Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Emiss Calc Hotmix

Caricato da

jnmanivannanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Emiss Calc Hotmix

Caricato da

jnmanivannanCopyright:

Formati disponibili

HOT MIX ASPHALT PLANT SPREADSHEET INSTRUCTIONS DRAFT

The objective of this spreadsheet is to aid in the calculation of emissions from Hot Mix Asphalt Plants.

Depending on their function, cells throughout the spreadsheet have been color coded as follows:

Function Description

Input Cells Please Enter the requested information into these cells.

Result Cells These cells show the result of a calculation and cannot be modified.

Input Cells These Cells show imported information from other sections of the spreadsheet, and may be modified.

Emission Factor Cells Show appropriate Emission Factor. May not be modified.

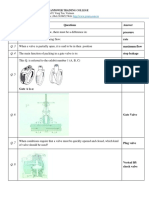

Please use the Following Flowchart to calculate emissions.

Required Steps are shown inside a red box. Optional steps are inside a black box.

Dryer Emission

Calculations

Cold Mix

Calculations

(if applicable)

Material

Handling

Stockpiles

Hot Oil Heater

Color

General

Information

Production and

Schedule

Internal

Combustion

Engine 1

Emissions Table

Internal

Combustion

Engine 2

Silo Filling &

Truck Loadout

Lime Silo

Emissions (if

available)

Recycled

Asphalt

Pavement

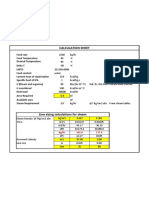

HOT MIX ASPHALT PLANT EMISSION CALCULATIONS WORKSHEET

DRAFT

Permit No.: Project No.:

Company: Project Type:

Plant ID No. or name: Nonattainment Area:

Regulated Entity Number: Customer Reference No:

City: Date:

County: Reviewer:

BACK TO FLOWCHART

Go to flowchart

DRAFT

hr/day

day/week

week/year

0 hr/year

MAXIMUM ACTUAL PRODUCTION RATES

MIX TYPE HOURLY WEEKLY ANNUAL

(ton/hr) (ton/wk) (ton/yr)

Standard -

Rubber Modified -

Cold- Rapid Cure

Cold - Medium Cure

Cold - Slow/Specialty Cure

Cold- Emulsion

Other Mixes (describe):

MAXIMUM: 0 TOTAL 0

OPERATING SCHEDULE

Go to flowchart

DRYER EMISSIONS

DRAFT

Please Answer the following questions and complete the following tables:

Is this an Asphalt batch plant? (Please type yes or no as appropriate) : yes

Type of Fuel:(Please type NG for natural gas, D for diesel, or RO for reclaimed oil):

d

DRYER EMISSIONS

NOX CO SO

2

Emission Factor (lb/ton) 0.008 0.120 0.400 0.088 0.226

Hourly Prod (ton/hr) 0 0 0 0 0

Annual Prod (ton/yr) 0 0 0 0 0

E1 (lb/hr) 0.00 0.00 0.00 0.00 0.00

E2 (ton/yr) 0.00 0.00 0.00 0.00 0.00

Go to AP-42

Chapter 1

Per Table 11.1-7 footnote(c), emissions of SO2 may be calculated based on fuel usage and EF from Chapter

1, Sections 1.3 and 1.4.

Go to AP-42 HMAP

Emission factors last updated on February 2006, according to EPA AP42, Chapter 11, Table 11.1-7 and 11.1-

8. Please Check Current Emission Factors, and notify spreadseet administrator of any change

Combustion

VOCs

Rubber Modified

VOCs

Go to flowchart

CONTROLLED PM EMISSIONS FROM DRYER

AP-42 EF (lb/ton) Emissions Based on AP-42

0 0 0.042 0.027 0.00 0.00 0.00 0.00

EPA Ap-42 Emission Factors will be used, please skip the following table

Design Max. Airflow Rate (acfm)

Temp (F)

Water Vapor Content (%) (3)

Outlet Grain Loading (gr/scf)

Max Sand Content of Mix (percent)

Standard Flow (scfm) 0

Dry Standard Flow (dscfm) 0

PM

10

(lb/hr) 0.00 Dryer Baghouse Stack Emission Results

PM

10

(ton/yr) 0.00 lb/hr tpy

Sand (lb/hr) 0.00 PM 0.00 0.00

Sand (ton/yr) 0.00 PM10 0.00 0.00

3- Use 20% if not known EPA AP-42 emission factors were used to calculate PM emissions

PM

10 ton/yr

Type GL if dryer emissions will be calculated using outlet grain loading method,

otherwise type EPA and AP-42 factors will be used will be used

epa

PM

10

PM (lb/hr) PM

10 (lb/hr)

PM (ton/yr HP (ton/hr) AP (ton/yr) PM

DRAFT

Please Complete the Following Tables:

COLD MIX VOCs

Rapid Cure Medium Cure Slow / Specialty Cure Emulsion Other

Hourly Production (ton/hr) 0 0 0 0 0

Annual Production (ton/yr) 0 0 0 0 0

Weekly Production (ton/wk) 0 0 0 0

Percent Shipped

EF1 (lb/ton) 2.5 3.5 2 1.75

EF2 (lb/hr-ton-week) n/a 0.0042 0.0024 0.0021 TOTAL

VOC (lb/hr) (stack) 0.00 0.00 0.00 0.00 0.00 0.00

VOC (ton/yr) (stack) 0.00 0.00 0.00 0.00 0.00 0.00

VOC (lb/hr) (fugitive) 0.00 0.00 0.00 0.00

VOC (ton/yr) (fugitive) 0.00 0.00 0.00 0.00

Max Unloading Rate (dcfm)

Outlet Grain Loading of Bagh(gr/scf)

Annual Unloading Hours (hr/yr)

PM10 (lb/hr) 0.00

PM10 (ton/yr) 0.00

PM EMISSIONS FROM HYDRATED LIME STORAGE

Go to flowchart

DRAFT

Please Complete the following Table:

RECLAIMED ASPHALT PRODUCT EMISSIONS

Crusher 1 Crusher 2 Screen 1 Screen 2 Screen 3 Total

Rap Throughput (ton/hr) (5)

Rap Throughput (ton/yr) (5)

PM Emission Factor (lb/ton) 0.00504 0.00504 0.025 0.025 0.025

PM

10

Emission Factor (lb/ton) 0.0024 0.0024 0.0087 0.0087 0.0087

Control Factor 1 1 1 1 1

PM (lb/hr) 0.00 0.00 0.00 0.00 0.00 0.00

PM (ton/yr) 0.00 0.00 0.00 0.00 0.00 0.00

PM10 (lb/hr) 0.00 0.00 0.00 0.00 0.00 0.00

PM

10

(ton/yr) 0.00 0.00 0.00 0.00 0.00 0.00

(5) Aggregate throughput is assumed to be 95% of asphalt production

Go to flowchart

TABLE 8: BATCH & CONTINUOUS DROP POINTS DRAFT

The following have a list of common material transfer points with their associated emission factors.

You may add custom drops in the blue cells

PM PM10

2 0.000034 0.000016

3 0.001764 0.00011

4 0.00014 0.000046

5 0.0084 0.00084

6 specify specify

7 specify specify

The following have a list of common control methods with their associated efficiencies

You may add custom controls in the blue cells

Control Method

None a 0 1

Wet Material b 50 0.5

Water c 70 0.3

Chemicals d 80 0.2

Enclosed e 90 0.1

Saturated Excess Water f 95 0.05

Define Custom Control g Specify specify

Please Complete the Following Table based on the above two tables

Drop Point Emission Calculation Table

1 0.00000

2 0.00000

3 0.00000

4 0.00000

5 0.00000

6 0.00000

7 0.00000

8 0.00000

9 0.00000

Throughput (5)

Other Drop Point

Drop Description

Control

Efficiency %

Control

Factor

Control

Type ID

0.00021 0.0001

Truck Unloading Crushed

Stone (Dry)

Truck Unloading Fragmented

Stone (Dry)

Aggregate Screen -Dry

Conveyor Transfer - Wet

Drop Type

ID

Emission Factors (lb/ton)

Aggregate Screen -Wet ()

Define Custom Drop Point

1

Drop No. Description

Control

Method

Drop Type

ID

Emission Factors

Control

Type ID

ton/hr ton/yr PM lb/ton

10 0.00000

Alternatively, if using the drop equation complete the following table, and enter the results in the PM emission factor table as Drop ID No. 6 or 7.

Drop Point Equations Table

wind speed (Appendix) Note: Resultant quality rating decreases significantly if:

% of moisture content [a] wind speed is less than 1.5 mph or greater than 15 mph, or

PM EF(lb/ton) 0.0000 [b] if moisture content is less than 0.25% or greater than 4.8%

PM10 EF(lb/ton) 0.0000 Drop point Equations Based on AP-42 Chapter 13 Section 2

Total Drop Point Emissions

0.000 0.000 0.000 0.000

0.000 0.000 0.000 0.000

0.000 0.000 0.000 0.000

0.000 0.000 0.000 0.000

0.000 0.000 0.000 0.000

0.000 0.000 0.000 0.000

0.000 0.000 0.000 0.000

0.000 0.000 0.000 0.000

0.000 0.000 0.000 0.000

0.000 0.000 0.000 0.000

Total 0.000 0.000 0.000 0.000

Error (6) means a "Water" or "Wet material" control factor may not be applied to a "Wet Emission Factor:.

Emissions

PM lb/hr PM ton/yr PM10 lb/hr PM ton/yr

0.00000 1

0.00000 1

0.00000 1

0.00000 1

0.00000 1

0.00000 1

0.00000 1

0.00000 1

0.00000 1

PM10

lb/ton

Control

Factor

Go to flowchart

Emission Factors

Number of

like points

0.00000 1

Alternatively, if using the drop equation complete the following table, and enter the results in the PM emission factor table as Drop ID No. 6 or 7.

[a] wind speed is less than 1.5 mph or greater than 15 mph, or

[b] if moisture content is less than 0.25% or greater than 4.8%

CHAPTER 13 Section2

Error (6) means a "Water" or "Wet material" control factor may not be applied to a "Wet Emission Factor:.

RAW MATERIAL STOCKPILES & GENERATOR EMISSIONS DRAFT

Stockpile Area (acres)

Control ID

Please Specify Control ID 1

Number of active days per year

PM inactive emissions (ton/yr) 0

PM10 inactive emissions (ton/yr) 0

PM active emissions (ton/yr) 0

PM10 active emissions (ton/yr) 0

TOTAL PM emissions (ton/yr) 0

TOTAL PM10 emissions (ton/yr) 0

Note: [8] Active stockpiles are those that have 8 or more hours of activity per 24 hours.

RAW MATERIAL STOCKPILES

Go to Material Drop Points Factors Table for CONTROL ID

Go to flowchart

Go to Material Drop Points Factors Table for CONTROL ID

GENERATOR No. 1 EMISSIONS DRAFT

Is there an additional engine or generator on site?

Engine make & model:

Maximum rated power: 0 hp kW

Hours of operation/yr: hr/yr

Distance to nearest property line: feet

Sulfur Content %

no

<600 hp

Pollutant EF (lb/hp-hr) lb/hr ton/yr

NOx 0.00 0.00

CO 0.00 0.00

SO2 0.0003417 0.00 0.00

PM10 0.00 0.00

VOC 0.00 0.00

Factors as specified in EPA AP 42 Chapter 3 Section 3. Last Updated October 1996. Please check current emission factors.

The minimum distance to the property line for NAAQS compliance is 0

Compliance OK? Yes

Note: [11] Reference Title 30 Texas Administrative Code Chapter 106 Paragraph 106.512(6)( c )(ii).

Additional review may vbe warranted on a case by case basis

0.00668

0.0022

0.0024141

Go to flowchart

Please complete Table 8 and attach a Table 29 for each generator.

Are Manufacturers Emission Factors Available ? (type yes or no)

emissions

0.031

Factors as specified in EPA AP 42 Chapter 3 Section 3. Last Updated October 1996. Please check current emission factors.

feet

CHAPTER 3

Go to flowchart

Please complete Table 8 and attach a Table 29 for each generator.

GENERATOR No. 2 EMISSIONS DRAFT

Is there an additional engine or generator on site?

Engine make & model:

Maximum rated power: 0 hp kW

Hours of operation/yr: hr/yr

Distance to nearest property line: feet

Sulfur Content %

no

<600 hp

Pollutant EF (lb/hp-hr) lb/hr ton/yr

NOx 0.00 0.00

CO 0.00 0.00

SO2 0.0003417 0.00 0.00

PM10 0.00 0.00

VOC 0.00 0.00

Factors as specified in EPA AP 42 Chapter 3 Section 3. Last Updated October 1996. Please check current emission factors.

The minimum distance to the property line for NAAQS compliance is 0

Compliance OK? Yes

Note: [11] Reference Title 30 Texas Administrative Code Chapter 106 Paragraph 106.512(6)( c )(ii).

Additional review may vbe warranted on a case by case basis

0.00668

0.0022

Go to flowchart

Please complete Table 8 and attach a Table 29 for each generator.

Are Manufacturers Emission Factors Available ? (type yes or no)

emissions

0.031

0.0024141

Factors as specified in EPA AP 42 Chapter 3 Section 3. Last Updated October 1996. Please check current emission factors.

feet

Go to flowchart

Please complete Table 8 and attach a Table 29 for each generator.

CHAPTER 3

HOT OIL HEATER/SILO FILLING AND TRUCK LOADOUT DRAFT

TANKS

SILO FILLING AND TRUCK LOADOUT lbs/hr Tons/Yr lbs/hr

Total PM 0.0003 0.00 0.00 Total PM 0.0002 0.00

Please Enter Asphalt Volatility Organic PM 0.0000 0.00 0.00 Organic PM 0.0000 0.00

Loadout Temperature TOC 0.0000 0.00 0.00 TOC 0.0000 0.00

Silo Filling Temperature CO 0.0000 0.00 0.00 CO 0.0000 0.00

VOC 0.0000 0.00 0.00 VOC 0.0000 0.00

Source: Table 11.1-14, page 11.1-31, AP 42

HOT OIL HEATER EMISSION CALCULATIONS

lb/hr ton/yr

SO

2

0 0.000 0.00

Nox 0 0.000 0.00

VOC 0 0.000 0.00

CO 0 0.000 0.00

PM10 0 0.000 0.00

CHAPTER 1 EF

EF (lb/ton)

Emissions

Based on EP AP-42 Chapter 1 Sections 3 and 4. CO

Emissions from Section 11.

Emissions

Hot Oil Heater Fuel Usage (gal/hr)

Hot Oil Heater Fuel Usage (gal/year)

Go to flowchart

Storage Tanks Are Calculated Using EPA TANKS software

LOADOUT

SILO

FILLING

EF

Type of Fuel Used "o" for diesel, "ng" for gas

Sulfur Percentage in Fuel (%)

EF (lb/ton)

Tons/Yr

0.00

0.00

0.00

0.00

0.00

Emissions

Source Pollutant lb/hr ton/yr

PM 0.00 0.00

PM10 0.00 0.00

VOC 0.00 0.00

Go there! VOC (cold mix) 0.00 0.00

VOC (rubber) 0.00 0.00

NOx 0.00 0.00

CO 0.00 0.00

SO

2 0.00 0.00

Go there! Lime Silo PM10 0.00 0.00

PM 0.00 0.00

Go there! PM10 0.00 0.00

PM 0.00

Go there! PM10 0.00

VOC (cold mix) 0.00 0.00

NOx 0.00 0.00

CO 0.00 0.00

Go there! SO2 0.00 0.00

PM10 0.00 0.00

VOC 0.00 0.00

NOx 0.00 0.00

Go there! CO 0.00 0.00

SO2 0.00 0.00

PM10 0.00 0.00

VOC 0.00 0.00

Go there! PM 0.00 0.00

CO 0.00 0.00

VOC 0.00 0.00

PM 0.00 0.00

Go there! CO 0.00 0.00

VOC 0.00 0.00

SO2 0.00 0.00

Nox 0.00 0.00

Go there! VOC 0.00 0.00

CO 0.00 0.00

PM10 0.00 0.00

Go there!

Silo Filling

Truck Loadout

Hot Oil Heater

Tanks

Dryer Stack

Stockpiles

Engine Generator 1

Material Handling (drop

points, screening and RAP)

Engine Generator 2

Go to flowchart

Average Wind Speeeds for Selected Cities

City Speed (mph)

Abilene 12.1

Amarillo 13.6

Austin 9.2

Brownsville 11.5

Corpus Christi 12.0

Dallas-Fort Worth 10.8

Del Rio 9.9

El Paso 9.0

Galveston 11.0

Houston 7.8

Lubbock 12.4

Midland 11.0

Port Arthur 9.8

San Angelo 10.4

San Antonio 9.4

Victoria 10.0

Waco 11.3

Wichita Falls 11.7

DRAFT Go to flowchart

Date Action

26-Mar Corrected RAP, so that the control factor was used.

10-May Changed emission factor for CO for large engine generators

Changed emission factor for SO2 for large engine generators

Changed emission factor for PM10

Changed Emsision factor fpr VOC

17-May Corrected CO Generator for small engines 0.0068 from 0.00068

8/29/2007 Corrected the hourly fugitive formula for Cold Mix VOCs.

19-Sep Sdded Flow Chart

18-Oct Linked Flowchart

18-Oct Added second engine

10-Dec Performed update

Modified Emission factor for Small Engines to include new Sulfur Content requirement of 0.05

DT

DT

DT

DT

DT

Modified Emission factor for Small Engines to include new Sulfur Content requirement of 0.05

Potrebbero piacerti anche

- Pump Selection SH BoilersDocumento4 paginePump Selection SH BoilersAnith kumar ReddyNessuna valutazione finora

- Mist Elimnator VelocityDocumento4 pagineMist Elimnator VelocityAnonymous pVoSWn8yh0Nessuna valutazione finora

- Calculation of Gas PollutantFrom Stack Emission Per YearDocumento2 pagineCalculation of Gas PollutantFrom Stack Emission Per YeartouhidNessuna valutazione finora

- Separator 01dyDocumento44 pagineSeparator 01dyFadhil KhalidNessuna valutazione finora

- Psuextension Particle Size 4mm MetricDocumento8 paginePsuextension Particle Size 4mm MetricRed RedNessuna valutazione finora

- Vent Dispersion Calc - OptionalDocumento4 pagineVent Dispersion Calc - OptionalPeddy Nesa0% (1)

- Cent PumpDocumento1 paginaCent PumpChem.EnggNessuna valutazione finora

- XCELDocumento2 pagineXCELridanormaNessuna valutazione finora

- ETP Corrossion Rate CalculationDocumento2 pagineETP Corrossion Rate Calculationdhavalesh1Nessuna valutazione finora

- Hopper CalulationDocumento1 paginaHopper CalulationHemantk8731100% (1)

- Tabel Kalkulasi Screw Conveyor LengkapDocumento13 pagineTabel Kalkulasi Screw Conveyor LengkapRefqi Kemal HabibNessuna valutazione finora

- Solid Retention Time Calc SheetDocumento1 paginaSolid Retention Time Calc SheetStanPuneetNessuna valutazione finora

- Mixer (So3 Jadi H2so4)Documento6 pagineMixer (So3 Jadi H2so4)Evi SiswantoNessuna valutazione finora

- Test Cyclone ExcelDocumento16 pagineTest Cyclone Excelvivek mishraNessuna valutazione finora

- CID FanDocumento2 pagineCID FanIrfan AhmedNessuna valutazione finora

- 1 Energy BalancesDocumento31 pagine1 Energy Balancesمصطفى العباديNessuna valutazione finora

- Calculation Sheet For Flares: User Supplied Inputs (Grey Cells)Documento1 paginaCalculation Sheet For Flares: User Supplied Inputs (Grey Cells)VishalNessuna valutazione finora

- Combustion of Fossil FuelsDocumento5 pagineCombustion of Fossil FuelsRahul ChandrawarNessuna valutazione finora

- Simulasi Boiler SpreadsheetDocumento5 pagineSimulasi Boiler SpreadsheetNHSNessuna valutazione finora

- Length Power Dynamic Viscosity Heat FluxDocumento9 pagineLength Power Dynamic Viscosity Heat FluxAnubhav KhandelwalNessuna valutazione finora

- Cyclone CalculatorDocumento19 pagineCyclone CalculatornarsingrameshNessuna valutazione finora

- Qaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secDocumento7 pagineQaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secHemantk8731100% (1)

- Flash CalculationsDocumento10 pagineFlash CalculationsHamza AliNessuna valutazione finora

- Bdsa Batch Evapration Saving CalculationDocumento15 pagineBdsa Batch Evapration Saving CalculationmayankNessuna valutazione finora

- CentrifugalCompressorPower SI UnitsDocumento4 pagineCentrifugalCompressorPower SI UnitsReza GhanavatiNessuna valutazione finora

- Debit td G T μ n KT ρ: *dipilih Flat paddles, 4 bladesDocumento4 pagineDebit td G T μ n KT ρ: *dipilih Flat paddles, 4 bladesichsan pururimpaNessuna valutazione finora

- STM Dosing and Feeding Systems For Air Pollution ControlDocumento42 pagineSTM Dosing and Feeding Systems For Air Pollution ControlJoseph RileyNessuna valutazione finora

- Bag Filter CalculationDocumento3 pagineBag Filter CalculationJag KhadseNessuna valutazione finora

- Total Types of Wastes:: Bostik IndiaDocumento23 pagineTotal Types of Wastes:: Bostik IndiaAnonymous pVoSWn8yh0Nessuna valutazione finora

- Calculation Sheet For Flares: User Supplied Inputs (Grey Cells)Documento1 paginaCalculation Sheet For Flares: User Supplied Inputs (Grey Cells)Satria 'igin' Girindra NugrahaNessuna valutazione finora

- Sand Washing Plant (Cde) Details SR No Description Cost Total RequiredDocumento3 pagineSand Washing Plant (Cde) Details SR No Description Cost Total RequiredKAMAL SINGHNessuna valutazione finora

- UWW PRTR Electronic Toolset V5.0Documento31 pagineUWW PRTR Electronic Toolset V5.0Galih SaputraNessuna valutazione finora

- T7111-DAS-1053-A-IFA-Baghouse Datasheet - 20170930 PDFDocumento4 pagineT7111-DAS-1053-A-IFA-Baghouse Datasheet - 20170930 PDFtiantaufikNessuna valutazione finora

- IPA PreheaterDocumento9 pagineIPA PreheaterNitin KurupNessuna valutazione finora

- Data Sheet Jet Pulse Bag FilterDocumento1 paginaData Sheet Jet Pulse Bag FilterHassan SleemNessuna valutazione finora

- Belt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldDocumento1 paginaBelt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldManoj ThakurNessuna valutazione finora

- Linear Mixing CalcDocumento12 pagineLinear Mixing CalcClarence AG YueNessuna valutazione finora

- Native File For Pump (Example)Documento2 pagineNative File For Pump (Example)Venturindo SiteNessuna valutazione finora

- Particle Size Distribution: 1. Calculating The Diameter of The CycloneDocumento6 pagineParticle Size Distribution: 1. Calculating The Diameter of The CycloneNaduni RanasingheNessuna valutazione finora

- LAMPIRAN C Spesifikasi PeralatanDocumento89 pagineLAMPIRAN C Spesifikasi PeralatanRahmaisa HarahapNessuna valutazione finora

- Fuel Consumption CalculatorDocumento12 pagineFuel Consumption CalculatorUSAHA KAWAN BERSAMANessuna valutazione finora

- Properties of Compressed Air at Required PressureDocumento3 pagineProperties of Compressed Air at Required PressureErol AydinNessuna valutazione finora

- Kubota Produktinfo U30 3ALPHA2Documento5 pagineKubota Produktinfo U30 3ALPHA2MarkiyanNessuna valutazione finora

- PAP 2 DISTILASI PACKED IYAH DKKDocumento254 paginePAP 2 DISTILASI PACKED IYAH DKKRifah Rizkiyah HasibuanNessuna valutazione finora

- Bag Filter & GasometerDocumento9 pagineBag Filter & GasometerPoovanaan Sathiya SeelanNessuna valutazione finora

- Cylcone Type Selection RouteDocumento75 pagineCylcone Type Selection RouteAnonymous pVoSWn8yh0Nessuna valutazione finora

- IncinerationDocumento11 pagineIncinerationPhyu Mar Thein KyawNessuna valutazione finora

- Latest Design of ChimneysDocumento2 pagineLatest Design of ChimneysHussam Udein0% (1)

- Sizing Calculation - AC214312UJ - R0 PDFDocumento1 paginaSizing Calculation - AC214312UJ - R0 PDFPavendhan PavNessuna valutazione finora

- Force CalculationsDocumento12 pagineForce CalculationssnehaNessuna valutazione finora

- Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A PumpDocumento11 pagineCalculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pumpthanh_79Nessuna valutazione finora

- Size ReductionDocumento24 pagineSize ReductionKarynne Bernardine Gerona SiclotNessuna valutazione finora

- Heat Exchanger Design Calculation EOR Condition Design InputsDocumento4 pagineHeat Exchanger Design Calculation EOR Condition Design InputsSiva baalanNessuna valutazione finora

- Select Form Type To Navigate To The Emission Calculator For The Source TypeDocumento60 pagineSelect Form Type To Navigate To The Emission Calculator For The Source TypesegunoyesNessuna valutazione finora

- Emissions Conversion CalculatorDocumento3 pagineEmissions Conversion Calculatormittal4662Nessuna valutazione finora

- Guidelines and Examples For Manual Data Input of Liquid Storage TanksDocumento12 pagineGuidelines and Examples For Manual Data Input of Liquid Storage TankscristinelbNessuna valutazione finora

- Material Balances Formalin Production: Process DescriptionDocumento5 pagineMaterial Balances Formalin Production: Process DescriptionAdi Mulyadi Putra ParhusipNessuna valutazione finora

- Emission Calculations - Oil & Gas - 06Documento3 pagineEmission Calculations - Oil & Gas - 06dbudyNessuna valutazione finora

- ++ - Hot Dip Galvanizing CalculationsDocumento22 pagine++ - Hot Dip Galvanizing Calculationsgfrank997050% (2)

- Instructions For Spreadsheet Calculations For The Potential To Emit From Stationary Internal Combustion EnginesDocumento4 pagineInstructions For Spreadsheet Calculations For The Potential To Emit From Stationary Internal Combustion EnginesAnonymous QiMB2lBCJLNessuna valutazione finora

- 04 DEC1 A DatabaseDocumento46 pagine04 DEC1 A DatabasejnmanivannanNessuna valutazione finora

- Pipe Rack Design Wind Forces: Z F F Z ZT D 2Documento7 paginePipe Rack Design Wind Forces: Z F F Z ZT D 2jnmanivannanNessuna valutazione finora

- Final Load List 30 04 12Documento14 pagineFinal Load List 30 04 12jnmanivannanNessuna valutazione finora

- Structural Sections SpreadsheetDocumento74 pagineStructural Sections Spreadsheetpiper1985Nessuna valutazione finora

- AHU Supply Front PackageDocumento10 pagineAHU Supply Front PackagejnmanivannanNessuna valutazione finora

- Chimney Design CalcDocumento5 pagineChimney Design CalcDenny ThomasNessuna valutazione finora

- Dfmea TeamDocumento2 pagineDfmea TeamjnmanivannanNessuna valutazione finora

- Plant SpecificationsDocumento4 paginePlant SpecificationsjnmanivannanNessuna valutazione finora

- Normality Acid, N Sample Vol: ML PHDocumento10 pagineNormality Acid, N Sample Vol: ML PHjnmanivannanNessuna valutazione finora

- GEMI Equations ToolDocumento10 pagineGEMI Equations TooljnmanivannanNessuna valutazione finora

- Calculation of Heat and Mass BalanceDocumento18 pagineCalculation of Heat and Mass BalanceJitendra Bhatia100% (3)

- BP s25 Wwta-DataDocumento20 pagineBP s25 Wwta-DatajnmanivannanNessuna valutazione finora

- H 2 EauDocumento4 pagineH 2 EaujnmanivannanNessuna valutazione finora

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Documento16 pagineVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanNessuna valutazione finora

- AE7E33 Excel Template Forced Convection H T Coeff Turb Pipe Flow Si UnitsDocumento3 pagineAE7E33 Excel Template Forced Convection H T Coeff Turb Pipe Flow Si UnitsjnmanivannanNessuna valutazione finora

- Table V BP Products North America Inc. - Whiting Refinery Wastewater Treament DescriptionDocumento1 paginaTable V BP Products North America Inc. - Whiting Refinery Wastewater Treament DescriptionjnmanivannanNessuna valutazione finora

- ASTM D4007 BS W by Centrifuge PDFDocumento13 pagineASTM D4007 BS W by Centrifuge PDFRony AgistaNessuna valutazione finora

- Carbon Alloy Steel Stainless SteelDocumento4 pagineCarbon Alloy Steel Stainless Steelaswar_mhNessuna valutazione finora

- Brittle Vs Sloughing ShaleDocumento9 pagineBrittle Vs Sloughing ShaleJoseph BimoNessuna valutazione finora

- Epoxy CuringDocumento8 pagineEpoxy CuringUrban Renewal Development100% (1)

- Arvedi Brief Presentation Modernisation ProgrammeDocumento30 pagineArvedi Brief Presentation Modernisation ProgrammeKetnipha SukwannawitNessuna valutazione finora

- Greensand Casting PDFDocumento10 pagineGreensand Casting PDFNirmal KushwahaNessuna valutazione finora

- Expt 3Documento5 pagineExpt 3Debmalya1997Nessuna valutazione finora

- A Method of Approximate Tool Wear Analysis in Cold Roll FormingDocumento6 pagineA Method of Approximate Tool Wear Analysis in Cold Roll FormingAly MahdyNessuna valutazione finora

- 3电气与信息系统L936L938ENGLISH PDFDocumento62 pagine3电气与信息系统L936L938ENGLISH PDFadelmomoura100% (1)

- Separ Filter SWK-2000 Series: Improves Diesel Engine ReliabilityDocumento2 pagineSepar Filter SWK-2000 Series: Improves Diesel Engine ReliabilityJoel AgbekponouNessuna valutazione finora

- Flowserve Durco CatalogDocumento36 pagineFlowserve Durco CatalogbryandownNessuna valutazione finora

- Experiment 4 CombustionDocumento8 pagineExperiment 4 CombustionJof RomanNessuna valutazione finora

- Quicseal Fabric: DescriptionDocumento2 pagineQuicseal Fabric: DescriptionJet ToledoNessuna valutazione finora

- Pour CardDocumento2 paginePour Cardsuchendra singhNessuna valutazione finora

- K-Tron Premier Rep Catalog Dec 2010 PDFDocumento429 pagineK-Tron Premier Rep Catalog Dec 2010 PDFGerardo González33% (3)

- ST014 Sod - MetasilicateDocumento1 paginaST014 Sod - MetasilicateAreIf Cron BmxStreetNessuna valutazione finora

- Project: 4 Doors Duplex Type Boarding House: Item Materials Qty. Unit U/P AmountDocumento4 pagineProject: 4 Doors Duplex Type Boarding House: Item Materials Qty. Unit U/P AmountReynaldo PesqueraNessuna valutazione finora

- LNG Technology SelectionDocumento9 pagineLNG Technology SelectionWayne MonneryNessuna valutazione finora

- No. Questions Answer Pressure Rate Maximum Flow Stop LeakageDocumento7 pagineNo. Questions Answer Pressure Rate Maximum Flow Stop LeakageTrường Tùng LýNessuna valutazione finora

- Technical Paper SiC Ceramic MembranesDocumento5 pagineTechnical Paper SiC Ceramic MembranesEman El DsoukyNessuna valutazione finora

- RF Series-Catalog 3800 - SectionADocumento3 pagineRF Series-Catalog 3800 - SectionAStefan DinuNessuna valutazione finora

- Effects of Alloying Elements On SteelDocumento2 pagineEffects of Alloying Elements On SteelKISHORNessuna valutazione finora

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocumento1 paginaSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaNessuna valutazione finora

- NSL Monobl EngDocumento27 pagineNSL Monobl EngLuis Quintana GodoyNessuna valutazione finora

- 2016good and ImportantDocumento4 pagine2016good and ImportantMahdi koolivandNessuna valutazione finora

- Zinc Flake Technology-Technical PDFDocumento1 paginaZinc Flake Technology-Technical PDFKalyan DhakaneNessuna valutazione finora

- Additive ManufacturingDocumento27 pagineAdditive Manufacturinglorraine SandyNessuna valutazione finora

- Hydrogen Power Energy HHO Generators PDFDocumento70 pagineHydrogen Power Energy HHO Generators PDFKiran Rangineni100% (4)

- 2011 VND O&M ManualDocumento12 pagine2011 VND O&M Manualsequeira.cedric6742Nessuna valutazione finora

- Optimization of Facility Layout For Improvement in ProductivityDocumento7 pagineOptimization of Facility Layout For Improvement in ProductivityTania MajumderNessuna valutazione finora