Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Specifications PDF

Caricato da

generalclimaticDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Specifications PDF

Caricato da

generalclimaticCopyright:

Formati disponibili

Protection

of petroleum

or gas tanks

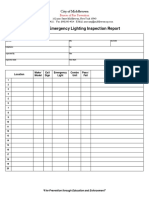

L I G H T N I N G P R O T E C T I O N S P E C I F I C A T I O N

Protection

of petroleum

or gas tanks

using a

PREVECTRON

early streamer emission

lightning conductor

GENERAL

1The lightning protection system should

be in full compliance with French lightning

protection standard NF C 17-102

(Protection of structures and open areas

against lightning using Early Streamer

Emission air terminals).

2To ensure an effective system and satisfac-

tory long term performance, all fittings need

to be mechanically robust and provide good

corrosion resistance in conditions of 50 C

and 95% relative humidity.

3All materials used should be suitable for

lightning protection installations.

AIR TERMINAL

1The air terminal should be of the

PREVECTRON

Early Streamer Emission

(E.S.E.) type which is equipped with a lower

series of energy collecting electrodes and

an upper series of spark-generating

electrodes. The triggering device of

the E.S.E. air terminal is sealed in a

stainless-steel housing fixed at the

centre of its central rod.

2The air terminal should be fixed at the top

of a free-standing ground mounted support

tower within the area to be protected.

The height of the tower would be dependent

on the level of protection and the protection

radii required. Guy wires must not be used.

3The tower should be installed outside the

safety area and a minimum distance of 8

metres from the tank must be respected.

One installation may protect several tanks.

USING A PREVECTRON

EARLY STREAMER EMISSION (E.S.E.)

LIGHTNING CONDUCTOR

PROTECTION OF

PETROLEUM OR GAS TANKS

DOWN CONDUCTOR

1The down conductor should be high

conductivity round or flat solid copper

conductor with minimum size 50 mm

2

.

It should be fixed to the structure of the

tower by means of 3 fasteners per metre.

2The down conductor should be connected

to the air terminal by a metallic adapter

located on the E.S.E. air terminal.

It should then run down the tower taking

the shortest direct route down to the

earth termination network, avoiding any

sharp corners, thereby providing a low

impedance path from the air terminal

to its earth termination system.

3A 6 digit Lightning Flash Counter may be

installed on the tower in order to count

the actual lightning strikes on the E.S.E.

air terminal.

4The base of the down conductor should

be protected from accidental knocks and

other damage by means of a 2 metre

stainless-steel protection sheath fixed

to the tower.

5A test clamp should be provided at the

bottom of the tower in a P.V.C or concrete

inspection pit so that the down conductor

may be disconnected from the earth

termination and regular checks of the earth

termination resistance be carried out.

EARTH TERMINATION SYSTEM

1The down conductor should be connected

to its own earth termination system using

a crow-foot earth termination. The crow-

foot termination is made of conductors of

the same cross-sectional area as the down

conductor of the installation and arranged

in a crow-foot fashion (three 7 to 8 metre

long conductors buried horizontally).

A copper-covered steel earth rod should

be added at the end of each copper run.

2The earth termination system should

be orientated away from storage tanks.

3The resistance value of the earth termination

system should be 10 Ohms or less.

4Each earth conductor and rod connection

should be housed in a proprietary concrete

or P.V.C pit in order to facilitate inspection.

The pit should be complete with a lid and

the assembly should be installed flush with

ground level.

5The lightning conductor earth termination

system must then be connected to the

general earthing network of the site in order

to achieve an equipotential earth network.

This connection should be equipped with a

disconnecting clamp housed in a concrete

or P.V.C inspection pit.

Conforming the international standard CEI 61643-11

and the French standard NF EN 61643-11, the installation of a type 1 overvoltage

arrester (DGS) is now mandatory for all structure equipped with a lightning air terminal.

5

2

6

8

4

10

7

11

3

9

Protection of

petroleum or gas tanks

T

h

e

c

o

m

p

o

n

e

n

t

p

a

r

t

s

s

h

o

w

n

o

n

t

h

e

l

e

f

t

a

r

e

g

i

v

e

n

b

y

w

a

y

o

f

e

x

a

m

p

l

e

o

n

l

y

.

T

h

i

s

d

r

a

w

i

n

g

i

s

n

o

t

t

o

s

c

a

l

e

.

-

I

V

O

I

A

R

T

-

L

I

L

L

E

/

F

R

A

N

C

E

-

+

3

3

(

0

)

3

2

8

5

2

6

7

5

4

-

P

h

o

t

o

:

I

n

d

e

le

c

-

D

O

C

0

3

3

.V

E

N

1 Prevectron2 S 6.60 ref : 1243

2 Self standing mast ref : 2063

3 Clamping collar ref : 6058

4 Copper conductor ref : 5001

5 Lightning flash counter ref : 8012

6 Protection sheath ref : 7014

7 Inspection housing ref : 7052

8 Test clamp ref : 7001B

9 Copper earthing ref : 7021

10 Earth rod ref : 7030

11 Rod-to-conductor clamp ref : 7039

Corporate Headquarters and Export Division

61, chemin des Postes 59500 DOUAI (France)

Tl : + 33 (0)327 944 944 - Fax : + 33 (0)327 944 955

www.indelec.com - e-mail : contact@indelec.com

USING A PREVECTRON

EARLY STREAMER EMISSION (E.S.E.) LIGHTNING CONDUCTOR

L I G H T N I N G P R O T E C T I O N S P E C I F I C A T I O N

Protection of

an open area

Protection of

an open area

using a

PREVECTRON

early streamer emission

lightning conductor

RECREATION AREA, SPORTS FIELD,

PARKING LOT, GOLF COURSE,

OUTDOOR STORAGE AREA,

GROUND PIPE NETWORK

GENERAL

1The lightning protection system should

be in full compliance with French lightning

protection standard NF C 17-102

(Protection of structures and of open areas

against lightning using Early Streamer

Emission air terminals).

2To ensure an effective system and satisfac-

tory long term performance, all fittings need

to be mechanically robust and provide good

corrosion resistance in the environment

50C and 95% relative humidity.

3All materials used should be suitable

for lightning protection installations.

AIR TERMINAL

1The air terminal should be of the

PREVECTRON

Early Streamer Emission

(E.S.E.) type which is equipped with a lower

series of energy collecting electrodes and

an upper series of spark-generating elec-

trodes. The triggering device of the E.S.E.

air terminals is sealed in a stainless-steel

housing fixed at the centre of its central rod.

2The E.S.E. air terminal should be securely

fixed at the top of a laminated wood mast

or, if this is not possible, at the top of a steel

self-standing mast installed on the ground

and located within the area to be protected.

The height of the mast would be dependent

on the level of protection and the protection

radii required for the project.

PROTECTION OF AN OPEN AREA

Recreation area, sports field, parking lot, golf course,

outdoor storage area, ground pipe network

USING A PREVECTRON

EARLY STREAMER EMISSION (E.S.E.)

LIGHTNING CONDUCTOR

DOWN CONDUCTOR

1Each E.S.E. air terminal should be equipped

with one down conductor. This conductor

should be high conductivity round or flat

solid copper conductor with a minimum

size of 50 mm

2

. It should be fixed on the

mast by means of 3 fasteners per metre.

2The down conductor should be connected

to the air terminal by a metallic adapter

located on the E.S.E. air terminal. It should

then run down the mast and take the

shortest direct route towards the earth

termination network, avoiding any sharp

corners, thereby providing a low impedan-

ce path from the air terminal to its earth

termination system.

3The base of the down conductor should

be protected from accidental knocks and

other damage by means of a 2 metre

stainless-steel protection sheath fixed

to the mast.

4A test clamp should be provided at the

bottom of the mast in a P.V.C or concrete

inspection pit so that the down conductor

may be disconnected from its earth termi-

nation system and regular checks of the

earth termination resistance be carried out.

EARTH TERMINATION SYSTEM

1The down conductor should be connected

to its own earth termination system using

a crow-foot earth termination. The crow-

foot termination is made of conductors of

the same material and cross-sectional area

as the down conductor of the installation

and should be arranged in a crow-foot

fashion (three 7 to 8 metre long conduc-

tors buried horizontally). A copper-covered

steel earth rod should be added at the end

of each copper run.

2The resistance value of each earth termi-

nation system should be 10 Ohms or less.

3Each earth conductor and rod connection

should be housed in a proprietary concrete

or P.V.C pit in order to facilitate inspection.

The pit should be complete with a lid and

the assembly should be installed flush with

ground level.

Conforming the international standard CEI 61643-11

and the French standard NF EN 61643-11, the installation of a type 1 overvoltage

arrester (DGS) is now mandatory for all structure equipped with a lightning air terminal.

Protection of an open area

RECREATION AREA, SPORTS FIELD, PARKING LOT, GOLF COURSE,

OUTDOOR STORAGE AREA, GROUND PIPE NETWORK ...

5

3

2

7

8

4

6

11

9

10

USING A PREVECTRON

EARLY STREAMER EMISSION (E.S.E.)

LIGHTNING CONDUCTOR

T

h

e

c

o

m

p

o

n

e

n

t

p

a

r

t

s

s

h

o

w

n

o

n

t

h

e

l

e

f

t

a

r

e

g

i

v

e

n

b

y

w

a

y

o

f

e

x

a

m

p

l

e

o

n

l

y

.

T

h

i

s

d

r

a

w

i

n

g

i

s

n

o

t

t

o

s

c

a

l

e

.

-

I

V

O

I

A

R

T

-

L

I

L

L

E

/

F

R

A

N

C

E

-

+

3

3

(

0

)

3

2

8

5

2

6

7

5

4

-

P

h

o

t

o

:

I

n

d

e

le

c

-

D

O

C

0

2

7

.V

E

N

Corporate Headquarters and Export Division

61, chemin des Postes 59500 DOUAI (France)

Tl : + 33 (0)327 944 944 - Fax : + 33 (0)327 944 955

www.indelec.com - e-mail : contact@indelec.com

1 Prevectron2 S 6.60 ref : 1243

2 Self standing mast ref : 2053

3 Clamping collar ref : 6058

4 Copper conductor ref : 5001

5 Lightning flash counter ref : 8012

6 Protection sheath ref : 7014

7 Inspection housing ref : 7052

8 Test clamp ref : 7001B

9 Copper earthing ref : 7021

10 Earth rod ref : 7030

11 Rod-to-conductor clamp ref : 7039

L I G H T N I N G P R O T E C T I O N S P E C I F I C A T I O N

using a

PREVECTRON

early streamer emission

lightning conductor

Protection

of a building

Protection

of a building

GENERAL

1The lightning protection system should be

in full compliance with French lightning

protection standard NF C 17-102

(Protection of structures and open areas

against lightning using Early Streamer

Emission air terminals).

2To ensure an effective system and

satisfactory long-term performance,

all fittings need to be mechanically robust

and provide good corrosion resistance

in conditions of 50 C and 95% relative

humidity.

3All materials used should be suitable

for lightning protection installations.

AIR TERMINAL

1The air terminal should be of the

PREVECTRON

Early Streamer Emission

(E.S.E.) type, which is equipped with a lower

series of energy collecting electrodes and

an upper series of spark-generating elec-

trodes. The triggering device of the E.S.E.

air terminal is sealed in a stainless-steel

housing fixed at the center of its central rod.

2The air terminal should be fixed at the top

of a steel elevation pole so as to be at least

2 metres above the structure to be protec-

ted. Its height above roof level would be

dependent on the level of protection and

the protection radii required.

3Should an aerial mast be located on the

roof of the building, the E.S.E. air terminal

should be installed at least 2 metres above

its tip. Where this aerial mast is located

within 10 metres of the E.S.E. air terminal

elevation pole, these 2 masts must be inter-

connected at roof level with a solid copper

conductor of the same cross-sectional area

as the down conductor. An aerial mast

diverter should also be installed.

4The elevation pole should be firmly attached

to the wall or roof, or on any protruding part

of the building. Guy wires may be used in

order to ensure the stability of the installation.

In this case, the bottom-end of each guy wire

should be connected to the down conductor.

5If the protection of the building requires

the installation of two or more E.S.E. air

terminals, the base of the elevation poles

should be interconnected at roof level by

a solid copper conductor of the same

cross-sectional area as the down

conductors of the installation.

PROTECTION OF A BUILDING

USING A PREVECTRON

EARLY STREAMER EMISSION (E.S.E.)

LIGHTNING CONDUCTOR

DOWN CONDUCTOR

1Each E.S.E. air terminal should be equipped

with at least one down conductor.

Two conductors should be installed on

opposite sides of the building if the protec-

ted structure is higher than 28 metres or if

the horizontal length of the down conduc-

tor is greater than its vertical length.

2The down conductor(s) should be high

conductivity round or flat solid bare or

tinned copper conductor with a minimum

size of 50 mm

2

. They should be fixed

to the structure by means of 3 fasteners

per metre.

3The down conductor(s) should be

connected to the air terminal by means

of a metallic adapter located on the E.S.E.

air terminal. It should then run down the

elevation pole and take the shortest direct

route down the outside of the building

to the earth termination network, avoiding

any sharp corners, thereby providing a low

impedance path from the air terminal to

its earth termination system.

4Any metallic object located less than

1 metre from the down conductor

should be connected to this latter

(for further information regarding bonding

specification, refer to NF C 17-102 - part 3).

5A test clamp should be installed 2 metres

above ground level so that the down

conductor may be disconnected from

the earth termination system for regular

checks of the earth termination resistance

value. This test clamp should be housed

within a concrete or P.V.C inspection pit if

the building is covered with metal cladding.

6The base of the down conductor should

be protected from accidental knocks and

other damage by means of a 2 metre

stainless-steel protection sheath fixed

to the building.

EARTH TERMINATION SYSTEM

1Each down conductor should be connected

to its own earth termination system using a

crow-foot or a triangular earth termination.

The crow-foot earthing is made of conduc-

tors of the same material and cross-sectio-

nal area as the down conductor(s) of the

installation arranged in crow-foot fashion

(three 7-to 8- metre long conductors buried

horizontally). A copper-covered steel earth

rod should be added at the end of each

copper length. The triangular earthing

system is made of a set of three vertical

copper-covered steel earth rods totalling

a minimum length of 6 metres arranged

as a triangle, each one separated from

the other by a distance equal to at least

the driven depth and interconnected by

a conductor identical to that used on

the down conductor(s).

2The resistance value of each earth termi-

nation system should be 10 Ohms or less.

3Each earth conductor and rod connection

should be housed in a proprietary concrete

or P.V.C pit in order to facilitate inspection.

The pit should be complete with a lid and

the assembly should be installed flush with

ground level.

4The lightning conductor(s) earth termination

system(s) should then be connected to the

general earth of the site in order to achieve

an equipotential earth network.

This connection should be equipped with a

disconnecting clamp housed in a concrete

or P.V.C inspection pit.

Conforming the international standard

CEI 61643-11and the French standard

NF EN 61643-11, the installation of

a type 1 overvoltage arrester (DGS) is now

mandatory for all structure equipped

with a lightning air terminal.

12

8

9

10

11

16

3

1

5

4

2

14

13

15

7

6

USING A PREVECTRON

EARLY STREAMER EMISSION (E.S.E.) LIGHTNING CONDUCTOR

Protection of a building

T

h

e

c

o

m

p

o

n

e

n

t

p

a

r

t

s

s

h

o

w

n

o

n

t

h

e

l

e

f

t

a

r

e

g

i

v

e

n

b

y

w

a

y

o

f

e

x

a

m

p

l

e

o

n

l

y

.

T

h

i

s

d

r

a

w

i

n

g

i

s

n

o

t

t

o

s

c

a

l

e

.

-

I

V

O

I

A

R

T

-

L

I

L

L

E

/

F

R

A

N

C

E

-

+

3

3

(

0

)

3

2

8

5

2

6

7

5

4

-

P

h

o

t

o

:

I

n

d

e

le

c

-

D

O

C

0

2

8

.V

E

N

Corporate Headquarters and Export Division

61, chemin des Postes 59500 DOUAI (France)

Tl : + 33 (0)327 944 944 - Fax : + 33 (0)327 944 955

www.indelec.com - e-mail : contact@indelec.com

1 Prevectron2 S 6.60 ref : 1243

2 Elevation pole ref : 2023

3 Clamping collar ref : 6058

4 Side mounting brackets ref : 3013

5 Copper conductor ref : 5001

6 Aerial mast diverter ref : 8760

7 Waterproofing holdfast ref : 6031

8 Galvanized steel hook ref : 6002

Lead plug ref : 6005

9 Lightning flash counter ref : 8010

10 Test clamp ref : 7001B

11 Protection sheath ref : 7014

12 Copper earthing ref : 7021

13 Earth rod ref : 7030

14 Rod-to-conductor clamp ref : 7039

15 Earth clamp ref : 8004

16 Inspection housing ref : 7052

Protection of

a transmission

tower

L I G H T N I N G P R O T E C T I O N S P E C I F I C A T I O N

using a

PREVECTRON

early streamer emission

lightning conductor

Protection of

a transmission

tower

GENERAL

1The lightning protection system should be

in full compliance with the French lightning

protection standard NF C 17-102

(Protection of structures and of open areas

against lightning using Early Streamer

Emission air terminals).

2To ensure an effective system and

satisfactory long-term performance,

all fittings need to be mechanically

robust and provide good corrosion

resistance in conditions of 50 C

and 95% relative humidity.

3All materials used should be suitable

for lightning protection installation.

AIR TERMINAL

1The air terminal should be of the

PREVECTRON

Early Streamer Emission

(E.S.E.) type which is equipped with a lower

series of energy collecting electrodes and

an upper series of spark-generating elec-

trodes. The triggering device of the E.S.E.

air terminal is sealed in a stainless-steel

housing fixed at the center of its central rod.

2The air terminal should be fixed at the top

of a steel elevation pole so as to be at

least 2 metres above any antenna and/or

the structure to be protected.

3The elevation pole should be firmly

attached to the top of the tower.

PROTECTION OF

A TRANSMISSION TOWER

USING A PREVECTRON

EARLY STREAMER EMISSION (E.S.E.)

LIGHTNING CONDUCTOR

DOWN CONDUCTOR

1At least two down conductors should be

fixed on opposite sides of the tower with

one being located on the prevailing wind

side. Three down conductors should be

installed if the height of the tower exceeds

40 metres. These conductors should be

interconnected every 30 metres by an

horizontal conductor. This configuration is

intended to provide the lowest impedance

path from the air terminal to the earth

termination network.

2The down conductor should be high

conductivity round or flat copper conductor

with a minimum size of 50 mm

2

. It should

be fixed to the structure by means of

3 fasteners per metre.

3Each down conductor should be connected

to the air terminal by a metallic adapter

located on the E.S.E. air terminal. It should

then run down the elevation pole and

tower taking the shortest direct route to

its earth termination network.

4In order to protect the waveguides or

coaxial cables running down the tower,

specific grounding kits should be installed.

5A 6 digit Lightning Flash Counter may be

installed on the tower in order to count the

actual lightning strikes on the E.S.E. air

terminal.

6The base of each down conductor should

be protected from accidental knocks and

other damage by means of a 2 metre

stainless-steel protection sheath fixed

to the tower.

7A test clamp should be provided for each

down conductor in a concrete or P.V.C pit

so that each down conductor may be

disconnected from its earth termination

and regular checks of the earth termina-

tion resistance value be carried out.

EARTH TERMINATION SYSTEM

1Each down conductor and the metallic

structure of the tower should be provided

with their own earth termination system

using a triangular earth termination.

The triangular termination is made of a

set of three copper-covered steel earth rods

totaling a minimum length of 6 metres

arranged in a triangular fashion and

separated from each other by a distance

at least equal to their driven depth and

interconnected by a conductor identical

to the down conductor.

2The resistance value of each earth termi-

nation system should be 10 Ohms or less.

3Each earth conductor and rod connection

should be housed in a proprietary concrete

or P.V.C pit in order to facilitate inspection.

The pit should be complete with a lid and

the assembly should be installed flush with

ground level.

4The triangular earth terminations should

then be connected together so as to form

an earth loop around the tower and achieve

the equipotential earth network of the

installation.

5This loop will then be connected to

the general earthing system of the trans-

mission building located near the tower.

This connection should be equipped

with a disconnecting clamp housed

in a concrete or P.V.C inspection pit.

Conforming the international standard

CEI 61643-11and the French standard

NF EN 61643-11, the installation of

a type 1 overvoltage arrester (DGS) is now

mandatory for all structure equipped

with a lightning air terminal.

Protection of

a transmission tower

USING A PREVECTRON

EARLY STREAMER EMISSION (E.S.E.)

LIGHTNING CONDUCTOR

1 Prevectron2 TS3.40 ref : 1213

2 Elevation pole ref : 2022

3 Clamping collar ref : 6058

4 Copper conductor ref : 5001

5 Lightning flash counter ref : 8012

6 Protection sheath ref : 7014

7 Test clamp ref : 7001B

8 Inspection housing ref : 7052

9 Copper earthing ref : 5001

10 Earth rod ref : 7030

11 Rod-to-conductor clamp ref : 7039

8

9

10

11

3

1

5

4

2

7

6

T

h

e

c

o

m

p

o

n

e

n

t

p

a

r

t

s

s

h

o

w

n

o

n

t

h

e

l

e

f

t

a

r

e

g

i

v

e

n

b

y

w

a

y

o

f

e

x

a

m

p

l

e

o

n

l

y

.

T

h

i

s

d

r

a

w

i

n

g

i

s

n

o

t

t

o

s

c

a

l

e

.

-

I

V

O

I

A

R

T

-

L

I

L

L

E

/

F

R

A

N

C

E

-

+

3

3

(

0

)

3

2

8

5

2

6

7

5

4

-

P

h

o

t

o

:

I

n

d

e

le

c

-

D

O

C

0

3

4

.V

E

N

Corporate Headquarters and Export Division

61, chemin des Postes 59500 DOUAI (France)

Tl : + 33 (0)327 944 944 - Fax : + 33 (0)327 944 955

www.indelec.com - e-mail : contact@indelec.com

L I G H T N I N G P R O T E C T I O N S P E C I F I C A T I O N

Protection of

an industrial

plant

using a

PREVECTRON

early streamer emission

lightning conductor

Protection of

an industrial

plant

GENERAL

1The lightning protection system should be

in full compliance with French lightning

protection standard NF C 17-102

(Protection of structures and of open

areas against lightning using Early

Streamer Emission air terminals).

2To ensure an effective system and

satisfactory long term performance,

all fittings need to be mechanically

robust and provide good corrosion

resistance in conditions of 50 C

and 95% relative humidity.

3All materials used should be suitable

for lightning protection installations.

AIR TERMINAL

1The air terminal should be of the

PREVECTRON

Early Streamer Emission

(E.S.E.) type which is equipped with a lower

series of energy collecting electrodes and an

upper series of spark-generating electrodes.

The triggering device of the E.S.E. air terminal

is sealed in a stainless-steel housing fixed

at the center of its central rod.

2The air terminal should be fixed at the top

of a steel elevation pole so as be at least

2 metres above the structure to be protec-

ted. Its height above roof level would be

dependent on the level of protection and

the protection radii required.

3The elevation pole should be firmly

attached to the wall, roof, or on any

protruding part of the building.

Guy wires may be used in order to ensure

the stability of the installation. In this case,

the bottom-end of each guy wire should be

connected to the down conductor.

4If the protection of the plant building

requires the installation of two or more E.S.E.

air terminals, the base of the elevation poles

should be interconnected at roof level by a

solid copper conductor of the same cross-

sectional area as the down conductors of

the installation.

PROTECTION

OF AN INDUSTRIAL PLANT

USING A PREVECTRON

EARLY STREAMER EMISSION (E.S.E.)

LIGHTNING CONDUCTOR

DOWN CONDUCTOR

1Each E.S.E. air terminal should be connected

to at least one down conductor. Two conduc-

tors should be installed on opposite sides

of the building if the protected structure is

higher than 28 metres or if the horizontal

length of the down conductor is greater

than its vertical length.

2The down conductor(s) should be high

conductivity round or flat solid bare or

tinned copper conductor with a minimum

size of 50 mm

2

. They should be fixed to the

structure by means of 3 fasteners per metre.

3The down conductor(s) should be

connected to the air terminal by means

of a metallic adapter located on the E.S.E.

air terminal. It should then run down the

elevation pole and take the shortest direct

route down the outside of the building to

the earth termination network, avoiding any

sharp corners, thereby providing a low

impedance path from the air terminal

to its earth termination system(s).

4Any metallic object located less than

1 metre from the down conductor should

be connected to the latter (for further

information regarding bonding specification,

refer to NF C 17-102 part 3).

5A 6 digit Lightning Flash Counter may

be installed in order to count the actual

lightning strikes on the E.S.E. air terminal.

6A test clamp should be installed

2 metres above ground level so that the

down conductor may be disconnected

from the earth termination system for

regular checks of the earth termination

resistance value. This test clamp should

be grounded to an inspection pit if the

building happens to be covered with

metal cladding.

7The base of the down conductor should

be protected from accidental knocks and

other damage by means of a 2 metre

stainless-steel protection sheath fixed

to the structure.

EARTH TERMINATION SYSTEM

1Each down conductor should be connected

to its own earth termination system using

a crow-foot or a triangular earth termination.

The crow-foot earthing is made of conduc-

tors of the same material and cross-sectional

area as the down conductor(s) of the installa-

tion and arranged in crow-foot fashion

(three 7 to 8 metre long conductors buried

horizontally). A copper-covered steel earth

rod should be added at the end of each

copper length. The triangular earthing

system is made of a set of three vertical

copper-covered steel earth rods totalling

a minimum length of 6 metres arranged

as a triangle and separated from each

other by a distance at least equal to the

driven depth and interconnected by a

conductor which is identical to the down

conductor(s) of the installation.

2The resistance value of each earth termi-

nation system should be 10 Ohms or less.

3Each earth conductor and rod connection

should be housed in a proprietary concrete

or P.V.C pit in order to facilitate inspection.

The pit should be complete with a lid and

the assembly should be installed flush with

ground level.

4The lightning conductor(s) earth termination

system(s) should then be connected to the

general earth of the site in order to acheive

an equipotential earth network.

This connection should be equipped with

a disconnecting clamp housed in a concrete

or P.V.C inspection pit.

Conforming the international standard

CEI 61643-11and the French standard

NF EN 61643-11, the installation of

a type 1 overvoltage arrester (DGS) is now

mandatory for all structure equipped

with a lightning air terminal.

9

Protection of an industrial plant

USING A PREVECTRON

EARLY STREAMER EMISSION (E.S.E.) LIGHTNING CONDUCTOR

1 Prevectron2 S 6.60 ref : 1243

2 Elevation pole ref : 2023

3 Clamping collar ref : 6058

4 Side mounting brackets ref : 3013

5 Copper conductor ref : 5001

6 PVC clips ref : 6071

7 Lightining flash counter ref : 8010

8 Test clamp ref : 7001B

9 Protection sheath ref : 7014

10 Copper earthing ref : 7021

11 Earth rod ref : 7030

12 Rod-to-conductor clamp ref : 7039

13 Earth clamp ref : 8004

14 Inspection housing ref : 7052

10

11

12

14

3

1

5

4

2

7

6

13

T

h

e

c

o

m

p

o

n

e

n

t

p

a

r

t

s

s

h

o

w

n

o

n

t

h

e

l

e

f

t

a

r

e

g

i

v

e

n

b

y

w

a

y

o

f

e

x

a

m

p

l

e

o

n

l

y

.

T

h

i

s

d

r

a

w

i

n

g

i

s

n

o

t

t

o

s

c

a

l

e

.

-

I

V

O

I

A

R

T

-

L

I

L

L

E

/

F

R

A

N

C

E

-

+

3

3

(

0

)

3

2

8

5

2

6

7

5

4

-

P

h

o

t

o

:

I

n

d

e

le

c

-

D

O

C

0

3

5

.V

E

N

Corporate Headquarters and Export Division

61, chemin des Postes 59500 DOUAI (France)

Tl : + 33 (0)327 944 944 - Fax : + 33 (0)327 944 955

www.indelec.com - e-mail : contact@indelec.com

Potrebbero piacerti anche

- Installation of Low Voltage Service Using 3 Core Bunched Wavecon CablesDocumento15 pagineInstallation of Low Voltage Service Using 3 Core Bunched Wavecon CablesphilipnartNessuna valutazione finora

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- 2011.10 Electra Report Non Conventional LPSDocumento6 pagine2011.10 Electra Report Non Conventional LPSRigoberto CuellarNessuna valutazione finora

- FAP128NDocumento2 pagineFAP128Ntienlam0% (1)

- Land Telegraph LinesDocumento26 pagineLand Telegraph LinesAlex WarHorseNessuna valutazione finora

- SIFANG CSC-103 V1.41 Line PTT User Manual ENUDocumento7 pagineSIFANG CSC-103 V1.41 Line PTT User Manual ENURaúlEmirGutiérrezLópezNessuna valutazione finora

- NDB System Setup GuideDocumento48 pagineNDB System Setup GuideFazz Yaakub100% (2)

- The Scenes of The Greatest ShowmanDocumento12 pagineThe Scenes of The Greatest Showmanberkk100% (1)

- AW Three Great PlaysDocumento3 pagineAW Three Great PlaysMark BraveNessuna valutazione finora

- 11kv and 33KVDocumento43 pagine11kv and 33KVArun KumarNessuna valutazione finora

- Lightning Protection SpecificationDocumento8 pagineLightning Protection SpecificationAyman SaberNessuna valutazione finora

- Lightning Protection Systems - Advantages and Disadvantages PDFDocumento11 pagineLightning Protection Systems - Advantages and Disadvantages PDFwahyuthp43Nessuna valutazione finora

- LIGHTNING - ARRESTER - PPT TMMDocumento122 pagineLIGHTNING - ARRESTER - PPT TMMtin mg mgNessuna valutazione finora

- 18.0 CRP Rev 09Documento55 pagine18.0 CRP Rev 09Anuj BhardwajNessuna valutazione finora

- Causes and Effects of LighteningDocumento7 pagineCauses and Effects of LighteningLAMIA LATANessuna valutazione finora

- AGL Jessore AirportDocumento6 pagineAGL Jessore AirportIshmum Monjur Nilock100% (1)

- Earthing System: BY: M.F.A.SolimanDocumento12 pagineEarthing System: BY: M.F.A.SolimanAmr OsamaNessuna valutazione finora

- Selection of Surge Protective Device (SPD) Types and Factors Affecting PerformanceDocumento8 pagineSelection of Surge Protective Device (SPD) Types and Factors Affecting PerformanceRahul ItaliyaNessuna valutazione finora

- Earthing (Grounding) and Bonding Guidelines For Uniprise Solutions F/UTP Cabling SystemDocumento11 pagineEarthing (Grounding) and Bonding Guidelines For Uniprise Solutions F/UTP Cabling Systemcharleselitb92Nessuna valutazione finora

- Name: Nagum, Carl Joseph, B. Date: April 23, 2021 Course/Section: TE1-PSE2-EE32S1 Midterm Exam Instructor: Engr. LaderoDocumento4 pagineName: Nagum, Carl Joseph, B. Date: April 23, 2021 Course/Section: TE1-PSE2-EE32S1 Midterm Exam Instructor: Engr. LaderoCarlnagum 123456789Nessuna valutazione finora

- Schneider Theory PDFDocumento12 pagineSchneider Theory PDFArbind KumarNessuna valutazione finora

- Protection Against Electric Shock: Electrical Power Engineering Lab IDocumento30 pagineProtection Against Electric Shock: Electrical Power Engineering Lab Irajpre1213Nessuna valutazione finora

- Earthing Is AbstractDocumento3 pagineEarthing Is AbstractShrikant KajaleNessuna valutazione finora

- XLPE UGC Withstand TestDocumento6 pagineXLPE UGC Withstand TestFuad BurhaniNessuna valutazione finora

- E Grupos DMimeDocumento3 pagineE Grupos DMimeue3b2Nessuna valutazione finora

- GE Airport Lighting Products 6.6 Amp SystemsDocumento2 pagineGE Airport Lighting Products 6.6 Amp SystemsMudassar Nore100% (1)

- Viewtenddoc PDFDocumento68 pagineViewtenddoc PDFSundaresan SabanayagamNessuna valutazione finora

- EE8701 Over Voltages in Electrical Power SystemsDocumento19 pagineEE8701 Over Voltages in Electrical Power SystemsEEE Conference100% (1)

- Voltage Sag GuideDocumento53 pagineVoltage Sag GuideHariNarayanNessuna valutazione finora

- CCR - Augier - 6021052Documento4 pagineCCR - Augier - 6021052lincoln9003198100% (1)

- Field Tests of Grounding at An Actual Wind Turbine Generator SystemDocumento6 pagineField Tests of Grounding at An Actual Wind Turbine Generator Systembal3xNessuna valutazione finora

- DanfossSemco Laustsen IWMC 2016Documento26 pagineDanfossSemco Laustsen IWMC 2016CristianLeotescuNessuna valutazione finora

- HVI Products PresentationDocumento33 pagineHVI Products PresentationAhmad HidayatNessuna valutazione finora

- Contact SystemDocumento52 pagineContact SystemdrivetecNessuna valutazione finora

- Concepts of EarthingDocumento6 pagineConcepts of EarthingKonda SrinivasNessuna valutazione finora

- Electric Fence Lightning DiverterDocumento5 pagineElectric Fence Lightning Divertersaipavan999Nessuna valutazione finora

- 3ee, Ef Seimens Surge ArrestersDocumento32 pagine3ee, Ef Seimens Surge ArrestersKenneth ParkerNessuna valutazione finora

- 11 KV SwitchgearDocumento13 pagine11 KV SwitchgearSandip AhireNessuna valutazione finora

- Bonding and Grounding FundamentalsDocumento45 pagineBonding and Grounding Fundamentalschibssa alemayehu100% (1)

- 200 Item Answer SheetDocumento4 pagine200 Item Answer SheetFroilan EspinosaNessuna valutazione finora

- REF Fuse Application GuideDocumento17 pagineREF Fuse Application GuidemuskanumeedNessuna valutazione finora

- Buku PUIL 2011 Edisi 2014Documento3 pagineBuku PUIL 2011 Edisi 2014slamet_rNessuna valutazione finora

- InsulationDocumento9 pagineInsulationASDFGHJKNessuna valutazione finora

- Motherson: (Interview Questions - Technical)Documento32 pagineMotherson: (Interview Questions - Technical)Vikas PanchalNessuna valutazione finora

- Introduction of CablesDocumento14 pagineIntroduction of CablesRanganath SriNessuna valutazione finora

- 4.4.1 On-Ceiling Sampling VESDA Pipe Network Design GuideDocumento1 pagina4.4.1 On-Ceiling Sampling VESDA Pipe Network Design GuideEduardo ParrudoNessuna valutazione finora

- Grounding Satellite Dish and Lead-In CablesDocumento5 pagineGrounding Satellite Dish and Lead-In CablesariorasalahNessuna valutazione finora

- Types of Earthing (As Per IEC Standards)Documento7 pagineTypes of Earthing (As Per IEC Standards)visakhgsNessuna valutazione finora

- 06 NFS2-3030 Prog 52545 JDocumento180 pagine06 NFS2-3030 Prog 52545 Jsiddiqui.rashidahmed96100% (1)

- Polymer Pin Insulator SpecificationDocumento14 paginePolymer Pin Insulator SpecificationdamlanNessuna valutazione finora

- GUIDE ESE InstallationDocumento1 paginaGUIDE ESE InstallationDelkan16Nessuna valutazione finora

- Motors and The NECDocumento7 pagineMotors and The NECjonathandacumosNessuna valutazione finora

- ABB Lightning ArrestersDocumento4 pagineABB Lightning ArrestersPrashanth ChandrashekarNessuna valutazione finora

- Capex ProjectsDocumento3 pagineCapex Projectspeter LamurenNessuna valutazione finora

- Switching Over Voltages in Air-Insulated Substation c4 - 301Documento8 pagineSwitching Over Voltages in Air-Insulated Substation c4 - 301rdcatano4267Nessuna valutazione finora

- A. General Description About Protection System in JordanDocumento13 pagineA. General Description About Protection System in JordanMahmoud Al-QudahNessuna valutazione finora

- 2020년 전기설비기술기준 질의회신 사례집 PDFDocumento866 pagine2020년 전기설비기술기준 질의회신 사례집 PDFSeongil KimNessuna valutazione finora

- Polyfuse Seminar Abstract - Circuit Protection That Resets AutomaticallyDocumento1 paginaPolyfuse Seminar Abstract - Circuit Protection That Resets AutomaticallyJobinHere100% (1)

- Burndy Grounding 101Documento73 pagineBurndy Grounding 101Anonymous NGXdt2BxNessuna valutazione finora

- Protection of Petroleum or Gas TanksDocumento4 pagineProtection of Petroleum or Gas TanksvidalNessuna valutazione finora

- Brasil 2003 V06.00.UKDocumento4 pagineBrasil 2003 V06.00.UKTarek FawzyNessuna valutazione finora

- Guide For Design - Early Streamer Emission Air TerminalsDocumento2 pagineGuide For Design - Early Streamer Emission Air TerminalsANDRESNessuna valutazione finora

- JE-2004 Building Risk Assessment Lightning Protection DesignDocumento3 pagineJE-2004 Building Risk Assessment Lightning Protection Designblack_3289Nessuna valutazione finora

- Brasil 2003 PDFDocumento4 pagineBrasil 2003 PDFgeneralclimaticNessuna valutazione finora

- Nadachi Wind Farm Lightning Testing Shows Prevectron Protection Above 90Documento4 pagineNadachi Wind Farm Lightning Testing Shows Prevectron Protection Above 90generalclimaticNessuna valutazione finora

- L-19 (NKK) (Ie) ( (Ee) Nptel)Documento9 pagineL-19 (NKK) (Ie) ( (Ee) Nptel)generalclimaticNessuna valutazione finora

- L-16 (NKK) (Ie) ( (Ee) Nptel)Documento9 pagineL-16 (NKK) (Ie) ( (Ee) Nptel)generalclimaticNessuna valutazione finora

- 07 - Sizing Busbar Trunkings V1 (Compatibility Mode)Documento34 pagine07 - Sizing Busbar Trunkings V1 (Compatibility Mode)generalclimaticNessuna valutazione finora

- Lighting Application: Version 2 EE IIT, Kharagpur 1Documento6 pagineLighting Application: Version 2 EE IIT, Kharagpur 1generalclimaticNessuna valutazione finora

- Intro Discrete Prob AsDocumento39 pagineIntro Discrete Prob AsCarlos Soza RossNessuna valutazione finora

- TutorialsDocumento42 pagineTutorialsnidharshanNessuna valutazione finora

- Abb Sace CurveDocumento40 pagineAbb Sace CurveAshok ChaniyaraNessuna valutazione finora

- L-20 (NKK) (Ie) ( (Ee) Nptel)Documento9 pagineL-20 (NKK) (Ie) ( (Ee) Nptel)generalclimaticNessuna valutazione finora

- L-17 (NKK) (Ie) ( (Ee) Nptel)Documento9 pagineL-17 (NKK) (Ie) ( (Ee) Nptel)generalclimaticNessuna valutazione finora

- L-18 (NKK) (Ie) ( (Ee) Nptel)Documento8 pagineL-18 (NKK) (Ie) ( (Ee) Nptel)generalclimaticNessuna valutazione finora

- L-13 (NKK) (Ie) ( (Ee) Nptel)Documento10 pagineL-13 (NKK) (Ie) ( (Ee) Nptel)generalclimaticNessuna valutazione finora

- Illumination Systems: Version 2 EE IIT, Kharagpur 1Documento5 pagineIllumination Systems: Version 2 EE IIT, Kharagpur 1generalclimaticNessuna valutazione finora

- Lamps: Version 2 EE IIT, Kharagpur 1Documento10 pagineLamps: Version 2 EE IIT, Kharagpur 1generalclimaticNessuna valutazione finora

- L-11 (NKK) (Ie) ( (Ee) Nptel)Documento6 pagineL-11 (NKK) (Ie) ( (Ee) Nptel)generalclimaticNessuna valutazione finora

- L-9 (NKK) (Ie) ( (Ee) Nptel)Documento8 pagineL-9 (NKK) (Ie) ( (Ee) Nptel)generalclimaticNessuna valutazione finora

- L-12 (NKK) (Ie) ( (Ee) Nptel)Documento8 pagineL-12 (NKK) (Ie) ( (Ee) Nptel)Laxman Naidu NNessuna valutazione finora

- L-8 (NKK) (Ie) ( (Ee) Nptel)Documento9 pagineL-8 (NKK) (Ie) ( (Ee) Nptel)TapasDattaNessuna valutazione finora

- L-7 (NKK) (Ie) ( (Ee) Nptel)Documento9 pagineL-7 (NKK) (Ie) ( (Ee) Nptel)generalclimaticNessuna valutazione finora

- L-3 (NKK) (Ie) ( (Ee) Nptel)Documento7 pagineL-3 (NKK) (Ie) ( (Ee) Nptel)Kalyanshis SadhuNessuna valutazione finora

- L-6 (NKK) (Ie) ( (Ee) Nptel)Documento9 pagineL-6 (NKK) (Ie) ( (Ee) Nptel)generalclimaticNessuna valutazione finora

- L-1 (NKK) (IE) ( (EE) NPTEL) Illumination EnginneringDocumento12 pagineL-1 (NKK) (IE) ( (EE) NPTEL) Illumination EnginneringVishal NarkhedeNessuna valutazione finora

- Illumination Engineering Basics LawsDocumento9 pagineIllumination Engineering Basics Lawscool_raagNessuna valutazione finora

- L-2 (NKK) (Ie) ( (Ee) Nptel)Documento9 pagineL-2 (NKK) (Ie) ( (Ee) Nptel)Kalyanshis SadhuNessuna valutazione finora

- Yrsb13 - Prague - Design Principles For The Street Connectivity of New Urbanism Projects - v.05 - Engl - 010213Documento12 pagineYrsb13 - Prague - Design Principles For The Street Connectivity of New Urbanism Projects - v.05 - Engl - 010213generalclimaticNessuna valutazione finora

- L-4 (NKK) (Ie) ( (Ee) Nptel)Documento10 pagineL-4 (NKK) (Ie) ( (Ee) Nptel)Latika PuchaNessuna valutazione finora

- Manual GBDocumento64 pagineManual GBgeneralclimaticNessuna valutazione finora

- The DALI Guide: Artistic LicenceDocumento16 pagineThe DALI Guide: Artistic LicenceappinassociatesNessuna valutazione finora

- Major Chords For Jazz GuitarDocumento17 pagineMajor Chords For Jazz GuitarjohnnyNessuna valutazione finora

- Guitar Technique - 60 Essential Scale Patterns For All Levels 1Documento87 pagineGuitar Technique - 60 Essential Scale Patterns For All Levels 1angel.quintero100% (4)

- TS20161015 T1690254517 No Limit Hold'em $6.82+$0.68Documento36 pagineTS20161015 T1690254517 No Limit Hold'em $6.82+$0.68Leo GuerraNessuna valutazione finora

- Instructions for Operating a TelevisionDocumento7 pagineInstructions for Operating a TelevisionAmbarwaty BilondatuNessuna valutazione finora

- Beethoven Ludwig Van Adagio Cantabile 6836 PDFDocumento4 pagineBeethoven Ludwig Van Adagio Cantabile 6836 PDFFrancescoModeoNessuna valutazione finora

- Common Fiddle Chords For Standard TuningDocumento4 pagineCommon Fiddle Chords For Standard TuningSimon WheatyNessuna valutazione finora

- BIHAR-Staff-Selection-Commission-Lists-Candidates-Rejected-Due-to-Challan-MismatchDocumento31 pagineBIHAR-Staff-Selection-Commission-Lists-Candidates-Rejected-Due-to-Challan-Mismatchkumarrahul1234Nessuna valutazione finora

- Manual Microfono AzdenDocumento2 pagineManual Microfono AzdenmarcomorenomunozNessuna valutazione finora

- Approach Towards Prelims PreparationDocumento11 pagineApproach Towards Prelims PreparationEnoch ArdenNessuna valutazione finora

- At The Five Spot, Vol. 2 - BookletDocumento6 pagineAt The Five Spot, Vol. 2 - BookletBenjamín Poblete100% (2)

- A Cinderella Story - Once Upon A Song - Wikipedia PDFDocumento26 pagineA Cinderella Story - Once Upon A Song - Wikipedia PDFRemigie CowayNessuna valutazione finora

- An-779 Low-Distortion 1.6 To 30 MHZ SSB Driver DesignsDocumento10 pagineAn-779 Low-Distortion 1.6 To 30 MHZ SSB Driver DesignsEdward YanezNessuna valutazione finora

- Pie Jesu - Full ScoreDocumento5 paginePie Jesu - Full ScoreShaun KlaasenNessuna valutazione finora

- Anca-Roberta Vlasan ResumeDocumento1 paginaAnca-Roberta Vlasan Resumeapi-245158673Nessuna valutazione finora

- About Mobiltex: Remote Monitoring UnitDocumento2 pagineAbout Mobiltex: Remote Monitoring UnitirfanlarikhotmailcomNessuna valutazione finora

- Owner's Manual PDF Manual To Obtain The PDF Manual 1. 2Documento180 pagineOwner's Manual PDF Manual To Obtain The PDF Manual 1. 2Paulo MuradNessuna valutazione finora

- 3S3 PhilipsDocumento18 pagine3S3 PhilipswiroNessuna valutazione finora

- Premio 20 DTDocumento35 paginePremio 20 DThyakueNessuna valutazione finora

- RNT Programmer NotesDocumento11 pagineRNT Programmer NotesgwillimwNessuna valutazione finora

- Global System For Mobile CommunicationDocumento53 pagineGlobal System For Mobile CommunicationJahan ZaibNessuna valutazione finora

- Coletânea Autores InstrumentosDocumento20 pagineColetânea Autores InstrumentosSergio Miguel MiguelNessuna valutazione finora

- Friday Night Lights 5x13 - AlwaysDocumento56 pagineFriday Night Lights 5x13 - Alwaysfil24Nessuna valutazione finora

- Datashee YS-1020Documento3 pagineDatashee YS-1020inyonggantengNessuna valutazione finora

- Lect A Plic 10102018Documento11 pagineLect A Plic 10102018CALORIE CALORIENessuna valutazione finora

- FadedDocumento7 pagineFadedËçël EcelNessuna valutazione finora

- RF Control System For RC Vehicle Based On ArduinoDocumento7 pagineRF Control System For RC Vehicle Based On ArduinoJosé Salvador PolancoNessuna valutazione finora

- ePSXe enDocumento20 pagineePSXe ensilindricNessuna valutazione finora