Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ARB 3438100 Fitting

Caricato da

thailanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ARB 3438100 Fitting

Caricato da

thailanCopyright:

Formati disponibili

26-11-08 REV C Page 1 of 7 3783048

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA: (08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

PART No 3438100

ARB NISSAN NAVARA COMBINATION BULL BAR TO SUIT BOTH

SRS AND NON-SRS EQUIPED VEHICLES.

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE INSTRUCTIONS

USING ONLY THE HARDWARE SUPPLIED.

IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT, CONTACT YOUR

NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR MODIFICATIONS TO THE

IMPACT ABSORTION SYSTEM MUST NO BE ATTEMPTED.

DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL, OTHER THAN

THOSE SPECIFIED BY ARB

DO NOT REMOVE LABELS FROM THIS BULL BAR.

THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

26-11-08 REVB Page 2 of 7 3783048

FITTING KIT NUMBER 6171790

USE PART No QTY DESCRIPTION

4581072 4 WASHER FLAT M6 CONTROL BOX TO

CONTROL BOX BRACKET

3756293 1 CONTROL BOX BRACKET

6151021 3 BOLT M8 X 20mm

4581044 3 WASHER FLAT M8

4581046 3 WASHER SPRING M8

6151303 4 M8 CAGE NUT

EG50 1 GROMMET RUBBER

CONTROL BOX TO BULL BAR

180302 4 CABLE TIES

3756538R 1 IMPACT ABSORBER RHS

3756538L 1 IMPACT ABSORBER LHS

6151095 2 BOLT M12 X 1.25 X 35mm

4581007 4 WASHER FLAT X 1 X 4mm

4581050 2 WASHER SPRING M12

6151135 2 NUT M12 X 1.25

4581290 4 WASHER M12 X 28 X 4mm

6151089 4 BOLT M10 X 1.25 X 40mm

4581040 4 WASHER FLAT M10

IMPACT ABSORBER TO CHASSIS

4581048 4 WASHER SPRING M10

6151232 6 BOLT M10 X 1.5 X 30

4581040 12 WASHER FLAT M10

4581048 6 WASHER SPRING M10

BULL BAR TO IMPACT ABSORBER

6151026 6 NUT M10 X 1.5

6151301 2 NUT CAGE M8

6151300 4 NUT CAGE M6

6151021 2 BOLT M8 X 20mm

4581044 2 WASHER FLAT M8

4581046 2 WASHER SPRING M8

6151213 4 BOLT M6 X 20mm BLACK

4581082 4 WASHER FLAT M6 BLACK

4581287 4 WASHER SPRING M6 BLACK

6151180 8 BOLT M6 X 20mm

6151046 8 WASHER FLAT M6

6151128 8 NUT FLANGE M6

3500200 1 BUFFER KIT (LH & RH WITH FLANGE NUTS

3162455 2 PLASTIC CAPS

3751313 1 BRACKET NUMBER PLATE

6781408 1 DOUBLE SIDED TAPE

AIR GUIDE, STONE GUARD,

NUMBER PLATE TO BULL BAR

6522027 1 STONE TRAY

BLB560 3 CABLE BLACK 560mm WINCH CABLES, INDICATORS

3500080 1 ARB INDICATOR KIT

TOOLS REQUIRED, Basic tool kit, drill, 10mm drill bit and circlips pliers.

READ ALL INSTRUCTIONS BEFORE PROCEDING WITH BULL BAR FITMENT

1. Fit the M6 cage nuts to lower pan of the bull bar

and the M8 cage nuts to the impact absorbers.

1a. M6 CAGE NUTS IN LOWER PAN

1b. M8 CAGE NUTS IN IMPACT ABSORBER.

1c. TO INSERT CAGE NUTS, PUT ONE SIDE IN

AND SQUEESE WHILE PRESSING DOWN.

2. Fit buffers to the bull bar using the 8mm nyloc

nuts and heavy-duty flat washers. (Do not over

tighten)

3. Fit indicators into the bar.

4. If no winch is being fitted fit the plastic caps

into both sides of the bar. If a winch is being

installed fit a plastic cap to the LHS wing only.

5. If a winch is not being fitted place double sided

tape across the back of the number plate and

fix in place to the lower holes in the bull bar

using 2 M6 x 20mm bolts, M6 flat washers and

M6 flange nuts.

ASSEMBLY SEQUENCE FOR WINCH INSTALATION

6. Remove the cover from the control box.

Remove the three main power cables that go

from the control box to the winch and replace

with the longer cables (BLB560) from the bolt

kit. MAKE SURE THAT YOU LABEL THE

NEW CABLES THE SAME AS THE CABLES

REMOVED FROM THE CONTROL BAX.

1a 1b

1c

26-11-08 REVB Page 3 of 7 3783048

7. Fit the rubber grommet into the control box

bracket as shown opposite.

8. Fit the control box bracket to the control box

using the 4 large M6 flat washers placed either

side of the bracket and secure using the original

nuts. Finger tighten only at this stage.

9. Fit the control box cables through the rubber

grommet of the control box bracket and cable

tie together.

10. Secure the control box to the inside of the bull

bar using 3 M8 x 20mm bolts; M8 flat washers

and M8 spring washers. Finger tighten only.

11. When the control box is secured to the bull bar,

adjust the control box so that the remote cap is

central in the cutout in the wing. When satisfied

tighten the control box to control box bracket

bolts and the control box bracket to bull bar

bolts.

Insert 4 cage nuts as

shown

26-11-08 REVB Page 4 of 7 3783048

12. To place the winch clutch handle in the correct

position and for ease of operation, the handle

must be rotated 144 in a clockwise direction.

Undo and remove all the capped head screws from the

gearbox end. Gently raise the gearbox just enough to

allow rotation .DO NOT COMPLETELY REMOVE THE

GEARBOX. Refit all capped head screws and tighten.

13. Place the winch on a stand with the mounting

holes facing upwards. Lower the bull bar onto

the winch. NOTE: THE WINCH MUST BE

LINED UP SO THAT WHEN ATTACHED TO

THE BAR THE CABLE SPOOLS FROM THE

BOTTOM OF THE WINCH. Align all four holes

and secure the top holes using the hardware

supplied with the winch. Finger tighten only.

14. Remove the circlips form the lower end of the

roller fairlead and position roller fairlead over

lower holes in bull bar cutout. Secure using

hardware supplied with the winch. Tighten all

bolts.

3

26-11-08 REVB Page 5 of 7 3783048

TIGHTEN LOWER BOLTS REPLACE CIRCLIP AFTER TIGHTENING BOLTS

REMOVE LOWER CIRCLIPS PUSH ROLLER SIDEWAYS FOR CLEARANCE

15. Connect the winch control box cables to the

winch. Refer to the Warn installation instruction

manual when wiring up winch.

USING CABLE TIES ENSURE THAT ALL CABLES

ARE INSTALLED WELL CLEAR OF ALL SHARP OR

MOVING PARTS.

16. Attach the impact absorbers to the bullbar using

four M10 x 30mm bolts, M10 nuts, M10 flat and

spring washers Do not fully tighten the bolts at

this stage.

17. Remove the bumper bar from the vehicle and

discard the bolts used to hold the bumper bar in

place.

18. Using the assistance of two people, position the

bull bar over the chassis rails. Insert the square

4mm washers between the chassis and the

impact absorber and fix in place using four M10

x 40mm bolts, M10 flat and spring washers.

Tighten bolts.

19. Secure the lower bull bar mounting holes to the

vehicle tie down plates using M12 x 35mm

bolts, heavy-duty flat washers, spring washers

and 12mm nuts. Tighten bolts until the heavy-

duty washers deform.

26-11-08 REVB Page 6 of 7 3783048

20. Position the bull bar so that a uniform gap is

obtained on either side and there is between 20

and 25mm gap between the wing and the

mudguard tighten the four bolts holding the bar

to the impact absorbers.

21. Using a 10mm drill bit, drill a pinning hole

through the impact absorber using the lower

hole in the upright as a guide and then fix using

two M10 x 30mm bolts, M10 flat and spring

washers. Tighten bolts.

22. Attach the stone guard to the vehicle using four

M6 x 20mm black bolts, M6 black flat and spring

washers along the front of the stone guard and

two M8 x 20 mm bolts M8 flat and spring

washers underneath.

FUNCTION

INDICATOR

HARNESS

VEHICLE

HARNESS

EARTH

BROWN

BLACK

AMBER

LENSE

BLUE

GREEN

23. Connect the wires of the indicator harness

supplied to the wires on the vehicles

combination lamp as per the table opposite

using the scotch locks provided.

NOTE: Remove the vehicles combination lamps as

follows. Remove the bolt from the top of the lamp into

the headlamp body. Remove the grill and the two bolts

located on the inside edge of the headlamp body.

Carefully pull the lamp forward. Cable tie any excess

wire harness to the hole located on the return fold of the

bar below the headlight.

Mounting holes for the use of a high lift jack

have been incorporated on both sides of the

bull bar.

26-11-08 REVB Page 7 of 7 3783048

Potrebbero piacerti anche

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDa EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesValutazione: 5 su 5 stelle5/5 (1)

- Timing Cover 190EDocumento8 pagineTiming Cover 190ESergio Belmar CrisostoNessuna valutazione finora

- Bedienungsanleitung Owner'S Handbook Manuel D'Utilisation: ART. NR. 320531 2/98Documento32 pagineBedienungsanleitung Owner'S Handbook Manuel D'Utilisation: ART. NR. 320531 2/98josit31415Nessuna valutazione finora

- Scott Bonnar 45 Owners Manual S1942892-IDocumento12 pagineScott Bonnar 45 Owners Manual S1942892-IAndrew Wilson0% (1)

- BOR Hemi Installation GuideDocumento43 pagineBOR Hemi Installation GuideBryan100% (2)

- Opel Corsa C Coolant Pump ReplacementDocumento10 pagineOpel Corsa C Coolant Pump ReplacementAndrásBakosNessuna valutazione finora

- Kawasaki Z1000 - 2009 - Manual de Usuario ENGDocumento165 pagineKawasaki Z1000 - 2009 - Manual de Usuario ENGParts JkawaNessuna valutazione finora

- CatalogDocumento45 pagineCatalogAbhinav SharmaNessuna valutazione finora

- Low Range HD 2 Inch Body Lift Kit (Sidekick, GV, Vitara, Tracker, X90)Documento45 pagineLow Range HD 2 Inch Body Lift Kit (Sidekick, GV, Vitara, Tracker, X90)Cesar Jesus Castellanos TrejoNessuna valutazione finora

- Defender MY2002 Wiring DiagramDocumento108 pagineDefender MY2002 Wiring DiagramsmartstepNessuna valutazione finora

- Service ManualDocumento115 pagineService Manualcarlos maradiagaNessuna valutazione finora

- Accent Compession Pressure InspectionDocumento12 pagineAccent Compession Pressure Inspectionflash_24014910Nessuna valutazione finora

- Aeon NEW SPORTY 125-180 Repair ManualDocumento93 pagineAeon NEW SPORTY 125-180 Repair ManualGassmeNessuna valutazione finora

- Electrical Test Program - Test: ABS/ASR Control Module (N30/1) Layout Connector 1 (Component Compartment)Documento2 pagineElectrical Test Program - Test: ABS/ASR Control Module (N30/1) Layout Connector 1 (Component Compartment)Paul Hanson Sr.Nessuna valutazione finora

- 01 WgedDocumento344 pagine01 WgedKenneth PaulNessuna valutazione finora

- Rear Light Removal & Earthing FixDocumento6 pagineRear Light Removal & Earthing FixKároly Dávid NyulasiNessuna valutazione finora

- Toyota Celica GT L4 1.8L 1ZZ FEDocumento21 pagineToyota Celica GT L4 1.8L 1ZZ FEWolfgang WilliamsNessuna valutazione finora

- How To Guide - Changing Spark Plugs On A RB25DETDocumento4 pagineHow To Guide - Changing Spark Plugs On A RB25DETseastate100% (1)

- Cylinder Head InstallDocumento2 pagineCylinder Head InstallMiguel Moreno FernándezNessuna valutazione finora

- How To Guide - Removing Stagea Series 1 HeadlightsDocumento2 pagineHow To Guide - Removing Stagea Series 1 HeadlightsseastateNessuna valutazione finora

- BMW 528i Sunroof RepairDocumento30 pagineBMW 528i Sunroof RepairNerijus BartusevičiusNessuna valutazione finora

- 4AG TuneDocumento9 pagine4AG TuneMohd Hatta100% (1)

- Kirisun PT260-Service-ManualDocumento29 pagineKirisun PT260-Service-ManualRobertinoNessuna valutazione finora

- Vanguard Twin Cylinder Ohv LC Briggs & StrattonDocumento85 pagineVanguard Twin Cylinder Ohv LC Briggs & StrattonKenn Ferro100% (1)

- VW Golf 5 Steering ColumnDocumento20 pagineVW Golf 5 Steering ColumnNPNessuna valutazione finora

- TIS - Scion 2006 Xa RepairDocumento5 pagineTIS - Scion 2006 Xa RepairJuan Antonio Ochoa PadronNessuna valutazione finora

- Chainsaw Chain Cross Reference ChartDocumento2 pagineChainsaw Chain Cross Reference ChartBrandon McCombsNessuna valutazione finora

- BMW E23 24 28 OdogearDocumento9 pagineBMW E23 24 28 OdogearporkfaceNessuna valutazione finora

- Transmission Unit 3Documento103 pagineTransmission Unit 3Ram SaaceNessuna valutazione finora

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDocumento13 pagineAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyNessuna valutazione finora

- Mountfield Westwood: Westwood Garden Tractors 1987 Parts CatalogueDocumento13 pagineMountfield Westwood: Westwood Garden Tractors 1987 Parts CatalogueWinfried SibbertNessuna valutazione finora

- Manual JPT Interface en v1.0.0Documento13 pagineManual JPT Interface en v1.0.0tokerodevNessuna valutazione finora

- Murray Model 42516x92b Lawn Tractor (2001) Parts ListDocumento16 pagineMurray Model 42516x92b Lawn Tractor (2001) Parts ListklmoebesNessuna valutazione finora

- LA204001 EAS Connector Water Ingress PDFDocumento3 pagineLA204001 EAS Connector Water Ingress PDFGino PierNessuna valutazione finora

- Volkswagen Jetta, Golf, GTI 1999, 2000 2.8 Liter VR6 2V Engine Mechanical, Engine Code(s) : AFPDocumento33 pagineVolkswagen Jetta, Golf, GTI 1999, 2000 2.8 Liter VR6 2V Engine Mechanical, Engine Code(s) : AFPBoris StoyanovNessuna valutazione finora

- Yamaha Motor Australia / New Zealand Ver5.0Documento18 pagineYamaha Motor Australia / New Zealand Ver5.0Meor Amri100% (5)

- Repair Guides - Nissan Electronic Concentrated Control (Port Fuel Injection) System (Eccs) - General Information - AutoZoneDocumento15 pagineRepair Guides - Nissan Electronic Concentrated Control (Port Fuel Injection) System (Eccs) - General Information - AutoZoneIbnu Zaqi FirdausNessuna valutazione finora

- Chrysler JX Stratus Sebring Convertible LHD RHD 1997 Service Manual Ignition SystemDocumento28 pagineChrysler JX Stratus Sebring Convertible LHD RHD 1997 Service Manual Ignition SystemjjrmgNessuna valutazione finora

- 02 RgebDocumento1.168 pagine02 Rgebprožnik100% (3)

- How To Guide - Fitting Brembo Brakes On A StageaDocumento4 pagineHow To Guide - Fitting Brembo Brakes On A StageaseastateNessuna valutazione finora

- Description and Operation: 303-01B-10 Engine - 3.0L 303-01B-10Documento11 pagineDescription and Operation: 303-01B-10 Engine - 3.0L 303-01B-10Troy J GautreauNessuna valutazione finora

- JEEP WJ 2000 Service ManualDocumento117 pagineJEEP WJ 2000 Service Manualdoniluz0% (4)

- 960 - 1996 Owner's ManualDocumento254 pagine960 - 1996 Owner's ManualhucnNessuna valutazione finora

- SM 43 PDFDocumento108 pagineSM 43 PDFsimon_someone217100% (1)

- DTCC Toyota SrsDocumento2 pagineDTCC Toyota SrsAbhi MohunNessuna valutazione finora

- Caddy LHN 130, 140, 200, (Caddy) PDFDocumento36 pagineCaddy LHN 130, 140, 200, (Caddy) PDFPE TruNessuna valutazione finora

- XR700 and XR3000: Ignition InspectionDocumento20 pagineXR700 and XR3000: Ignition InspectionDevine LightNessuna valutazione finora

- Swissauto 250Documento51 pagineSwissauto 250Mothi Ram100% (1)

- Mini r53 HeadDocumento10 pagineMini r53 Headisrael negreteNessuna valutazione finora

- SECTION 307-01: Automatic Transaxle/Transmission - 6R80 2012 F-150 Workshop Manual General ProceduresDocumento3 pagineSECTION 307-01: Automatic Transaxle/Transmission - 6R80 2012 F-150 Workshop Manual General ProceduresPriscilla Kelly Freitas dos SantosNessuna valutazione finora

- 1.4 Golf Fluctuating Idle and Poor StartingDocumento23 pagine1.4 Golf Fluctuating Idle and Poor StartingEngine Tuning UPNessuna valutazione finora

- Instrument Panel Yaris 2008Documento89 pagineInstrument Panel Yaris 2008Pat NeenanNessuna valutazione finora

- M65 6speedDocumento33 pagineM65 6speedeuroporsche9148810Nessuna valutazione finora

- MY12 Electric Reference LibraryDocumento772 pagineMY12 Electric Reference LibraryJose Maria Castro Pazos100% (2)

- MazdaDocumento30 pagineMazdagerber damianNessuna valutazione finora

- TD 5 EngineDocumento6 pagineTD 5 Enginenormy112Nessuna valutazione finora

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Da EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Valutazione: 5 su 5 stelle5/5 (1)

- MV99 - Load Sensing VVDocumento46 pagineMV99 - Load Sensing VVthailanNessuna valutazione finora

- Miniskaff Assembly Instructions PDFDocumento2 pagineMiniskaff Assembly Instructions PDFthailanNessuna valutazione finora

- Possible Frame IssueDocumento10 paginePossible Frame IssuethailanNessuna valutazione finora

- Miniskaff Assembly Instructions PDFDocumento2 pagineMiniskaff Assembly Instructions PDFthailanNessuna valutazione finora

- 2016 Mining Catalogue MASTERDocumento79 pagine2016 Mining Catalogue MASTERthailanNessuna valutazione finora

- 1654 71ac PDFDocumento2 pagine1654 71ac PDFthailanNessuna valutazione finora

- VigoElecWiringDiagram PDFDocumento244 pagineVigoElecWiringDiagram PDFthailan100% (2)

- Norma Normaquick Quick ConnectorDocumento16 pagineNorma Normaquick Quick ConnectorthailanNessuna valutazione finora

- Ar Industrial Catalog en 2016 WebDocumento120 pagineAr Industrial Catalog en 2016 WebthailanNessuna valutazione finora

- Portable Repair WorkshopsDocumento24 paginePortable Repair WorkshopsthailanNessuna valutazione finora

- 40 Foot Container DimensionsDocumento3 pagine40 Foot Container DimensionsthailanNessuna valutazione finora

- Cummins Heavy Duty Product Guide PDFDocumento22 pagineCummins Heavy Duty Product Guide PDFthailanNessuna valutazione finora

- Bul SAE J2044 PDFDocumento8 pagineBul SAE J2044 PDFthailanNessuna valutazione finora

- AMastersGuidetoContainerSecuring2ndEdition 3 PDFDocumento50 pagineAMastersGuidetoContainerSecuring2ndEdition 3 PDFthailanNessuna valutazione finora

- JIS ThreadsDocumento7 pagineJIS Threadsthailan0% (1)

- SERIES-90 180cc SERVICE BLN-2-41695 1997-05Documento52 pagineSERIES-90 180cc SERVICE BLN-2-41695 1997-05thailanNessuna valutazione finora

- 520L0893 PDFDocumento240 pagine520L0893 PDFthailanNessuna valutazione finora

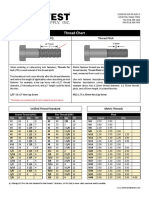

- Unc Unf Metric Thread Chart Northwest FastenerDocumento1 paginaUnc Unf Metric Thread Chart Northwest FastenerthailanNessuna valutazione finora

- Alemite CatalogDocumento177 pagineAlemite CatalogthailanNessuna valutazione finora

- 38 Alemite Product Catalog PDFDocumento277 pagine38 Alemite Product Catalog PDFthailan100% (1)

- Type of ThreadDocumento13 pagineType of ThreadVils ArabadzhievaNessuna valutazione finora

- How To Identify Fluid Ports and ConnectorsDocumento24 pagineHow To Identify Fluid Ports and ConnectorsKathryn WorkmanNessuna valutazione finora

- 3 o Ring Guide Issue 7 PDFDocumento32 pagine3 o Ring Guide Issue 7 PDFthailanNessuna valutazione finora

- Alemite CatalogDocumento177 pagineAlemite CatalogthailanNessuna valutazione finora

- NPTDocumento6 pagineNPTthailanNessuna valutazione finora

- Mounting Flange HZW EngDocumento2 pagineMounting Flange HZW EngthailanNessuna valutazione finora

- 3c EngDocumento2 pagine3c EngthailanNessuna valutazione finora

- Mounting Flange HZW EngDocumento2 pagineMounting Flange HZW EngthailanNessuna valutazione finora

- Ourproductconcept Eng PDFDocumento8 pagineOurproductconcept Eng PDFthailan100% (1)

- Dseries Eng PDFDocumento3 pagineDseries Eng PDFthailanNessuna valutazione finora

- 19A Time Collection Device Integration Activity Guide PDFDocumento78 pagine19A Time Collection Device Integration Activity Guide PDFAliya AmarNessuna valutazione finora

- Linked List: Singly, Doubly and CircularDocumento53 pagineLinked List: Singly, Doubly and CircularMia SamNessuna valutazione finora

- Microsoft Word - Exercise 3 Subsea P&PDocumento5 pagineMicrosoft Word - Exercise 3 Subsea P&PKRNessuna valutazione finora

- MagnetostictiveDocumento17 pagineMagnetostictivekanikasharma22Nessuna valutazione finora

- SAS Hot Fix Analysis Download and Deployment ToolDocumento11 pagineSAS Hot Fix Analysis Download and Deployment ToolAdrian GallegosNessuna valutazione finora

- WEBINAR: Ballast Water Management - Be Ready For The Discharge Standard D-2Documento32 pagineWEBINAR: Ballast Water Management - Be Ready For The Discharge Standard D-2sukhjit78Nessuna valutazione finora

- Ingrid Olderock La Mujer de Los Perros by Nancy GuzmnDocumento14 pagineIngrid Olderock La Mujer de Los Perros by Nancy GuzmnYuki Hotaru0% (3)

- TA - 031 - en General Information For Diaphragm SealsDocumento5 pagineTA - 031 - en General Information For Diaphragm Sealstudonghoa tmpNessuna valutazione finora

- Links Deep WebDocumento2 pagineLinks Deep WebArnoldTorresNessuna valutazione finora

- Checklists 4yrDocumento2 pagineChecklists 4yrKarla TreviñoNessuna valutazione finora

- 06 NetNumen U31 System DescriptionDocumento39 pagine06 NetNumen U31 System Descriptionمحيي الدين الكميشى100% (1)

- (ENG) C&T Catalog Hydrelio® Technology 2021Documento24 pagine(ENG) C&T Catalog Hydrelio® Technology 2021ReenNessuna valutazione finora

- Company Profile Metro GoldrichDocumento29 pagineCompany Profile Metro GoldrichBids and Awards CommitteeNessuna valutazione finora

- Materi 1 - Analisis SinyalDocumento17 pagineMateri 1 - Analisis SinyalUsmanNessuna valutazione finora

- Position PaperDocumento3 paginePosition Paperapi-178099475100% (1)

- Fireplace ManualDocumento40 pagineFireplace Manualresistancebeta6Nessuna valutazione finora

- CE5604 Term PaperDocumento6 pagineCE5604 Term PaperCemre CaglarNessuna valutazione finora

- ABB REL5xx RIOConverterDocumento10 pagineABB REL5xx RIOConverterzinab90100% (1)

- QAch 02Documento13 pagineQAch 02Rami Alnajjar100% (1)

- Baan ERP HistoryDocumento18 pagineBaan ERP HistoryBalaji_SAPNessuna valutazione finora

- Technology Architecture For NginX, postgreSQL, postgRESTDocumento5 pagineTechnology Architecture For NginX, postgreSQL, postgRESTkarelvdwalt9366Nessuna valutazione finora

- S2N Gyro Interface ManualDocumento20 pagineS2N Gyro Interface ManualAfrizal Setiawan100% (1)

- Ta Elastomer Cure DatesDocumento3 pagineTa Elastomer Cure DatesRay FaiersNessuna valutazione finora

- 4 10 59 08 Juni 2023Documento5 pagine4 10 59 08 Juni 2023ihor.vezhninNessuna valutazione finora

- Manual New AswanDocumento18 pagineManual New AswanmohamedmosallamNessuna valutazione finora

- Assessing The Impact of Premier Information Systems Research OverDocumento20 pagineAssessing The Impact of Premier Information Systems Research OvergasibuteaNessuna valutazione finora

- Sap BarcodesDocumento59 pagineSap BarcodesDarmin MemiševićNessuna valutazione finora

- Installation InstructionsDocumento3 pagineInstallation InstructionsRosaLovaNessuna valutazione finora

- Performance Analysis of Cooperative Communication For Wireless NetworksDocumento164 paginePerformance Analysis of Cooperative Communication For Wireless NetworksIhtesham JadoonNessuna valutazione finora

- Acetic 2520acid 2520 Energy 2520balanceDocumento6 pagineAcetic 2520acid 2520 Energy 2520balancembeni0751Nessuna valutazione finora