Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Republic Aircraft Twin Bee Flight Manual

Caricato da

rayduxCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Republic Aircraft Twin Bee Flight Manual

Caricato da

rayduxCopyright:

Formati disponibili

Page I

UNITED

CONSULTANTS'

CORP.

Nonvood, ,

Mass.

ThLs docunent

roust

be kcpt ln airptane

at all tines'

F.A.t. APproved

Date-..--

Model UC-I (J

pl ace)

normal

cate8ory

No.

F. A. A. I dent i f i cat i on

!

Seri al

No

r..SiIE!!.grs'

the following

limitations

al rpl anel

:

nust be observed

in he operation

of thie

-gEC&S,r

1[wo Lycoming

Moclel Io-350-BlD

engines

Eneine linltsr

For all operations-2?O0

R'P'S'

'

180 HP

Arej.,

1OO Mininurn octane

aviation

gasoline'

Prooellersr

llwo }lartzell

Morlel }iC-C2YK-2RB'

G;fTlilifs)ins,

with ?666L-z

brades.

Pitch

c onstant sPeed full feather-

setf,ing at

30

inch stationt

],ow l 4 deg.,

Feather-79' 3

deg'

Diarneterr ?2

inches

to

74

inches'

Avoid

continuous

operation

between

2o00 and 2250 R'P'M'

power gj]-Eeruexelglet

green trrc(nonoal

operation) 50

deg' to

JtrEII9EE4EJI20 ateg.

C3 Yellow

Arc

(caution) 20 deg. to

50

deg' cl

Red Li ne

(Max)

120 deg'

C'

Oll- Pressurer

Green Arc

(norual

operating)

50 to

90

psi

I

YeIIow

Arc

(caution) z5 to 5o

psi an't

90

to 100

psil

Red l i ne

(mi n)

25

psi t Red ti ne

(rnax)

I00

pei '

Fuel Pr es s ur el Gr eenAr c ( nor r nal oper at i ng) 0t o} l ps i

Red Li ne

(uax)

ff

Psi .

Irelgpelelt

Green Arc

(nornal

operating)

60o to 2000 RPII

and 2250 to 2700 RPMI

Real Arct(avoid

contlnuous

operation)

20o0 to 2250 RPM

Red Li ner

(max)

2700 RPM.

I Green Arc

(Norrnal

oPeratlng

c ,

range) 90

deg. to

Red line(max,

260

260

deg.

deg.

Table of

finitC.

(contd)

Page

2

Airspeed lfunits

and

r

narklngs

t

" "rliuilieq

-elrEpegl

ntH:"H":if,

(v',.)

Maneuvering

sPeed

(vn)

l{ax Struc tural

Cnrlslng

speed

(Vrro)

Max Flaps extended

sPeed

-

(vr")

'Max

oear Extended sPeed

(vr")

Single Engfne

l4in.control

speed

(Vr")

Slngle Engine

Sest rate

of

clirob speed

Caution range

N ormal operating range

Flaps Ex&nded

Range

r56lrPir

(red

l i ne)

131 MPt{

r32 MPlt

IO5 MPH

100 r[PH

58

MPH

(Red

Radi al l i ne)

79

lPH

(Blue

railial line

L32 to r55 MPli

(YeIIow

arc)

52

to L32 wrr

( green arc)

49 to I05 MPlt

(white

arc

)

Not er Dl ar r euver l ngi nvol vi ngappr oacht ost al l i ngangl eor f ul l appl i ca-

t l onof el ev at or , r udder , or ai l er ons , s houl dbec onf i nedt os peeds

below'naneuverS.ng.

sPeed.

Flleht load factorst

Max Positive

Max. Negatlve

Dlaxisun--yeiehJr 380O

lbs.

-C-G:--Eg1ggL

See diagran

on page

3

for

C'G' range with

Bear retraction

monent is

+2900 ln'-lbs'

1. 80" 9"

No inverted DaneuverB

approved.

gear

extended.

97.5

i nches

ftrd. of wi ng L.E.

is the responsibility

of the airplane owner and

ensure

that the airplane Ls'

properly loaded.

Datun is

Not er Lt

pilot to

h1z .5

E-

l,tnitations

BfaserEn

(

conttl ) Page

4

a) On cover assenbly, Just

aft of controls

for main fle1

shut-off

valves'

in fuII view of

pilott

nust be ted as a nomal

cate

trDo

not

144 Kf CAS Flaps uP.'

tMa.rteuve

s at Max. Grose weight-114

Kt cas. "

airolane

in conpliance

wlth the operating

lirnitations-

stated

in the Form of

placarde, narklngs

and nanuals"'

tic Maneuvere( incl

"Max.

S for

ar

tion and extension

8? KT

CAS. ,

s

control

Kf cAs. "

tDenonstrated

Crosswind velocity

I7 KT"

of

f ) I nsi d e

rudder

aerodYnaraic

balance

l-ower ribr

,rTranEfer

Aux. Fuel- to rnain tank in l.gvel fU;ghl onIV

"

nAux.

ta.nk nust be filLed

for water

talce-off and landing"

t into known Ic ,

conditions

bl t ed.

"

b)

"Rvd.

baggege conpartrnenfpon

top of uain fuel tank filler

neck coverr

,r'Ma:r

Baggage caPac ity

200 1b6,. "

c) Aft baggage

cornpartment,

on vertical

upholstered

panel

at aft end of conPartnent

r

"Max.

Baggage cap4gity-199-fbs."

d) Adj acent

to fuel fi l l er

caPst

Tank Capacityr

8 on6, Ioo,/130 nin.

grade

"Aux.

tank capacityr

15

gallons loo,/130 nin'

grade

"'

e)

on sill of each

main

cabin doorr

down e( s)

when

door(s) for entrance

or

- ^ * * ^ a a r r ^

i

f

s

Er'*.glgeC

pase

5

FueI

Svstenr

Auxiliary

Fuel Svstenr

l r ans f er aux i t i ar y f uel t onai nt ank i nl ev e] . f l i ght on] . y

when rnain tank ig between

J/4

and L/8 fulI.

Putr etectric

tranefer

slvitch in the

'enpty"

position to

trangfer

fue; fron aux. tahtr to mai'n tank,

(red

indicator

light near

switch will cone on.

)

Flow froD aux' tank

to

main tank is bY gravitY.

Aux. tarlc is nornally filled whtle al rplane ie

on the

ground

(cap.

16

u.S. gal l ons). However, aux'

tank can be fi l l ed

while in

flight by transfering

fuel fron the nain tank

by

use of the electric

transfer

punp.

to

transfer

fuel fron rnaln tank to aux. tank

Fut

electrlc

t r ansf er swi t chi nt he' Fu1l ' posi t l on( r et l l ni I i cat or J. i ght

near

swltch

will corne on) '

Holdl fuel

quantlty selector e$itch in.the "AUll'"

position

to

determine

quantlty of fuel in the aux. tan*"'

The additlonal

heat arormd the engine

fuel

punp and linesr

as a result of

prolongetl

growrd idIe,

can result in fuel

vapors

which will affect idle operatlon,

particularly on

hot days.

l{hen

engine

RPM starts

to drop below noI:nal

ictle

RPM, turn electric

auxiliary

punps

"0N"

'

Pronellers

t

FuIl- trhottlg

on operative

engine

to naintain altitude

an{.a5.rspeeQ.

l{aintaln

at least ?9

IPH

CAS' the best

elngLe engine

rate of clinb

speed

(btue

radial line on

ai rspeed

i ndi cator).

Inoperative

engine

procedure is as followsl

a) Cl ose throttl e

U) Pul l

prop control back,

past stop, to

"Feather"posi ti on'

e) Mi i i ure control

rr1df6

Cut-offr' .

d) Igni ti on swi tch

"0ff".

e) Electrlc auxiliary

punp

!'offl

.

.f)

Main fuel valve

"off"

on inoperative engine side'

Procedures

[contd) Page

5

Stall Speedt

(cal i brat ed

ai rspeed)

(power

of f )

Unfeatherine Procedure t

a) turn nain fuel valvenon".

b) Advance

propeller control to low BPM position(approx-

inately halfruay between eaeh end of nor"nal travel).

c) Start engine. following the nonlal starting

procedure

d) Allow engine to idle at loo to 1J0o RPM until oil

*

sl i p

**Accel.

at lroderate

i"ate into a ro11-

of f .

Less than I0O ft. al t i s

Lo6t fron

point of uncroL-

lable cond. to

point where

Level flight is regained.

tenperature begirpe to rise.

e) Re-eynchronl.ze engineg.

Performance r

Flisht

CharacteriEtics

Cridtcal Engine Inoperative

(left)

(FulI

Power on operatlve engine).

Gear and flaps upr

52

MPH

Gear and llaos down

(fuol

fl aps,-

30

deg.) 49 rFH

c

h t

E '

r ) d

> G

o o

o o

. G t {

a)

6 <

f , ( . )

o* ) |

q l

6 ; a

o t rt r

Fl

-r

=

l O e

r J L

6 Or l

t o

o t r

o o P

o t r

q

C.i O

U) oc)

Confl 8.

Cond.

o

fa

B O

rl

o t o

o t r

o o

I . i

r{ a6

ql

,

o d t

6 r {

o ( )

t 5

o c o

C o

F t L

! ' l aps a Goar Ext .

Fl epr Rot r . &

Goar Ext

"

Fl aps & Gcer Ro t ! .

Fr

t-{

4

c

C o

d o

6 A

q ' o

o f l

r <

J . b 0

c E

6

+,1

[ i o

o

r O O

.1 E

Fl aps & Goa: r Ext .

F' l aps Fot r . &

Gcst ' I , : x.

! ' l apa

& Goar Rc t r.

Eneines

-Page

7

The lwin

Bee

ls

equipped

with

two tyconing

nodel I0-350-B1D

fuel injection

engines

'

The fuel iniection

system is the Bendix RSA-

5fDI.

Rated horsepower

le 180 at 2700

'iiPM'

-gggg9g98

are

ScintilLa Type SIIN-200 on left side' and type

s 4l N- 2o4onr i ght s i de. Thes 4l J { . z oonagnet ohas ar et ar dbr eak er

pr ovi ct i ngf i xedr et ar dandl ongdur at i onbooet edspar kf or st ar t l ng.

The

.!Eggf-tgg,

is a vane tYPe'

setti ng of 2O-?2

Psi .

The

leg.W-!g1

is a dry type.

Care should be exercieed

when

c l eani ngt heengi neac c es s or y s ec t i ont oav oi dt heengr anc eof oi l '

dirt or cleaning

fluid

lnto the

purnpr through the exhaust

port. Engranc e

of anyf or ei gnmat er i af . i nt ot hepr r mpwi l l ser i ousl yaf f ect i t sser vi ce

Iife.

It is recormended

that the vacuum

pwnp exhaust

port be taped

closed when cleaning

the engine.

9PIP-EIEINET

I . Set pr opel l er gover nor cont r o] . l ever l n" Hi ghRPM" posi t i on.

2.Turn

nain firel valve on'

J.Mixture

control ln

"Idle-Cut-0ff"

'

4.Crack throttle to approxina\'ely

l/8 open

position'

5. Tur nf uel boos t er punponandnov er ai x t ur et o" Ful l Ri c h,

pos i t i onunt i l as l t ght but s t eady f uel f l owi s i ndi c at ed

'by

tnovement

of the fuel

pressure

gauge needle'

5.Return nixture control

to

"Idle-cut'0ff"

and open throttle

aPProxirnatelY

one inch.

?. Tur nst ar t er swi t cht o. . St ar t uposi t i onar r dcr ankengi ne.

Ther nagnet o- st ar t er swi t chwi l l aut omat i cal l yr et ur nt o

',Both,r

when released fro3 the

"Start"

position.

S. Asengi nef i r es, t 0oveni xt ur econt r ol sl owl yandsmoot hl y

t o" Ful l

Ri ch" .

9.When

engi ne fi resr set the throttl e for

"Fsst

l dl e' r' If

oil

pressure is not indicated

within

thi;tt''

second6'

stop the engine aid deternine the trouble'

Note t

Gf engine fails to achieve a nornal start, assume it to be frooded

and use standard

clearlng procedure. Ehen repeat ab.ovd proce-

.

dure.

dnd has a preaaur relLef

valve

i

CofS ensine

startinE

procedure

(contd)

r

I0.t{arn

up engine

betrveen

800 and I3O0 RPII'

Hot ensine

t

Because of the fact that the fuel

percolates and the systen

must be

purged of vapor, I' t 5' e recornnendeil

.that the same

procedure'

as outlined 3qr s

icold

Engine' r

be used for

starting

a hot englne '

Generally,

less primlng ls required

foi a hot engine'

Ihis is controllec!

b y a l l o wl n g t h e f u e l t o f l o wf o r a s h o r t e r p e r l . o d o f t i j e i n s t e p J

on the

previous

Page.

The additlonal

heat around

the engine

fuel

purop and lines'

as a

result

of

prolonged

ground idle,

can result ln fuel vapors which

will

af f ec t i dl eoper at l on, par t l c uJ . ar l y onhot day s . Whenengi neRPMs t ar t g

to

drop below nornal

ltlle

RPM, turn electric

booa!

-punpa

on.

For proper operation

and rnaintenanrce

of the Twin Bee engines '

refer

to the FAA approved

Lyconing

Operators

rnanual',

PN 50299-l-5'

P:elcllegt

The Twin Bee is equ' ipped

with Hartzell

dConpacts

12"

d!a'

I

constant speed,

feathering

propellers,

No' HC-C2YX-2RB/?666L' 2' -

I,or

proper operatlon and roaintenance

of theee

propellers' refer

to the

fAA approved

llartzell Propeller

Ownerrs nanual

PN I15'

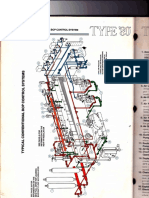

Fuel SYst emr

(A

schenatic

diagram

of the fuel

systen

ls shonnt'

nn";page lI'

Total fue}

capalcty is ].ol

gallongs;

8J

g311ons in the main

tank,

Iocated

in

the hul1 under

the forrard

baggage

compartnent '

and

16

gallons ln the aux '

tank located

In

the tail

boon below

the horl-

zontal

tail

position.

the nain tank

ls a

pllo-ceIl

pa!

supportetl

by

the hull

structure '

and

the aruc '

tarrk is

an lntegral

type of tank '

Each engine

has an lndividual

fuel

systen

conslsting

of the

following

I

FueI Svstem

(contd) page

9

a) An individual

aubrnerged fuel

pick-up in the nain tank, with

a finger strdiner at the end of the

pick-up'

b) fuet Ehut-off valve located

on hulL deek above nain tank '

c) Electric energency f,ue]-

punp located on hull deck above

nain tank. Re1ief valvc eetting 2Q-22

psl.

Ihe fuel shut-off valve and ernergency

fueJ'

punp are accea6-

ibte by renoving a section

of the forrrard

baggage

floor'

d) A 104 roicron fuel fllter located on the

$lng root rib. Filter

is accessibre by removing an acceag cover in the J'ower wing

root

gap cover.

e) Engine drLven vane,,, tylre fuel

purnp. Relief valve setting on

punp

is between 2A'22

Pat'.

f) Bendix type RSA-jiADL fue1 5.nJector unit Located on engine'

lhis unit contains the airftow senslng eyeten, aervo regulatot

and fuel c ontrol 6ysterd.

g) Flow divider located on top of engine.

h)

Conti nuous l l ow al r bl eed nozzl es, one"at each cyl i nder'

i) Fuel

pressure

aue r

located on instrument

panel. The gauge

reads inJector nozzle

pl|aslrf

r

Red ll.ne rnark on

gauge

is JL

11

psi. Due to the

gauge position relative to the injector

nozzles

the

gauge will read approximately

1 psl when the

engines

are inoPerative.

Io transfer

fuel fron aux. tank to nain tank,

Put

toggle switcht loca-

ted in the upper left hantl corner of the instnutent

panef in the

"Enpty"

posS.tion

(red

incticator light near switch will cone on). Ttrls

opens two electric

valves located in the fuel line approxiDately

nidway

between aux.

tank is by

gravltY.

and nain tanks.

Fuel flow fron aux. tant to nain

Transfer aux. fuel to nain tank in level flight

Aux. tank is nornally

filled while the airplane Ls on the

grourrd.

However, aux. tank can be filled

while ln ffight by transfering fuel

fron the nain

tank. [o transfer

fuel fron nain tank to aux. tankt

put

the toggle

8wl-tch, Iocated in the upper left hand comer of the instru-

ment

panel, in the

"Fi11"

position

(red

indicator llght near switch will

cone on).

This starts the electric

transfer

punp and

-oP9r':-!491199-

tric valve in line with_!he-!ut0P.

The two electric

valves

on elther

side

of the

PumP

remain

closed'

Purnp and valves

are Located

approxlnately

rnidway

between aux' and

FueL

Svstern

(contd)

Page

10

nain

tank. fhey are accessible

by renoving

over these uni ts.

an acces3

cover di rectl y

i s 4 p s l t 1 .

Rell,ef nalve setting

on transfer

punp

1. lltain fuel shut-off,

valve

2. EmergencY fuel

PunP

3.

Fuel fl l ter

4. Engine driven fuel

PunP

J.

FueI i nJector

6. Fl ow tti vi der

f .

I nj ect or nozzl es

8. ltlain tank filler neck

9.

llain tank vent

I0. l4ain tank vent

l-I.

Fuel pressure

gauge

12. l,/lain fuel tanlr

(85 gals)

13.

Fuel transfer

PunP

14. Electric 6hut-off

valve

15. Aux. fuel tank

15. Aruc. Tank FiIIer

Neck

17. Inter-Tank

vent

18. Aux. fank vent

19..dut(.

Tank sunP drain

valve.

2O. ldatn tank sunP

drain valve

21. Tank Conpartnent vent

22. fank Conpartment

vent

2J. Fi nter strai ner.

Hvdraulic

SvstelBl

Th e f l a p s r ma i n l a n d i n g g e a r a r r d t h e t a l ] - wh e e t a r e e x t e n d e d a n d

rietr^acted

hytlraulically.

A eingle manually-operated

hydraullc

pressure

system actlvates

both the landing

gear and the flaps'

Al ev er ex t endl ngupwar df r onbeneat ht hef l oor bet weent het wo

front 6eats actlvates

the

puEp with whlch hydraullc

pressure ls built

up.

Two srnaller levers extending

fron

the

power pack unit

control the

act i on of t he. hydraul i c

f l ui d.

Bhe ri ght

l ever

di rect s

t he sect i on

of

the tanatlng

gear while the one located

on

the left

side

detennines

the

po sitr,on

of the

flaps'

The hy' Iraulic

power

Pack

incorporates

a

Pcre ttr

I

?

p:(u

n4;<o"

<Y'

Bts,

Eng.

/t R^n

rPir

3 olrcnrb lc'

Futl

SYolGn

15ce

gegrn{

Pa-,St-

l

ol

afY,+F

'

(tv'

2l

"F$*

e '

5.Jl^e

DFAI$

Hydraul i c

Systen

(contd)

Page 12

ser i es of

pressure

flaps or

and uses

reverse.

The systen has a three and one-half

pint capacity

a petroleun base hydraulic fluid, Snec Mll,l)-lf!!

A schematic cliagran of the hydraulic systen is shown on

page 13.

Vacugm svstent

(A

scheraatic

diagran of the vacuum systen ls shown on

page 14')

A tlry tlrlre vacuum Purnp is provided on each englne.

In case

one

punp becornes inoperative,

suctLon frour the operative

punp will

close the check valve on the inoperative

pump side and thereby a1low

the the operating

punp to supply the required vacuun to operate

the instru.nents.

Ihe check valve is located between the wing root

rib and the cabin.

The relief

valve is located in the engine

c onpartment on the left

side of the engine

rnount

just

forrrard of the firewall. It ig accessible

by rernoving

the left

cowl door of the engine r

a

systen operatlng

range is

4.0 to

5.5"

Hg

gauge

reading at crulse

RpM.

with only one engine

operating the relief vavle is eet to obtain

4.5" HG

gauge and

with both engines operating

at cruise RPM the

gauge

wiLl read apProxinateLy 5.5"

I1g..

An air filter in installed behind the instrument

panel to provide

Ionger insteument

serwice life. Replace filter after approxlnately 250

hours of fLying tine.

Check vacuum

pumps for proper operation

during

grotmd

run-up '

When both engines are at ldle RPM, observe suction

gauge whlle increas-

tng RPM on one engine to 1800. If the vacuum

pump is operating the

suction

gauge reading

wiLl incraase as RPM is inc reased '

The above

check can be nade when RPM is increased

for the nag'

Check'

Landine seart

9snerclt

The hydraulically

controlled

laniling

gear is tnaintained

ln the

up or down lock

position by the

geonretry of the liirkage.

lhe ].inkage

is designed so aB to

"break"

during the transition

phase.of the

gear

operation

and to

' remake"

pivots of the linkage are

at the up or down

position, so that the center

past daad center

travel ' In this

marmer

po.sitive

Lock is rnaintained

until

hytlrauU'c

pressure is applied

to the

check

valves

which

Prevent

the

when transf ering the hYdraulic

tenporary

droPPing

off of

action fron landing

gear to

Hydraulic System

Page l l

tr

=

c o

4 3 6

t o B

E f i '

l { d

qt l . t

c , ' .

o d ao( '

q00)

|

q,

I u {, Et}

o t

t r l

C O

. F a

o

. . i q

Fl g

Ff

..t .A

F{ OF{

o !

t r C , E

5 t { o t {

t t , u t ,

O P O P

t r o k o

A h A t l

k k

o o

E E

.rt ..1

..{ F{ lr

t r t { > > o

' } 4 o o o o d

o . . { P C

d P o hD h0 rl

R. { o

t r C

F {

la r{

"-{

--l

>:

t { O o P . P O

o r p i n d ( 0

- t t b o

o t { C P P C

A d o o o . r l

o f t

d

q t P

o hl'

.+, (d

l ! ' { k t r 5

-{ blt o s! d d {t

t c. P o o o o

d. . l c r A ht ' bl ) d

- l

l . { d o

ctl

15

Cr{ P{ C Fl Pr

Zl h ct o

(d '.1 ..1 (d

Etr E

Fl Ul F{ .i d

rl

( 5 I + | E P ' r - r

r{l

Fll

-l At a\

+

rn \O

d A

a

ul

A @

d A

F l d

q-r

r.{

l q {

a r l

t r o

..t

C

Fl --t

Fl

{.}

k E

, h

u t 5

O'

,P

l r a ,

A l l

E

B

o

u,

d

F{

q{

I

c)

tr

Fl

tr

.P

o

Ir

o

d

J

(H

I

o,

c

r{

o

h

a

ul

o

o

k

Vac uulr Sys;ten

Page 14

tn \o t\

F{ N

(n

-t

t{

>r

r t O

u)

A A

d c l t {

c u l o

6 P

* l q r l

.P

O :r-{

o d + {

o + t

t r o k

, { t d

a u t <

o t r

o > o o

E - l >

I l

5 d F.l rl

g >

d l t r

> o

E q { t

5 0 . ! 4

t + { o O

O F I O T r r

d o . c h

> 0 4 o c t

Lanllins Qear

(contd)

page 15

cylinder pernitting a

"break"

in the linkage. fhe tail wheel is

rotated to the up and down position and the

gain gear is retracted and

extended .

A control is provided in the cockpit to engage or disengage a

tail wheel lock thus

pernitting the tail wheel to be locked in the

cent er posi t i on or t o be . unl ocked i n order t o swi vel .

The cont rol i s

Iocated above the hull deck

Just

aft of the h3rdraulic

power

' pack.

t he nai n wheel s are 610O x 6 and t i ree are

7r0O

x 6. The t ai l

.qltree1

is a 10" srnooth contour type.

The naln

gear dl6c type brakes are actuated by toe pedals on the

pi).ot' s rudder pedals. llydraullc brake cylinders located in front of

the rudder pedals are readily accessible in the cockpit: for servi:cing.

A brake fluid reservoir which is attached to the brake cylinders wlth

flexible llneb

providee a reserve of fluld for the braJce systen. A

parking valve is lnstalled in each of the linee between the naster

brake cylinder

and the

wheel. The

positions of these

parking valves

are controlled by a single parking control locatec

Just

below the instru-

ment

pahel at the extrene left side.

Sesj.;llcl

Sjfesr

Inflate main wheel tires to

JB

psi and inflate the tail

wheel ti re to 4J

Psi .

Efqlesr

The bralre systen ls filled with MIL-0-J6o6

(petroleurn

base.). hydraulic brake fluid.

.Po

not use vegetablc base Urake fluids

when refllling

the systen.

If it is necessary

to bleed the

brake system to

get

air out of

the lines, fluid should be addett under

pressure at the bleeder attach-

ment on the bralce unit.

No ad

justnent

of brake clearances is necessary on the Twin Bee

brakes. If after extended service, braking action requires too uruch

movenent of the toe

pedals, new brake llnings can easily be installed

by renoving the four bolts which attach the bralce units, then replacing

the brake linings.

Shsr,!-gtEult

llhe followlng service instrpctions

when followed will result in

a' rapl d

and proper servi ci ng of

your shoek absorber. Al l referenced

used in thls outline

pertaLn to the illustration

belowt

EhocLSlru!

(contd)

Page

J-6

Instructions

are

given for both ptesaure readings

and

neasurements.

Before atterapting to tal<e an extengion

measurenent

the ariplane

nust be vigorously

rocked'

Thls is necessary

since

the rear is equlpped

with

pack-

ing

and is subJect

ibo the usual blnding

toads' It is

aleo reconmended

that

the gear be lnflated to a hlghor

pressure and air

bled to achieve proper extensioni.

rather than try to bulld up the

prqper preesure by

,

tifting the entire

airplane wlth air pressure.

fhe flulct leve1 ehould be checkeal with the

gear

in the fully

compressed condition

before lnfLation.

before

attenptlng to add to,

or check, the fluid it is absolutely necesBary to flrst bleed off any

air that might be

present by depressing the al.r valve.

lfhen alI air

i

tras escaped

the valve houslng nay be removed so that fluid

can be added.

,

l . Depress Ai r Val ve

(A).

Al Low al l ai r to escape.

2. Rock airplane

vigorously. Check dlnension

(X)

for full

conpresslon.

lhis should be 2-?/16 lnches.

3.

Rernove air valve body

(A)

and filt to overflowing

with petro-

Ier.rn oil base hydraulic f1uid. Spec. MIL-0'5606.- Do not use

alcohol or caster olL base fluids in Twin Bee struts'

4. Replace and tighten air valve body and with airpfane in enpty

wei ght condi ti on, i nfl ate to approx. I65' L?5 psi . RocI' the

airplane

vigourousily to

get a true extengion reading at

"X"

This shoulal

ue 6-t/zt.!

Ut+i

5.

If necessary

to obtain this reading, slowly bleed the air valve.

rocking

the airplane at intervals

until the desired dimension

has been reached.

6. should the gas tanks be full but the airplane otherwl-se empty

i nf l at et oappr ox . 22a- 2J ops L, Bl eedai r pr es s ur e' r oc k i ng

airplane at interrals

until ttre

'X"

dinension is

5n

!

L/4'

?.

to service the

gear on a

jacked-up

air?lane '

the strut should

be lnf].atect

to

?a

psi

5.

This shou].d indicate full extension

of Lo-?/t6,;

!

t/+.

4\{

Elegtrical

Svstern Page

U

Thc Twin Bee ie equipped with a l2-volt electrical

systen and the

power supply conBists of one

J4

a,np-hr. battery and tYto

35-at0p

genera-

torsone

on each engine

(wo

50-anp

generatDrc can be supplieil as

optl onal equl pment).

The electrical

systen schenatic dlagran is shown on page 18.

The two

35

arnp

generator installation is the baslc

-1

systen' and the

two

5o-anp

generator installation ls the

-J

system.

above the aft baggage compartroent, and is accessible from the outside

by removing an access

cover dLrectly abovethe battery. The battery

relay swltch is located at the fonvatd end of the battery

Just

above

the wing rear- apar cross-tie member and ie accessl.ble .through the

opening

provided for the battery.

, Circuit breakers are

provLded

for

protection of the indlvidual

circuits and are located on an aft sloping panel above the hu1l

tieek

floor

Just

forward of the raain fuel shut-off valve' controls and hydraulic

power pack.

'

The paralleling relay and voltage regulatora are located on a

horizontal- shelf

Just

aft of the instruroent

panel.

Each engine is equippett with a 12 volt

geared starter. Th:

starter soLenoid operated switches are located in the area of the

battery

Just

above the wing rear spar cross-tie nenber. They are

accessible

through the opening

provided for the battery.

I nsoect i on Page 1P

Pre-LLigL!r

The following safety procedure

instructions

nust becone an inte-

gral part of the aircraft owner' s operational

routine and./or preflight

tnspec ti on.

Before each flight, visually inspect the airplane,

and/ot deter-

nine that t

1.The tires are satisfactorily inflated

and not excessively worn.

2.The Landing

gear shock struts are properly

inflated and have

t he

proper ext ensi on.

J. The

propel l ers are f ree of det ri nent al

nl cks.

4.Bhe engine cowling and inspection opening coyers

are securer

5.There

Ls no external damage or operational

ihterference to con-

t rol surf aces, wi ngs, hul 1, cabi n or f l oat e.

6.There is no corosion of structure

r

particularly

if airplane is

operating in salt water.

?.Phe

hull is drained of water, and that the hulI drain plugs are

properl y i nst al l ed.

8. The surf ace cont rol l ocks, i f used, are renoved.

p.The

fuel tanks are ful1 or are at a

.safe

level of proper

fuel.

l0.fhe fuel tank filler caps are tieht.

1l . | l he f uel syst em vent s are open.

12.Ihe nain and aux. tank sumps are free of water by draining once

a day.

I J. The f uel f i l t er, l ocat ed on- wi ng root ri b, i s f ree of wat er

and sedinent by draining once a week.

14.There are no obvious fuel dr oil leaks.

15. The engi ne oi l i s at

, proper

l evel .

15.The brakes are working properly.

17. The wi ndshi el d i s cl ean and f ree of def ect s.

l 8. There Ls no snow or i ce on t he wi ngs or cont rol surf aces.

' 19.411

required

papers

are in order and in the airplane.

20.The weather is satisfactory for the type of flylng

you

expect

t o do i .

Z1. l l he raai o equi i ment i s i n order.

22.Upon entering the airplane, ascertain that all surface controls

are free and operate normalIy, that the landing gear

and other

cont rol s

are i n proper posi t i ons, t hat al l engi ne cont rol s

operate

properly, that bow door is locked and the main eabin

doors are l ocked and t he saf et y l at ch engaged.

I nsoect i on

( cont d)

Page 2o

Not er I f t he mai n cabi n doors are l ocked'

at

upper center of instrument

panel

,

are unl ocked

t he red l i ght ' adj acent

onr

t he

green 1i ght , l -ocat ed

wi l l be on. I f t he doors

t o t he anber 1i ght , wi l l be

It i s the

pi Lots responsi bi l i ty to l oad the ai rpl ane wi thi n the

approved

C. G. l i mi ts

Approved

the Figure on

Airplane

Loadlng Index"

A typical loadtng is

I t em

Pi l ot & co-pi l ot

2 nassengers

@

'

st i . 95. 0

baggage @ St a. LI 8. 0

anchor & line

Fi re ext i ngui sher

Fuel-main tanx(3/4

fu1l)

Enpty weight

S otals

wei ght and C.G. Li mi ts

(l nches

aft daturn) are

$i ven

i n

page 2L.

wei ght and C.G. i s control l ed by usl ng the

"Ai rpl ane

tables on pageE 22 & 23.'

gi ven bel ow r

Weight Index

340

2I

340

3i

r40 t7

I 0 . 3

?

o , 5

349

40

25L2 ir5

3796

'

t+2?.8(428)

From the figure on

Page

6r

f!rd. limit index=

423

(tandplane)

I

t

.,

,'

=

44I

(

seaplane

)

aft linit index

=454 (

landplane

& seaplane)

The above calculated index of 428 is within linits for operation as a

landplane .

For wat er operat i on l ncrease i ndex

t 44r-428)=

13 uni t s. Transf er f uel

from main tank to aux. tank.

with aux. tank empty, and filllng aux.

tank to

3/l+

nark on

gauge wiLl increase

Index 1l units

(see

page 23) '

Potrebbero piacerti anche

- Bosch p7100 Injection Pump Service Manual PDFDocumento2 pagineBosch p7100 Injection Pump Service Manual PDFAdam Johnson7% (14)

- BE-76 Systems and Limitations.246151541Documento9 pagineBE-76 Systems and Limitations.246151541Adam Nasr El Din100% (2)

- Mikuni Sudco Tuning Manual Ed4 OcrDocumento97 pagineMikuni Sudco Tuning Manual Ed4 OcrAlexander Chekalin50% (2)

- 2gnt 420a OverhaulDocumento62 pagine2gnt 420a OverhaulElsa Elizabeta Dekovic100% (1)

- M20C 1966 Mark 21Documento0 pagineM20C 1966 Mark 21dtoftenNessuna valutazione finora

- Dino 2 4 Ferrari Manual CompleteDocumento258 pagineDino 2 4 Ferrari Manual CompleteRicardo Hurtado MuñozNessuna valutazione finora

- Kawasaki KR 150 ManualDocumento48 pagineKawasaki KR 150 Manualantrax74% (19)

- Workshop Manual Aub Bby BBZ BkyDocumento253 pagineWorkshop Manual Aub Bby BBZ Bkylefteris8450% (2)

- Pilots Notes Tempest V (Sabre IIA)Documento42 paginePilots Notes Tempest V (Sabre IIA)Bobby Chipping100% (1)

- Pre-Solo Written Exam (Cessna 172P)Documento7 paginePre-Solo Written Exam (Cessna 172P)raydux0% (1)

- Aerial Applicators ManualDocumento134 pagineAerial Applicators ManualairsorNessuna valutazione finora

- Commercial Pilot Study GuideDocumento11 pagineCommercial Pilot Study Guideraydux75% (16)

- 1970-1971 Ski-DooDocumento375 pagine1970-1971 Ski-DooVincent Roy100% (1)

- 6277-4 VPH 6-12-16 Cylinder O&MDocumento310 pagine6277-4 VPH 6-12-16 Cylinder O&Mchejoman1979100% (1)

- TWF Helicopter Fly GuideDocumento22 pagineTWF Helicopter Fly Guiderubenbp2Nessuna valutazione finora

- Allison Prop-Jet Engine Models 501-D13, - D13A, - D13D Troubleshooting Handbook Publ. No. 1RC21 Edition 2 15 November 1963Documento72 pagineAllison Prop-Jet Engine Models 501-D13, - D13A, - D13D Troubleshooting Handbook Publ. No. 1RC21 Edition 2 15 November 1963Michael Kubler50% (2)

- CESSNA 152A Study MaterialDocumento24 pagineCESSNA 152A Study MaterialjpanruiNessuna valutazione finora

- CessnaCaravanII F406 POH 1986Documento692 pagineCessnaCaravanII F406 POH 1986Eric Francis100% (2)

- Actros 8x4 TipperDocumento4 pagineActros 8x4 TipperGigi Palalau0% (1)

- 2RZ 3RZ SC PDFDocumento21 pagine2RZ 3RZ SC PDFUliAlejandroRodriguezCoriangaNessuna valutazione finora

- Technical Data: @perkinsDocumento6 pagineTechnical Data: @perkinsHendra SyalalaNessuna valutazione finora

- Cessna 172 Skyhawk, Owners Manual, (English) Manual Del RioDocumento48 pagineCessna 172 Skyhawk, Owners Manual, (English) Manual Del Riofedor andres100% (1)

- Lambretta 175 TV - Owners Manual - #3676Documento32 pagineLambretta 175 TV - Owners Manual - #3676Mariano KokoNessuna valutazione finora

- Pilot Checklist CompleteDocumento123 paginePilot Checklist CompletetachelmemoriesNessuna valutazione finora

- NAVAIR 01-250HDB-1B CH-46D.CH-46F & CH-46D Pocket Checklist (15 June 1970) PDFDocumento113 pagineNAVAIR 01-250HDB-1B CH-46D.CH-46F & CH-46D Pocket Checklist (15 June 1970) PDFBlaze123xNessuna valutazione finora

- BmwhandbookDocumento34 pagineBmwhandbookNissan-club HrNessuna valutazione finora

- Pachino 200 Ownes ManualDocumento18 paginePachino 200 Ownes ManualrforsNessuna valutazione finora

- Extra Than P68C Question BankDocumento33 pagineExtra Than P68C Question Bankakshaydeswal47Nessuna valutazione finora

- TurboArrow SC7Documento33 pagineTurboArrow SC7Alexandre F. M.Nessuna valutazione finora

- Koomey AccumulatorDocumento7 pagineKoomey AccumulatorQadriNessuna valutazione finora

- 2 Stroke Top End and PerformanceDocumento41 pagine2 Stroke Top End and PerformancePaul Martin0% (1)

- Engine QuestionsDocumento8 pagineEngine QuestionsSara AzamNessuna valutazione finora

- CAT 140 TransDocumento4 pagineCAT 140 TranshayaNessuna valutazione finora

- Ah-1j InformationDocumento41 pagineAh-1j Informationali shNessuna valutazione finora

- Cat D-3600sek PDFDocumento2 pagineCat D-3600sek PDFMargaret DaughertyNessuna valutazione finora

- Cessna 152 A ManualDocumento13 pagineCessna 152 A Manualmikerick747100% (1)

- Boiler Emergency Control ProcedureDocumento34 pagineBoiler Emergency Control ProcedureAshish LanjewarNessuna valutazione finora

- MS Erecting of Precast ElementsDocumento18 pagineMS Erecting of Precast ElementsJaafar LagayanNessuna valutazione finora

- Phase 7Documento15 paginePhase 7pknight2010Nessuna valutazione finora

- Tech Specific 172 RDocumento28 pagineTech Specific 172 RPrerak KumarNessuna valutazione finora

- Cat 3306 Ta - Spec PDFDocumento12 pagineCat 3306 Ta - Spec PDFAdrian Cojocaru100% (1)

- 1953 1954 1955 Corvette Operations ManualDocumento71 pagine1953 1954 1955 Corvette Operations ManualDavid EvansNessuna valutazione finora

- Cat 3406CDocumento2 pagineCat 3406CJose Ferrer100% (1)

- Diesel Engine ManualDocumento243 pagineDiesel Engine ManualDavid SeddonNessuna valutazione finora

- 2C Diesel Generator Set Engine Unit PDFDocumento337 pagine2C Diesel Generator Set Engine Unit PDFTaufik Perdana100% (1)

- 900 RRmanualDocumento407 pagine900 RRmanualChris ChapmanNessuna valutazione finora

- TurboArrow SC7Documento33 pagineTurboArrow SC7helioNessuna valutazione finora

- Tec Specific CESSNA 172-R QuestionsDocumento5 pagineTec Specific CESSNA 172-R QuestionsShaurya KhuranaNessuna valutazione finora

- lw450 Service ManualDocumento36 paginelw450 Service ManualAngelNessuna valutazione finora

- Metro 3 Operating Tips PDFDocumento18 pagineMetro 3 Operating Tips PDFFatih Iscan100% (1)

- Multiple Choice QuestionsDocumento5 pagineMultiple Choice QuestionsshekhadaaNessuna valutazione finora

- p68 Imp NotesDocumento2 paginep68 Imp NotesDhyey MehtaNessuna valutazione finora

- Cessna152 POHDocumento235 pagineCessna152 POHGeoff BeuerleinNessuna valutazione finora

- 2013 launched GenTrax 4.4kVA Inverter generator is a dream come true for satisfying your need of portable 240V Pure Sine Wave power. GenTrax 4.4kva is by far our most popular models. Its 3.5kW capacity allows it to run a few accessories at the same time. Powered by an advanced 150cc over head Cam 4 stroke engine, this machine is capable of powering all your camping appliances including kettle, toaster, frying pan and more. It can also run AIR CONDITIONER with low start up draw. With microcomputer-controlled sinewave inverter, the GenTrax 4.4kVA produces high quality, stable pure sine wave power perfect for sensitive equipment such as laptops and tv. Economy mode can be switched on when running small appliances like laptop to save fuel extending maximum running time up to 10 hours. This model comes with dual weatherproof Australian Approved 240V 15Amps outlet. It also has a single DC outlet which allows you to use it to run 12v appliances or charge up your 12v battery. Design compaDocumento20 pagine2013 launched GenTrax 4.4kVA Inverter generator is a dream come true for satisfying your need of portable 240V Pure Sine Wave power. GenTrax 4.4kva is by far our most popular models. Its 3.5kW capacity allows it to run a few accessories at the same time. Powered by an advanced 150cc over head Cam 4 stroke engine, this machine is capable of powering all your camping appliances including kettle, toaster, frying pan and more. It can also run AIR CONDITIONER with low start up draw. With microcomputer-controlled sinewave inverter, the GenTrax 4.4kVA produces high quality, stable pure sine wave power perfect for sensitive equipment such as laptops and tv. Economy mode can be switched on when running small appliances like laptop to save fuel extending maximum running time up to 10 hours. This model comes with dual weatherproof Australian Approved 240V 15Amps outlet. It also has a single DC outlet which allows you to use it to run 12v appliances or charge up your 12v battery. Design compaJulie McRaeNessuna valutazione finora

- C4203 (New Syllabus) : General InfoDocumento6 pagineC4203 (New Syllabus) : General InfoMatt ConlonNessuna valutazione finora

- Handbook For Mechanical SystemsDocumento191 pagineHandbook For Mechanical Systemsmiguelmarchanm100% (1)

- Manual Focke Wulf 190A-8Documento0 pagineManual Focke Wulf 190A-8aabdallaNessuna valutazione finora

- Commissioning Procedure For Governing SystemDocumento25 pagineCommissioning Procedure For Governing SystemmurugesanramasamyNessuna valutazione finora

- Tech Gen: P 68-CDocumento4 pagineTech Gen: P 68-CSE Kotari100% (1)

- Programed FiDocumento60 pagineProgramed FiJulio LindaoNessuna valutazione finora

- Winche Neumatico JoyDocumento6 pagineWinche Neumatico JoyWilliam QuilicheNessuna valutazione finora

- 141 Constant Speed DriveDocumento37 pagine141 Constant Speed DriveJimyToasaNessuna valutazione finora

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SDa EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNessuna valutazione finora

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentDa EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Motorcycle, Solo (Harley-Davidson Model WLA)Da EverandMotorcycle, Solo (Harley-Davidson Model WLA)Nessuna valutazione finora

- Pre-Solo Written Exam C-152Documento7 paginePre-Solo Written Exam C-152rayduxNessuna valutazione finora

- AIPSingapore 7march2013Documento636 pagineAIPSingapore 7march2013rayduxNessuna valutazione finora

- PPL 2.5 Visual Navigation FundamentalsDocumento23 paginePPL 2.5 Visual Navigation Fundamentalsraydux100% (1)

- PPL 3.1 Takeoff&Landing, Enroute PerformanceDocumento40 paginePPL 3.1 Takeoff&Landing, Enroute PerformancerayduxNessuna valutazione finora

- Pre-Solo Written Exam (Cessna 172N)Documento7 paginePre-Solo Written Exam (Cessna 172N)rayduxNessuna valutazione finora

- Piper PA-34-200T Seneca II, G-ROLA Accident ReportDocumento7 paginePiper PA-34-200T Seneca II, G-ROLA Accident ReportrayduxNessuna valutazione finora

- FAA Information Publication On Malaysia.Documento15 pagineFAA Information Publication On Malaysia.rayduxNessuna valutazione finora

- FAA P 8740 02 DensityAltitude (Hi Res) BrandedDocumento8 pagineFAA P 8740 02 DensityAltitude (Hi Res) BrandedrayduxNessuna valutazione finora

- Singapore Virtual Airlines Ops Manual 31Documento15 pagineSingapore Virtual Airlines Ops Manual 31rayduxNessuna valutazione finora

- CBP Guidelines Knee BoardDocumento1 paginaCBP Guidelines Knee BoardrayduxNessuna valutazione finora

- VFR SymbolsDocumento29 pagineVFR SymbolsEdward Rehr100% (4)

- Widd (BTH) AppchartDocumento6 pagineWidd (BTH) AppchartrayduxNessuna valutazione finora

- AOPA Research-The Flight Training ExperienceDocumento48 pagineAOPA Research-The Flight Training ExperienceAbdul Rehman WahabNessuna valutazione finora

- Med Xpress Users GuideDocumento31 pagineMed Xpress Users GuiderayduxNessuna valutazione finora

- Approach Brief ChecklistDocumento2 pagineApproach Brief Checklistraydux100% (1)

- The Small House Book (2009) BBSDocumento198 pagineThe Small House Book (2009) BBSmtanner3100% (18)

- Faa S 8081 4e PDFDocumento54 pagineFaa S 8081 4e PDFHoyNo VineNessuna valutazione finora

- IFR - Aeronautical Chart SymbolsDocumento10 pagineIFR - Aeronautical Chart SymbolsGustavo Adolfo Dominguez VilladaNessuna valutazione finora

- AerodynamicsDocumento221 pagineAerodynamicskyoobumNessuna valutazione finora

- 182q PohDocumento330 pagine182q PohrayduxNessuna valutazione finora

- 2.engine Master Presentation 2Documento165 pagine2.engine Master Presentation 2Harinderpal Singh PannuNessuna valutazione finora

- T113 - DX225LCA DB58 Engine ManualDocumento203 pagineT113 - DX225LCA DB58 Engine Manualdaniel alberto galvis jaimes75% (4)

- Diagnostic Trouble Code (DTC) List - Vehicle (Vehicle DTC Information) Document ID# 910473Documento20 pagineDiagnostic Trouble Code (DTC) List - Vehicle (Vehicle DTC Information) Document ID# 910473Carlos Alberto CruzNessuna valutazione finora

- HILUX 2.4G / 2.8G (Diesel Auto) : Model Code: GUN125, 126Documento10 pagineHILUX 2.4G / 2.8G (Diesel Auto) : Model Code: GUN125, 126Stanley WongNessuna valutazione finora

- 6HK1Documento70 pagine6HK1Yew LimNessuna valutazione finora

- Dash 7: Microsoft Flightsimulator 2004Documento4 pagineDash 7: Microsoft Flightsimulator 2004Raph 1123Nessuna valutazione finora

- Rear Axle DriveDocumento14 pagineRear Axle Drivescott glackenNessuna valutazione finora

- Midlife Bobcat A770 PT PimDocumento1 paginaMidlife Bobcat A770 PT PimPutera Bumi NusantaraNessuna valutazione finora

- Numerical and Experimental Study Supersonic Combustor Employing Swept Ramp Fuel InjectorsDocumento1 paginaNumerical and Experimental Study Supersonic Combustor Employing Swept Ramp Fuel InjectorsKumbamNessuna valutazione finora

- QSX15 G7Documento2 pagineQSX15 G7Hernan VarelaNessuna valutazione finora

- LM Product BrochureDocumento20 pagineLM Product BrochurekashishNessuna valutazione finora

- Training of G-3520 H PresentationDocumento87 pagineTraining of G-3520 H PresentationLio Messi100% (1)

- List Parts OH FM260JD & TIDocumento9 pagineList Parts OH FM260JD & TIMaintenance PlannerNessuna valutazione finora

- Bombardier-Challenger 01-Automatic Flight Control SystemDocumento28 pagineBombardier-Challenger 01-Automatic Flight Control SystemEmanøel AlvesNessuna valutazione finora

- BMW ABS DSC Pump Problems Troubleshooting YOUCANICDocumento22 pagineBMW ABS DSC Pump Problems Troubleshooting YOUCANICBriliana MalaikaNessuna valutazione finora

- FI135 Aplicaciones NavistarDocumento2 pagineFI135 Aplicaciones NavistarBogar PinedaNessuna valutazione finora

- 4 Motor 4G1 MitsubishiDocumento96 pagine4 Motor 4G1 Mitsubishijasson meloNessuna valutazione finora

- Engine Guideline Engine Guideline: Engine Mechanical F8B EngineDocumento42 pagineEngine Guideline Engine Guideline: Engine Mechanical F8B EnginePraveen KumarNessuna valutazione finora

- Bridgestone LoadTablesDocumento39 pagineBridgestone LoadTablesAbrar HussainNessuna valutazione finora

- Capri 1984-1994 - EEC Engine Supplement - CarDocumento44 pagineCapri 1984-1994 - EEC Engine Supplement - Carjanuar1983Nessuna valutazione finora

- Accent P0012 Camshaft Position-Timing Over-Retarded (Bank 1)Documento5 pagineAccent P0012 Camshaft Position-Timing Over-Retarded (Bank 1)flash_24014910Nessuna valutazione finora

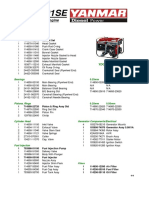

- Yanmar Seri Ydg5001se Part ListDocumento1 paginaYanmar Seri Ydg5001se Part Listahmat ramadaniNessuna valutazione finora