Antonio Mira NiloNessuna valutazione finora

- Discrete Element Method to Model 3D Continuous MaterialsDa EverandDiscrete Element Method to Model 3D Continuous MaterialsNessuna valutazione finora

- Astm D 4439 00 Standard Terminology For Geosynthetics PDFDocumento5 pagineAstm D 4439 00 Standard Terminology For Geosynthetics PDFDeyvi ManriqueNessuna valutazione finora

- 07 Elevators Deep Buckets DIN 15234 02Documento1 pagina07 Elevators Deep Buckets DIN 15234 02mkiani2Nessuna valutazione finora

- Astm D 1265Documento5 pagineAstm D 1265Jorge Kovach Alvarado50% (2)

- Kiln Shell Laser Manual 1Documento24 pagineKiln Shell Laser Manual 1uddinsalahNessuna valutazione finora

- ASTM D 854-Specific GravityDocumento7 pagineASTM D 854-Specific GravityKurnia Budi Hendrawan100% (2)

- Asme b16.47 Cl.150 SR, B - Drilling STDDocumento1 paginaAsme b16.47 Cl.150 SR, B - Drilling STDchannu rolliNessuna valutazione finora

- Dimensionamento Depolveratore A Ciclone Portata Volumetrica (m3/h)Documento2 pagineDimensionamento Depolveratore A Ciclone Portata Volumetrica (m3/h)wilderness_666Nessuna valutazione finora

- DSM ScreenDocumento2 pagineDSM ScreenAnonymous OnzJpzNessuna valutazione finora

- Chapter Five Equipment Design 5.1 Design of Vertical Ribbon MixerDocumento12 pagineChapter Five Equipment Design 5.1 Design of Vertical Ribbon MixerHamza Al MahanaNessuna valutazione finora

- Astm A24 (2001) PDFDocumento4 pagineAstm A24 (2001) PDFJim FrostNessuna valutazione finora

- Cascade Air Separator KVT enDocumento6 pagineCascade Air Separator KVT enkamjulajayNessuna valutazione finora

- FEECO Complete OfferingsDocumento8 pagineFEECO Complete OfferingsawfahNessuna valutazione finora

- Mechanical Operations PDFDocumento50 pagineMechanical Operations PDFAyush DubeyNessuna valutazione finora

- Charpy Impact TestDocumento2 pagineCharpy Impact TestAnonymous QmVGKZSM100% (1)

- Mechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期Documento1 paginaMechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期saidNessuna valutazione finora

- AISI 1050 Carbon Steel Wire AlloyDocumento1 paginaAISI 1050 Carbon Steel Wire Alloyjuprijupri25Nessuna valutazione finora

- ASTM A356 A356M - 07 Steel CastingsDocumento6 pagineASTM A356 A356M - 07 Steel CastingsMacario LeyvaNessuna valutazione finora

- LAB Manual PDFDocumento35 pagineLAB Manual PDFAbhinav Shukla100% (1)

- Application Note Hardness Testing EnglishDocumento12 pagineApplication Note Hardness Testing EnglishAnubhav LakhmaniNessuna valutazione finora

- Dura FlexDocumento2 pagineDura FlexMuktaf Ajib El WatsiNessuna valutazione finora

- A Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueDocumento3 pagineA Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueVerónica CharresNessuna valutazione finora

- Fiber TestingDocumento11 pagineFiber TestingSandy YansikuNessuna valutazione finora

- Types of AlloyDocumento2 pagineTypes of AlloyOliver Reidsil M. RojalesNessuna valutazione finora

- Deaerators BrochureDocumento4 pagineDeaerators BrochurefahimshkNessuna valutazione finora

- Amail Blain Air ManualDocumento19 pagineAmail Blain Air ManualRaviNessuna valutazione finora

- Science Raking in Gravity Thickeners PDFDocumento17 pagineScience Raking in Gravity Thickeners PDFJuan Alberto Giglio FernándezNessuna valutazione finora

- Anodic ProtectionDocumento30 pagineAnodic ProtectionChintoo GeeNessuna valutazione finora

- New Full Report PDFDocumento58 pagineNew Full Report PDFiqbal100% (1)

- Ramdas Osborne Ortt 1980 PDFDocumento10 pagineRamdas Osborne Ortt 1980 PDFSebastian PinzonNessuna valutazione finora

- Building Technologies: HVAC ProductsDocumento7 pagineBuilding Technologies: HVAC Productsshivv230Nessuna valutazione finora

- PMPa006 A Comparison of Extenders in Semi-Gloss Emulsion Paints June 2009Documento2 paginePMPa006 A Comparison of Extenders in Semi-Gloss Emulsion Paints June 2009Dian Pires100% (2)

- High Carbon Wire RodDocumento9 pagineHigh Carbon Wire Rodninganray6316100% (1)

- Lab Manual For Trommel CitDocumento2 pagineLab Manual For Trommel CitRyle ArbonNessuna valutazione finora

- SAIL BSBK Visit Docx-15.06. R-1rtfDocumento7 pagineSAIL BSBK Visit Docx-15.06. R-1rtfsssadangi100% (1)

- Mekanika Retak SedikitDocumento29 pagineMekanika Retak SedikitEko Hermawan75% (4)

- Powder Cooler - BrochureDocumento4 paginePowder Cooler - BrochureAnonymous Cxriyx9HIX100% (1)

- Linear Screen SizingDocumento4 pagineLinear Screen SizingHARIPRASADNessuna valutazione finora

- Rotary Valves ZRSDocumento7 pagineRotary Valves ZRSkosmcNessuna valutazione finora

- Mathematical Modeling and Manufacturing of Hdpe/pp Bricks Using Different Fillers by Continuous Extrusion ProcessDocumento65 pagineMathematical Modeling and Manufacturing of Hdpe/pp Bricks Using Different Fillers by Continuous Extrusion ProcessEkta ChaturvediNessuna valutazione finora

- Design Requirements of Precoat Filters For Water FiltrationDocumento445 pagineDesign Requirements of Precoat Filters For Water FiltrationYesi CeballosNessuna valutazione finora

- Filtros de Mangas para DespoeiramentoDocumento3 pagineFiltros de Mangas para DespoeiramentoEder PereiraNessuna valutazione finora

- Theories and Applications of CFD-DEM Coupling Approach For Granular Flow: A ReviewDocumento42 pagineTheories and Applications of CFD-DEM Coupling Approach For Granular Flow: A ReviewgfdczxNessuna valutazione finora

- Bin DesignDocumento14 pagineBin DesignHogar Belo HorizonteNessuna valutazione finora

- Utkarsh Sankrityayan-Effect of Particle Size Distribution On Grinding Kinetics in Dry and Wet Ball Milling OperationsDocumento26 pagineUtkarsh Sankrityayan-Effect of Particle Size Distribution On Grinding Kinetics in Dry and Wet Ball Milling OperationsUtkarsh SankrityayanNessuna valutazione finora

- Tensile Test Lab 3Documento15 pagineTensile Test Lab 3Jss Aircond & ElectricalNessuna valutazione finora

- 061 MullerDocumento18 pagine061 MullerolongkodokNessuna valutazione finora

- VEGA T For Terminal Version 1.0 - 8639080e2eDocumento6 pagineVEGA T For Terminal Version 1.0 - 8639080e2eProcurement PardisanNessuna valutazione finora

- 275kV T TS 10 001 Construction SC 2021Documento7 pagine275kV T TS 10 001 Construction SC 2021Huang HanNessuna valutazione finora

- Is 8183Documento11 pagineIs 8183Arunprasad MurugesanNessuna valutazione finora

- CE325 - 08 Consolidation TheoryDocumento25 pagineCE325 - 08 Consolidation TheoryRobert PrinceNessuna valutazione finora

- Postharvest Technology-Units Operations NotesDocumento83 paginePostharvest Technology-Units Operations Notesntjanv100% (4)

- 30.csec Maths January 2019Documento34 pagine30.csec Maths January 2019Brad CapricornNessuna valutazione finora

- Strength Analysis of Stabilized Mud Blocks IJERTCONV9IS01010Documento4 pagineStrength Analysis of Stabilized Mud Blocks IJERTCONV9IS01010Ar Faraz Faisal KhanNessuna valutazione finora

- Chap 1 Quiz AssignmentDocumento2 pagineChap 1 Quiz AssignmentHanz Gabriel DegomaNessuna valutazione finora

- Chaurette J. - Centrifugal Pump Systems Tutorial (2005)Documento63 pagineChaurette J. - Centrifugal Pump Systems Tutorial (2005)Olga ĆalasanNessuna valutazione finora

- Modeling Pyrolyzing Ablative Materials With COMSOL MultiphysicsDocumento53 pagineModeling Pyrolyzing Ablative Materials With COMSOL MultiphysicsAmir HamedNessuna valutazione finora

- 10 1016@j Jnoncrysol 2015 11 028Documento8 pagine10 1016@j Jnoncrysol 2015 11 028Renato EvangelistaNessuna valutazione finora

- D 2737 - 01 - Rdi3mzctukve PDFDocumento8 pagineD 2737 - 01 - Rdi3mzctukve PDFAndre CasteloNessuna valutazione finora

- EurokinDocumento14 pagineEurokinapitbhuNessuna valutazione finora

- Holman Wilfley Trial Report FinalDocumento46 pagineHolman Wilfley Trial Report Finalearthplight100% (1)

- CL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarDocumento7 pagineCL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarPradeep DiwakarNessuna valutazione finora

- General Physics I: Physical Quantities & Vectors Quarter 1, Module 1Documento9 pagineGeneral Physics I: Physical Quantities & Vectors Quarter 1, Module 1Denies VargasNessuna valutazione finora