Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

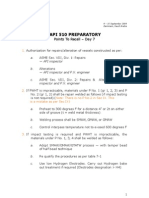

Api 510 Preparatory: Points To Recall - Day 9

Caricato da

Ranaweera Ariyamanjula0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

49 visualizzazioni4 pagineapi510

Titolo originale

510_PC_OCT04_PTR_D-9_PSJ

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoapi510

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

49 visualizzazioni4 pagineApi 510 Preparatory: Points To Recall - Day 9

Caricato da

Ranaweera Ariyamanjulaapi510

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

4 15 September 2004

Dammam, Saudi Arabia

API 510 PREPARATORY

Points To Recall Day 9

1. For MT (Art.7):

a. Yoke Type: Electromagnet or Permanent Magnet.

Suitable or !urace "eect!.

b. Pro" Type: Electromagnet

Suitable or !urace#!ub$!urace "eect!

c. E%amination Me"ium: &ry po'"er or (et Po'"er

&ry po'"er !uitable or )ig)er temperature!

". For Electromagnet!: E*uipment Ammeter! !)all be c)ecke"

anually 'it) a Ma!ter Ammeter. + ,ea"ing!

to be taken an" !)oul" be 'it)in -$ 1./ o ull !cale.

e. 0iting Po'er o Yoke!

A1 !)all )a2e liting po'er o at lea!t 3.4 5g

&1 !)all )a2e liting po'er o at lea!t 16.1 5g

(eig)t too !)all be c)ecke" prior to ir!t u!e

. Min. t'o e%amination! on eac) area7 t)e !econ" i!

perpen"icular to ir!t

g. Pro" Spacing $ 8ot e%cee" 69 an" not le!! t)an +9

:. SE$7;7 <T Mea!urement:

a. Pul!e$ Ec)o met)o" can be a"opte" up to :.. "eg. F. 8ot

!uitable on 1oar!e$=rain 1a!ting!.

b. Apparatu!: $ + type! > 1,T rea" out

$ 1,T - "irect rea" out

$ &irect t)ickne!! rea" out

1

c. Searc) <nit!: + type!

$ Straig)t beam contact type

$ &elay line type. (&elay block to minimi?e "ea" ?one).

Suitable or 0o' t)ickne!!

$ &ual element type. (T'o cry!tal! in one unit).

0o' roo angle u!e" or )ig)er t)ickne!! range an"

2ice$2er!a. 0o' t)ickne!!e! mea!urement! re*uire

@ee$error correction.

". Aig) t)ickne!! mea!urement:

<!e o multiple ec)o i! ma"e by u!ing t)inner calibration

block. T)e !econ" la!t back$ec)o coinci"e! to ?eroB t)e la!t

ec)o to t)e en" o !creen7 t)e !creen i! t)u! calibrate" to

t)ickne!! o t)e calibration block.

e. ()ile taking mea!urement or )ig) temperature

con"ition a po!iti2e error o 1/ per 44C1 (1..CF)

'ill re!ult!. Aence temperature correction i! nece!!ary.

. 1,T rea" out i! recommen"e" ')en relecting !urace i!

corro"e" or roug).

+. Acceptance criteria are to be applie" to in"ication! an" not

actual !i?e o "i!continuity.

3. T)e c)lori"e !alt! in 1ru"e7 in t)e pre!ence o 'ater (or "uring

!team !tripping) pro"uce! A1l aci" ')ic) can attack t)e !teel

an" in pre!ence o A

:

S7 t)e A1l i! regenerate" continuing t)e

corro!ion o !teel e*uipment!

Fe - :A1l $$D Fe1l

:

- :A

Fe10

:

- :A1l $$D FeS - :A1l

4. Atomic Ay"rogen can cau!e Ay"rogen En"uce" 1racking (AE1) an"

Ay"rogen Fli!tering (AF) at )ig) temp (D6..CF). En a""ition to

AE1 an" AF7 t)e !teel become! !pongy a! met)ane ga! ormation

take! place by combining Ay"rogen 'it) ree 1arbon ')ic) i!

coming rom "ecompo!ition o 1ementite.

2

G. A

:

S 'ill cau!e AE1 an" AF "ue to ormation o Atomic Ay"rogen

"uring !ulp)i"e corro!ion o !teel (Fe - A

:

S $$D FeS - :A). an"

A

:

S al!o regenerate! A1l a! in (6) abo2e.

7. Ero!ion i! cau!e" "ue to )ig) 2elocity lo' o !oli" !u!pen!ion! in

li*ui"! an" ga!e! or li*ui" !u!pen!ion! in ga!e!. ,.H.E. 2arie! a!

1ube o 2elocity.

6. Entergranular corro!ion o aut)entic S.S. i! cau!e" "ue to

1)romium carbi"e precipitation at grain boun"rie!7 making t)e

area! clo!e to grain boun"rie! "epleting c)romium belo'

!tainle!! limit o 11.4/.

;. @e!!el in!pection! are or T)e !aety7 continuity7 reliability.

1.. =rap)iti?ation in 1arbon Steel! take! place "ue to prolonge"

e%po!ure in 6:4 to 13.. "eg. F range re!ulting in "ecompo!ition

o Steel into Ferrite 1ry!tal! an" =rap)ite 8o"ule!. En$!itu

Metallograp)y i! u!e" to "etect t)e =rap)iti?ation

11. E%ternal in!pection o Pr. @e!!el! an" E%c)anger! !)oul" !tart

'it) la""er!7 platorm!7 !tair'ay! connecte" to or bearing on

2e!!el.

1:. E%ternal !urace! o 2e!!el! !)all be e%amine" or not only or

corro!ion but al!o or leak!7 crack!7 buckle!7 etc.

1+. E any !ettling i! !een on 2e!!el7 no??le! an" a"Iacent !)ell area

!)all be in!pecte" or "i!tortion an" cracking.

13. Aammer te!t !)all be ollo'e" by !uitable 8&T.

14. =roun"ing connection re!i!tance !)all not e%cee" :4 o)m! but 4

o)m! i! normally preerre".

1G. En pre!ence o aci"ic co ro"ent! (PA J 7) )y"rogen bli!tering i!

e%pecte" abo2e an" belo' (clo!e to) li*ui" le2el.

17. Au%iliary e*uipment! (Pr. gauge!7 !ig)t gla!!7 !aety 2al2e! etc.

may be 2i!ually in!pecte" ')ile in !er2ice. <n"ue 2ibration!

!)all be arre!te" by pro2i"ing a""itional !upport! or *ualiie"

engineer !)oul" "etermine i t)e!e coul" lea" to atigue ailure.

3

16. Fir!t !tep or internal in!pection i! re2ie' o pre2iou! recor"!.

1;. For )ea2y 'all 2e!!el! at )ig) pre!!ure7 maIor concern i! crack

"amage particularly at t)e 'el"! ( (el" K AAL).

:.. En pre!ence o aci"ic co ro"ent! (PAJ7) )y"rogen bli!tering i!

e%pecte" abo2e an" belo' (clo!e to) li*ui" le2el.

:1. 0amination! run !lant ')ile crack! run normal to !urace.

::. Spark te!ting i! eecti2e met)o" or break!#leak! in paint7 gla!!7

pla!tic an" rubber lining.

:+. <T i! t)e primary mean! o obtaining t)ickne!! mea!urement!.

Ht)er met)o"! like proile ra"iograp)y7 Step$'e"ge compari!on

ra"iograp)!7 1orro!ion button!7 te!t )ole! an" "ept) "rilling are

!ome ot)er met)o"!

:3. pAM7 repre!ent! neutral lui". pAD7 in"icate! ba!ic ')ile

pAJ7 in"icate! aci"ic lui".

4

Potrebbero piacerti anche

- 132 K.V Sub-Station Nakodar, JalandharDocumento24 pagine132 K.V Sub-Station Nakodar, JalandharMrJatinder Singh100% (1)

- HVAC Guide Specifications Air-Cooled Liquid Chiller 9.6 To 54.3 Tons (25 To 200 KW) Nominal 30RA Part 1 - GeneralDocumento6 pagineHVAC Guide Specifications Air-Cooled Liquid Chiller 9.6 To 54.3 Tons (25 To 200 KW) Nominal 30RA Part 1 - GeneralB De Jesus AlbornozNessuna valutazione finora

- Fractional Differential Equations: An Introduction to Fractional Derivatives, Fractional Differential Equations, to Methods of Their Solution and Some of Their ApplicationsDa EverandFractional Differential Equations: An Introduction to Fractional Derivatives, Fractional Differential Equations, to Methods of Their Solution and Some of Their ApplicationsNessuna valutazione finora

- The Zeeman Effect Lab ReportDocumento11 pagineThe Zeeman Effect Lab ReportShweta SridharNessuna valutazione finora

- Pressure Vessel and Stacks Field Repair ManualDa EverandPressure Vessel and Stacks Field Repair ManualValutazione: 4 su 5 stelle4/5 (4)

- Tectono-Magmatic Precursors For Porphyry Cu - (Mo-Au) Deposit FormationDocumento18 pagineTectono-Magmatic Precursors For Porphyry Cu - (Mo-Au) Deposit FormationAnonymous XTsbOs4oUWNessuna valutazione finora

- THERMAL BREAKDOWNDocumento15 pagineTHERMAL BREAKDOWNAlexander MartinNessuna valutazione finora

- Renewable Energy: Thermodynamic Analysis of A Type Stirling Engine With A Displacer Driving Mechanism by Means of A LeverDocumento17 pagineRenewable Energy: Thermodynamic Analysis of A Type Stirling Engine With A Displacer Driving Mechanism by Means of A LeverAditia Putra KurniawanNessuna valutazione finora

- Post Tensioning ManualDocumento11 paginePost Tensioning ManualSatish KumarNessuna valutazione finora

- Pengujian Harmonisa Dan Upaya Pengurangan Gangguan Harmonisa Pada Lampu Hemat EnergiDocumento13 paginePengujian Harmonisa Dan Upaya Pengurangan Gangguan Harmonisa Pada Lampu Hemat EnergiFallah MaulanaNessuna valutazione finora

- The Quantum ComputerDocumento18 pagineThe Quantum ComputerAbhishek BendigeriNessuna valutazione finora

- ASME Pressure Vessel Fabrication Rules SummaryDocumento7 pagineASME Pressure Vessel Fabrication Rules SummaryviswamanojNessuna valutazione finora

- Scheme of Work 13Documento13 pagineScheme of Work 13Raj Nittiya SugumaranNessuna valutazione finora

- Engineering Survey 2: Measuring Distance OpticallyDocumento48 pagineEngineering Survey 2: Measuring Distance OpticallyEmanErNessuna valutazione finora

- Predictive Maintainance Using Thermal ImagingDocumento28 paginePredictive Maintainance Using Thermal ImagingGeetha_Sulaksh_9338Nessuna valutazione finora

- API 510 Certification Data Sheets Title GeneratorDocumento11 pagineAPI 510 Certification Data Sheets Title Generatornikafiq100% (1)

- Introduction To Drilling TechnologyDocumento37 pagineIntroduction To Drilling TechnologyBetzabé CarolinaNessuna valutazione finora

- Construction Project: Atomic BombDocumento5 pagineConstruction Project: Atomic BombLeone2008Nessuna valutazione finora

- Successq 88Documento6 pagineSuccessq 88Anonymous UCveMQ100% (1)

- The Development of ASME SA 213 T23 High Pressure Boiler TubeDocumento8 pagineThe Development of ASME SA 213 T23 High Pressure Boiler TubesusanwebNessuna valutazione finora

- The Problem and Its SettingDocumento6 pagineThe Problem and Its SettingJude Maala OnanadNessuna valutazione finora

- Engineering Thermodynamics615PT103Documento4 pagineEngineering Thermodynamics615PT103sankarsuper83Nessuna valutazione finora

- Advances in Structural Concrete: Association of Engineers, Gaza Governorates, PalestineDocumento33 pagineAdvances in Structural Concrete: Association of Engineers, Gaza Governorates, Palestinehanan-3000-1999Nessuna valutazione finora

- Ferrous Alloys: Applications and Processing of Metal AlloysDocumento56 pagineFerrous Alloys: Applications and Processing of Metal AlloysMartha Isabel SernaNessuna valutazione finora

- Pipeline Hydrotest PlanDocumento16 paginePipeline Hydrotest PlanSunday Paul0% (1)

- Simple Electrolysis Bath For Cleaning Old Coins How Does It Work?Documento4 pagineSimple Electrolysis Bath For Cleaning Old Coins How Does It Work?arxo_9Nessuna valutazione finora

- Fundación Belén Educación examen de ciencias celularesDocumento4 pagineFundación Belén Educación examen de ciencias celularesConstanza Rojos AlmunaNessuna valutazione finora

- Capaoj - Tat ..: Aht Auao - Tcihw Pdatr-Z-.Pazt Imn (15) Bue F1Documento8 pagineCapaoj - Tat ..: Aht Auao - Tcihw Pdatr-Z-.Pazt Imn (15) Bue F1Alin PinkNessuna valutazione finora

- University of Craiova Faculty of Electrotechnics: Eng. George Marian PISCDocumento10 pagineUniversity of Craiova Faculty of Electrotechnics: Eng. George Marian PISCcfcshakerNessuna valutazione finora

- Experiment 9: Preparation and Analysis of A Coordination CompoundDocumento4 pagineExperiment 9: Preparation and Analysis of A Coordination CompoundDaizLee AhmadNessuna valutazione finora

- Structural Precast SpecificationsDocumento10 pagineStructural Precast SpecificationsrammirisNessuna valutazione finora

- Tender For Supply and Delivery of 1650 Tonne of Aluminium Sulphate Contract No.: AGM/SUP/CHEM/ALS/2013/01Documento2 pagineTender For Supply and Delivery of 1650 Tonne of Aluminium Sulphate Contract No.: AGM/SUP/CHEM/ALS/2013/01Nilanthi KumariNessuna valutazione finora

- Major Engineering Failures 1977-2007 Part 1: Material, Corrosion, Design, ConstructionDocumento22 pagineMajor Engineering Failures 1977-2007 Part 1: Material, Corrosion, Design, ConstructionMarius Bodea100% (1)

- COMPONENT INTEGRITY ASSESSMENT IN HEAVY WATER PLANTSDocumento4 pagineCOMPONENT INTEGRITY ASSESSMENT IN HEAVY WATER PLANTSVicky GautamNessuna valutazione finora

- MDF and Protective Devices-Ind TRGDocumento7 pagineMDF and Protective Devices-Ind TRGAyush GoswamiNessuna valutazione finora

- Modelling the Injection Stretch Blow Moulding of PET Containers via a Pressure-Volume-Time Thermodynamic RelationshipDocumento4 pagineModelling the Injection Stretch Blow Moulding of PET Containers via a Pressure-Volume-Time Thermodynamic RelationshipRafael Calle Napoleon LuisNessuna valutazione finora

- Kumar ViswasDocumento32 pagineKumar Viswaserkant007Nessuna valutazione finora

- Nuclear Energy & Its Effect: A Term Paper OnDocumento20 pagineNuclear Energy & Its Effect: A Term Paper Onharshdpatel34Nessuna valutazione finora

- Bgas 1Documento25 pagineBgas 1Manoranjan Nayak60% (5)

- Anchor BlockDocumento65 pagineAnchor Blocknirez14Nessuna valutazione finora

- HUP & LUP CCS C64A HDB Housekeeping & Safety Audit Report 13.01.2011Documento9 pagineHUP & LUP CCS C64A HDB Housekeeping & Safety Audit Report 13.01.2011Shahid AliNessuna valutazione finora

- Modern Theory of CorrosionDocumento98 pagineModern Theory of CorrosionMujahid HaddadNessuna valutazione finora

- Sathyabama University: (Established Under Section 3 of UGC Act, 1956)Documento2 pagineSathyabama University: (Established Under Section 3 of UGC Act, 1956)rahulmnm007Nessuna valutazione finora

- FisaTehnologica-3 2 FT2 - 87Documento67 pagineFisaTehnologica-3 2 FT2 - 8717ges100% (1)

- 2010 A Level CH P2 AnsDocumento6 pagine2010 A Level CH P2 AnsClementMakNessuna valutazione finora

- PHY-201 physics band structure superconductivityDocumento2 paginePHY-201 physics band structure superconductivityMukul SuryawanshiNessuna valutazione finora

- Second Semester Examination 2006 Secondary 1 Express: East Spring Secondary SchoolDocumento23 pagineSecond Semester Examination 2006 Secondary 1 Express: East Spring Secondary SchoolLim Kew ChongNessuna valutazione finora

- 4 Geoengineering Projects Doomed To Fail 1. Stratospheric AerosolsDocumento6 pagine4 Geoengineering Projects Doomed To Fail 1. Stratospheric AerosolsTara AlvaradoNessuna valutazione finora

- Chapter - 2: 2.1 Demineralization (DM) Water Treatment PlantsDocumento17 pagineChapter - 2: 2.1 Demineralization (DM) Water Treatment PlantskoolmanojsainiNessuna valutazione finora

- 8 Chemistry: B.SC.: ElectiveDocumento8 pagine8 Chemistry: B.SC.: ElectiveHF HabibNessuna valutazione finora

- Advanced Physicsprize2011Documento19 pagineAdvanced Physicsprize2011Pechey FernandezNessuna valutazione finora

- 12ME102 - Workshop Practice LAB MANUALDocumento16 pagine12ME102 - Workshop Practice LAB MANUALBenuel SathishNessuna valutazione finora

- Paper and Iron Booking DetailsDocumento1 paginaPaper and Iron Booking DetailsTiago Teixeira LealNessuna valutazione finora

- Inflammatory Bowel Disease in The Elderly: Gastroenterology ClinicsDocumento21 pagineInflammatory Bowel Disease in The Elderly: Gastroenterology ClinicsOana BucataruNessuna valutazione finora

- Project Report On CutchDocumento19 pagineProject Report On CutchMeghal VadhvanaNessuna valutazione finora

- Electrochemistry (AP MC)Documento5 pagineElectrochemistry (AP MC)Nyxas IoannisNessuna valutazione finora

- FEC O&M Manual for Sugar Plant Fire Protection SystemsDocumento38 pagineFEC O&M Manual for Sugar Plant Fire Protection SystemsRajkumar Prasad100% (2)

- Gap Control For Socket Weld Back Welded Threaded FittingsDocumento12 pagineGap Control For Socket Weld Back Welded Threaded Fittingslaz_k100% (1)

- Diessel MsdsDocumento10 pagineDiessel MsdsajuhaseenNessuna valutazione finora

- API 510 Preparatory Course GuideDocumento7 pagineAPI 510 Preparatory Course GuideRanaweera AriyamanjulaNessuna valutazione finora

- Jitsi Mobile App InstallDocumento2 pagineJitsi Mobile App InstallRanaweera AriyamanjulaNessuna valutazione finora

- Ev Homeowner BrochureDocumento2 pagineEv Homeowner BrochureRanaweera AriyamanjulaNessuna valutazione finora

- API 510 Prep Course QuestionsDocumento30 pagineAPI 510 Prep Course QuestionsRanaweera AriyamanjulaNessuna valutazione finora

- ASME IX ExerciseDocumento11 pagineASME IX ExerciseRanaweera Ariyamanjula100% (1)

- Examination Information-570 PDFDocumento1 paginaExamination Information-570 PDFJeganeswaranNessuna valutazione finora

- Touring en LowRes NewlogoDocumento13 pagineTouring en LowRes NewlogoAndrea FilipNessuna valutazione finora

- API CoursesDocumento14 pagineAPI CoursesOmar Alkubaici100% (2)

- 577 ExerciseDocumento40 pagine577 Exerciseariyamanjula2914100% (1)

- API 572 Study Guide QuestionsDocumento21 pagineAPI 572 Study Guide QuestionsRanaweera Ariyamanjula100% (1)

- Api 510 Preparatory: Points To Recall - Day 2Documento2 pagineApi 510 Preparatory: Points To Recall - Day 2Ranaweera AriyamanjulaNessuna valutazione finora

- API 510 Study QuestionsDocumento49 pagineAPI 510 Study QuestionsDavid Drolet Tremblay100% (1)

- API 576 ExerciseDocumento10 pagineAPI 576 Exerciseariyamanjula2914100% (1)

- API 572 Study Guide QuestionsDocumento21 pagineAPI 572 Study Guide QuestionsRanaweera Ariyamanjula100% (1)

- Garlock GasketsDocumento46 pagineGarlock GasketskfchksdhbvkjhshfNessuna valutazione finora

- 510 PC Oct04 PTR D-7 PSJDocumento3 pagine510 PC Oct04 PTR D-7 PSJRanaweera AriyamanjulaNessuna valutazione finora

- Api 510 Preparatory: Points To Recall - Day 4Documento2 pagineApi 510 Preparatory: Points To Recall - Day 4Ranaweera AriyamanjulaNessuna valutazione finora

- Api 510 Preparatory: Points To Recall - Day 5Documento1 paginaApi 510 Preparatory: Points To Recall - Day 5Ranaweera AriyamanjulaNessuna valutazione finora

- Api 510 Preparatory: Points To Recall - Day 8Documento3 pagineApi 510 Preparatory: Points To Recall - Day 8Ranaweera AriyamanjulaNessuna valutazione finora

- Api 510 QB A-FDocumento54 pagineApi 510 QB A-FRanaweera Ariyamanjula100% (1)

- Api 510 Preparatory: Points To Recall - Day 6Documento2 pagineApi 510 Preparatory: Points To Recall - Day 6Ranaweera AriyamanjulaNessuna valutazione finora

- 510 PC Oct04 PTR D-10 PSJDocumento1 pagina510 PC Oct04 PTR D-10 PSJRanaweera AriyamanjulaNessuna valutazione finora

- Lesson 14 Quizzes - 30 - To - 32 PDFDocumento1 paginaLesson 14 Quizzes - 30 - To - 32 PDFRanaweera AriyamanjulaNessuna valutazione finora

- Lesson 2 Quizzes 7 To 9Documento3 pagineLesson 2 Quizzes 7 To 9Ranaweera AriyamanjulaNessuna valutazione finora

- Lesson 8 Quizzes 19 To 21Documento1 paginaLesson 8 Quizzes 19 To 21Ranaweera AriyamanjulaNessuna valutazione finora

- API 510 Closed ExamDocumento20 pagineAPI 510 Closed Examariyamanjula2914100% (9)

- 510 Closed Exam A, Rev 9Documento21 pagine510 Closed Exam A, Rev 9Pamela Lee100% (1)

- 510 Closed Exam B, Rev8Documento20 pagine510 Closed Exam B, Rev8Ranaweera AriyamanjulaNessuna valutazione finora

- Comparisonofweldingeconomy Kehlnaht 12551752Documento10 pagineComparisonofweldingeconomy Kehlnaht 12551752Asebaho BadrNessuna valutazione finora

- Sample Quiz OM Chapter2Documento2 pagineSample Quiz OM Chapter2Patleen Monica MicuaNessuna valutazione finora

- Tuomo Summanen Michael Pollitt: Case Study: British Telecom: Searching For A Winning StrategyDocumento34 pagineTuomo Summanen Michael Pollitt: Case Study: British Telecom: Searching For A Winning StrategyRanganath ChowdaryNessuna valutazione finora

- Transmission Line Surge Impedance Loading ExplainedDocumento3 pagineTransmission Line Surge Impedance Loading ExplainedviksoniNessuna valutazione finora

- Flutter Layout Cheat SheetDocumento11 pagineFlutter Layout Cheat SheetJarrett Yew0% (1)

- 3D Printing Seminar REPORT-srijanDocumento26 pagine3D Printing Seminar REPORT-srijanSrijan UpadhyayNessuna valutazione finora

- SANY HDForklift Brochure-112018Documento14 pagineSANY HDForklift Brochure-112018Rossman Mejicanos100% (1)

- UAE Branch AGM 2018/19 ElectionsDocumento6 pagineUAE Branch AGM 2018/19 ElectionsDavidNessuna valutazione finora

- Adv - Student - HandbookDocumento61 pagineAdv - Student - HandbookOmkar BezzankiNessuna valutazione finora

- Project 4 FinalDocumento2 pagineProject 4 Finalapi-307253935Nessuna valutazione finora

- Phy433 Lab Report 1Documento9 paginePhy433 Lab Report 1rabbani abdul rahimNessuna valutazione finora

- Area Manager ChecklistDocumento7 pagineArea Manager ChecklistUtkarsh RaiNessuna valutazione finora

- HypnosisDocumento2 pagineHypnosisEsteban MendozaNessuna valutazione finora

- Bid ProcessDocumento85 pagineBid ProcessRobiatol Adawiah Mohammad ShamsidiNessuna valutazione finora

- Rosalind FranklinDocumento1 paginaRosalind FranklinMichael SmithNessuna valutazione finora

- Map Book 4Documento58 pagineMap Book 4executive engineerNessuna valutazione finora

- Materials Selection For Engineering DesignDocumento31 pagineMaterials Selection For Engineering Designsyamsudin2006Nessuna valutazione finora

- New Membership Application GemsDocumento5 pagineNew Membership Application Gemslaguila18Nessuna valutazione finora

- Sdo385 50hz Doosan GeneratorDocumento4 pagineSdo385 50hz Doosan GeneratorsunshinemachineryNessuna valutazione finora

- False CeilingDocumento70 pagineFalse CeilingBharti Sikri93% (15)

- Directory StructureDocumento47 pagineDirectory StructureStevenNessuna valutazione finora

- 1SM6 2015Documento63 pagine1SM6 2015chikoo499Nessuna valutazione finora

- 5 & 6 Risk AssessmentDocumento23 pagine5 & 6 Risk AssessmentAzam HasanNessuna valutazione finora

- English Test 03Documento6 pagineEnglish Test 03smkyapkesbi bjbNessuna valutazione finora

- Vehicle and Driver Vibration - PPTDocumento16 pagineVehicle and Driver Vibration - PPTAnirban MitraNessuna valutazione finora

- Line BalancingDocumento21 pagineLine Balancingarno6antonio6spinaNessuna valutazione finora

- Ake Products 001 2016Documento171 pagineAke Products 001 2016davidNessuna valutazione finora

- How To Review A Book in Up To 5,000 Words: First StepsDocumento3 pagineHow To Review A Book in Up To 5,000 Words: First StepsAnnaNessuna valutazione finora

- Technical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemDocumento12 pagineTechnical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemAna RojasNessuna valutazione finora

- Decision Tree Classifier On Private DataDocumento8 pagineDecision Tree Classifier On Private DataBianca RodriguesNessuna valutazione finora

- A Brief History of Time: From the Big Bang to Black HolesDa EverandA Brief History of Time: From the Big Bang to Black HolesValutazione: 4 su 5 stelle4/5 (2193)

- Quantum Physics for Beginners Who Flunked Math And Science: Quantum Mechanics And Physics Made Easy Guide In Plain Simple EnglishDa EverandQuantum Physics for Beginners Who Flunked Math And Science: Quantum Mechanics And Physics Made Easy Guide In Plain Simple EnglishValutazione: 4.5 su 5 stelle4.5/5 (18)

- Summary and Interpretation of Reality TransurfingDa EverandSummary and Interpretation of Reality TransurfingValutazione: 5 su 5 stelle5/5 (5)

- The Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeDa EverandThe Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeNessuna valutazione finora

- When the Earth Had Two Moons: Cannibal Planets, Icy Giants, Dirty Comets, Dreadful Orbits, and the Origins of the Night SkyDa EverandWhen the Earth Had Two Moons: Cannibal Planets, Icy Giants, Dirty Comets, Dreadful Orbits, and the Origins of the Night SkyValutazione: 3 su 5 stelle3/5 (7)

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessDa EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessValutazione: 4 su 5 stelle4/5 (6)

- The Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismDa EverandThe Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismValutazione: 4 su 5 stelle4/5 (500)

- Strange Angel: The Otherworldly Life of Rocket Scientist John Whiteside ParsonsDa EverandStrange Angel: The Otherworldly Life of Rocket Scientist John Whiteside ParsonsValutazione: 4 su 5 stelle4/5 (94)

- Infinite Powers: How Calculus Reveals the Secrets of the UniverseDa EverandInfinite Powers: How Calculus Reveals the Secrets of the UniverseValutazione: 4.5 su 5 stelle4.5/5 (126)

- Midnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterDa EverandMidnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterValutazione: 4.5 su 5 stelle4.5/5 (409)

- Too Big for a Single Mind: How the Greatest Generation of Physicists Uncovered the Quantum WorldDa EverandToo Big for a Single Mind: How the Greatest Generation of Physicists Uncovered the Quantum WorldValutazione: 4.5 su 5 stelle4.5/5 (8)

- What is Life?: With Mind and Matter and Autobiographical SketchesDa EverandWhat is Life?: With Mind and Matter and Autobiographical SketchesValutazione: 4 su 5 stelle4/5 (139)

- The Holographic Universe: The Revolutionary Theory of RealityDa EverandThe Holographic Universe: The Revolutionary Theory of RealityValutazione: 4.5 su 5 stelle4.5/5 (75)

- The Beginning of Infinity: Explanations That Transform the WorldDa EverandThe Beginning of Infinity: Explanations That Transform the WorldValutazione: 5 su 5 stelle5/5 (60)

- Bedeviled: A Shadow History of Demons in ScienceDa EverandBedeviled: A Shadow History of Demons in ScienceValutazione: 5 su 5 stelle5/5 (5)

- Packing for Mars: The Curious Science of Life in the VoidDa EverandPacking for Mars: The Curious Science of Life in the VoidValutazione: 4 su 5 stelle4/5 (1395)

- Quantum Physics: What Everyone Needs to KnowDa EverandQuantum Physics: What Everyone Needs to KnowValutazione: 4.5 su 5 stelle4.5/5 (48)

- The Physics of God: How the Deepest Theories of Science Explain Religion and How the Deepest Truths of Religion Explain ScienceDa EverandThe Physics of God: How the Deepest Theories of Science Explain Religion and How the Deepest Truths of Religion Explain ScienceValutazione: 4.5 su 5 stelle4.5/5 (23)

- The Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldDa EverandThe Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldValutazione: 4.5 su 5 stelle4.5/5 (53)

- Chasing Heisenberg: The Race for the Atom BombDa EverandChasing Heisenberg: The Race for the Atom BombValutazione: 4.5 su 5 stelle4.5/5 (8)

- Lost in Math: How Beauty Leads Physics AstrayDa EverandLost in Math: How Beauty Leads Physics AstrayValutazione: 4.5 su 5 stelle4.5/5 (125)

- Starry Messenger: Cosmic Perspectives on CivilizationDa EverandStarry Messenger: Cosmic Perspectives on CivilizationValutazione: 4.5 su 5 stelle4.5/5 (158)

- Quantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityDa EverandQuantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityValutazione: 2 su 5 stelle2/5 (1)

- The End of Everything: (Astrophysically Speaking)Da EverandThe End of Everything: (Astrophysically Speaking)Valutazione: 4.5 su 5 stelle4.5/5 (155)