Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

03 Lewabrane Manual System Design 03

Caricato da

Abraham BrayTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

03 Lewabrane Manual System Design 03

Caricato da

Abraham BrayCopyright:

Formati disponibili

DESIGN

Guidelines for the Design

of Reverse Osmosis

Membrane Systems

LANXESS

Energizing Chemistry

2

Inde

1. System Design............................................................................................................................... 3

1.1 Introduction of RO System ..................................................................................................... 3

1.1.1 Material Balance of RO System ................................................................................. 3

1.1. Single!Module System ............................................................................................... 3

1.1.3 Single!Stage System .................................................................................................. 3

1.1." Multi!Stage System .................................................................................................... 3

1.1.# $ass RO System ..................................................................................................... "

1.1.% $ermeate Blending &ith 'eed (ater ......................................................................... "

1.1.) $ermeate Recirculation .............................................................................................. "

1. Items of (ater *nalysis .......................................................................................................... "

1.3 Basic E+uations for RO Calculations ..................................................................................... #

1.3.1 (ater ,rans-ort ......................................................................................................... #

1.3. Solute ,rans-ort ......................................................................................................... %

1.3.3 Correlation of O-erating Conditions........................................................................... %

1." RO System Design .uidelines ............................................................................................... %

1.".1 'ouling ,endency &ith O-erating Conditions ............................................................ %

1.". Recommended Range of Element O-erating Conditions /Design .uideline0 .......... )

1.# Ste-s to design RO mem1rane system ................................................................................. 2

1.#.1 System Design Information and 'eed (ater ............................................................. 2

1.#. Selection of Element ,y-e and *3erage $ermeate 'lu4 ........................................... 2

1.#.3 Calculation of 5um1er of ,otal RO Elements ............................................................ 2

1.#." Decision of Reco3ery Rate......................................................................................... 2

1.#.# Decision of 5um1er of Stages ................................................................................. 16

1.#.% Decision of 5um1er of RO Elements -er $ressure 7essel ..................................... 16

1.#.) Decision of Element *rrangement ........................................................................... 11

1.#.8 Relations 1et&een 5ominal $erformances and 'ield Results................................. 11

1.#.2 Com-aring *ctual $erformance of 9e&a1rane: Elements to $ro;ection $rogram. 1

5otice< $lease note that the information and recommendations -ro3ided in this technical 1rochure do not claim to 1e

uni3ersally 3alid= in -articular> they are not meant to su1stitute> amend or su--lement the information and?or

instructions -ro3ided 1y the OEM of the RO mem1rane system and?or the facility o-erator. In fact> 9*5@ESS strongly

recommends to o1tain &ritten confirmation from the OEM of the RO system and?or the facility o-erator 1efore using

the chemicals descri1ed in our technical 1rochure> installation of the RO elements and o-eration of the RO

mem1rane system> and to 3erify the ad3ice and information -ro3ided herein in each case as to its com-ati1il ity

&ith the o3erall &ater treatment facility and RO mem1rane system.

!" System Design

!"! Introdu#tion of RO System

!"!"! Material $alan#e of RO

System

,he RO system includes a set of RO

mem1rane elements> housed in -ressure

3essels that are arranged in a design manner.

* high!-ressure -um- is used to feed the

-ressure 3essels. ,he RO system is o-erated

in crossflo& filtration mode> not in dead end

mode> 1ecause of the osmotic -ressure of

re;ected solute.

,he RO system is usually designed for

continuous o-eration and the o-erating

conditions are constant &ith time. 'igure 1.1

illustrates the material 1alance of a ty-ical RO

system. ,he feed flo& is de3ided to -ermeate

and concentrate flo&.

'igure 1.1< Material 1alance of RO system

!"!"% Single&Module System

*n RO mem1rane system consists of RO

elements arranged in -ressure 3essels. ,he

arrangement of the RO system can 1e single

or dou1le $ass &ith the s-ecific geometry of

the -ressure 3essel arrangement descri1ed in

Stages> and &ith -ressure 3essels inside a

Stage arranged in &hat is called an *rray.

Inside the -ressure 3essel> the elements are

connected se+uentially in series format &ith

u- to eight elements -er -ressure 3essel.

,he concentrate of first element 1ecomes

the feed to the second> and so on. ,he

-roduct &ater tu1es /center -i-e0 of all

elements are cou-led> and connected to the

module -ermeate -ort. In a single!module RO

system> the system reco3ery rate is a--ro4

#6A. ,his 3alue is a--lica1le to standard

single $ass sea&ater desalination systems.

,o achie3e the reco3ery rate of more than

#6A> concentrate recirculation is -erformed.

In this system configuration -art of

concentrate is recycled and added to the

suction side of the high!-ressure -um-> thus

increasing the feed flo& rate /sho&n in 'igure

1.0. * high fraction of the concentrate 1eing

recycled hel-s reduce single element

reco3ery> and thus> the risB of fouling or

scaling. On the other hand> it has design

issues that need consideration< larger high!

-ressure -um-> higher energy consum-tion

and -ermeate +uality decrease.

'igure 1.< Single module system &ith concentrate

recirculation

!"!"' Single&Stage System

In a single!stage system> t&o or more

3essels are arranged in -arallel. 'eed>

concentrate and -ermeate lines are

connected to manifolds. ,he system is in the

same case as a single!module system.

Single!stage system is ty-ically used &here

the reco3ery rate is less than #6A> e.g.> in

sea&ater desalination.

!"!"( Multi&Stage System

Systems &ith more than one stage are

used for higher system reco3ery rates &ithout

e4ceeding the single element reco3ery limit.

Csually t&o stages &ill 1e a--lied for reco3ery

rate u- to )#!86A. ,o com-ensate for the

-ermeate &hich is remo3ed and to maintain a

uniform flo& rate to each stage> the num1er of

-ressure 3essels -er stage decreases in flo&

direction. In a ty-ical t&o!stage system

/sho&n in 'igure 1.30> the ratio of 3essel

num1er is <1 /u-stream< do&nstream0.

'igure 1.3< E4am-le of nd stage system

,he relation 1et&een reco3ery rate and the

stage num1er is as follo&s<

1 stage < D #6A=

stage < D )#!86A=

3 stage < D 8#!26A

!"!") % *ass RO System

* -ass RO system is used if a 3ery high

-ermeate +uality is re+uired. In this system

configuration> the -ermeate of the 1st -ass

RO is the feed of nd -ass RO. 'igure 1."

sho&s a schematic flo& diagram of the -ass

RO system. ,he concentrate of the nd -ass

RO is recycled 1acB to the feed of 1st RO

1ecause its +uality is usually 1etter than the

system feed &ater. *nd 1ecause the feed of

the nd RO is high +uality> the reco3ery of the

nd -ass RO can 1e as high as ma4imum

/26!2#A0.

'igure 1."< -ass RO system

!"!"+ *ermeate $lending ,ith

-eed .ater

$ermeate 1lending is ado-ted &hen a

certain salinity of -ermeate is re+uested e.g.

drinBing &ater. In this case> some additional

system feed &ater /1lending flo&0 is taBen and

added to the -ermeate /sho&n in 'igure 1.#0.

By ado-ting this system> num1er of RO

element can 1e decreased.

'igure 1.#< $ermeate 1lending system of a t&o stage

system

!"!"/ *ermeate Re#ir#ulation

In the case that the feed tem-erature

greatly differs /e.g. summer and &inter0> the

feed -ressure should 1e changed to Bee- the

-ermeate constant. ,his change in feed

-ressure may cause -ermeate +uality

insta1ility. ,o -re3ent the insta1ility> a -art of

the -ermeate is recycled and added to the

suction side of the high!-ressure -um-

/sho&n in 'igure 1.%0> &hen the -ermeate flo&

is higher than the estimated 3alue. By Bee-ing

the feed -ressure constant> the -ermeate

+uality is Be-t constant.

'igure 1.%< $ermeate recirculation of a t&o stage

system

!"% Items of .ater Analysis

,he ma;or &ater ty-es treated 1y RO

mem1rane are roughly di3ided into sea&ater>

1racBish &ater> &aste&ater> munici-al &ater

and RO -ermeate. In addition> these &ater

ty-es are finely classified 1y the ty-e of

-retreatment /natural or artificial0. (ith

res-ect to ,DS concentration> 3#>666 mg?l is

considered to 1e the standard.

Eo&e3er> the actual ,DS concentration

may 3ary from )>666 mg?l u- to "#>666 mg?l.

,he com-osition may 1e -ro-ortionally

estimated from the standard sea&ater

com-osition /sho&n in ,a1le 1.10.

(hereas the com-osition of 1racBish &ater

and &aste&ater may 1e e4tremely &ide in

3ariation> and accordingly> feed &ater analysis

is 3ery im-ortant for a good -rocess design.

Because in 1racBish &ater desalination>

calcium car1onate and silica scale are

fre+uent occurrences> at least concentrate of

,DS> calcium ion> 1icar1onate ion /alBalinity0>

silica and -E 3alue are needed to design RO

-rocess. If the &ater analysis is not 1alanced>

!"' $asi# E0uations for RO

1al#ulations

!"'"! .ater 2rans3ort

(ater trans-ort through the mem1rane is

e4-ressed as a -ermeate flu4. ,he flu4 is

generally defined as the 3olumetric flo& rate

of &ater through a gi3en mem1rane area. In

the case of RO> the unit of flu4 is e4-ressed

as liters of &ater -er s+uare meter of

mem1rane area -er hour /lmh0 or gallons -er

s+uare foot -er day /gfd0. ,he -ermeate flu4 is

-ro-ortional to the net dri3ing -ressure /5D$0.

the addition of either sodium ion or chloride

ion to achie3e electroneutrality is

recommended.

Jv = A NDP

NDP = P 0.5

dp

/1.10

/1.0

In &hich<

differential

P = P

f

P

p

> -ressure

= (C

fave

) (C

p

) > a3erage

osmotic -ressure differential

F

7

> -ermeate flu4> *> &ater -ermea1ility

/s-ecific flu40> 5D$> net dri3ing -ressure

$

f

> feed -ressure> $

-

> -ermeate -ressure>

$

c

> concentrate -ressure> d-> -ressure dro-

/C

a3e

0> a3erage feed osmotic -ressure>

/C

-

0> -ermeate osmotic -ressure

C

f

> feed concentration> C

-

> -ermeate

concentration> Cc> concentrate concentration

C

fave

= (C

f

concentration

+ C

c

) / 2 > a3erage feed

5D$ is calculated 1y -ressure difference>

osmotic -ressure difference and -ressure

dro-. ,he a3erage feed concentration /feed

and concentrate0 is used to calculate osmotic

-ressure.

,a1le 1.1< Standard sea&ater com-osition

,he -roduct flo& rate can 1e o1tained 1y

multi-lying the -ermeate flu4 1y total

mem1rane area.

Q

p

= M

A

J

V

/1.30

the o-erating conditions influencing the RO

-erformances as follo&s<

In

&hich<

Ion Concentration /mg?l0

Calcium "6

Magnesium 1>36

Sodium 16>886

$otassium "66

Barium 6.63

Strontium 16

Iron D 6.6

Manganese D 6.61

Silica .6

Chloride 12>866

Sulfate >%%6

'luoride 1.3

Bromide %#

5itrate D 6.)

Bicar1onate 1#6

Boron "!#

,DS /,otal Dissol3ed

Solid0

3#>666

-E 8.1 G 8. /!0

H-> -roduct flo& rate> M

*

> total mem1rane

area

A

S

= A

n

TCF

1

SCF

1

FF

/1.80

,he -ressure dro- is calculated 1y the

a3erage flo& rate /feed and concentrate0 as

follo&s<

SP

s

= SP

n

{(J

V

)

n

/( J

V

)

s

}TCF

2

SCF

2

/1.20

In &hich<

dp = a {(Q + Q ) /

2}

b

/1."0

*

S

> s-ecific flu4 at o-erating conditions>

In &hich a and 1 are coefficients> s-ecific

for element and feed s-acer configuration.

,he 3alues for these coefficients are o1tained

e4-erimentally.

!"'"% Solute 2rans3ort

Solute trans-ort through an RO mem1rane

is e4-ressed as a solute flu4. ,his solute flu4

is -ro-ortional to the concentration difference

across the mem1rane. ,he a3erage feed

concentration /feed and concentrate0 is used

in the feed side to calculate solute trans-ort.

*nd the rate of solute trans-ort is defined 1y

re;ection or salt -assage as follo&s<

*

n

> s-ecific flu4 at nominal conditions

S$

S

> salt -assage at o-erating conditions>

S$

n

> salt -assage at nominal conditions

/F

7

0

n

> -ermeate flu4 at o-erating

conditions> /F

7

0

n

> -ermeate flu4 at nominal

conditions

,C'> correlation factor of tem-erature /1=

on s-ecific flu4> = on salt -assage0

SC'> correlation factor of feed

concentration /1= on s-ecific flu4> = on salt

-assage0

''> fouling factor

J

S

= B (C

fave

C

p

)

R = 1 (C

p

/ C

fave

)

SP = 1 R = C

p

/ C

fave

In &hich<

/1.#0

/1.%0

/1.)0

In com-uter -rogramming> estimated

-erformance 1ased on the nominal 3alue is

automatically calculated 1y using a1o3e

e+uations.

!"( RO System Design

Guidelines

F

S

> solute flu4> B> solute -ermea1ility> R>

re;ection> S$> salt -assage

Re;ection and salt -assage are usually

e4-ressed as -ercent.

!"'"' 1orrelation of O3erating

1onditions

RO mem1rane system -erformance /flu4

and re;ection or salt -assage0 is influenced 1y

o-erating conditions such as o-erating

-ressure> tem-erature> feed concentration etc.

So the -arameters of RO -erformance

/s-ecific flu4 and salt -assage0 are re3ised 1y

!"("! -ouling 2enden#y ,ith

O3erating 1onditions

,he factor &hich has the greatest influence

on the RO system design guideline is the

fouling tendency of the feed &ater. Mem1rane

fouling is caused 1y -articles and colloidal

materials &hich are -resent in the feed &ater

and 1ecome concentrated at the mem1rane

surface. ,he Silt Density Inde4 /SDI0 of

-retreated feed &ater is an inde4 of the fouling

-otential of -article or colloidal materials in the

RO system. ,he concentration of the fouling

materials at the mem1rane surface increases

&ith increasing -ermeate flu4> increasing

f c

element reco3ery and decreasing concentrate

flo& rate. ,herefore the a3erage -ermeate flu4

of the RO system /total -roduct flo& rate

di3ided 1y total mem1rane area0 should 1e

lo& if a strong fouling en3ironment is

antici-ated.

!"("% Re#ommended Range of

Element O3erating

1onditions 4Design

Guideline5

,he RO mem1rane system should 1e

designed such that each element of the

system o-erates &ithin the recommended

o-erating conditions to minimize the fouling

-ossi1ility> and to e4clude mechanical

damage. ,he limiting conditions are the

ma4imum reco3ery /system and element0> the

ma4imum a3erage -ermeate flu4> the

minimum concentrate flo& rate> the ma4imum

feed flo& rate> the ma4imum lead element

-ermeate flu4> and so on. ,he higher the

fouling tendency of the feed &ater> the limits

of the -arameters 1ecome stricter.

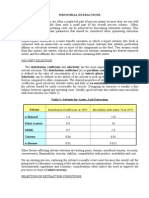

,a1le 1. sho&s the range of these

-arameters according to the ty-e of the feed

&ater and the ty-e of -retreatment. ,he

mem1rane -retreatment im-ro3es the feed

&ater +uality in 3ie& of the fouling. In the ta1le

the -arameter of mem1rane -erformance

changes &ith time is added /flu4 decline rate

and salt -assage increase0.

,he range of -arameters sho&n in the

ta1le is recommended 3alue to minimize the

fouling -ossi1ility> 1ut it does not mean that

the system design out of the -arameter range

is im-ossi1le. It means that the -ossi1ility of

the fouling 1ecomes higher.

Lead

Element

*ermeate

-lu

Average

*ermeate

-lu

1on#en&

trate -lo,

Rate

*ressure

Dro3 3er

6essel

Element

Re#overy

Rate

-lu

De#line

Rate

Salt

*assage

In#rease

-eed .ater

2y3e

-eed -lo,

Rate

Munici-al

Su--ly

/12!#0

D 3 I 3.% D 13 D .6 D 1# I 16 I 16

BracBish (ells

2

/#!330

D "3 I 3.6 D 1% D 3.6 D 6 I ) I 16

Surface (ater

Media 'iltration

1

/18!"0

D 31 I 3.% D 13 D .6 D 1# I 16 I 16

Surface (ater

M'?C'

'iltration

)

/3!20

D 32 I 3.6 D 1# D 3.6 D 1) I ) I 16

Secondary

(aste

Media 'iltration

11

/2!130

D 12 I 3.% D 1 D .6 D 1 I 1# I 1#

Secondary

(aste

M'?C'

'iltration

1)

/13!60

D # I 3.% D 13 D .6 D 13 I 1# I 16

Sea&ater

IntaBe

Media 'iltration

1"

/1!1%0

D 8 I 3.% D 1" D .6 D 16 I 16 I 16

Sea&ater

IntaBe

M'?C'

'iltration

1)

/1#!120

D 3 I 3.% D 1" D 3.6 D 1 I 16 I 16

Sea&ater

Beach (ells

1)

/1#!120

D 3# I 3.% D 1# D 3.6 D 1 I ) I 16

RO $ermeate

3#

/36!320

D "8 I ." D 1) D 3.6 D 36 I 3 I #

,a1le 1.< RO system design guideline

8

9

!") Ste3s to design RO

gi3en. ,he 9*5@ESS recommended design

:

membrane system

flu4 3alues for 9e&a1rane RO mem1rane

!")"! System Design Information

and -eed .ater

,he RO mem1rane system highly de-ends

on the a3aila1le feed &ater. ,herefore> the

system design information /customer?OEM>

re+uired -roduct flo& rate> e4-ected reco3ery

rate> annual &ater tem-erature> &ater source>

a--lication> -retreatment> re+uired -roduct

&ater +uality> o-erating -ressure limit> etc.0

and the feed &ater analysis should 1e

thoroughly studied and considered in selection

elements are listed in ,a1le 1.. In some

cases> the design flu4 3alue is determined 1y

-ilot e4-eriment data or customerJs

e4-erience.

!")"' 1al#ulation of Number of

2otal RO Elements

,he relationshi- 1et&een the num1er of

total elements> the -roduct flo& rate and the

a3erage -ermeate flu4 is e4-ressed as follo&

e+uation<

of the RO system design. If the re+uired

-ermeate &ater +uality is so high that the

+uality cannot 1e achie3ed 1y 1-ass RO

system> and then a -ass RO system should

1e considered. *s an alternati3e to the -ass

RO> an ion e4change resin system may also

1e a 3ia1le design o-tion.

!")"% Sele#tion of Element 2y3e

N

E

=Q

p

/ J

V ,ave

(M

A

)

E

In &hich<

5

E

K total element num1ers

H

-

K -roduct flo& rate

F

7> a3e

K a3erage -ermeate flu4

/3.160

and Average *ermeate -lu

*ccording to the feed &ater source>

-retreatment and feed &ater salinity> the ty-e

of RO mem1rane element is selected. ,he

relationshi- 1et&een the feed salinity and

general selection of RO element is sho&n in

,a1le 1.3. In the case that the RO feed &ater

is a &aste&ater> the lo& fouling RO element

may 1e also 1e considered.

/M

*

0

E

K mem1rane area of element /as

sho&n in data sheet0

,he calculated num1er of RO elements

may 1e a slightly changed 1ased on the

decision of element arrangement> that is> the

num1er of -ressure 3essels and RO elements

-er -ressure 3essel.

!")"( De#ision of Re#overy Rate

9o& conc. BracBish &ater

/u- to #66mg?l0

BracBish &ater /u- to

< B(RO /9o& energy0

In an RO mem1rane system> a reco3ery

rate as high as -ossi1le is desira1le> 1ut a

high reco3ery rate can also cause some

#>666 mg?l0

< B(RO /Standard0

BracBish &ater /more

-ro1lems as follo&s<

than #>666 mg?l0>

Sea&ater

< S(RO

$ossi1ility of scale formation increase

1ecause of the increase of

concentration factor

,a1le 1.3< Selection of RO element according to the

feed salinity

Once the &ater source> -retreatment and

RO element ty-e are fi4ed 1y the designer>

the recommended 3alue of the a3erage

-ermeate flu4 /also called Ldesign flu4M0 is

Osmotic -ressure increase 1ecause of

the increase of concentration factor

Concentrate flo& rate decrease

$ermeate &ater +uality deterioration

1ecause of a3erage feed

concentration increase

Re#overy Rate 1on#entration -a#tor

10

#6A

)#A "

86A #

26A 16

,a1le 1."< Relationshi- 1et&een Reco3ery Rate and

Concentration 'actor

,he relationshi- 1et&een reco3ery rate

and concentration factor is sho&n in ,a1le

1.".

Csually in 1racBish &ater desalination> the

reco3ery rate is decided 1y scale formation>

and in sea&ater desalination> 1y feed

-ressure limit. Some customers often re+uire

the highest -ossi1le reco3ery rate> 1ut in that

case> the 3alue of the reco3ery rate should 1e

decided 1y considering the -otential for the

a1o3e -ro1lems.

!")") De#ision of Number of

Stages

,he num1er of RO stages defines ho&

many -ressure 3essels are in series in the RO

mem1rane system. E3ery stage consists of a

certain num1er of -ressure 3essels in -arallel.

,he num1er of stages is a function of the

system reco3ery rate> the num1er of elements

-er 3essel> and the feed &ater +uality sho&n

in ,a1le 1.#.

!")"+ De#ision of Number of RO

Elements 3er *ressure

6essel

RO mem1rane elements can 1e cou-led

together in series in the -ressure 3essel>

ty-ically 1!8 elements -er one -ressure

3essel. In deciding the num1er of RO

elements -er -ressure 3essel> -lant size is

usually considered first. In a large!scale -lant

/I "6 m3?h0> %!8 elements -er -ressure 3essel

are usually ado-ted> and in a smaller -lant> 3!

# elements -er -ressure 3essel. In all cases>

the s-ace re+uired to install or remo3e the RO

elements should 1e considered in the -lant

design.

By increasing the num1er of RO elements

-er -ressure 3essel> almost all RO design

-arameters &ill change. RO design

-arameters are a3erage -ermeate flu4> lead

element -ermeate flu4> concentrate flo& rate>

feed flo& rate> indi3idual element reco3ery

rate> and -ressure dro- -er 3essel> etc.. Some

factors im-ro3e /1ecome desira1le0 and some

factors 1ecome &orse /undesira1le0. ,a1le

1.% sho&s RO system design -arameters and

the correlation 1et&een an increase in num1er

of RO element -er -ressure 3essel> and

change in RO system design -arameters. It is

recommended that these -arameters are in

accordance &ith the design guideline /,a1le

1.%0.

1 stage system< D #6A

Csual reco3ery S(RO /D #6A0

stage system< D )#!86A

Csual reco3ery B(RO /D 86A0

Eigh reco3ery S(RO /D %6A0

Eigh reco3ery nd -ass /D 26A0

3 stage system< D 8#!26A

Eigh reco3ery B(RO /D 26A0

Eigh reco3ery nd -ass /D 2#A0

/s-ecial case0

S(RO< sea&ater desalination> B(RO<

BracBish &ater desalination

,a1le 1.#< Relationshi- 1et&een reco3ery rate

and num1er of RO stage

RO System

Design *arameters

Effe#t of in#reasing number of

Elements76essel

8udgement of

the effe#t

*3erage $ermeate 'lu4 Same 5o change

9ead Element 'lu4 9arger Cndesira1le

Concentrate 'lo& Rate -er

7essel

9arger Desira1le

'eed 'lo& Rate -er 7essel 9arger Cndesira1le

$ressure Dro- -er 7essel 9arger Cndesira1le

$ressure Dro- -er Element 9arger Cndesira1le

Reco3ery Rate of Element Smaller Desira1le

Reco3ery Rate of System Same 5o change

5um1er of 7essel Smaller Desira1le

,a1le 1.%< Effects of changing the RO design

!")"/ De#ision of Element

Arrangement

,he RO element arrangement /array0

means element num1ers -er 3essel> 3essel

num1ers -er stage and stage num1ers -er

-ass. 'or the decision of element

arrangement> the system design -arameters

should 1e consistent &ith the design flu4

guideline. Eo&e3er> not all the -arameters are

suita1le to the guideline. In the case that not

e3ery -arameter is in accordance &ith the

design guideline> it is necessary to maBe a

-riority in the -arameters. Csually a3erage

-ermeate flu4> concentrate flo& rate and

-ressure dro- -er 3essel should 1e of higher

-riority.

,o decide the array> se3eral calculations

for case study should 1e done 1y com-uter

-rogram and these results should 1e

com-ared. Some case studies should 1e done

&ith the consideration of different o-erating

conditions /feed concentration> tem-erature>

etc.0 or -erformance changes &ith time. 'or

each ty-ical case> a com-arison should 1e

done in consideration of 3alue of design

-arameter> the num1ers of RO elements or

-ressure 3essel> and satisfying the customers

demand /-roduct &ater +uality> limit of feed

-ressure etc.0.

!")"9 Relations bet,een Nominal

*erforman#es and -ield

Results

,he relationshi- 1et&een nominal

-erformances /data sheet 3alues0 and actual

field results are as follo&s<

a0 (ith same mem1rane area and at the

same nominal test conditions> a higher

nominal flo& rate element &ill re+uire lo&er

feed -ressure.

10 *t different test conditions and ?or

different mem1rane area> feed -ressure &ill

1e defined 1y &ater -ermea1ility /s-ecific

flu40.

c0 (ith the same mem1rane area> the

same nominal test conditions> and the same

-ermeate flo& rate> a higher salt re;ection

element &ill -roduce a -ermeate of lo&er

salinity.

d0 *t different mem1rane area and? or

nominal test conditions> a lo&er relati3e salt

-assage element /multi-lier of nominal

-ermeate flu4 1y nominal salt -assage0 &ill

-roduce a -ermeate of lo&er salinity.

e0 ,he nominal -ermeate flu4 /catalogue

3alue0 is usually +uite large /large enough that

it &ill not cause mem1rane fouling0>

,herefore> the a3erage -ermeate flu4 in

actual field 1ecomes smaller than the nominal

-ermeate flu4.

!")": 1om3aring A#tual

*erforman#e of Le,abrane;

Elements to *ro<e#tion

*rogram

,he 9e&a$lus

,M

-ro;ection -rogram is a

tool used to estimate sta1ilized -erformance

for a s-ecific RO mem1rane system under

design or actual conditions. ,he -ro;ected RO

mem1rane system -erformance is 1ased on a

nominal -erformance s-ecification for the

9e&a1rane: elements used in the gi3en

system. * fouling factor of 1 in the -ro;ection

-rogram is used to calculate the -erformance

of ne& elements 1ased on the nominal flo&

rate /data sheet 3alue0. * fouling factor of D 1

should 1e used &hen maBing a design for

long!term o-eration.

In the actual RO mem1rane system> the

RO elements may ha3e a flo& rate 3ariation of

N?!1#A of the nominal 3alue> or &hate3er

3ariation is s-ecified for a gi3en element ty-e.

*lso> the salt re;ection of an indi3idual element

may 1e higher or lo&er than the nominal salt

re;ection /1ut more than the minimum 3alue0.

,herefore> the measured sta1ilized

-erformance is unliBely to 1e e4actly the same

as the com-uter -ro;ected -erformance> 1ut

as a rule of thum1> the com-uter -ro;ection for

RO systems &ith more than 3% ne& elements

should come close to the com-uter design

-ro;ection.

,he actual fouling factor of a sta1ilized ne&

RO system &ith at least 3% elements should

range 1et&een 6.2# and 1.6#. ,he actual

measured ,DS 3alue of -ermeate should 1e

no higher than a1out 1.# times the calculated

,DS 3alue. 'or RO mem1rane systems &ith

only one> or a fe& elements> the de3iation of

the measured actual -erformance from the

-ro;ected -erformance may 1ecome as large

as the s-ecified -erformance 3ariation.

DIS1LAIMER

Eealth and Safety Information< *--ro-riate

literature has 1een assem1led &hich -ro3ides

information concerning the health and safety

-recautions that must 1e o1ser3ed &hen

handling the 9*5@ESS -roducts mentioned in

this -u1lication. 'or materials mentioned

&hich are not 9*5@ESS -roducts> a--ro-riate

industrial hygiene and other safety

-recautions recommended 1y their

manufacturers should 1e follo&ed. Before

&orBing &ith any of these -roducts> you must

read and 1ecome familiar &ith the a3aila1le

information on their hazards> -ro-er use and

handling. ,his cannot 1e o3erem-hasized.

Information is a3aila1le in se3eral forms> e.g.>

material safety data sheets> -roduct

information and -roduct la1els. Consult your

9*5@ESS re-resentati3e in .ermany or

contact the Regulatory *ffairs and $roduct

Safety De-artment of 9*5@ESS Deutschland

.m1E or ! for 1usiness in the CS* ! the

9*5@ESS $roduct Safety and Regulatory

*ffairs De-artment in $itts1urgh> $*> CS*.

Regulatory Com-liance Information< Some

of the end uses of the -roducts descri1ed in

this -u1lication must com-ly &ith a--lica1le

regulations> such as the 'D*> BfR> 5S'>

CSD*> and C$SC. If you ha3e any +uestions

on the regulatory status of these -roducts>

contact ! for 1usiness in the CS* ! your

9*5@ESS Cor-oration re-resentati3e> the

9*5@ESS Regulatory *ffairs Manager in

$itts1urgh> $*> CS* or for 1usiness outside

CS the Regulatory *ffairs and $roduct Safety

De-artment of 9*5@ESS Deutschland .m1E

in .ermany.

,he manner in &hich you use and the

-ur-ose to &hich you -ut and utilize our

-roducts> technical assistance and information

/&hether 3er1al> &ritten or 1y &ay of

-roduction e3aluations0> including any

suggested formulations and recommendations

are 1eyond our control.

,herefore> it is im-erati3e that you test our

-roducts> technical assistance and information

to determine to your o&n satisfaction &hether

they are suita1le for your intended uses and

a--lications. ,his a--lication!s-ecific analysis

must at least include testing to determine

suita1ility from a technical as &ell as health>

safety> and en3ironmental stand-oint. Such

testing has not necessarily 1een done 1y us.

Cnless &e other&ise agree in &riting> all

-roducts are sold strictly -ursuant to the terms

of our standard conditions of sale. *ll

information and technical assistance is gi3en

&ithout &arranty or guarantee and is su1;ect

to change &ithout notice. It is e4-ressly

understood and agreed that you assume and

here1y e4-ressly release us from all lia1ility>

in tort> contract or other&ise> incurred in

connection &ith the use of our -roducts>

technical assistance> and information.

*ny statement or recommendation not

contained herein is unauthorized and shall not

1ind us. 5othing herein shall 1e construed as

a recommendation to use any -roduct in

conflict &ith -atents co3ering any material or

its use. 5o license is im-lied or in fact granted

under the claims of any -atent.

O 61 G *ll Rights Reser3ed

9*5@ESS Deutschland .m1E

1ON2A12

9*5@ESS Deutschland .m1E

Business Cnit Ion E4change Resins

Chem-arB 9e3erBusen

#13%2 9e3erBusen> .ermany

Email< l e & a1ra n e P l an 4 e s s .c o m

Edition= Octo1er 61

Potrebbero piacerti anche

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceDa EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNessuna valutazione finora

- Batch and Semi-batch Reactors: Practical Guides in Chemical EngineeringDa EverandBatch and Semi-batch Reactors: Practical Guides in Chemical EngineeringNessuna valutazione finora

- 03 Lewabrane Manual System Design 03Documento13 pagine03 Lewabrane Manual System Design 03zamijakaNessuna valutazione finora

- Plug Flow vs Concentrate RecirculationDocumento4 paginePlug Flow vs Concentrate Recirculationtatoo1Nessuna valutazione finora

- Design Criteria SBRDocumento8 pagineDesign Criteria SBRmah61Nessuna valutazione finora

- Steps To Design RO SystemDocumento5 pagineSteps To Design RO SystemBiljana TausanovicNessuna valutazione finora

- Mass Balance Analysis TechniquesDocumento8 pagineMass Balance Analysis TechniquesJef PerezNessuna valutazione finora

- Osmosis Manual EnglishDocumento46 pagineOsmosis Manual EnglishIacob Daniel100% (1)

- Analyzer Best Practices SRU TGTUDocumento25 pagineAnalyzer Best Practices SRU TGTUoujda1977Nessuna valutazione finora

- Liquid-Liquid Extraction Optimization GuideDocumento8 pagineLiquid-Liquid Extraction Optimization Guideananth2012Nessuna valutazione finora

- Flow of Discussion - Title DefenseDocumento3 pagineFlow of Discussion - Title DefenseFrancis DacutananNessuna valutazione finora

- Presentation 1Documento22 paginePresentation 1Faizal YaacobNessuna valutazione finora

- Recycling Effect on Steady State SystemDocumento31 pagineRecycling Effect on Steady State SystemJim100% (2)

- Reverse Osmosis User's Manual: ModelDocumento28 pagineReverse Osmosis User's Manual: ModelHamid SuliamanNessuna valutazione finora

- Adv 885 Ro Pac M QuickrefguideDocumento8 pagineAdv 885 Ro Pac M QuickrefguideAlejandroOdioCastilloNessuna valutazione finora

- RO & NF Performance Calculations GuideDocumento5 pagineRO & NF Performance Calculations GuideLoka GaneshanNessuna valutazione finora

- Precoating: Precoating or Body-MixDocumento52 paginePrecoating: Precoating or Body-MixsreenuNessuna valutazione finora

- Boiler Water Treatment Chemicals, Feed, and Control - Perhaps It Is More Complicated Than We ThoughtDocumento14 pagineBoiler Water Treatment Chemicals, Feed, and Control - Perhaps It Is More Complicated Than We ThoughtDiego Soto SandovalNessuna valutazione finora

- Isopropyl Alcohol PurificationDocumento13 pagineIsopropyl Alcohol PurificationMiraj savaniNessuna valutazione finora

- Environmental Code of Practice For Elimination of Fluorocarbon EmissionsDocumento8 pagineEnvironmental Code of Practice For Elimination of Fluorocarbon EmissionsPassmore DubeNessuna valutazione finora

- Complexity of EA - 1Documento7 pagineComplexity of EA - 1Don BakerNessuna valutazione finora

- Operation and Control of STPDocumento11 pagineOperation and Control of STPHari Krishna.MNessuna valutazione finora

- Summative Mass Closure: Laboratory Analytical Procedure (LAP) Review and IntegrationDocumento14 pagineSummative Mass Closure: Laboratory Analytical Procedure (LAP) Review and IntegrationanurdiaNessuna valutazione finora

- Top Ten Frequently Asked Questions On Feeder AccuracyDocumento12 pagineTop Ten Frequently Asked Questions On Feeder AccuracyfakhriNessuna valutazione finora

- MODELS OF IMPERFECTLY MIXED REACTORSDocumento7 pagineMODELS OF IMPERFECTLY MIXED REACTORSBlessy Gabayno100% (1)

- Manual_IfU_ReUse-Line_2737353-000-00_-eDocumento18 pagineManual_IfU_ReUse-Line_2737353-000-00_-eMartín BenzoNessuna valutazione finora

- Waste in ReactorsDocumento4 pagineWaste in ReactorsjamesNessuna valutazione finora

- Best-Practises RO PlantDocumento25 pagineBest-Practises RO PlantjdadhaNessuna valutazione finora

- Mass Balance PDFDocumento8 pagineMass Balance PDFssfoodtechNessuna valutazione finora

- Session V - Energy & Environmental Management: A. Sulfur Recovery 1. Amine PlantsDocumento32 pagineSession V - Energy & Environmental Management: A. Sulfur Recovery 1. Amine PlantsMallela Sampath KumarNessuna valutazione finora

- PP ControlDocumento32 paginePP Controlhasan099Nessuna valutazione finora

- Polye-304 Polymer Reaction Engineering: Dr.M.Bilal Manzoor Polymer and Process Engineering Uet, LahoreDocumento11 paginePolye-304 Polymer Reaction Engineering: Dr.M.Bilal Manzoor Polymer and Process Engineering Uet, LahoreNabeelAhmadKhanNessuna valutazione finora

- PST 522E – Synthesis and Characterization of Macromolecules by GPCDocumento17 paginePST 522E – Synthesis and Characterization of Macromolecules by GPCilknurNessuna valutazione finora

- 969 Final QDocumento11 pagine969 Final QMuhammad MusharrafNessuna valutazione finora

- Water Softeners Residential ProFloSXT Downflow Upflow Valve Softeners US ManualDocumento16 pagineWater Softeners Residential ProFloSXT Downflow Upflow Valve Softeners US ManualPromagEnviro.comNessuna valutazione finora

- Rotor-Stator Devices: The Role of Shear and The StatorDocumento16 pagineRotor-Stator Devices: The Role of Shear and The StatorwidhisaputrawijayaNessuna valutazione finora

- Operasi Anaerobic DigesterDocumento34 pagineOperasi Anaerobic DigesterRatih Dwi AnggraeniNessuna valutazione finora

- Water Filters Residential 5600SXT Chemical Free Iron Filters ENGLISH Canadian ManualDocumento18 pagineWater Filters Residential 5600SXT Chemical Free Iron Filters ENGLISH Canadian ManualPromagEnviro.comNessuna valutazione finora

- A Model For Flotation Processes, AMINPRO, August 2007Documento16 pagineA Model For Flotation Processes, AMINPRO, August 2007JFSFNessuna valutazione finora

- Water Filters Residential 5600SXT Activated Carbon Filters ENGLISH Canadian ManualDocumento12 pagineWater Filters Residential 5600SXT Activated Carbon Filters ENGLISH Canadian ManualPromagEnviro.comNessuna valutazione finora

- White Paper c01742311Documento19 pagineWhite Paper c01742311atanusenNessuna valutazione finora

- Vacuum PanDocumento7 pagineVacuum Pananon_33049728Nessuna valutazione finora

- Bulletin 826E: HPLC Troubleshooting GuideDocumento20 pagineBulletin 826E: HPLC Troubleshooting GuideHuynh Ghi NaNessuna valutazione finora

- 5 Reactor Control SystemsDocumento40 pagine5 Reactor Control SystemssyafiqNessuna valutazione finora

- Pressure-Sensing Line Problems and SolutionsDocumento10 paginePressure-Sensing Line Problems and SolutionsAhmad Adel El TantawyNessuna valutazione finora

- Volatile Organic Compounds in Various Sample Matrices Using Equilibrium Headspace AnalysisDocumento25 pagineVolatile Organic Compounds in Various Sample Matrices Using Equilibrium Headspace AnalysisBianny Gempell Velarde PazNessuna valutazione finora

- Distillation Column Control DesignDocumento22 pagineDistillation Column Control DesignAnand Dudheliya0% (1)

- Tutorial Exp 4Documento4 pagineTutorial Exp 4Faris Hamir100% (4)

- Chapter 00 - OverviewDocumento7 pagineChapter 00 - OverviewLeonardo Octavio Olarte SánchezNessuna valutazione finora

- Simulation Based Synthesis, Design and Optimization of Actual Pressure Swing Adsorption (PSA) UnitDocumento10 pagineSimulation Based Synthesis, Design and Optimization of Actual Pressure Swing Adsorption (PSA) UnitGustavo PalaciosNessuna valutazione finora

- 1.technical Traits of Extractive Distillation With Salt in SolventDocumento6 pagine1.technical Traits of Extractive Distillation With Salt in SolventlaunajeraNessuna valutazione finora

- Packed Beds BulletinDocumento27 paginePacked Beds BulletinKrunal BhosaleNessuna valutazione finora

- Boiler Water Management Guidelines For Black Liquor Recovery Boilers (April 2016)Documento58 pagineBoiler Water Management Guidelines For Black Liquor Recovery Boilers (April 2016)OsniNessuna valutazione finora

- Mass BalanceDocumento9 pagineMass Balancerr1819Nessuna valutazione finora

- Solve The Five Most Common FCC ProblemsDocumento21 pagineSolve The Five Most Common FCC ProblemsOMID464Nessuna valutazione finora

- Draw Frames Auto LevellersDocumento4 pagineDraw Frames Auto LevellersSENTHIL KUMARNessuna valutazione finora

- Controlling The Addition of Chlorine Into A ProcessDocumento4 pagineControlling The Addition of Chlorine Into A Processfreddyxx2010Nessuna valutazione finora

- Robust adaptive control of sucker-rod pumping systemDocumento6 pagineRobust adaptive control of sucker-rod pumping systemMohamed GhareebNessuna valutazione finora

- Rheology of Dispersions: Principles and ApplicationsDa EverandRheology of Dispersions: Principles and ApplicationsNessuna valutazione finora

- Advanced Temperature Measurement and Control, Second EditionDa EverandAdvanced Temperature Measurement and Control, Second EditionNessuna valutazione finora

- Organic Chemistry Worksheet 4Documento4 pagineOrganic Chemistry Worksheet 4tun1123tNessuna valutazione finora

- Metal Forming ProcessesDocumento52 pagineMetal Forming ProcessesJoaNessuna valutazione finora

- GCE Chemistry Mark SchemeDocumento23 pagineGCE Chemistry Mark SchemeraaaaaawrNessuna valutazione finora

- Alkhalaf 2019Documento15 pagineAlkhalaf 2019Christian Echeverri ZapataNessuna valutazione finora

- High-N Causes Cast Iron CracksDocumento3 pagineHigh-N Causes Cast Iron CracksGh AbadiNessuna valutazione finora

- Isomers 101Documento26 pagineIsomers 101krisnuNessuna valutazione finora

- Lect 5 - Liquefaction - 2015 PDFDocumento6 pagineLect 5 - Liquefaction - 2015 PDFAnonymous oqlnO8e100% (1)

- Au 178 Ic Oscs Heparin Lpn2715 enDocumento6 pagineAu 178 Ic Oscs Heparin Lpn2715 enHendy Dwi WarmikoNessuna valutazione finora

- Oow Duties Wet CargoDocumento28 pagineOow Duties Wet CargoJhon FernandesNessuna valutazione finora

- Nomenclature of Polyfunctional Organic CompoundsDocumento19 pagineNomenclature of Polyfunctional Organic CompoundsH to O ChemistryNessuna valutazione finora

- Chemical Equilibrium and Le Chatelier's Principle: Chemistry 1Documento17 pagineChemical Equilibrium and Le Chatelier's Principle: Chemistry 1azamatNessuna valutazione finora

- Boiler Water ChemistryDocumento60 pagineBoiler Water ChemistryBhargav Chaudhari93% (14)

- Adisive Tape MFG Flow Chart PDFDocumento19 pagineAdisive Tape MFG Flow Chart PDFRedicle ConsultantsNessuna valutazione finora

- PetrochemicalDocumento3 paginePetrochemicalVidhi DaveNessuna valutazione finora

- Ncert Solutions Class 9 Science Chapter 3Documento8 pagineNcert Solutions Class 9 Science Chapter 3Mukesh KharbNessuna valutazione finora

- 1.2.4 HDG - Painting Issues PDFDocumento2 pagine1.2.4 HDG - Painting Issues PDFAnonymous 1AAjd0Nessuna valutazione finora

- Reviewer 1 PDFDocumento4 pagineReviewer 1 PDFNorjiel BrandinoNessuna valutazione finora

- Mühlen Sohn: Airslide FabricsDocumento9 pagineMühlen Sohn: Airslide FabricsengfaridmalkNessuna valutazione finora

- Powders Cogne MXDocumento5 paginePowders Cogne MXhamidrezachamaniNessuna valutazione finora

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocumento2 pagineAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNessuna valutazione finora

- Litesse IDocumento1 paginaLitesse IAnthonyPonceParedesNessuna valutazione finora

- Report Icce Tanznia 2829.07 .16 1Documento42 pagineReport Icce Tanznia 2829.07 .16 1bissauNessuna valutazione finora

- High Performance Thin Layer ChromatographyDocumento69 pagineHigh Performance Thin Layer ChromatographyAliefanugerahsani Attabe100% (1)

- NEW Tablet Manufacturing Process PDFDocumento32 pagineNEW Tablet Manufacturing Process PDFShmmon Ahmad0% (1)

- Pre-Medical All India Major Test Series (Phase-I & Ii)Documento4 paginePre-Medical All India Major Test Series (Phase-I & Ii)Tejas DhandaNessuna valutazione finora

- High Pressure Acid Leaching of A Refractory Lateritic Nickel OreDocumento10 pagineHigh Pressure Acid Leaching of A Refractory Lateritic Nickel OreFabian MansillaNessuna valutazione finora

- FreseDocumento140 pagineFresea9r8f4g5d4s8r0% (1)

- A532A532M-10 (2014) Standard Specification For Abrasion-Resistant Cast IronsDocumento4 pagineA532A532M-10 (2014) Standard Specification For Abrasion-Resistant Cast Ironsalexander zuritaNessuna valutazione finora

- Aerospace Material Specification: (R) Gas Nitriding of Low-Alloy Steel PartsDocumento10 pagineAerospace Material Specification: (R) Gas Nitriding of Low-Alloy Steel PartsVIJAY YADAVNessuna valutazione finora

- Standardization of Acids and BasesDocumento37 pagineStandardization of Acids and BasesNarayanRajNessuna valutazione finora