Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Interior Motives Seat Trim 201110 Tcm1023 197896

Caricato da

Kev LatCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Interior Motives Seat Trim 201110 Tcm1023 197896

Caricato da

Kev LatCopyright:

Formati disponibili

4

VISTAGY, Inc.

Product type: CAD/engineering software

Global HQ: Waltham, Massachusetts, USA

Opened: 1991

Web: www.vistagy.com

In todays hyper-competitive automotive industry, theres no

substitute for getting new designs to market quickly. This is equally

true for seat trim covers, which play an important role in dening

the aesthetics of vehicle interiors. Faurecia, the sixth largest

automotive supplier in the world, recognized the need to improve

the speed, efciency, and quality of its seat trim process, and

found the answer in VISTAGYs Seat Design Environment (SDE)

software (pictured here in use by Faurecia designers).

1

VISTAGY, Inc. is a leading global provider of industry-specic engineering software and services that

enable engineers to efciently create rich product descriptions for better-informed decision-making

early in development. The Massachusetts-based company (founded in 1991) has sales and support

ofces throughout North and South America, Asia and Europe, and boasts nearly 300 customers

and over 4,500 software users. SDE is the rst seat design software application to address the entire

seat engineering process. It allows engineers to capture a complete digital product denition of a

seat system, accurately and efciently share design detail, increase the reuse of engineering data and

eliminate extensive physical prototyping. That is why companies such as Faurecia Group, General

Motors and Lear use SDE to reduce cost, improve quality, and cut time to market.

2

SDE enabled Faurecia to cut the time it took to develop the rst prototype of a seat trim cover by 20

percent, provided a master model that was tailored to the needs of the seat trim engineer, increased

the accuracy of its bids, and reduced the cost of the entire process. Theres no question that SDE has

transformed our seat trim cover processes and enhanced our competitiveness, says Nicolas Michot,

manager of Faurecias R&D Seat Division and senior trim expert. Faurecia, which is based in Nanterre,

France, has four business groups: Automotive Seating, Emissions Control Technologies, Interior

Systems, and Automotive Exteriors. The company works with many of the worlds leading automotive

manufacturers, including Volkswagen, PSA-Peugeot-Citroen, Ford, Renault-Nissan and BMW.

3

1

2

5

3 4

58 autumn 2011

4 Pictured here are seats designed by Faurecia

for the Mitsubishi Colt, created using VISTAGYs

SDE software in conjunction with the CATIA

V5 platform. Based on our comparison, SDE

offered the best compatibility with all systems

used by Faurecia and allows the most intelligent

design-to-manufacturing process, says Michot.

Typically, the automotive seat trim cover process

starts with a bid. OEMs provide suppliers with a

seat trim outline and ask them to provide pricing

and a delivery date. Having the ability to generate

a bid quickly and accurately enables suppliers

to identify product costs and producibility issues

as soon as possible and make any necessary

changes. SDE facilitates this process because

it has a utility for exporting data directly into a

suppliers or OEMs cost model, thus enabling it

to quickly calculate a bid based on its parameters

and requirements. The best part of SDE is that it

provides us with an early calculation of the cover

cost, which gives us a competitive advantage,

especially when submitting a bid, says Michot. It

also enables us to react quickly to manufacturing

issues. SDE helped us reduce the cost of the

entire design-to-manufacturing process.

Theres no

question that

SDE has

transformed our

seat trim cover

processes and

enhanced our

competitiveness

Nicolas Michot,

Faurecia R&D

Seat Division

Prior to implementing SDE, Faurecia used a

2D CAD process with work being performed

manually. The foam was developed rst and

then the at patterns for the seat trim cover were

created by hand, which greatly increased the

time it took to develop the patterns. Using SDE,

engineers are able to deliver the rst pattern

more quickly because they can create it virtually

without the foam. With SDE, the foam pad can

be built in parallel. Current 3D CAD systems

provide the necessary geometry, but not a way

to easily author the non-geometric data required

to fully dene a seat trim cover which requires

5,000 bits of data for a single seat cushion,

backrest, and headrest. Since SDE is fully

integrated into commercial 3D CAD systems,

its possible to capture geometric and non-

geometric data in a way that is perfectly intuitive

to seat trim engineers. Creating a CAD-based

master model enables engineers to spend

more time on designing and innovating, rather

than doing non-value added tasks, such as re-

entering data, creating drawings, and manually

generating at patterns. If a rm wants to be

competitive in the worlds automotive market, it

must enable its engineering and design teams

to easily author and share information and

expertise, points out Michot. A common

CAD-based interface for trim design makes it

easier to have common engineering processes

for sharing information, improvements, and

best practices. The importance of the master

model is magnied in the supply chain

currently, there is no efcient way for data to be

exchanged between OEMs, Tier 1 and Tier 2

suppliers. Using a detailed CAD master model

facilitates faster interaction between OEMs and

suppliers by allowing more detailed data-driven

communication about design, manufacturing

challenges and costs. Ultimately, Faurecia

found that the key to developing a more

efcient process was using a CAD-integrated

environment where geometric and non-

geometric information could be captured and

linked within a single master model, allowing

engineers and other key personnel to efciently

create and modify trim cover product denitions

and associated manufacturing and nancial

data. In the highly competitive world of seat trim

covers, that kind of efciency pays off.

5

59 autumn 2011

Potrebbero piacerti anche

- CAD Engineering Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #3Da EverandCAD Engineering Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #3Valutazione: 4.5 su 5 stelle4.5/5 (4)

- CATIA ICEM Shape Design Brochure PDFDocumento4 pagineCATIA ICEM Shape Design Brochure PDFCalin PopaNessuna valutazione finora

- Strategies For Mass CustomizationDocumento8 pagineStrategies For Mass CustomizationMirza SinanovicNessuna valutazione finora

- PLM Softwares: American Motors CorporationDocumento5 paginePLM Softwares: American Motors CorporationAkansha KalraNessuna valutazione finora

- Visi 20shoes USWebDocumento2 pagineVisi 20shoes USWebkimo480Nessuna valutazione finora

- What Is Catia Mechanical EngineeringDocumento3 pagineWhat Is Catia Mechanical EngineeringDhyan AcademyNessuna valutazione finora

- Digital Model DefinitionDocumento3 pagineDigital Model DefinitionMilin JainNessuna valutazione finora

- Geometric Newsletter July2012Documento8 pagineGeometric Newsletter July2012Rajesh P ParvekarNessuna valutazione finora

- Siemens PLM EASi Cs z3Documento2 pagineSiemens PLM EASi Cs z3rasgeetsinghNessuna valutazione finora

- Proctor and Gamble Case StudyDocumento2 pagineProctor and Gamble Case StudyMahendra Chauhan0% (1)

- Future of CAD CAMDocumento7 pagineFuture of CAD CAMtuongnvNessuna valutazione finora

- modeFRONTIER - Formula Sae UsersDocumento2 paginemodeFRONTIER - Formula Sae UsersEstecoNessuna valutazione finora

- Digital ManufacturingDocumento33 pagineDigital ManufacturingRakeshSaini100% (1)

- Term Paper of Mechanical SciencesDocumento12 pagineTerm Paper of Mechanical SciencesamitmaheshpurNessuna valutazione finora

- Report F1 SteeringDocumento7 pagineReport F1 SteeringMuhammad AsyrafNessuna valutazione finora

- Aerosport Case StudyDocumento3 pagineAerosport Case StudykadiravanNessuna valutazione finora

- Business in Focus: Burner Systems International: Improving Collaboration With Product Data Management (PDM)Documento8 pagineBusiness in Focus: Burner Systems International: Improving Collaboration With Product Data Management (PDM)Nihit SandNessuna valutazione finora

- CATIA ICEM Shape Design BrochureDocumento5 pagineCATIA ICEM Shape Design Brochureva79inNessuna valutazione finora

- Solid Edge. Design BetterDocumento8 pagineSolid Edge. Design Betterprashant6942Nessuna valutazione finora

- Tech Clarity IssueinFocus CAD PLMDocumento11 pagineTech Clarity IssueinFocus CAD PLMMit GuptaNessuna valutazione finora

- 37.cad &necessary Hardware Embeddedsystem Design ImplementationDocumento6 pagine37.cad &necessary Hardware Embeddedsystem Design ImplementationSoundarya SvsNessuna valutazione finora

- 3D: Designing Competitive Advantage.Documento9 pagine3D: Designing Competitive Advantage.Bruno GraneroNessuna valutazione finora

- MDBSDocumento14 pagineMDBSApurva MalikNessuna valutazione finora

- About AprioriDocumento15 pagineAbout Aprioriswapnil pandeNessuna valutazione finora

- Strategies For MassDocumento7 pagineStrategies For MassMirza SinanovicNessuna valutazione finora

- TargetZeroDefect News Release Distrib 11 June 2013 FINALDocumento2 pagineTargetZeroDefect News Release Distrib 11 June 2013 FINALomar_3dxNessuna valutazione finora

- Flowfront 2004apr LRDocumento32 pagineFlowfront 2004apr LRgipszjakabNessuna valutazione finora

- Computer Aided DesignDocumento51 pagineComputer Aided DesignshranjuNessuna valutazione finora

- CATIA For Mold and Die WhitepaperDocumento10 pagineCATIA For Mold and Die WhitepapercaioltbgNessuna valutazione finora

- FHGJHDocumento32 pagineFHGJHthrilok SuryaNessuna valutazione finora

- LCI Report Config - EnglDocumento19 pagineLCI Report Config - EnglMihai Cristian LascuNessuna valutazione finora

- Computers in EngineeringDocumento4 pagineComputers in EngineeringIvanNessuna valutazione finora

- Computers in EngineeringDocumento4 pagineComputers in EngineeringIvanNessuna valutazione finora

- Virtual Reality As A Tool For Verification of AsseDocumento26 pagineVirtual Reality As A Tool For Verification of AsseValentina ScarabinoNessuna valutazione finora

- Microsoft Connected Vehicle Platform Whitepaper en USDocumento17 pagineMicrosoft Connected Vehicle Platform Whitepaper en USPratik SharmaNessuna valutazione finora

- Digital Prototyping For Industrial Machinery ManufacturersDocumento2 pagineDigital Prototyping For Industrial Machinery ManufacturersSaravanan Kumar PNessuna valutazione finora

- ABCO Case StudyDocumento3 pagineABCO Case StudykadiravanNessuna valutazione finora

- Applicationofcomputerintextilemanufacturing 190922145900Documento63 pagineApplicationofcomputerintextilemanufacturing 190922145900arif hasanNessuna valutazione finora

- CAD/CAM Technologies - VR HeadsetDocumento10 pagineCAD/CAM Technologies - VR HeadsetChristian PiponidesNessuna valutazione finora

- Discussion CADCAMDocumento3 pagineDiscussion CADCAMAnonymous OyZEvN03MFNessuna valutazione finora

- Cad/Cam: Md. Mazharul HelalDocumento42 pagineCad/Cam: Md. Mazharul HelalGreen University TextileNessuna valutazione finora

- The Application of Pro Engineer in CADCAMDocumento9 pagineThe Application of Pro Engineer in CADCAMHafiezul HassanNessuna valutazione finora

- Application of Computer in Textile ManufacturingDocumento32 pagineApplication of Computer in Textile ManufacturingMd NurunnabiNessuna valutazione finora

- Unit IDocumento6 pagineUnit IDhaneshNessuna valutazione finora

- White Paper - The Future of Parametric Design Is Collaboration - ESPpdfDocumento26 pagineWhite Paper - The Future of Parametric Design Is Collaboration - ESPpdfPixelPlotNessuna valutazione finora

- Cad Cam PDFDocumento4 pagineCad Cam PDFAmishaNessuna valutazione finora

- CS Eicher Engineering SolutionsDocumento3 pagineCS Eicher Engineering SolutionsPutra Imam ArisfadillahNessuna valutazione finora

- Research Reprot 1Documento7 pagineResearch Reprot 1Siyeon YeungNessuna valutazione finora

- Tata Nano CaseDocumento3 pagineTata Nano CaseGaurav GodaraNessuna valutazione finora

- DELMIA Virtual Ergonomics TataDocumento2 pagineDELMIA Virtual Ergonomics TataJordi V FerrandizNessuna valutazione finora

- IS1105: Impact of Information Systems On The Automobile IndustryDocumento12 pagineIS1105: Impact of Information Systems On The Automobile Industrypkchukiss100% (7)

- TATA NANO Section1 Group7Documento3 pagineTATA NANO Section1 Group7Vineet KhandelwalNessuna valutazione finora

- Volkswagen PR - English - FINAL 030707Documento2 pagineVolkswagen PR - English - FINAL 030707Lvar UstoNessuna valutazione finora

- Tata NanoDocumento2 pagineTata NanoRajalakshmi MuthukrishnanNessuna valutazione finora

- Ac 2008-708: Digital Manufacturing and Simulation CurriculumDocumento12 pagineAc 2008-708: Digital Manufacturing and Simulation CurriculumBhavesh ShiyaniNessuna valutazione finora

- Automotive Software Development Reliability and SaftyDocumento26 pagineAutomotive Software Development Reliability and SaftyCășeriu BiancaNessuna valutazione finora

- Se Synch Tech2 Top 10reasons WP W16Documento18 pagineSe Synch Tech2 Top 10reasons WP W16Ferney AlexisNessuna valutazione finora

- T3.QS Software ApplicationDocumento64 pagineT3.QS Software Application槐序初夏Nessuna valutazione finora

- Gov - Uk: Check If You Need A UK VisaDocumento2 pagineGov - Uk: Check If You Need A UK VisaKev LatNessuna valutazione finora

- Tesis Example LunDocumento77 pagineTesis Example LunKev LatNessuna valutazione finora

- IELTS Handbook 2007Documento22 pagineIELTS Handbook 2007srikwaits4u100% (15)

- Transforming Transformation in Higher EducationDocumento13 pagineTransforming Transformation in Higher EducationKev LatNessuna valutazione finora

- KYDEX ColorPaletteDocumento3 pagineKYDEX ColorPaletteKev Lat100% (1)

- Polip CatalogueDocumento28 paginePolip CatalogueKev LatNessuna valutazione finora

- 2015-2016 Western Washington University CatalogDocumento1.443 pagine2015-2016 Western Washington University CatalogKev LatNessuna valutazione finora

- 6 Keys For Turning Your Company Into A Design PowerhouseDocumento5 pagine6 Keys For Turning Your Company Into A Design PowerhouseKev LatNessuna valutazione finora

- The50 Things Every Creative Should Know PDFDocumento21 pagineThe50 Things Every Creative Should Know PDFKev LatNessuna valutazione finora

- Better by DesignDocumento36 pagineBetter by DesignKev LatNessuna valutazione finora

- Adidias Design Head InerviewDocumento7 pagineAdidias Design Head InerviewKev LatNessuna valutazione finora

- FastenersDocumento3 pagineFastenersAniruddha KulkarniNessuna valutazione finora

- PDMVSPLM 2010 Eng FinalDocumento7 paginePDMVSPLM 2010 Eng FinalKev LatNessuna valutazione finora

- SW-PLM Whitepaper 2012Documento12 pagineSW-PLM Whitepaper 2012Kev LatNessuna valutazione finora

- Reporte Eco InventorDocumento11 pagineReporte Eco InventorKev LatNessuna valutazione finora

- Design Process Design InnovationDocumento4 pagineDesign Process Design InnovationKev LatNessuna valutazione finora

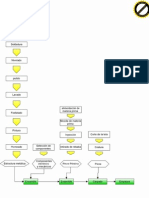

- Diagrama de Proceso de Fabricación y EnsambleDocumento1 paginaDiagrama de Proceso de Fabricación y EnsambleKev LatNessuna valutazione finora

- CI3704: Civil 3D Survey: What Is Behind The Curtain?: Seth CohenDocumento63 pagineCI3704: Civil 3D Survey: What Is Behind The Curtain?: Seth CohenRiChard AnDreeNessuna valutazione finora

- #2. C2-Product DesignDocumento14 pagine#2. C2-Product DesignHashane PereraNessuna valutazione finora

- Resume of Sameer Kadam IEDocumento4 pagineResume of Sameer Kadam IEsameerNessuna valutazione finora

- TLE ICT Technical Drafting Grade 10 TG PDFDocumento42 pagineTLE ICT Technical Drafting Grade 10 TG PDFRayNessuna valutazione finora

- Passenger Boats and Yachts Interior Design - Course SyllabusDocumento4 paginePassenger Boats and Yachts Interior Design - Course SyllabusArt Matters S.A.Nessuna valutazione finora

- WP Braided Corrugated HoseDocumento23 pagineWP Braided Corrugated HoseKARTHIK PILLAINessuna valutazione finora

- B-TD - GRade 10 - LM - Module 3 Preparing Computer-Aided Drawing PDFDocumento81 pagineB-TD - GRade 10 - LM - Module 3 Preparing Computer-Aided Drawing PDFKyle Domenden GacusanaNessuna valutazione finora

- Plant Integrity Case Study Teletest Focus SystemDocumento1 paginaPlant Integrity Case Study Teletest Focus SystemhcmcrlhoNessuna valutazione finora

- PTC Design Engineers With Simulation 2Documento19 paginePTC Design Engineers With Simulation 2Ashish ParasharNessuna valutazione finora

- My Portfolio MBDocumento25 pagineMy Portfolio MBKoti Subba Nara ArjunNessuna valutazione finora

- Operating Instructions Lava Design 5.0 US ComplexDocumento85 pagineOperating Instructions Lava Design 5.0 US ComplexAlexander EliboNessuna valutazione finora

- Creo Simulation CapabilitiesDocumento8 pagineCreo Simulation CapabilitiesIvan CastilloNessuna valutazione finora

- Advanced CAD ModelingDocumento259 pagineAdvanced CAD ModelingMarianoNessuna valutazione finora

- Autocad Part 1Documento1.000 pagineAutocad Part 1Anonymous 9qKdViDP4Nessuna valutazione finora

- Cad Cam NotesDocumento21 pagineCad Cam NotesarivaazhiNessuna valutazione finora

- Regras Tecnicas 2022 2023Documento36 pagineRegras Tecnicas 2022 2023Rui SilvaNessuna valutazione finora

- StrucadTraining Manual v10 PDFDocumento290 pagineStrucadTraining Manual v10 PDFPeceTo 2013100% (1)

- The Blender Bros - Game Asset GuideDocumento2 pagineThe Blender Bros - Game Asset Guidegimaxah pahedNessuna valutazione finora

- PDDDocumento33 paginePDDDamotharan Sathesh KumarNessuna valutazione finora

- LaserQC Brochure PDFDocumento4 pagineLaserQC Brochure PDFChandan A SNessuna valutazione finora

- Hand 3D Model: 3D Models Register Login TOP 500 NEW 500Documento1 paginaHand 3D Model: 3D Models Register Login TOP 500 NEW 500Srinivas NiceNessuna valutazione finora

- Dom Equ and Sys Eng Sol v5r18 enDocumento20 pagineDom Equ and Sys Eng Sol v5r18 enbelal MahmoudNessuna valutazione finora

- Datasheet AVEVA PID 07-20 FINAL - Pdf.coredownloadDocumento6 pagineDatasheet AVEVA PID 07-20 FINAL - Pdf.coredownloadDark KnightNessuna valutazione finora

- Welding RobotDocumento2 pagineWelding RobotengrodeNessuna valutazione finora

- Ravikant Training ReportDocumento43 pagineRavikant Training ReportRajan RoyNessuna valutazione finora

- Idiot's Guides 3D Printing by Cameron Coward - 2015Documento302 pagineIdiot's Guides 3D Printing by Cameron Coward - 2015Angel Miranda100% (3)

- Introduction To CAD CAM MasterCAMDocumento28 pagineIntroduction To CAD CAM MasterCAMMuhammad TausiqueNessuna valutazione finora

- ImplantDocumento12 pagineImplantmesescuNessuna valutazione finora

- 300039Documento7 pagine300039jagg_studNessuna valutazione finora

- NX Advanced Simulation Fs W 9 - tcm841-4362Documento9 pagineNX Advanced Simulation Fs W 9 - tcm841-4362Thyagaraj A HNessuna valutazione finora