Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Footings Foundations Concrete

Caricato da

RajaImran0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni7 paginelll

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentolll

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni7 pagineFootings Foundations Concrete

Caricato da

RajaImranlll

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

FOOTINGS, FOUNDATIONS, & CONCRETE

STAKING OUT HOUSE LOCATION

Stake out dimensions for the house are provided on the plot plan

Required instruments:

- measuring tape (100)

- contractors level

- transit

- plumb bob

- batter boards and stakes

- string

Staking steps:

1. ocate house corners from plot plan b! driving stakes at these spots (use the

"#1$#1% triangle to square the corners or a transit)

$. &lace batter boards ' feet off of the footing line (outside of footing)

(. Stretch string bet)een batter boards directl! above corner stakes. * line can

be painted on the ground belo) the string to outline the house. * plumb bob

is used to accuratel! locate the string over the corner stakes.

EXCAVATION

Removing the top soil is the first step in e+cavation. ,his material can be used for final

grading purposes after the footings and foundations are completed.

-+cavations for footing should e+tend either.

- at least /0 into undisturbed soil# no backfilling

- at least /0 belo) the average ma+imum frost penetration

- at least /0 into e+isting rock if the footing is sitting on bedrock

1Soil bearing conditions )ill determine the e+cavation depth and )idth

-+cavation must be )ide enough to allo) for )ork space to construct the forms

FOOTING SHAPES AND SPECIFICATIONS

2ootings increase the support capacit! of the foundation )all b! spreading the loads

over a )ider area

2ooting design ()idth and thickness) depend on the building loads and the soil bearing

capacit!

3eneral footing proportions

4t is important to take into consideration an! var!ing soil t!pes )ithin the footing area.

5ifferent soils (cla!. sand. organic. rock. etc.) respond differentl! to loading. 6ou dont

)ant differential settlement of var!ing degree occurring during construction.

ongitudinal reinforcement )ith $# 7/ bars

4n hill! terrain. stepped footings can be used as long as the height of the step is not

more than three#fourths ((8') the hori9ontal distance bet)een the steps. ,o :tie0 the

footing together. $# 7' bars should be used.

FOUNDATION WALLS

;onnects the footing to the slab or floor <oists or ma! be a basement )all

=aterials: poured concrete. concrete block. stone or brick. pressure#treated )ood

2our basic t!pes (2ig. $(.> ? ")

- ,# foundation

- Slab foundation

- &ier or post foundation

- &ermanent )ood foundation

@asement )alls must have adequate drainage at the footing to relieve h!drostatic

pressure

T-Foundation (2ig. $(.1')

=ost common t!pe.

2ootings and foundation )all are formed to be cast as a single unit

2W

W

W

Sa! "oundation (2ig. $(.$%)

4t is an e+tension of a slab floor.

,he slab and foundation are cast as one unit

*dvantages

- requires less time

- less e+pensive

- less labor time to construct

Slab foundation construction is used for interior bearing )all partitions

Pi#$ and %o&t "oundation& (2igs. $(.(0 ? (()

;ommonl! used in combination )ith ,#foundations as support for interior beams and

floor <oists.

*lso used )ith columns in a basement )here the distance is too great to span )ith floor

<oists.

* :lall!0 column is used in this situation

&ier vs. column

- ,he difference bet)een and pier and a column is the length.

- &ier are usuall! shorter and located under the house

- ;olumns are made of t)o pieces. a footing and a post (2ig. "#1A)

Wood "oundation& (2igs. $(.(" ? '0)

*B* permanent )ood foundation (&C2). all#)eather )ood foundation (*CC2). and

treated )ood foundation

* )ood foundation is a belo) grade. pressure#treated pl!)ood#sheathed stud )all.

;ommon in climates )here t!pical foundation )ork (concrete and masonr!) stops in

free9ing or )et )eather

2or cra)l space

- depth of e+cavation allo)s for $0 of sand or /0 of crushed rock that is placed

belo) the ma+imum average frost depth

- footing trench should be at least 1$0 deep and 100 to 1$0 )ide (check local

code)

- level sand and rock is essential to ensure a level floor

2or basement )alls

- bottom of footing e+cavation is covered )ith /0 to >0 of porous gravel and

leveled

- footing plates are either $+>. $+10. or $+1$ pressure#treated material

*ll fasteners (nails. brackets. etc.) must be made of silicon bron9e. copper. or hot#

dipped galvani9ed 9inc coated steel

Special caulking compounds are used to seal <oints

* pol!eth!lene film is placed on the gravel base to prevent moisture and a concrete slab

is placed on top of that

*ttention must be given to the connection of the floor <oists to the basement )alls to

correctl! transfer in)ard soil forces to the floor structure

1@ackfilling should not begin until the basement floor has cured and the first floor is

installed

CONCRETE AND 'ASONR( )ASE'ENT WALLS

Call thickness depends on lateral earth pressure (soil and h!dostatic pressure) and

vertical load (>0 minimum)

2actors influencing strength and stabilit!

- height and thickness

- mortar bond ((8>0)

- vertical load

- support from cross )alls. pilasters or )all stiffeners and support from the first

floor framing

Strong earth pressures require stiffening through.

- pilasters

- vertical and hori9ontal bar reinforcement through hollo) core block )ith

concrete

@asement )alls e+tend a minimum of >0 above finished grade (using )ood framing)

@asement )alls are slightl! shorter than first and secondar! stor! )alls

oad#bearing cross )alls are tied to e+terior )alls through metal tie bars (18'0 thick.

D0 )ide. and $>0 long)

2loor loads are distributed uniforml! along the basement )all top course of block using

- '0 solid block

- solid top block

- reinforced concrete masonr! bond beam

- cores in the top course filled )ith concrete or mortar

5amp proofing is essential# use a parge coat ($#18'0 mortar coats and hot tar or

equivalent material

Call drains and sump pumps

)EA'S AND GIRDERS

* beam or girder is used to support the floor <oists and prevent sagging.

&laced equidistant from e+terior )alls and under bearing )alls ()alls designed to

support part of the load)

@eams are either )ood or steel ()ood is t!pical for residential construction)

Cood beams are either built#up or solid

Steel beams are commonl! S#beams or C#beams ()ide flanged) 2ig. $/.10

;alculations to determine the beam si9e depends on the load the beam )ill support

Ceights are combinations of ive or 5ead loads

ive load ()# fi+ed or moving )eights not a structural part of the house

- furniture. people. sno). )ind. etc.

5ead load (5)# static or fi+ed )eights of the structure

- )eight of roof. )alls. floors. siding. <oists. foundation )alls. etc.

Simplified loads

2irst floor# E 5F %0 pounds per square foot (psf)

Second floor# E 5F %0 psf

;eiling# E 5F (0 psf

Calls# E 5F 10 psf

Roof# E 5F ,!picall! none since most load from the roof transfer directl! to the

e+terior )alls

Ceight ;alculations

See *ppendi+ @ for =athematical ;alculations for loads

,ributar! *rea# *rea supported b! a beam. girder or column and is equal to half the

span length in an! given direction

oads are based on kips (Gne kip is equal to 1000 pounds)

,ables for ma+imum allo)able loads are:

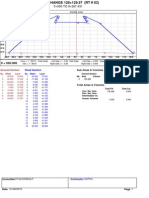

2ig. @.(>. *merican Standard 4#beams )ith lateral support (S#beams)

2ig. @#'$. *llo)able concentric loads for standard steel pipe columns

4f a span is too great. additional columns must be provided to reduce the span length

-+ample calc for beam

St$u*tu$a *o+%on#nt T$i!uta$, A$#a

-&".

Load&

-%&".

W#i/0t

-1i%&.

$nd floor %/0 %0 $>.0

1st floor %/0 %0 $>.0

1st ceiling %/0 (0 1/.>

$nd bearing )all (b)) ($0 10 (.$

1st b) ($0 10 (.$

,otal )eight on beam A".$

intels

intel# * hori9ontal structural member that supports the load over an opening such as a

door or )indo)

;onstructed of:

- precast concrete

- cast#in#place concrete

- lintel blocks

- steel angle iron

CONCRETE AND 'ASONR(

;oncrete is ordered b! the !ard ($A cubic feet F 1 !ard)

=inimum compressive strength of structural concrete is (000 pounds per square inch

(psi)

;uring time and temperature affect the curing of concrete

;oncrete reaches its ma+imum compressive strength at about $> da!s

4t must be kept moist for several da!s

,he process for placing concrete

- &our and vibrate

- Screed

- 2loat

- ,ro)el

- ;ontraction <oints

&our and Hibrate# ,he vibrating or tamping reduces the air pockets )hich reduce

strength

Screed# Ising a long straightedge. the concrete is )orked back and forth to smooth the

surface. bring e+cess )ater to the surface and settle aggregate

2loat# * short board )ith a handle and flat sides. 2loating embeds large aggregate.

removes slight imperfections. lumps and voids and consolidates mortar at the

surface

,ro)el# Rectangular and used in circular motion. ,ro)eling hardens the surface and

develops a ver! smooth surface

;ontraction <oints# ;ontrol the cracking of concrete from e+pansion and contraction due

to temperature. ,he! are placed in line )ith interior columns. at

changes in slab )idth. or at ma+imum spacing of $0 ft.

;oncrete slab floors should not be bonded to footings or columns. * 10 cushion of sand

should be provided )here the slab rests on the footing. @uilding paper (a sleeve of (

thicknesses) can be used to separate the column from the slab.

;oncrete @locks (2ig. $%.>)

Ised to form e+terior and sometimes interior )alls. ,!pical block si9e is an >0+>0+1/0.

but the actual dimensions are A %8>0 + A %8>0 + 1% %8>0. ,hese dimensions allo) for (8>0

mortar <oints.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- TDOT Section 903 PDFDocumento22 pagineTDOT Section 903 PDFRajaImranNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- McAsphalt Asphalt Technician Training ManualDocumento38 pagineMcAsphalt Asphalt Technician Training ManualRajaImran100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- SR No Description Dia No L Bar No Weight: Well Trust LLC Project: Rsidencial BuldingDocumento3 pagineSR No Description Dia No L Bar No Weight: Well Trust LLC Project: Rsidencial BuldingRajaImranNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Basis of DesignDocumento1 paginaBasis of DesignRajaImranNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Summery Total 0+100 (11 Cell)Documento3 pagineSummery Total 0+100 (11 Cell)RajaImranNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Rate Analysis IbisDocumento23 pagineRate Analysis IbisRajaImranNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Boh Finishes QtyDocumento3 pagineBoh Finishes QtyRajaImran100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Arfan CVDocumento3 pagineArfan CVRajaImranNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Recruitment English PDFDocumento16 pagineRecruitment English PDFRajaImranNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Description Shape of Bar Dia of Bar Spacing Span Cut Length # Meter Meter MeterDocumento2 pagineDescription Shape of Bar Dia of Bar Spacing Span Cut Length # Meter Meter MeterRajaImranNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Subject: Data Handover Receiving: Regards: Imran Sikandar. Quantity Surveyor. Employee No. 1806/5 Date: 02/04/2016Documento2 pagineSubject: Data Handover Receiving: Regards: Imran Sikandar. Quantity Surveyor. Employee No. 1806/5 Date: 02/04/2016RajaImranNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- China Civil Engineering Construction Corporation: Project Title: King Abdulaziz Tunnel Project (Structure Work)Documento2 pagineChina Civil Engineering Construction Corporation: Project Title: King Abdulaziz Tunnel Project (Structure Work)RajaImranNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Letter of Recommendation: Imran Sikandar B.Tech Civil Technology (Hons)Documento2 pagineLetter of Recommendation: Imran Sikandar B.Tech Civil Technology (Hons)RajaImranNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Remaining BBCDocumento30 pagineRemaining BBCRajaImranNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Center Line: Road SectionDocumento36 pagineCenter Line: Road SectionRajaImranNessuna valutazione finora

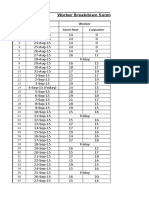

- Worker Breakdown SummaryDocumento10 pagineWorker Breakdown SummaryRajaImranNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Job Application Questionnaire Form: Sikandar ImranDocumento1 paginaJob Application Questionnaire Form: Sikandar ImranRajaImranNessuna valutazione finora

- MpaDocumento40 pagineMpaRajaImranNessuna valutazione finora

- Kingdom of Saudi Arabia: Ministry of Transport Conversion of Jeddah Jizan To Expressway Sec 3Documento12 pagineKingdom of Saudi Arabia: Ministry of Transport Conversion of Jeddah Jizan To Expressway Sec 3RajaImranNessuna valutazione finora

- New Summary Earth WorkDocumento30 pagineNew Summary Earth WorkRajaImranNessuna valutazione finora

- Ead Grammar v1Documento225 pagineEad Grammar v1RajaImranNessuna valutazione finora

- Road Section: Center LineDocumento11 pagineRoad Section: Center LineRajaImranNessuna valutazione finora

- 8 TH Linear Equations DBDocumento1 pagina8 TH Linear Equations DBParth GoyalNessuna valutazione finora

- SWAMINATHAN Ajanta RhapsodyDocumento227 pagineSWAMINATHAN Ajanta RhapsodyRoberto E. García100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- 2 MercaptoEthanolDocumento8 pagine2 MercaptoEthanolMuhamad ZakyNessuna valutazione finora

- MODULE 1 - Contemporary WorldDocumento4 pagineMODULE 1 - Contemporary WorldaapNessuna valutazione finora

- Asian RegionalismDocumento15 pagineAsian RegionalismLiezel AalaNessuna valutazione finora

- Being Agile. Staying Resilient.: ANNUAL REPORT 2021-22Documento296 pagineBeing Agile. Staying Resilient.: ANNUAL REPORT 2021-22PrabhatNessuna valutazione finora

- Understanding PumpDocumento113 pagineUnderstanding Pumpnyr1981_942955963100% (5)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- BOMA - Office Building Standard Methods of Measurement AppendixDocumento41 pagineBOMA - Office Building Standard Methods of Measurement Appendixxavest100% (7)

- TuberkulosisDocumento285 pagineTuberkulosisTeuku M. FebriansyahNessuna valutazione finora

- Śāntarak ItaDocumento8 pagineŚāntarak ItaÁtilaNessuna valutazione finora

- Algorithm Design: Figure 1. Architecture Diagram For Greykite Library's Main Forecasting Algorithm, SilverkiteDocumento3 pagineAlgorithm Design: Figure 1. Architecture Diagram For Greykite Library's Main Forecasting Algorithm, Silverkitesiper34606Nessuna valutazione finora

- Test Iii Cultural Social and Political OrganizationDocumento2 pagineTest Iii Cultural Social and Political OrganizationTin NatayNessuna valutazione finora

- Goal SettingDocumento11 pagineGoal Settingraul_mahadikNessuna valutazione finora

- Cpa f1.1 - Business Mathematics & Quantitative Methods - Study ManualDocumento573 pagineCpa f1.1 - Business Mathematics & Quantitative Methods - Study ManualMarcellin MarcaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Curriculum Vitae: Career ObjectiveDocumento3 pagineCurriculum Vitae: Career ObjectiveRākesh Rakhi100% (1)

- To Tell The TruthDocumento5 pagineTo Tell The TruthNabeel Ahmed KhanNessuna valutazione finora

- Jo - Mc.Donough. ESP in Perspective A Practical Guide. London. Collin ELT. 1984. p.3Documento6 pagineJo - Mc.Donough. ESP in Perspective A Practical Guide. London. Collin ELT. 1984. p.3Falihatul Kholidiyah100% (1)

- AnnexIIRecommendationsbyHOTCCommittee06 11 18Documento6 pagineAnnexIIRecommendationsbyHOTCCommittee06 11 18Bilal AbbasNessuna valutazione finora

- PICUDocumento107 paginePICUsarikaNessuna valutazione finora

- Ageing World ReportDocumento4 pagineAgeing World Reporttheresia anggitaNessuna valutazione finora

- Atlantis Implant Compatibility Chart 79214-US-1107Documento2 pagineAtlantis Implant Compatibility Chart 79214-US-1107Jean-Christophe PopeNessuna valutazione finora

- თინათინ ზურაბიშვილი, თვისებრივი მეთოდებიDocumento111 pagineთინათინ ზურაბიშვილი, თვისებრივი მეთოდებიNino LomaiaNessuna valutazione finora

- Firststep To AlaskaDocumento28 pagineFirststep To AlaskaBarbara NelsonNessuna valutazione finora

- STRESS HealthDocumento40 pagineSTRESS HealthHajra KhanNessuna valutazione finora

- Introduction of Woman Role in SocietyDocumento12 pagineIntroduction of Woman Role in SocietyApple DogNessuna valutazione finora

- Metro Depot: (Aar 422) Pre-Thesis SeminarDocumento3 pagineMetro Depot: (Aar 422) Pre-Thesis SeminarSri VirimchiNessuna valutazione finora

- Text Descriptive Tentang HewanDocumento15 pagineText Descriptive Tentang HewanHAPPY ARIFIANTONessuna valutazione finora

- Yazaki BrochureDocumento4 pagineYazaki Brochureguzman_10Nessuna valutazione finora

- Cover PageDocumento10 pagineCover PageAvijit GhoshNessuna valutazione finora

- The Roti Canai StoryDocumento5 pagineThe Roti Canai StoryDr Bugs TanNessuna valutazione finora

- Real Life: Construction Management Guide from A-ZDa EverandReal Life: Construction Management Guide from A-ZValutazione: 4.5 su 5 stelle4.5/5 (4)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDa EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedValutazione: 5 su 5 stelle5/5 (1)

- Process Plant Equipment: Operation, Control, and ReliabilityDa EverandProcess Plant Equipment: Operation, Control, and ReliabilityValutazione: 5 su 5 stelle5/5 (1)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (242)