Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Evpump PDF

Caricato da

Miguel Chacon0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

108 visualizzazioni34 pagineThis Service M anual has been prepared by TR W C om m ercial Steering System s for reference and use by m echanics w ho have been trained to repair and service steering com ponents and system s. If inspection or testing reveals evidence of abnorm al w ear or dam age to the EV pum p, STOP - CONSULT the vehicle MANUFACTURER'S service MANUAL

Descrizione originale:

Titolo originale

EVPUMP.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis Service M anual has been prepared by TR W C om m ercial Steering System s for reference and use by m echanics w ho have been trained to repair and service steering com ponents and system s. If inspection or testing reveals evidence of abnorm al w ear or dam age to the EV pum p, STOP - CONSULT the vehicle MANUFACTURER'S service MANUAL

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

108 visualizzazioni34 pagineEvpump PDF

Caricato da

Miguel ChaconThis Service M anual has been prepared by TR W C om m ercial Steering System s for reference and use by m echanics w ho have been trained to repair and service steering com ponents and system s. If inspection or testing reveals evidence of abnorm al w ear or dam age to the EV pum p, STOP - CONSULT the vehicle MANUFACTURER'S service MANUAL

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 34

TRW Automotive

Commercial Steering Systems

Power Steering Pump

Service Manual

EV SERIES

Hazard Warning Definitions

Disclaimer

This Service M anual has been prepared by TR W C om m ercial Steering System s for

reference and use by m echanics w ho have been trained to repair and service steering

com ponents and system s on heavy com m ercial vehicles. TR W C om m ercial Steering

System s has exercised reasonable care and diligence to present accurate, clear and

com plete inform ation and instructions regarding the TR W C om m ercial Steering EV

Series Pow er Steering Pum ps. Since this is a general Service M anual, the photo-

graphs and illustrations m ay not look exactly like the pum p being serviced. The

procedures, therefore , m ust be carefully read and understood before servicing.

If inspection or testing reveals evidence of abnorm al w ear or dam age to the EV pum p

or if you encounter circum stances not covered in the M anual, STOP - CONSULT THE

VEHICLE MANUFACTURER'S SERVICE MANUAL AND WARRANTY. DO NOT TRY TO REPAIR OR

SERVICE AN EV POWER STEERING PUMP WHICH HAS BEEN DAMAGED OR INCLUDES ANY

PART THAT SHOWS EXCESSIVE WEAR UNLESS THE DAMAGED AND WORN PARTS ARE

REPLACED WITH ORIGINAL TRW REPLACEMENT AND SERVICE PARTS AND THE UNIT IS

RESTORED TO TRW'S SPECIFICATIONS FOR THE EV POWER STEERING PUMP.

It is the responsibility of the m echanic perform ing the m aintenance, repairs or service

on a particular EV pow er steering pum p to (a) inspect the pum p for abnorm al w ear and

dam age, (b) choose a repair procedure w hich w ill not endanger his/her safety, the

safety of others, the vehicle, or the safe operation of the vehicle, and (c) fully inspect

and test the EV pum p and the vehicle steering system to ensure that the repair or

service of the pum p has been properly perform ed and that the pum p and system w ill

function properly.

Patents

The TR W C om m ercial Steering System s EV Series Pow er Steering Pum p is covered

by several U nited States and foreign patents, either issued or pending.

TR W Inc., 2002

A warning describes hazards or unsafe practices which could result in

severe personal injury or death.

A caution describes hazards or unsafe practices which could result in

personal injury or product or property damage.

A note gives key inform ation to m ake follow ing a procedure easier or

quicker.

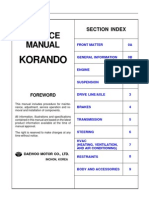

Table of Contents

Section 1 General Information

Introduction ...................................................................................4

G eneral D esign & O peration .........................................................5

Torque C hart.................................................................................6

Specification N um bers ..................................................................6

Part N um ber B reakdow n ..............................................................7

Service Parts List..........................................................................8

Exploded View ..............................................................................9

O il Flow Illustration .....................................................................10

A pproved H ydraulic Fluids ..........................................................10

Section 2 Installation

Installation Procedures................................................................12

M aintenance Tips........................................................................13

Section 3 Reseal & Repair

D isassem bly Preparation ............................................................17

D isassem bly................................................................................18

Inspection ...................................................................................22

A ssem bly Preparation/A ssem bly ................................................24

Section 4 Reinstallation

R einstallation ...............................................................................31

G lossary ......................................................................................32

It is imperative that the instructions in this booklet be followed to the letter.

Failure to observe the procedures may result in a loss of steering.

3

Section 1 General Information

Introduction .....................................................................4

G eneral D esign & O peration ...........................................5

Torque C hart....................................................................6

Specification N um bers ....................................................6

Part N um ber B reakdow n .................................................7

Service Parts List.............................................................8

Exploded View .................................................................9

O il Flow Illustration ........................................................10

A pproved H ydraulic Fluids .............................................10

4

Introduction

The three-colum n form at used in the Service M anual w ill help m ake it easy for you to

service a pow er steering pum p. C olum n 1 illustrates the procedure w ith photographs,

colum n 2 gives a brief key as w ell as tools to be used for each procedure, and colum n

3 explains in detail the procedure you should follow . Pay special attention to the notes,

cautions and warnings.

Item num bers on the exploded view correspond w ith item num bers used throughout

this service m anual.

A s you gain experience in servicing EV Series pow er steering pum ps, you m ay find

that som e inform ation in this Service M anual could be clearer and m ore com plete. If

so, let us know about it. D on't try to second-guess the Service M anual; if you do not

understand a procedure, or are stuck, contact our Field Service D epartm ent at 1-800-

TR W -0899. Servicing EV Series pum ps should be safe and productive.

5

General Design

Description of the EV Series Power Steering Pump

The EV Series pow er steering pum p is a balanced, positive displacem ent, sliding vane type, tw o line pum p w ith an

internal pilot operated flow control and relief valve. The com ponents of this description are broken dow n and

explained below :

Balanced

The pum ping elem ent has tw o pum ping pockets opposed 180 from each other w hich balance the internal forces

due to the pressure generated by the pum ping action.

Positive Displacement

The pum p w ill output a fixed volum e for each revolution of the input shaft. The fixed volum e is determ ined by the

internal contour of the cam ring.

Sliding Vane Type

This describes the type of pum ping elem ent. The EV pum ping elem ent consists of three com ponents.

1. The rotor that holds the vanes and is driven by the engine w ith the pum p input shaft.

2. The vanes that slide back and forth in slots in the rotor w hile follow ing the internal contour of the

cam ring as the rotor is being turned, thus a sliding vane.

3. The cam ring that contains the internal contour that defines the am ount of fluid that is output w ith each

revolution of the rotor.

Two Line

The EV pum p requires an inlet line to supply oil to the pum p and an outlet line to take the oil supplied by the pum p

to the steering gear. A ll excess (bypass) oil is diverted internally in the pum p housing back to the inlet of the

pum ping elem ent. O ther system s m ay have a third line w hich takes this excess oil back to the reservoir.

Internal flow Control Valve

The pum p has a pilot operated valve built into the pum p housing that w ill control the am ount of oil that is output to

the steering gear. This allow s the output flow to rem ain w ithin specification for alm ost any input speed variation.

Relief Valve (if equipped)

The pum p has a pilot operated relief valve built into the flow control valve spool w hich w ill lim it the m axim um

pressure the pum p can produce. W hen the pressure lim it has been reached, the relief section w ill cause the flow

control to bypass m ore oil internal to the pum p, lim iting the outlet pressure.

General Operation

What is a Power Steering Pump?

The pum p is the heart of the hydraulic steering system . It converts the rotational energy supplied by the engine

into hydraulic energy, flow and pressure, for use by the steering gear.

Theory of Operation

A ll pum ps function by creating a partial vacuum at the inlet, w hich causes atm ospheric pressure to force fluid into

the pum p from the reservoir. The pum p then pushes this fluid into the system for use. The fluid is used to pow er

the steering gear. Pum p output flow relates to steering gear speed and pum p output pressure relates to steering

gear force (w ork).

6

Part Name Item# Torque Dry

B olts (4) 19 24 ftlb (33 N m )

R elief valve seat assem bly 3E 7 ftlb (9 N m )

Plug 6 65 ftlb (88 N m )

Pressure port (outlet) 37 ftlb m axim um (50 N m )

Suction port (inlet) 74 ftlb m axim um (100 N m )

Torque Chart

Specification Numbers

The EV pow er steering pum p TR W part num ber,

serial num ber, and custom er part num ber are

stam ped on a m achined surface located on the

bottom of the pum p, opposite the input shaft.

Item num bers referenced above are show n on the exploded view on page 9 .

TRW NO. EVXXXXXXXXXXXX

SERIAL NO. XXXXX-XXX

CUST. NO. XXXXXXXXXXXX

7

Part Number

Fam ily designation

D isplacem ent per revolution

18 = 18 cc (1.10 cir)

22 = 22 cc (1.34 cir)

25 = 25 cc (1.53 cir)

28 = 28 cc (1.71 cir)

Flow control

12 = 12 lpm (3.17 gpm )

14 = 14 lpm (3.70 gpm )

16 = 16 lpm (4.23 gpm )

R elief setting

09 = 90 bar (1305 psi)

15 = 150 bar (2175 psi)

16 = 160 bar (2320 psi)

17 = 170 bar (2465 psi)

18 = 185 bar (2683 psi)

D irection of rotation

R = clockw ise rotation

L = counterclockw ise rotation

Shaft type

1 = 11 tooth 16/32 spline

H ousing

01 = SA E A Flange - JIC ports

02 = SA E A Flange - M etric ports

C ustom er version

00 = Standard

EV 18 12 15 R 1 01 00

8

Item Description Part Number

Seal Kit SK000255

(Includes follow ing parts)

2 Shaft seal 032847

5 O -ring seal 032845

8 O -ring seal 032852

11 O -ring seal 032853

17 O -ring seal 032851

G rease pack 406036

M SD S sheet A 10007

Service Parts List

9

EV Series Exploded View

1 H ousing

2 Shaft seal

3 Valve spool assem bly

a. Spool

b.Spring

c. Poppet

d.Shim s

e.R elief valve seat assem bly

4 Spring

5 O -ring

6 Plug

7 Input shaft

8 O -ring

9 W ave spring

10 Pressure plate

11 O -ring

12 R otor

13 Vanes

14 E-ring

15 Locating pins

16 C am ring

17 O -ring

18 End cover

19 B olts (4)

20 O rifice

21 Snap ring

1

2

20

3a

3b

3c

3d

3e

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

21

10

Approved Hydraulic Fluids

A utom atic Transm ission Fluid D exron II

A utom atic Transm ission Fluid Type "E" or "F"

C hevron 10W -40

C hevron C ustom 10W -40 M otor O il

C hevron Torque 5 Fluid

Exxon N uto H 32 H ydraulic Fluid

Fleetrite PSF (C an #990625C 2)

Ford Spec. M 2C 138C J

M ack EO -K2 Engine O il

Completely flush the steering systemwith one of the recommended fluids above only. Do

not mix oil types. Any mixture or any unapproved oil could lead to seal deterioration and

leaks. A leak could ultimately cause the loss of fluid, which could result in a loss of power

steering assist.

Oil Flow Illustration

M obil A TF 210

M obil Super 10W -40 M otor O il

Prem ium B lue 2000 - SA E 15W -40

Texaco 10W -40

Texaco TL-1833 Pow er Steering Fluid

U nion 10W -40

U nion 15W -40

U nocal G uardol 15W -40 M otor O il

The steering system should be kept filled w ith an approved hydraulic fluid specified by your O EM or w ith one of the

above fluids listed above.

Outlet Pressure

Boost Pressure

Pilot Pressure

Seal Drain

Inlet Pressure

Fluids approved and recommended for use in TRW steering systems include:

Automatic Transmission Fluid Dextron II, III, Mercon

Automatic Transmission Fluid ATF +4

NOTE Use of fluids other than approved and

recommended may void the steering system

warranty.

NOTE

1 1

Section 2 Initial Installation

Installation .....................................................................12

M aintenance Tips ..........................................................13

1 2

Initial Installation

1 . Install fittings to input and output ports, if fittings for

this application can be preinstalled.

2 . Position either a gasket or o-ring, dependent on the

application, w hich w ill seal the pum p face to the

m ounting surface.

3 . Engage the input shaft and pilot

4 . Tighten the m ounting bolts to m anufacturer's

specifications.

5 . C onnect the input and output lines.

6 . Fill the reservoir.

7 . Start the vehicle to purge the system and increase

engine speed to prim e the pum p

8 . Turn off the vehicle and check the fluid level in the

reservoir. A dd fluid as necessary.

9 . B leed the system , if necessary, using instructions in

your steering gear service m anual.

1 3

Maintenance Tips

Never high-pressure wash or steamclean a power steering pump while off the vehicle. Doing so could force contaminants

inside the pump and cause it to malfunction.

Regularly check the fluid and the fluid level in the pow er steering reservoir.

Encourage drivers to report any malfunctions or accidents w hich could have dam aged steering com ponents.

Do not attempt to weld any broken steering component. R eplace the com ponent w ith original equipm ent only.

Do not cold-straighten, hot straighten, or bend any steering systemcomponent.

A lw ays clean off around the reservoir filler cap before you rem ove it. Prevent dirt or other foreign m atter from

entering the hydraulic system .

Investigate and correct any external leaks, no m atter how m inor.

Replace reservoir filters according to requirem ents.

If you feel the vehicle is developing excessively high hydraulic fluid temperatures, consult w ith your vehicle m anu-

facturer for recom m endations.

1 4

This page intentionally left blank.

15

Section 3 Reseal & Repair

D isassem bly ..................................................................17

Inspection ......................................................................22

A ssem bly.......................................................................24

This page intentionally left blank.

17

C lean off all outside dirt from around fittings and hose connections before you rem ove the pum p.

R em ove the pum p from the vehicle and take it to a clean w ork surface.

C lean and dry the pum p before you start to disassem ble it.

A s you disassem ble the pum p, clean all parts in clean, O SH A approved solvent, and air blow -dry them

only.

Because they are flammable, be extremely careful when using any solvents. Even a small

explosion or fire could cause injury or death.

Wear eye protection and be sure to comply with OSHA or other maximumair pressure require-

ments.

CAUTION: Never steamclean or high-pressure wash hydraulic steering components. Do not

force or abuse closely fitted parts. Use care that bearing and sealing surfaces are not

damaged by the assembly and disassembly procedures.

Keep each part separate to avoid nicks and burrs.

Disassembly Preparation

18

Tools Required

Vise

N eedle-nose pliers

Sm all screw driver

Soft ham m er

Sockets: 1/2", 7/16", 1-1/16"

1-1/4"

Disassembly

Materials Required

Position pump in

vise

1. Place the pum p in a vise, clam ping firm ly on the

flange area. D o not deform the housing w ith

excessive clam ping force.

Remove plug 2. Prepare for fluid drainage. W ear eye protection

(the plug is spring-loaded) and rem ove the

hydraulic plug (6) and o-ring (5). D iscard the

o-ring.

Remove valve

spool assembly

4. R em ove the valve spool assem bly (3) using

needle-nose pliers (if necessary).

N ote w hether or not the valve spool assem bly

slides freely in the housing.

Be careful not to damage spool or

spool bore surface when removing

the spool assembly (3).

3. R em ove the spring (4), if it didn't com e out w ith

the plug.

Remove spring

1-1/4" Socket

Vise

N eedle-nose

pliers

C ollet

Press

Spacer: ID 3-1/4", depth 3"

19

5. Prepare for fluid drainage and rem ove 4 bolts (19). Remove bolts

6. Separate the end cover (18) from the housing by

prying w ith a sm all screw driver.

Be careful not to damage the end

cover sealing surface when re-

moving the end cover.

Remove housing

1/2" Socket

Sm all

screw driver

7. R em ove the o-ring (17) from the end cover.

D iscard.

Remove o-ring

Sm all

screw driver

or pick

8. Tip the assem bly in the vise and tap lightly on the

end of the input shaft w ith a soft ham m er until

the rotating group just breaks free.

Loosen rotating

group

Soft ham m er

9. R em ove the assem bly from the vise. C over the

housing bore opening w ith your hand and turn the

assem bly upside-dow n. Push on the input shaft

until the rotating group falls into your hand.

Remove rotating

group

20

11. R em ove the cam ring (16). N ote and record

w hether the circled, indented num ber near the

locating pin holes on the cam ring is up or dow n.

Remove camring,

locate number

13. Look for w ear on the face of the vanes. R em ove

the rotor (12) and vanes (13) carefully, being

prepared for the vanes to slip from their slots in

the rotor.

10. R em ove the locating pins (15).

Remove rotor and

vanes

Remove locating

pins

12. R em ove the e-ring (14) using a sm all screw driver. Remove e-ring

Sm all

screw driver

14. Push the input shaft (7) out of the pressure plate

(10).

Remove input shaft

Circled Number

21

15. R em ove tw o o-rings (8 & 11), and the w ave

spring (9) from the pressure plate (10).

Remove o-rings

and wave spring

17. Press the shaft seal (2) out of the housing, being

careful not to dam age the bore. D iscard the shaft

seal.

Damage to the bore could cause

leakage.

Remove shaft seal

Press

1-1/16" socket

Spacer:3-1/4"ID ,

3" deep

18. R em ove the relief valve seat assem bly (3E) from

the valve spool assem bly (3). Place the spool in a

collet if necessary to begin the rem oval. The seat

assem bly is spring-loaded. C om plete the rem oval

by hand and prepare to catch the com ponents.

Take care not to deformthe spool nor

make nicks or burrs on the surface.

If the spool is damaged, the pump

must be replaced.

Remove relief

valve seat assem-

bly

19. R em ove the shim s (3D ) (m ake sure to count

them ), poppet (3C ) and spring (3B ) from the spool

(3A ).

Remove spool

assembly compo-

nents

C ollet

7/16" Socket

Socket

Spacer

16. U se a sm all screw driver to rem ove the snap ring

(21) near the input shaft seal.

Remove snap ring

22

Inspection

M ake sure all sealing surfaces and seal cavities are free from nicks and corrosion. A ny nicked or

corroded surface requires part replacem ent to ensure proper sealing.

W ash all parts in clean, O SH A approved solvent. A ir blow them dry only.

Because they are flammable, be extremely careful when using any solvents. Even a small

explosion or fire could cause injury or death.

Wear eye protection and be sure to comply with OSHA or other maximumair pressure require-

ments.

1. Inspect the housing (1) for cracks, stripped threads,

dam aged valve bore and dam aged sealing areas.

M ake sure the seal drain hole is open.

2. Inspect the end cover (18) for nicks in o-ring seal

grooves.

Inspect the plate area for seal area nicks, and

abnorm al w ear or erosion. A polished pattern

from the rotor and vanes is norm al, grooves you

can feel w ith your fingernail are not norm al and

require pum p replacem ent.

Inspect housing

Inspect end cover

3. Look for obvious dam age on the inside of the

cam ring (16) like abnorm al w ear, erosion or

surface im perfections. G rooves you can feel w ith

your fingernail are not norm al and require pum p

replacem ent.

Inspect camring

4. Inspect the rotor (12) and vanes (13) for abnorm al

w ear or dam age. There w ill be norm al polish

m arks on both the top and bottom . G rooves you

can feel w ith your fingernail are not norm al and

require pum p replacem ent.

The vanes need to be free to slide both up and

dow n and in and out. If vanes are rem oved for

inspection, m ake sure to reinstall them w ith the

rounded edge out.

Inspect rotor and

vanes

23

Inspect pressure

plate

5. C heck the pressure plate (10) for abnorm al w ear

patterns. G rooves you can feel w ith your finger-

nail are not norm al and require pum p replace-

m ent.

6. C heck the input shaft (7) for dam aged splines and

unusual w ear or grooves around the shaft seal

area. G rooves you can detect w ith your fingernail

necessitate replacem ent of the pum p.

Inspect input shaft

7. Inspect spool com ponents as follow s: C heck all

com ponents for dam age. C heck the relief valve

seat assem bly (3E) for w ear or chipping. B ack

flush w ith air and solvent if necessary. C heck the

spool for nicks or burrs. G rooves you can feel

w ith your fingernail are not norm al and require

pum p replacem ent.

Inspect spool

components

24

Assembly Preparation

W ash all parts in clean, O SH A approved solvent. A ir blow -dry them only.

Because they are flammable, be extremely careful when using any solvents. Even a small

explosion or fire could cause injury or death.

Wear eye protection and be sure to comply with OSHA or other maximumair pressure require-

ments.

Tools Required

FtLb Torque w rench

Press

R atchet

J37073

N eedle-nose pliers

Materials Required

Seal Kit (if resealing the pum p)

G rease (provided in kit)

Shop tow el

Spacers for press

Assembly

1. Press the shaft seal into the housing, w ith the

lettered side facing tow ard the housing. The

installed seal should be flush w ith, or just below

the sealing surface on the housing.

Make sure the press is clean and free

of debris, and cover with a shop towel

so as not to damage the face of the

cover on which the housing rests. If

damage occurs to the housing, the

pump will not function properly.

Press in shaft seal

Press

Kent M oore

tool J37073

3. G rease the inside diam eter of the shaft seal (2)

w ith the special grease provided.

Grease shaft seal

G rease

Sockets: 1/2", 7/16", 1-1/4"

1-11/16" (2)

Vise

J 37073

Shop

Towel

2. Install the input shaft seal snap ring (21). M ake

sure it is fully seated in the groove.

Install snap ring

25

8. Insert the input shaft (7) into the pressure plate

(10). The m achined surface of the pressure plate

should be tow ard the narrow er splines on the

input shaft.

Install pressure

plate

Install end cover

o-ring

7. Install the o-ring (17) on the end cover (18). M ake

sure it is seated properly.

Do not twist or distort the o-ring

when installing.

Install large o-ring 4. Install the large o-ring (11) into its groove on the

pressure plate (10), w ith the flat side out.

Do not twist or distort the o-ring

when installing.

Install wave spring 5. Install the w ave spring (9).

Install small o-ring 6. Install the sm all o-ring (8) into its groove.

Do not twist or distort the o-ring

when installing.

Wave

Spring

O-ring

26

Install end cover

13. Install the end cover (18), aligning the holes w ith

the locating pins. The elongated locating pin hole

in the end cover aligns w ith the sim ilar holes in

the pressure plate and cam ring.

12. Install the cam ring (16) w ith the num bers facing

up O R dow n as noted during disassem bly.

Locating pins go into the sm aller holes. The

elongated locating pin hole on the pressure plate

aligns w ith the elongated locating pin hole in the

cam ring.

The installed cam ring should be fairly flush w ith

the pressure plate at the large outside diam eter.

M ake sure all vanes (13) are installed w ith the

squared edge tow ard the center of the rotor.

If not sure whether the circled

indented number should go up or

down: Check to see if the end cover

is marked with an "R" or an "L". An

"R" means the number on the cam

goes up; an "L" means the number on

the camgoes down.

Install camring

and vanes

11. Install the locating pins (15). Install locating

pins

Install e-ring 10. Install the e-ring using needle nose pliers. M ake

sure the clip is seated properly in its groove.

E-ring may become a projectile

when being installed using this

method. Use safety glasses for eye

protection.

N eedle nose

pliers

Install rotor 9. Install the rotor (12).

27

14. Assemble valve spool components: Insert spring (3B), and

poppet (3C) (blunt end rst) into the spool (3A). Install shims

(3D) onto the relief valve seat assembly (3E).

Make sure to install the same number of shims as were

removed.

Assemble valve

spool assembly

Install valve spool

assembly

Install relief valve

seat assembly

15. Screw the relief valve seat assembly (3E) into the spool (3A)

and torque to 7 ftlb (9 Nm). Placing the spool in a collet will

facilitate torquing.

Take care not to deform the spool nor

make nicks or burrs on the surface.

If the spool is damaged, the pump

must be replaced.

7/16" Socket

Torque wrench

16. Insert the valve spool assembly (3), screen end last, into the

housing. Make sure the spool slides freely in the housing. If

the cleaned spool does not slide freely, replace the pump.

17. Install the spring (4). Install spring

18. Install a new o-ring (5) onto the plug (6).

Do not twist or distort the o-ring

when installing.

Install o-ring

WARNING

Do not install the valve spool backwards; doing so disables the

pressure relief function of the pump. Serious personal injury may

occur if hydraulic components burst due to over-pressurizing

the power steering system.

28

20. Place the housing (1) over the rotating group

assem bly. M ake sure the orientation is correct

by m atching the recessed area on the end cover

w ith the plug. turn the input shaft to allow the

housing to drop on. There w ill be a gap betw een

the housing and the end cover.

21. Install the bolts (19). Thread all four bolts into the

cover evenly, and tighten finger-tight.

Install housing

Start bolts

22. Take the assem bly to a press. Place a spacer

under the end cover to clear the bolts. Place a

spacer around the input shaft, to clear the input

shaft. Place a plate on top of the spacer. Press

until the housing bottom s onto the end cover.

Press housing onto

end cover

Press

Spacers (or tw o

1-11/16"

sockets

Plate

23. Torque the bolts evenly, in an "X" pattern to 24ftlb

(33Nm)

Torque bolts

1/2" Socket

Torque w rench

Plate

Spacer

Spacer

19. Lightly grease the o-ring (5) and plug (6) threads.

Install into housing, and torque to 65ftlb (88Nm)

Install plug &

o-ring

1-1/4" Socket

Torque w rench

29

Section 4 Reinstallation

R einstallation .................................................................31

G lossary.........................................................................32

30

This page intentionally left blank.

31

Reinstallation

1. R einstall any fittings rem oved prior to disassem bly.

2. Position the new gasket or o-ring (w hichever w as

rem oved) w hich w ill seal the pum p face to the

m ounting surface.

3. Engage the input shaft and pilot.

4. Tighten the m ounting bolts to m anufacturer's

specifications.

5. U nplug and reconnect the input and output lines.

6. Fill the reservoir.

7. Start the vehicle to purge the system and increase

engine speed to prim e the pum p

8. Turn off the vehicle and check the fluid level in the

reservoir. A dd fluid as necessary.

9. B leed the system , if necessary, using instructions in

your steering gear service m anual.

32

Glossary

Abnormal Wear

A ny w ear other than norm al "polish

m arks" m ade by the spinning m otion

of the rotor and vanes. A bnorm al

w ear w ould include nicks, chips,

cracks and grooves.

Burrs

R ough edges or ridges left on m etal

by cutting or drilling.

Corrosion

G radual w earing aw ay by rust or

chem ical action.

Cracks

breaks or splits in the surface.

Damaged Splines

C racked, broken or chipped splines

on the input shaft.

Displacement

Volum e of output fluid transferred

through the pum p.

Drain Hole

Excess fluid from lubricating the seal

is diverted internally in the pum p

housing back to the inlet of the

pum ping elem ent via the drain holes

located in the cover and housing.

Erosion

G radual w earing aw ay or deteriorat-

ing.

Full Turn

A xle contacts axle stop

Grooves

A long, narrow furrow cut in a

surface.

Input Port

O pening in the pum p through w hich

fluid is received from the reservoir.

(Suction port).

Manual Bleed Systems

G ears are m ounted in such a w ay

that an air pocket could form in one

end of the steering gear. The bleed

screw is positioned so trapped air can

be forced out w hen loosened.

Nicks

Sm all cuts, indentations or chips on

the edge or surface.

OSHA

O ccupational Safety and H ealth

A dm inistration

Output Port

O pening in the pum p through w hich

fluid is forced to the steering gear.

(Pressure port).

Relief Valve

Lim its m axim um supply pressure

Subassembly

A n assem bled unit that fits into a

larger unit

Stripped Threads

B roken or dam aged threads.

Surface Imperfections

B lem ish on a m achined surface.

TRW Automotive

Commercial Steering Systems

800 Heath Street

Lafayette, IN 47904

Tel 765.423.5377

Fax 765.429.1868

http://www.trucksteering.com

http://trucksteering.trw.com

TRW Inc. 2002 TRW1313 Rev. 4/02

Potrebbero piacerti anche

- TRW1313 TRW Power Steering Pump EV Series PDFDocumento34 pagineTRW1313 TRW Power Steering Pump EV Series PDFviemey1952Nessuna valutazione finora

- PSPumpDocumento39 paginePSPumpacido4020Nessuna valutazione finora

- Manual DANA T12000 Trans MainDocumento140 pagineManual DANA T12000 Trans Maincristiannnnnnnnnn75% (8)

- TRW Steering Box Service ManualDocumento0 pagineTRW Steering Box Service ManualJuanLopez64Ch100% (1)

- Bosch MW ManualDocumento59 pagineBosch MW Manualsteynhen100% (7)

- TAS Steering Gear Service Manual: TRW AutomotiveDocumento0 pagineTAS Steering Gear Service Manual: TRW AutomotiveJulio Ramirez100% (1)

- Derbi Atlantis 50 - 100 4T (En)Documento91 pagineDerbi Atlantis 50 - 100 4T (En)Manualles0% (1)

- Mr547792en 12 01 01 PDFDocumento534 pagineMr547792en 12 01 01 PDFPolished AllNessuna valutazione finora

- Toyota Hilux Applicable Models:: Repair Manual EngineDocumento0 pagineToyota Hilux Applicable Models:: Repair Manual EngineJohn Williams100% (9)

- Outboard Manual 70-75-80-90-100-115Documento391 pagineOutboard Manual 70-75-80-90-100-115Possis76% (74)

- ZT 2800 3100 3400 PDFDocumento52 pagineZT 2800 3100 3400 PDFScott ZastrowNessuna valutazione finora

- V40232 Clark C270 Torque ConverterDocumento44 pagineV40232 Clark C270 Torque ConverterRemHenry100% (4)

- 777F MG SistemasDocumento118 pagine777F MG SistemasDenerMendozaLayza100% (6)

- CAT 3412 Air Inlet and Exhaust SystemDocumento8 pagineCAT 3412 Air Inlet and Exhaust SystemCEVegaO100% (2)

- TORQUES Actuator For Ball Valve PDFDocumento12 pagineTORQUES Actuator For Ball Valve PDFChaerul AnwarNessuna valutazione finora

- Clark CL32000 Transmission ManualDocumento152 pagineClark CL32000 Transmission ManualAnonymous iu95trpxN80% (10)

- Elecon Scoop Coupling Installation Maintenance ManualDocumento21 pagineElecon Scoop Coupling Installation Maintenance ManualVignesh VenkatasubramanianNessuna valutazione finora

- PowershiftDocumento64 paginePowershiftbenjaminNessuna valutazione finora

- 1980 Dual Jet E2 MDocumento40 pagine1980 Dual Jet E2 MNestor CastilloNessuna valutazione finora

- GTSIO 520 H OperatorsDocumento84 pagineGTSIO 520 H OperatorscarlNessuna valutazione finora

- LANCER Workshop ManualDocumento21 pagineLANCER Workshop ManualHameed0% (1)

- Torque Converter C-300 OWI - Service ManualDocumento12 pagineTorque Converter C-300 OWI - Service Manualaldino020203100% (3)

- Bosch Model Pe(s) - 6 MW Fip Service ManualDocumento50 pagineBosch Model Pe(s) - 6 MW Fip Service ManualStarchyLittleOleMeNessuna valutazione finora

- Royal Enfield Bullet Workshop Manual PDFDocumento110 pagineRoyal Enfield Bullet Workshop Manual PDFaakk7567% (6)

- ME Manual AppendixDocumento641 pagineME Manual AppendixAnonymous uTO1WI0% (1)

- BD2F BS3F Service Manual OCRDocumento340 pagineBD2F BS3F Service Manual OCRpiteng194575% (4)

- Tr7-8fi ManualDocumento82 pagineTr7-8fi ManualClint CooperNessuna valutazione finora

- Dacco 2012 Catalog Body PDFDocumento300 pagineDacco 2012 Catalog Body PDFAnonymous 59Fvbi100% (7)

- Rover 100Documento106 pagineRover 100Daniel Card100% (1)

- Powershift TransmissionDocumento124 paginePowershift TransmissionRuben Antonio Huaranca Cruz90% (10)

- 3208 Marine 75v1-Up 01z1-UpDocumento52 pagine3208 Marine 75v1-Up 01z1-UpCristobal Campos100% (3)

- Questionniares Ce & First AeDocumento67 pagineQuestionniares Ce & First AeJack PotNessuna valutazione finora

- 4.1.1 Ex3600-5Documento276 pagine4.1.1 Ex3600-5Kolo BenduNessuna valutazione finora

- Off LeakDocumento26 pagineOff LeakPatriciaH20Nessuna valutazione finora

- Pruebas y Adjustes - Troubleshooting 3512G PDFDocumento32 paginePruebas y Adjustes - Troubleshooting 3512G PDFPLANTAS ELECTRICAS H&BNessuna valutazione finora

- Nissan Td42 EngineDocumento100 pagineNissan Td42 Enginearjun c75% (4)

- Buggy Service Manual: 239 County Road 4435 Brundidge, AL 36081 P: 1-888-562-9ACE F: 1-888-562-8ACEDocumento79 pagineBuggy Service Manual: 239 County Road 4435 Brundidge, AL 36081 P: 1-888-562-9ACE F: 1-888-562-8ACELILA LAZARNessuna valutazione finora

- 201-09rev Ajuste Actuador Turbo S-60 EPA-04Documento6 pagine201-09rev Ajuste Actuador Turbo S-60 EPA-04Angel Dlsg100% (1)

- Caterpillar 3208 Maintenance EngDocumento51 pagineCaterpillar 3208 Maintenance EngGonzalo Ferreiro Soto100% (5)

- Basic Testing Pajero 1991Documento12 pagineBasic Testing Pajero 1991nadaNessuna valutazione finora

- Yamaha Seca Turbo ManualDocumento135 pagineYamaha Seca Turbo Manualsc196059100% (14)

- Outboard Manual 70 75 80 90 100 115 PDFDocumento391 pagineOutboard Manual 70 75 80 90 100 115 PDFTudorel Iancu0% (1)

- WG Instruction ManualDocumento84 pagineWG Instruction ManualsercopetrolNessuna valutazione finora

- Actuator Torque Calc PDFDocumento12 pagineActuator Torque Calc PDFNishith0% (1)

- Tulsa Guinches Manual Operativo PDFDocumento17 pagineTulsa Guinches Manual Operativo PDFJuan MorgadoNessuna valutazione finora

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Da EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Valutazione: 1 su 5 stelle1/5 (3)

- VW Transporter T4 Workshop Manual Diesel 2000-2004Da EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Valutazione: 5 su 5 stelle5/5 (5)

- Major Process Equipment Maintenance and RepairDa EverandMajor Process Equipment Maintenance and RepairValutazione: 4 su 5 stelle4/5 (4)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- Motorcycle, Solo (Harley-Davidson Model WLA)Da EverandMotorcycle, Solo (Harley-Davidson Model WLA)Nessuna valutazione finora

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BDa EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNessuna valutazione finora

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionDa EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionValutazione: 4 su 5 stelle4/5 (1)

- Outboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairDa EverandOutboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairValutazione: 3 su 5 stelle3/5 (1)

- Construction and Manufacture of AutomobilesDa EverandConstruction and Manufacture of AutomobilesValutazione: 5 su 5 stelle5/5 (1)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsDa EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsValutazione: 5 su 5 stelle5/5 (5)

- Vo Ling Micro MetroDocumento1 paginaVo Ling Micro MetroMiguel ChaconNessuna valutazione finora

- Wingle Engine ServicemanualDocumento196 pagineWingle Engine ServicemanualJoch Caso Alvariño85% (13)

- Engine Torque SpecsDocumento124 pagineEngine Torque SpecsZack Leon85% (13)

- DITEX Catalogue2005 PDFDocumento193 pagineDITEX Catalogue2005 PDFMiguel ChaconNessuna valutazione finora

- Aplic Bombas ChinasDocumento2 pagineAplic Bombas ChinasMiguel ChaconNessuna valutazione finora

- Great Wall Service ManualDocumento484 pagineGreat Wall Service ManualJeison Isaza100% (1)

- Great Wall Service ManualDocumento484 pagineGreat Wall Service ManualJeison Isaza100% (1)

- Stanadyne Inyectores y ToberasDocumento70 pagineStanadyne Inyectores y ToberasMas Inyeccion Electronica100% (1)

- Evinrude Johnson Gale ID ChartDocumento80 pagineEvinrude Johnson Gale ID ChartMichaelNessuna valutazione finora

- Mini 05 03M V3 PDFDocumento75 pagineMini 05 03M V3 PDFMiguel Chacon100% (1)

- Calibrating Nozzle Holder AssyDocumento1 paginaCalibrating Nozzle Holder AssyMiguel ChaconNessuna valutazione finora

- Kubota Manual 9Y011-02153 PDFDocumento124 pagineKubota Manual 9Y011-02153 PDFMiguel Chacon100% (2)

- 58a447service ManualDocumento132 pagine58a447service ManualMiguel Chacon100% (2)

- Owners Manual: AppendixDocumento84 pagineOwners Manual: AppendixMiguel ChaconNessuna valutazione finora

- Supplier Self Assessment Productive Material PDFDocumento2 pagineSupplier Self Assessment Productive Material PDFMiguel ChaconNessuna valutazione finora

- Service Manual Common Rail System Isuzu 4HK1 6HK1Documento48 pagineService Manual Common Rail System Isuzu 4HK1 6HK1vagpoul95% (148)

- PDFDocumento47 paginePDFMiguel Chacon100% (2)

- CR Calibration GasketsDocumento4 pagineCR Calibration GasketsMiguel ChaconNessuna valutazione finora

- PDFDocumento47 paginePDFMiguel Chacon100% (2)

- Service Manual Common Rail System (CRS) - DensoDocumento134 pagineService Manual Common Rail System (CRS) - DensoThang Tong86% (7)

- Kamaz Civil VehiclesDocumento84 pagineKamaz Civil VehiclesTudor Costin100% (1)

- Daewoo Korando Service ManualDocumento1.462 pagineDaewoo Korando Service Manualzambila4088% (17)

- FLYER HANDPRUEFSTAND en PDFDocumento6 pagineFLYER HANDPRUEFSTAND en PDFMiguel ChaconNessuna valutazione finora

- FLYER HANDPRUEFSTAND en PDFDocumento6 pagineFLYER HANDPRUEFSTAND en PDFMiguel ChaconNessuna valutazione finora

- 2010 NEXIQ Catalog PDFDocumento12 pagine2010 NEXIQ Catalog PDFMiguel ChaconNessuna valutazione finora

- Inyeccion CombustibleDocumento38 pagineInyeccion CombustiblehenryvilchezvalenciaNessuna valutazione finora

- M2 2007 Electrical Body Builder Manual Rev NewDocumento20 pagineM2 2007 Electrical Body Builder Manual Rev NewRoger Lechado Garcia93% (29)

- PDFDocumento16 paginePDFMiguel Chacon100% (1)

- Air ParkerDocumento8 pagineAir Parkeradvancedlab6Nessuna valutazione finora

- Kobelco Sk603 Parts Sec WatDocumento112 pagineKobelco Sk603 Parts Sec Wateng_ebrahim_2000100% (2)

- Seals GuideDocumento40 pagineSeals GuideMIANessuna valutazione finora

- Cushion Sub: Instruction Manual 4105Documento20 pagineCushion Sub: Instruction Manual 4105Foros IscNessuna valutazione finora

- Blackmer Parts List Pump Model: X2BDocumento2 pagineBlackmer Parts List Pump Model: X2BVinicius AraujoNessuna valutazione finora

- 2007 Approximation of Contact Stress For A Compressed and Laterally One Side Restrained O-RingDocumento13 pagine2007 Approximation of Contact Stress For A Compressed and Laterally One Side Restrained O-RingBib GmzNessuna valutazione finora

- Repuestos Sugeridos LF90D Final 2020Documento7 pagineRepuestos Sugeridos LF90D Final 2020Felipe BernalNessuna valutazione finora

- Ohlins General Workshop ManualDocumento61 pagineOhlins General Workshop Manualhusa501100% (6)

- Pi StonesDocumento211 paginePi StonesRPINILLA (EICO S.A.)Nessuna valutazione finora

- WS-600SH-OMM For PPS3228383 PDFDocumento46 pagineWS-600SH-OMM For PPS3228383 PDFAndres NavarroNessuna valutazione finora

- Agitator DatasheetDocumento1 paginaAgitator DatasheetpavanNessuna valutazione finora

- Vacuum Breakers Brochure (Metric)Documento4 pagineVacuum Breakers Brochure (Metric)avgpaulNessuna valutazione finora

- Serie 90 Bomba 42cc Manual de PartesDocumento68 pagineSerie 90 Bomba 42cc Manual de PartesMauricio Ariel H. Orellana100% (1)

- Engine Oil Cooler - InstallDocumento2 pagineEngine Oil Cooler - InstallAbdul AzisNessuna valutazione finora

- RL Docking SS KT Jayakarta 3Documento198 pagineRL Docking SS KT Jayakarta 3Agustinus Leonardo SijabatNessuna valutazione finora

- O Ring ChartDocumento2 pagineO Ring ChartMani Kandan100% (1)

- PSL-2 Seal KitDocumento10 paginePSL-2 Seal KitbrunosamaeianNessuna valutazione finora

- Suppressor Engineering 101Documento6 pagineSuppressor Engineering 101Irma Knutt80% (5)

- ZT 6000 VSDocumento14 pagineZT 6000 VSdesign_artNessuna valutazione finora

- 24 Serrage D'une Culasse.Documento6 pagine24 Serrage D'une Culasse.AliHabesNessuna valutazione finora

- 06-2 Data Sheet Oil FilterDocumento2 pagine06-2 Data Sheet Oil FilterAnonymous 9WNqHZNessuna valutazione finora

- Cast Cat 2013Documento360 pagineCast Cat 2013megatornadoNessuna valutazione finora

- Apple Rubber O-RingsDocumento6 pagineApple Rubber O-RingsKiran Kumar K TNessuna valutazione finora

- Sellos Hidraulicos PDFDocumento883 pagineSellos Hidraulicos PDFmarcoNessuna valutazione finora

- Operator'S Manual: Ept-55 Hand Pallet TruckDocumento18 pagineOperator'S Manual: Ept-55 Hand Pallet TruckKenneth SaganNessuna valutazione finora

- ZF ActuatorDocumento40 pagineZF Actuatorgiapy000093% (45)

- Catalogo Gardner Denver.Documento12 pagineCatalogo Gardner Denver.fabiancho1969Nessuna valutazione finora

- Type A31A High PerformanceDocumento24 pagineType A31A High PerformanceJesus BolivarNessuna valutazione finora

- D85E-SS-2 S/N J11264-UP: Control Valve (1-Spool) (1/3)Documento4 pagineD85E-SS-2 S/N J11264-UP: Control Valve (1-Spool) (1/3)Hendry PardedeNessuna valutazione finora

- PartesCOP MD20Documento68 paginePartesCOP MD20Francisco Gajardo67% (3)