Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SPE 10923 Liquid Holdup Correlations For Inclined Two-Phase Flow PDF

Caricato da

David HernandezDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SPE 10923 Liquid Holdup Correlations For Inclined Two-Phase Flow PDF

Caricato da

David HernandezCopyright:

Formati disponibili

Liquid Holdup Correlations

Inclined Two-Phase Flow

Hemanta Mukherjee, sPE, Johnstm-Maccco Schl.tnbwgp

James P. Brill, SPE, u. of Tulsa

summary

Liquid holdup behavior in two-phase inclined flow was

studied in an inclined pipe-flow simulator. Two sets of

empirical equations, one each for uphill and downhill

flow, are presented. For downhill stratified flow, a third

equation is presented. The liquid holdup equations arc

functions of dimensionless liquid and gas velocity

numbers in addition to liquid viscosity number and angle

of inclination. These four parameters uniquely define the

flow-pattern transitions in inclined two-phase flow. Con-

sequently, the hoIdup equations are also implicitly flow-

pattern dependent.

Introduction

An accurate prediction of liquid holdup is rcquied to

compute the hydrostatic head loss in two-phase inclined

flow. In this case, hydrostatic head maybe the most im-

portant of the pressure gradient components. There are

many liquid holdup correlations in the Iitcramre, but

nfmost d are for horizontnf or vertical uphilI flow.

Eaton et al. 1 proposed a holdup correlation based on

dnta for natnral gas, water, crude oil, and distillate oil

mixtures in 2- and 4-in. (5- and 10-cm) diameter

horizontal pipes. This correlation is based on tive dimen-

sionless groups reflecting various physicaf properties,

flow rates, system pressures, and pipe diameters. A

study by Vohra et al. 2 showed that MIS correlation per-

formed best on a collection of horizontal data taken .by

Eaton et al. 1 and Beggs and Brill. 3 Cunliffe4 found that

using the Eaton et al. correlation to predkt the total liq-

uid volume in a wet gas pipeline was quite successful for

determining the incremental volume of liquid removed

from rak increases.

Using dyn~ic similarity annlysis, Dukler et at. 5

developed a boldup corm?lation for horizontal two-phase

flow. This holdup correlation is implicit in Iiquid

holdup, ~quiring an iterative calculation. Experience

has shown that most wet gas-transmission applications

will result in a nwslip liquid holdup calculation when the

Dukfer et at. correlation is used.

0149-25 36/S3{0041 .0923500 ,25

CoPYrlglIt ,983 socie>y of Petrde.m E@nws of AJ.4E

MAY 1983

.

for

The Beggs and Brill correlation was developed from

data obtained in an air/water flow system with 1- and

1,~.in. (2.5- and 3.8-cm) diameter pipes. They con-

sidered a rsnge of inclination angles from O to & 90.

Use of the correla~on requires first detemnining the

holduv for horizontal flow according to cmdicted

horiz&tal flow patterns. The horizontarholdu~ is then

corrected for angle of inclination. Palmer6 found that the

Beggs snd Brifl liquid holdup was overpredicted for both

uphill and dowrdill flow and suggested proper correction

--

factors.

For uphill flow from O to 9, Guzhov et al. 7 pmposed

a holdup correlation that is independent of inclination

angle. Hughmark and Pressburg g developed a general

holdup correlation for gaslliquid flow covering a wide

range of physical properties and diarnetem. This correla-

tion is based on data taken in 1-in. (2,54-cm) diameter

pipe for vertical uphill flow of air, water, oils of different

viscosities, and carcfolly selected data of other

investigators.

In addition to these empirical liquid holdup correla-

tions, at least two analytical holdup correlations deserve

mention. Bonnccaze et al. 9 developed a slug flow model

for inclined pipe based on a mass and force balance

around a simplified slug unit. The pressure drop con-

tributions caused by the Iiqnid film and the gas bubble

were negfected, Using this holdup correlation, they cor-

related pressure dmp data obtained in 1 x-in. (3.8-cm)

diameter pipe inclined at various angles around + 10 to

find an expression for friction factor. The holdup equa-

tion and friction factor correlation were compared with

field dsta taken in a 6-in. (15.24-cm) dinrneter, 10,000-ft

(3C48-m) long pipe with a maximum deviation of 5 %.

With a very similar mechanistic approach, Singh and

Griffith 10 proposed a simple model for two-phase sIug

flow in inclined pipes. Most of their mndel pammetera

were experimentally determined using five different

diameters of copper pipe at 5, 10, and 15 inclinations

with an air/water system. For stratified tlow, the authors

developed a holdup model based on Chezys open-

channel flow equation. This equation shows that the liq-

uid holdup is independent of gas flow, which is contrnry

1003

. . . .. . k,.,. 4

q-:?----- . ...- ,

TEST S3CT10N

v

TO TRANSDUCER

+

DETAIL A [>.:4

. .

SOLENOID

DRAIN VALVE

~

-X- GATE VALVE

- CHECK VALVE

+ ACTUATED BALL VALVE

+ MOTOR VALVE

~ ROTAMETER

@ OFJF,C,METER

- OIL F[LTER

a.

Ml, TANK

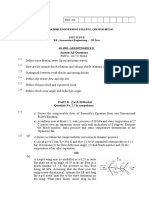

Fig. lSchematic of inched flow simulator.

to accepted phenomena. They also suggested a. method

of calculating liquid holdup for annular flow that is

iterative in nature. Their liquid holdup models repro-

duced their data with rcasoaable accuracy.

Experimental Program

An experimental facility was designed and constructed to

obtain the desired test data. Fig. 1 is a schematic of the

test facility. The test sections consisted of an inverted U-

shapc 1.5-in. (3.8-cm) ID nominal steel pipe. The closed

end of the U-shape test sections could be raised or

lowered to any angle from O to +90 from horizontal.

Each leg of the U was 56 ft (17 m) long with 22 ft (6.7

m) entrance lengths followed by 32- ft (9.8-m) long test

sections on both uphill and downhill sides. Each test sec-

tion could be isolated from the rest of the piping by

pneumatically actuated ball valves tint could be opened

or closed simultmeously when calibrating holdup sen-

sors. Pressure taps 30.5 ft (9.3 m) apmt were located in

each test section to permit measuring absolute and dlf-

fercntiaJ pressures using Vnlidyne transducers. A 7-ft

(2-m) long transpammt Lexin pipe section was located in

each test section to permit flow pattern observations and

mounting of capacitance-type holdup sensors shown in

F@ 2. The outputs from tiese two sensors were record-

ed on an oscillograph as a time-varying trace. For ob-

taining am integnited value of holdup over a particular

period of time, a digital multimeter was used to note the

gain in voltage output over that particular time. This

voltage gain can easily be converted to a liquid holdup

fraction using a linear interpolation over the calibrated

values of voltage gain for O and 100% oil in the pipe.

The oil and gas phases were carefully metered before

mixing, turbbre meters, orifice meters, or rotametera

wece used. depending on the phase and the flow rates.

1004

The two-phase mixmm flowed through the test sections

and into a horizontal separator. The gas (air) was vented

to the atmosphere and the liquid passed through a filter

and into a storage tank.

Kerosene and lube oil were used as the liquid phas~s.

The surface tension, density, and viscosity of the

kerosene at 60F (15 .56C) were 26 dyne{cm (26

mN/m), 51 lbm/cu ft (816.9 kg/m3) and 2 cp (0.002

Pa. s), respectively. Corresponding values for the lube

oil were 35 dyne/cm (35 mN/m), 53. lbmlcu fr (849

kg/m3 ) and 29 cp (O .029 Pa.s). Temperatures between

18 and 132F (7.8 and 55.56C) were encountered

during the tests.

Phase Slippage and Liquid Holdup

Ia inclined two-phaae pipe flow, a substantial part of the

totrd pressure losses may be contributed by, the

hydrostatic pressure difference. The relative contribu-

tions of friction gradient and hydrostatic gradient maybe

dictated by the prevailing flow patterns, angle of inclina-

tion, and dwction of flow. Many of the current design

pmcedurcs used for two-phase pipelines fiil to account

for these effects with any rigor. Part of the problem. ii

most design procedrm?a is the assumption that the void

fraction is a unique function of quality and physical

properties of the fluids. This is prnbably tme where

homogeneous flow can be assumed or during bubble

flow at very low gas flow rates. Similar situations may

also arise where the phase velocity ii very Klgh, so that

friction pressurs drop governs the total pressure loss. But

in the remaining cases erirm may arise from. neglecting

the slip velocity between phases. Thk concept of slip

velocity comes from the physical phenomenon called

Slippage.

The term slippage is used to describe a natural

JOLRNAL OF PETROLEUM TECHNOLOGY

Fig. 2Capacitance sensor test cell and local electmics board.

phenomenon of one phase slipping past the other in two-

phase pipe flow. There are several causes for slippage

between phases, Frictional resistances to flow or irrever-

sible energy losses in the direction of flow arc much less

in the gas phase than in the liquid phase. This makes the

gas more transmissible than liquid in two-phase flow,

even in the absence of strong buoyancy effects such as in

horizontal flow. This effect can be ve~ prenounccd in

ariy segregated flow regime such as stratified flow. The

large difference ~ compressibilities between gas snd Iiq-

uid causes the expanding gas to travel at a higher veloci-

ty and to slip past the liquid when pressure decreases in

the direction of flow. Slippage between phases is also

premoted by the difference in buoyant forces acting on

the phases. In a static liquid medium, less-dense gas

tends to rise with a veIocity proportional to the density

difference. Zukoski 11 studied the effect of pipe inclina-

tion angle on bubble rise velocity in a stagnant liquid. He

concluded that, depending on the pipe diameter, surface

tension and viscosity of fluids may appreciably affect the

bubble rise velnci~. His findings also showed that for

some conditions an inclimtion angle as small as 1 from

the horizontal can cause the bubble rise velocity to be

mo= than 1.5 times the value obtained for horizontal

pipes. This establishes a strong dependence.between in-

clination angle and phase slippage. In the absence of any

annlyticzd formulation, the phenomenon of slippage

caused by bubble rise velocity is studlcd empirically.

Cheater gravitational forces on the more-dense liquid

phase promotes fallback of liquid when shear forces and

buoyant forces fail to support the liquid in upward flow.

For downward flow it causes the liquid to travel faster

than the gas. Thus, while buoyancy aIways causes the

gas phase to rise dative to the liquid phase, gravity

always tends to cause the liquid to faU faster than the

gas.

A few impommt conclusions can be made from the

preceding discussion. Except for homogeneous flow, the

MAY 1983

.

presence of slippage between phases in two-phase pipe

flow is unavoidable at any angle of inclination. In both

uphill and downhill bubbie or slug flow, when the liquid

phase is continuous and is capable of being suppmted by

itself, buoyant forces generate bubble rise velocity caus-

ing slippage between phases. Near the slug and annula-

mist flow transition or when the slug length becomes

long [> 1.5 to 3 ft (0.5 to 1 m)], the phases become

discontinuous. During this type of flow, broken liquid

slugs or rippIes incapable of bridging the pipe are seen to

fall back against the direction of uphill flow. Vecy

similar flow phenomena occur in dowabill stratified flow

when the liquid falls back and accelerates until the liquid

kinetic energy is balanced by the shear energy around the

liquid layer. In stratified flow, large ir-situ velocities at-

tained by the liquid as a result of acceleration by grsvity

normally causes a very smaU liquid holdup. This

phenomenon is shown in Fig. 3, where, in stratified flow

at O. 363-ft/sec (O. 11-m/s) liquid superficial velocity,

void fmction rises rnpidly to nearly 97% when very little

air flows simultaneously. At bigher liquid velocities in

bubble or slug flow, the void fraction builds up mop

sIowly. An important deduction at this point is that in

uphill flow, slippage causes liquid velocity to SIOW

down, resulting in a net accuqndation of liquid in the

flow channel or pipe and increasing the in-situ liquid

fraction. The in-situ liquid fraction is commonly called

liquid holdup. In downMll flow, slippage causes the

in-situ liquid velocity to increase, resulting in a decrease

in liquid holdup. AU these causes of phase slippage and

the resulting flow patterns will occur as soon as one end

of the pipe is raised about one pipe diameter from the

other end, regardless of the angle of inclination. Thus,

depending on the Iengtl of the pipe snd direction of

flow, characteristic flow patterns or liquid hoIdup for in-

cliied flow should be observed even at extremely low

angles. For exsmple, at my low uphiU angle, the

s~titied flow pattern should never be observed.

11305

,.o~

,, ,0 ,0 m ,00 ,,0

S ,EX,,C,AL 0.4, VS,OCITY (FT/$EC1

Fig. 3Void fraction vs. V%g at different values of V,L fOr

- 30~ angle.

. .

0 20 40 ,0 m IOD 120

SUPERFICIAL0,$ vEmcnY (fTmc)

Fig. 4Void fraction vs. Vw at different values of V,L for

horizontal flow.

! .0

:

2 ,,4

:.

, s, = p..:,M,;sEc

. s!. : ,.,6, FV5,c

0,1 ~ ,,L, f.;.,+!,:;,,=

(mm ./s1

,o~o

,PERFIc,.+L . AS ,LOC,T, (FvwC)

Fig. 5Void fraction vs. Vw at different values of V,L for

+90 angle.

1006

Development of Liquid HoIdup Correlation

ArmIytical expressions for liquid holdup have been at-

tempted for uphill two-phase slug flow in vertical pipes

and for downhill flow at low angles of inclination in the

range of O to 15. Considering the complex slippage

mechanism, a global liquid holdup model for any pipe

inclination has not been attempted before.

More than 1,500 liquid holdup measurements at uphiIl

and downhill inclination angles from O to +90 from

horizontal were obtained in this stndy. Attempts to cor-

relate these data into a global empirical liquid holdup

correlation are presented in the following. At each uphill

and downhii angle, void fraction was plotted as a func-

tion of superficial gas velocity for fixed supeflcial liquid

velocity. Each of these pIots was continuous within the

error tolerance of the holdup measurements. Example

plots are shown in Figs. 4 through 6. At very high gas

rates, the curves almost become asymptotic with the

100% void fraction (O% liquid holdup). For downhiil

stratified flow at very low gas rates, the void fraction

rises rapidly and then almost linearly increases with in-

creased gas rates. However, the void fraction plot for

horizontal ffow is sirniIar to the uphiIl plot, even in the

stratified flow regime. The geneml shapes of these plots

prompted sekction of a nonlinear regression equation of

the focm

[

HL =exp (cl +c2sin@+cssin26 +c4NZ )

NC. 5

1

. , , , , , , . , , , , , , ,

NL, 6

. . . . . . ...(1)

Subsequently, three liquid holdup correlations were at-

tempted, one for uphiII and horizontal flow and the other

two for downhill stratified flow and the other downhill

flow patterns. The regression coefficients are given in

Table 1. The coefficients were obtained by using the

nonlinear BMDP regrcsaion programs. 12 In each of the

regression analyses, the outliers in the residual plot w, w

deleted from the data set and the anaIysis was repeate~.

The seIection of phase velocity numbers as the in-

dependent variables instead of the phase supefllcial

velocities as shown in Figs. 4 through 6 was done to

make the variables dimensionless. These numbers were

also suggested as correlating parameters by Duns and

Ros, 13 Hagedorn and Brown, 14 and Eaton et al. 1 The

velocity numbers, together with the inclination angle,

also formed the independent variables defining the flow

patterns. Hence, inclusion of all these variables implicitl-

y makes the holdup conflation flow-regime-dependent.

The use of dimensionless numbem should not affect the

shapes of curves shown in Figs. 4 through 6 since, for a

fixed oil, convecting superficial velocities to dimen-

sionless form reqnires multiplication by a nearly constant

quantity of appmxima.tely 2.5 for this study.

Effects of In&nation Angle and Viscosity

The second-degree polynomial function of the form

c1 +c2sinO+c3sin2@ was selected by plotting liquid

holdups for differsnt angles of inclination at fixed liquid

and gas velocity numbers. This relation was also con-

firmed by comparing results of other equation forms in

trisl runs of the regmsion analysis. The best error as in-

JOURNAL OF PETROLEUM TEcHNOLOGY

dicated by the sum of squares was obtained using the

second-degree relation. The equation is ako consistent

with the Beggs and Brill discove~ that liquid holdup

passes through maximums and minimums at fixed in-

clination angles of approximately +5o 0 and 500,

~spectively, for their data. Eq. 1 shows that the liquid

holdup should increase as the uphill angle of inclination

increases: Thk can be shown graphically by comparing

liquid holdup values obtained fmm the plots in F@. 7

and 8, where void fractions arc plotted for the iame oil at

three simif.w &pirOciaI liquid velocities for horizontal

and uphill 30 pipe inclination.

Intuitively, increased liquid viscosity should increase

viscous shear, causing irrcrcased liquid holdup regardless

of iriclination angle. Positive coet%cients of the liquid

viscosity n~ber in all the holdup correlations support

this hypothesis,

In general, any force that creates drag on any phase

against the direction of flow tends to increase the in-situ

fraction of that phase. As a result, viscous dtag on the

liquid will always tend to increase the liquid hoIdup, ir-

respective of inclination angle. However, gratihy forces

on the mo~ dense phase will tend to increase the holdup

of that phase for uphill flow and decrease it for downhill

flow. Similarly, buoyant forces will tend to decrease

void fraction for uphill flow, while increasing it for

downhill flow,

Discussion of Results

The proposed fiquid holdup corrdatirm was tested with

the observed data to check the reproducibility of the

obsewed holdup values. For both the oils at different

angles .of inclination, the relative percerit errors were

calculated for individual experimental observations. For

each angle and each oil, the average percent errors md

their standard deviations (Table 2) were also calculated.

The capacitance sensor for liquid holdup rneasurcment

was found to be less. accurate in the fwtge of liquid

holdups less than 10% or more than 90%. In these

ranges of liquid holdups, ve~ high percent errors were

observed (more than 30%). More than 80% of these data

points wiib high percent errors wee found to be in an-

nular or stratified flow regime, III both of these flow

regimes, the contribution from hydrostatic head to the

total p~ssure loss is quite insignificant. As such, those

data points with more than 30% relative percent error

were not used for the calculation of either average per-

cent errors or the standard deviations.

In the development of these liquid holdup correlations,

the BMDP nordirrcar regression package was used. This

regression method minimizes the residual sum of squares

to calculate the regression coefficients. The observation

correspondkrg to the otitf ien in the residual plot were ex-

cluded in the development of the holdup correlations.

Normally, these outliera indicated erroneous observa-

tions. This criterion for cuHing data does not correspond

to minimizing the average percent error. Hence, when

these corrdations were applied to the observed data, a

fu~er culling of data based on average percent error

was required. Normally, dependbrg on the value of the

absolute relative error, the sensitivity of the holdup

measurement techniques reflects a great deal on the

average percent error. For very small values of obsemed

holdup, even with acceptable absolute error, relative er-

MAY 1983

,.0

?- .-

*

0.,

0.,

,.4

e = W%s=

. s, = ,.,,, ,,/s,.

0.2 G ,,, . 0.55;.gj,,c

(0.09 .,s

Fig. aVoid fraction vs. V,g at different values of v~L for

-90 angle,

!.,

,.8

6 0,

~

. s,

~ [FT/?.Ecl

$ ,., . ,,,,4 (mm ,s1

s

o ,.,6, (0.,, km

G $.9 (u, MI,)

0,2

. 7.i 12.2s MIS)

K 1,.0 13.66 MB)

Fig. 7Void fraction vs. superficial gas velocity at fixed

superficial liquid velocity for horizontal flow.

Fig. 8Void fraction vs. superficial gas velocity at fixed

superficial fiquid vefocity for uphill flow at 30.

1007

-.

TABLE 1COEFFICIENTS OF LIQUID HOLOUP EQUATION

Flow

Flow Direction Pattern

e, C2 Cs c. C5 C6

__ _ _ z .-

Uphill flow all -0.380113 0,129875 -0.119788 2.343227 0.475686

downhll flow stratified -1,330282

0.288657

4. S08139

other -0.5i6644 0.78s805

4.17< 584 56.262268 0.079951 0.504S87

0.551627 15.519214 0.371771 0.393952

TABLE 2STAT13TICAL PARAMETERS FOR tiOLDUp

CORRELATIONS APPLIEO TO OBSERVED DATA

Average Standard

Anale Number of Error Deviation

(degkes)

Kerosene

5

20

30

45

50

60

70

80

90

0

-x

-30

-50

-70

-80

-90

Lube al

30

90

0

-30

-90

Data

35

48

57

2

6:

49

35

42

40

41

42

31

33

29

29

(%)

2.79

0.04

4.71

5.49

- ? .96

-2.17

4,98

-2,77

2,95

-1,86

2.44

-0.33

6.81

-1.71

5.35

-0.05

6.19

33 -1.01

43 -7.52

38 -4.34

23 -0.26

37 -7,15

(%)

13.64

14.25

13.40

1.77

12.30

3.16

11,92

i3.55

16.80

13.95

13.79

25,95

18.73

20.32

18.91

19.s9

21.20

15.01

8,22

13,58

15.43

15.83

ror may be very kuge. This is often caused by division of

a small quantity in the calculation of percent error.

Values of average percent error and sfsndard deviations

for liquid holdup for each oil at different angles of in-

clination are shown in Table2.

Conclusions

Ari empirical model forinclined two-phase flow liquid

holdup is proposed. The proposed model enables. the

determination of liquid holdup regardless of the angle of

inclination and the direction of flow. The set of holdup

correlations is dependent on the snrne dlmension168s

painmeters that control the flow pattern transitions in

two-phase. flow. Except for downhll stratified flow, the

liquid holdup correlations are continuous across flow-

pattem transitions.

Nomenclature

c = ~~pirial constant

g =mvitationd accelemtion, ft/secz (m/sz)

HL =Iiq!iid holdup

N8V =gas velocity number, vfcbL/(g@]O25

NL =liquid viscosity number, pL~/(pLn3)]0Z

1008

NLP =liqtidvelocity nuniber, U$L[P@T)]025

P,g = supefIcisJ gas velocity, ft/5ec (m/s)

VSL = supefllcial liquid veloci~, ft/sec (m/s)

x = viscosity,, cp (Pas)

p = density, lbm/cu ft (kg/m3)

~ = s<~ace tension, dynelcm (mN/m)

@ = pipe inclinatiori angle from horizontal,

degree (rad)

. . . . . ----

1. Eaton, B.A. t-r cd.: ..The Prediction of FIOW Patterns, Liquid

Holdup and Pressure Lasses Occurring During Continuous Two-

Phase F70w in Horkontal Pipelines, Tram., AJME (1967) 240,

815-28.

2. Vohra, LR. et al,: Comparison of Liq.id Holdup and J+iction-

Facmr Correlations for Gas-Liquid Flow,,, J. Per, Tech. (May

1975) 564-68.

3. Beggs, H.D. and Brill, J. P.: A,$fudy or Two-Ph&se F30w in In-

clined Pipes, ?, J. Pa. Tech. (t&y 1973) 607-17.

4, Cm[iffe, R, S,: Prediction of Condensate Flow Rates in LarEe

Diameter High Press.= Wet Gas Pipelines, APEA J. (197~)

171.

5. Dukler, A. E., Wicks, M. HI, md Cleveland, R, G.: Frictional

Pressure Drop in Two-Phase Flow: B. An Approach Through

3imilirity Analysis,, AIChE J. (Ian., 1964) 10, M-51.

6. Palmer, C. M,: Evaluadon of Inclined Pipe Two-Phase Li@id

Holdup Correlations Using Experirnmaal Data,, MS thesis, U. of

7.1s (1975).

7. Guzho., A.1., Marnaycv, V.A., and OdisbariYa, G. E.: A Study

of Tmspadadon in Gas-Liquid Systems,,, Pro.., 10tb Jnd. Gas

Conference, Hamburg, West Germany (1967).

8, Hughmwk, G.A. ad Pressburg, B. S.: .Holdup and pressure

Dmp with Gas Liquid Flow in a Vertical Pipe,, AIChE J. (Dec.

9.

10.

11.

12.

13.

1961) 7, 677.

Bamecaze, R. H., Erskine, W., and Greskovich, E. J,: Holdnp

and PEssure Dmp for, Two Phase Slug Flow in Inclined

Pipelims,., AJCIUE J. (Sept. 1971) 17, 1109,

Sigh, G, and Griftifh, P.: Determination of PEssure Drop Op-

tinium Pipe Size for a Two:Phase Slug Flow in an Inclined P!pe,

J. En*. fo, Ind, (My. 1970); Tram., ASME 92, 717-26.

Zukoski, E. E.: %fl.erice of Viscosity, Surface Tension and In-

clination Angle on Motio of !-ong Bubbles in Closed Tubes, J.

Fluid ,?dech. (1966) 25,821-37.

Dixon, W .J.: BMDP-Biomedical Compuler Programs, P-

Series,v, U, of California Press, Los Angeles (1977).

0..s. H. Jr. and Ros. N. C. J.: Vetical Flow of Gas and Licwid

Mi.m& in Wells,,, Pro.., SMh Wodd Pi. Cong., Frank~mt

(19S3> 451. . .. ----

14. Haged?m, A.R, and Bmym, K. E.: .Experimerdal Study of

PIEssure Gradients OcmnrirIE Dwig CoMin.ous Two-Phase

Flow i. Small Diameter Verdcal Ccmduits,,, J. Pet Tech. (Apdf

1965) 475-84.

S1 Metric Conversion Factors

in. x 2.54* E+OO = cm

ft X 3.048* E01 = m

.Conversion factor k exact. m

Original manuscript received in Sociely of Petroleum Engine.m o!hm March 22,

1 S82. Revised ma.uscr;pl received Jan. 21, 19S3. Paw acwted for Pubkaao.

Ocl 8, 1SS2.

JOURNAL OF PETROLEUM TECHNOLOGY

-.. .

time. This voltage gain can easily be converted to a liquid holdup fraction

using a linear interpolation over the calibrated values of voltage gain for

zero percent and 100 percent oil in the pipe.

The oil and gas phases were carefully metered before mixing; turbine

meters, orifice meters or rotameters were used depending on the phase and the

flow rates. The two-phase mixture flowed through the test sections and i nto a

horizontal separator. The gas (air) was

liquid passed through a filter and into

Kerosene and lube oil were used as

vented to the atmosphere and the

a storage tank.

the liquid phases. The surface

tension, density and viscosity of the kerosene at 60F were 26 dynesjcn,

51 lb#ft3 and 2 cp, respectively. Corresponding values for the lube oil were

35 dynes/cm, 53 lb~ft3 and 29

encountered during the tests.

CP, Temperature between 18 and 132F were

PHASESLIPPAGEANDLIQUID HOLDUP

In inclined two-phase pipe flow a substantial part of the total pressure

losses may be contributed by the hydrostatic pressure difference. The relative

contributions of friction gradient and hydrostatic gradient may be dictated by

the prevailing flow patterns, angle of inclination and direction of flow. Many

of the current design procedures used for two-phase pipelines fail to account

for these ef}ects with any rigor. Part of the problem Inmost design

procedures is the assumption that the void fraction is a unique function of

quality and physical properties of

homogeneous flow can be assumed or

rates, Similar situations may also

the fluids. This is probably true where

during bubble flow at very low gas flow

arise where the phase velocity is very

high, so that friction pressure drop

the remaining cases errors may arise

between phases. This concept of slip

governs the total pressure loss. But in

due to neglect of the slip velocity

velocity comes fr@m the physical

phenomena called slippage.

The term slippage is used to describe a natural phenomena of one phase

slipping past the other in two-phase pipe flow. There are several causes for

slippage between phases. Frictional resistances to flow or irreversible energy

losses in the direction of flow are much less in the gas phase than in the

liquid phase. This makes the gas more transmissible than liquid in two-phase

flow, even in the absence of strong buoyancy effects such as in horizontal

flow. This effect can be very pronounced in any segregated flow regime such as

stratified flow. The large difference in compressibilities between gas and

liquid causes the expanding gas to travel at a higher velocity and slip past

the liquid when pressure decreases in the direction of flow. Slippage between

phases is also promoted by the difference in buoyant forces acting on the

phases. In a static liquid medium, less dense gas tends to rise with a

velocity proportional to the density difference. Zukoski

15

studled the effect

of pipe inclination angle on bubble rise velocity in a stagnant liquid. He

concluded that, depending on the pipe diameter, surface tension and viscosity

of fluids may appreciably affectthe bubble rise velocity. His fixidings also

showed that for some conditions an inclination angle as small as one degree

from the horizontal can cause the bubble rise velocity to be more that 1.5

times the value obtained for vertical pipes. This establishes a strong

dependence between inclination angle and phase slippage. In the absence of any

analytical formulation, the phenomenon of slippage caused by bubble rise

velocity is studied empirically.

Greater gravitational f orces on the more dense liquid phase promotes fall

back of liquid when shear forces and buoyant forces fail to support the liquid

in upward flow. For downward flow it causacth liquid to travel faster than

the gas. Thus, while buoyancy always causes the gas phase to rise relative to

the liquid phase, gravity always tends to cause the liquid to fall faster than

the 8as,

A few

Except for

phase pipe

important conclusions can be made from the precedin8 discussion.

houiogeneous flow the presence of slippage between phases in two-

flow is unavoidable at any angle of inclination. In both uphill and

downhill bubble or slug flow, when the liquid phase is continuous and is

capable of being supported, buoyant forces generate bubble rise velocity

causing slippage between phases. Near the slug and annular-mist flow

transition or when the slug length becomes long (more than about two to three

ft) the phases become discontinuous. During this type of flow, broken liquid

slugs or ripples incapable of bridging the pipe are seen to fall back against

the direction of uphill flow. Very similar flow phenomena occur in downhill

stratified flow when the liquid falls back and accelerates until the liquid

kinetic energy is balanced by the shear Gner8y around the liquid layer, In

stratified flow, large insitu velocities attained by the liquid as a result of

acceleration due to 8ravity normally causes a very small liquid holdup, This

phenomenon is shown in Fig. 3 where in stratified

superficial veloci:y, void fraction rises rapidly

little air flows simultaneously. At higher liqutd

flow, the void fraction builds up more slowly. An

flow at 0.363 ft/sec liquid

to almost 97%when very

velocities in bubble or slug

important deduction at this

point is that in uphill flow, slippage causes liquid velocity to slow down

resulting in a net accumulation of liquid in the flow channel or pipe and

increasing the insitu liquid fraction,

called liquid holdup. In downhill flow

to increase resultlng in a decrease in

The insitu liquid fraction is commonl y

slippage causes insitu liquid velocity

liquid holdv,p. AM these causes of

phase slippa8e and the result$n8 flow patterns will occur as soon as one end

of the pipe i8 raised about one pipe diameter from the other end regardless of

the an81e of inclination. Thus, dependins OR the lmgth of the pipe and

direction of flow, characteristic f l ow patterns or liquid holdup for inclined

flow should be observed even at extremely low angles. For example, at any low

uphill angle, the stratified flow pattern should never be observed.

.

1.0

0,8

006

O*4

0.2

O*O

G

E

G o

G

G

I

I

000

0

lB o

w

3

)

m VSL = 12,041FT/SEC

O VSL =

3,910 FT/SEC

I

G vSL = 0,363 FT/SEC

t

I I

1 1

n mn .-

4U

80 100

superficial GASvELOcITY(FT/sEc) ~

120

Fig. 3- Voi d Fraction w v8g at

Different Values of VSL

for -30 Degrees Angle

Development of Liquid Holdup Correlation

Analytical expressions for liquid holdup have been attempted for uphill

two-phase S1U8 flow in vertical pipes and for downhill flow at low angles of

,.

Inclination ln,the range of O to 15 degrees. Considering the complex slippage

mechanism, a global liquid holdup model for any pipe inclination has not been

attempted previously.

More than 1500 liquid holdup measurements at uphill and downhill

inclination an81es from 0 to f90 from horizontal were obtained in this

study. Attempts to correlate these data Into a global empirical liquid holdup

correlation are presented below. At each uphill and downhill an81e, void

fraction was plotted as a function of superficial 8ae velocity for fixed

superficial liquid velocity. Each of these plots was continuous within the

error tolerance of the holdup measurements. Example plots are shown tn Fi8s. 4

throu8h 6. At very high 8as rates the curves almost become asymptotic with the

100%void fraction (O%liquid holdup). For downhill stratified flow at very

low8as rates the void fraction rises rapidly and then almost linearly

increases with increased gas rates. However, the void fraction plot for

horizontal flow Is similar to the uphill plot, even in the stratified flow

reeime. The general shapes of these plots prompted selection of a non-linear

\

regression equation of the f orm,

2

N C5

HL=EXF(Cl+C2 Sin e+C3Sin 0+C4NL) ~.. .o~**. .~C(l)*..C(l)

NLV 6

Subsequently, three liquid holdup correlations were attempted, one for uphill

Gnd horizontal flow and the other two for downhill strat~fied flow and the

other downhill flow patterns. The re8ress&on cwdikients are given In Table

1. The coefficients were obta~ned by using the non-ltnuar BIOMED4regression

pro8ramao In each of the regression analysee, the outliers in the res$dual

plot were deleted f romthe data set and the analyees wao repeated.

100

0,8

0.6

0.4

0.2

0.0

+ VSL = 7.325 FT/SEC

G VSL = Oc363FT/SEC

.

x VSL = 0.094 FT/SEC

o 20 40 60 80 100 120

SUPERFICIALGASVELOCITY(FT/SEC) ~

.

.

100

0.8

0.6

0.4

0.2

I

.

)

m

I VSL = 10,679FT/SEC

G VSL = 0.363FT/SEC

m

x VSL = 0.094FT/SEC

I

i 1 I 1 1

0 20 40 80 80 100 120

superficial GASVELOCITY(FT/sEC) ~

Fig. 6- Void Fraution w Vs g at

Different Values of V~L for

+90 Degrees Angle

~. A

I

I m VSL = 10.679FT/SEC

A VSL = 1.817FT/SEC

G VSL =

0.305 FT/SEC

I I I I I

o 20 40 60 80 100 120

SUPERFICIALGASVELOCITY(FT/SEC)~

Fig. 6- Void Fraction vs

Different Values of

-90 Degrees Angle

VW at

vsL for

I I

Table 1

Coefficients of Liquid Holdup Equation

i

I I

I !

Values of Coefficients

Flow Direction Flow Pattern

i

1 1 I 1 B I 1 @ 1

I 1 I IC I 1 I I

1 I Ic

I

lc~cvlc I

1 ! I I I j ~

I ! I I

~ Uphill Flow ~ All ~ -0.380113 ~ 0.129875 ~ -0.119788 ~ 2.343227 ~ 0.475686 ~ 0.288657 I

1 !

1

1

I

I 1 ~ I ~

I

t 1

1

I

Downhill Flow

!

I Stratified

i

- 1. 330282 ~ 4.808139

.1 i

~ 4.171584 i 56.262268 ~ 0.079951 i 0.5048W !

I i

~Other ~ -0.51644 ~ 0.789805 ~

~

0.551627 ~ 15.519214 ~ 0.371771 \ 0.393952 I

I i I I I I I

-

.

The selection of phase velocity numbers as the independent variables

instead of the phase superficial velocities as shown in Figs. 4-6 was done to

make the variables dimensionless. These numbers were also suggested as

6 9

correlating parameters by Duns and Ros , Hagedorn and Brown , and Eaton

et al. The velocity numbers, together with the inclination angle, also formed

the independent variables defining the flow patterns. Hence, inclusion of all

these variables implicitly makes the holdup correlation flow regime dnpendent.

The use of dimensionless numbers should not affect the shapes of curves shown

.

in Figs. 4-6 since, for a ~xed oil, converting superficial velocities to

dimensionless

approximately

/

form requ~.- _. ~lication by a nearly constant quantity of

2.5 for this study.

Effects of Inclination Angle and Viscosity

The second degree polynomial function of the form Cl + C2 Sin e +C3 Sinz e

was selected by plotting liquid holdups for different angles of inclination at

fixed liquid and gas velocity numbers. This relation was also confirmed by

comparing results of other equation forms in trial runs of the regression

analysis. The best error as indicated by the sum of squares was obtained using

the second degree relation. The equation is also consistent with the Beggs and

Brill discovery that liquid holdup passes through maximums and minimums at

fixed inclination angles of approximately +50 and -50, respectively for

their data. Eq. 1 shows that the liquid holdup should increase as the uphill

angle of inclination increases. fiis fact can be shown graphically by

comparing liquid holdup values obtained from the plots in Figs. 7-8 where void

fractions are plotted for the same oil at three similar superficial liquid

velocities for horizontal and uphill 30 pipe Inclination.

Intuitively, increased liquid viscosity should increase viscous shear

causing increased liquid holdup irrespective of inclination angle. Positive

coefficients of the liquid viscosity number in all the holdup correlations

support this hypothesis,

1.0

g

-.

0.8

006

0.4

0.2

000

.0.094

.

//

,

3.9

7.3

1200

VSL

(FT/SEC)

A 0.094

0 0.363

G 3.9

x 7.3

I 12.0

1 1 I 1 1

0

20 40 60 80 100 120

SUPERFICIALGASVELOCITY(FT/SEC)~

Fig. 7-, Figure ShowingVoidFraction w Superficial (3as Velodty

at Fixed Superficial LiquidVelocity for Horizontal Flow

.

o

A

G

i,

VSL

(FT/SEC)

oG 094

3*9

12.0

0 20 40 60 80

100 120

SUPERFICIALGAS VELOCITY(FT/SEC)~

Fig. 8- Figure Showing Void Fraction vs Superficial Gas Velocity at Fixed

Superficial LiquidVelocity for Uphill Flowat 300

In general any force which creates drag on any phase against the

direction of flow tends to increase the insitu fraction of that phase. As a

result, viscous drag on the liquid will always tend to increase the liquid

holdup, irrespective of inclination angle. However, gravity forces on the more

dense phase will tend to increase the holdup of that phase for uphill flow and

decrease it for downhill flow. Similarly, buoyant forces will tend te decrease

void fraction for uphill flow while increasing it for downhill flow.

DISCUSSIONOF RESULTS

The proposed liquid holdup correlation was tested with the observed data

to check the reproducibility of the observed holdup values. For both

experimental oils at different angles of inclination the relative percent

errors were calculated for individual experimental observations. For each

angle and each oil the average percent errors and their standard deviations

were calculated. The data points with more than 30 percent relative percent

error were not used for the calculation of either average percent errors or

the standard deviations. A majority of these data were for liquid hcldups less

than 10 percent or more than 90 percent. In this range of liquid holdup the

capacitance sensor was found to be less accurate and high percent errors in

the measured values were expected. However, for most of these very low or very

high liquid holdup cases, the sensitivity of total pressure loss to the liquid

holdup was greatly reduced.

In the development of these liquid holdup correlations, the BMDPnon-

linear re~ression package was used, Thts regression method minimizes the

residual sum of squares to calculate the regression coefficients, The

observations corresponding to the outliers in the res&dual plot we~= c~cludei

in the development of the holdup correlations. Normally, these outliers

indicated erroneous observations, This criterion for culli~ data does not

correspond to minimizing the average percent error. Hence, when these

correlations were applied to the observed data, a further culling of data

based on average percent error was required. Normally, depending on the value

of the absolute relative error, the sensitivity of the holdup measurement

techniques reflests a great deal on the average percent error. For very small

values of observed holdup, even with acceptable absolute error, relative error

may be very large. This is often caused by division of a small quantity in the

calculation of percent error. Values of average percent error and standard

deviations for liquid holdup for each oil at different angles of inclination

are shown in Table 2.

CONCLUSIONS

An empirical model for inclined two-phase flow liquid holdup is proposed.

The proposed model enables the determination of liquid holdup irrespective of

the angle of inclination and the direction of flow. The set of holdup

correlations is dependent on the same dimensionless parameters that control

the flow pattern transitions in two-phase flow. Except for

flow, the liquid holdup correlations are continuous across

transitions.

downhill stratified

flow pattern

Table 2

Statistical Parameters for Holdup Correlations

Applied to Obeerved Data

oil Angle

i

I &~f /Average

(degrees) ~ , % Error

i I

Standard

i

Deviation

I

~

5

20

:;

!5J

70

80

90

-;

-20 .

-30

-50

-70

-80

-90

35

i

I

2.79

48

I

O*O4

57

I

4.71

I

5*49

4; \ -1.96

-2.17

I

6; ~ 4.98

-2.77

% ~ 2.95

42

/

-1.86

40

I

2.44

-O*33

:; ~

6.81

31

I

-1.71

33

I

5*35

29

1

- os05

29

1

6. 19

13,64

14.25

13040

1.77

12.30

3.16

11.92

13.55

16.80

13.95

13079

25.95

10.73

20.32

18,91

19.89

21.20

I

I

-1 G01

:; I

I

15.01

-7.52

I

8.22

-4.34 13.58

:

I

I

-Oe26

I

I

15*43

37 -7.15 15.87

NOMENCLATURE

c

L

gv

*Lv

L

Sg

s1

u

P

u

e

empirical constazs

l~quid holdup

gas-velocity number, v

Sg {pL/(gu)}25

liquid-velocity number, v

sl {@@}25

liquid viscosity number, p

L {!j/(pLu3)}*25

superficial gas velocity, ft/sec

superficial liquid velocity, ft/sec

viscosity, Cp

density, lbm/ft3

surface tension,

pipe Inclination

dynes/cm

angle from horizontal

S1 METRICCONVERSION FACTORS

Cp x 1*O* E-03 = Pa.S

dyne x 1.0* E-02 = mN

F *F

- 32)/1.8

= c

ft X 3.048* E-01 = m

inx 2.54* E+OO = cm

lbm X 4.535924 E-01 = KS

* Conversion factor is exact.

.

1.

2.

3*

4.

50

6.

7.

8.

9.

10*

llQ

Beggs, H.D. and Brill, J.P.: A Study of Two-Phase Flow in Inclined

Pipes, J. Pet. Tech. (May 1973), 607-617.

Bonnecaze, R.H., Erskine, W. and Greskovich, E.J.: Holdup and Pressure

Drop for No Phase Slug Flow in Inclined Pipelines, AIChE J. (Sept. 1971)

17, 1109*

Cunliffe, R.S.: Prediction of Condensate Flow Rates in Large Diameter

High Pressure Wet Gas Pipelines, APEAJ. (1978), 171.

Dixon, W.J.: BMDP- Biomedical Computer Pro8rams, P-Series, Univ. of

California Press (1977).

Dukler, A.E., Wicks, III, M. and Cleveland, R.G.: Frictional Pressure

Drop in Two-Phase Flow: B. An Approach Throu8h Similarity Analysis,

AIChE J. (Jan. 1964) 10, No. 1.

Duns, H., Jr. and Ros$ N.C.J.: Vertical Flow of Gas and Liquid Mixtures

in Wells, ~roc. 6t~ World Pet. Cong. (1963), 451.

Eaton, B.A., et al: The Prediction of Flow F~ttems, Liquid Holdup and

Prescure Lo.sacs 0ccurrin8 Durin8 Continuous Two-Phase Flow in Horizontal

Pipelines, Trans. AIME, (1967)$ 815.

Guzhov, A.I., Mamaye~?,V*A. and Odishariya, G.E.: A Study of Transport-

ation in Gas-Liquid Systems, 10th Int, Gae Conference, Hamburg, Germany

(1967).

Hagedorn, A.R. and Brown, K.E.: Experimental Study of Pressure Gradients

During Continuous Two-Phase Flow in Small Diameter Vertical Occurring

Conduits, J. Pet. Tech. (April 1965), 475-484.

Hu8hmark, G.A, and Pressbur8, B.S.: Holdup and Pressure Drop with Gas

Liquid Flow in a Vertical Pipe, AIChE J. (Dec. 1961) ~, 677.

Mukherjee, H.: An Experimental Study of Inclined Two-Phase Flow, Ph.D.

Dissertation, The Univ. of Tulsa (1979).

12. Palmer, CoM@: Evaluation of Inclined Pipe Two-Phase Liquid Holdup

Correlations Usin8 Experimental Data , M.S. Thesis, The U. of Tu1s8(1975).

13. Singh, G. and Griffith, P.: Determination of Pressure Drop Optimum Pipe

Size for a Two-Phase Slug Flow In an Inclined P$pe, J, Eng. for Ind.

(Nov. 1970), Trans. ASME, 92, 717-726.

14. Vohra, I.R., et al: Comparison of Liquid Holdup and Friction-Factor

Correlations for Gas-Liquid Flow$t, J. Pet. Tech. (May 1975), 564-568.

15. Zukoski, E.E.: Influence of V?.scosity, Surface Tension and Inclination

Angle on Motion of Long Bubblas in Closed Tubes, J. Fluid Mech. (1966)

2S, Part 4, 821-837.

e,

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- PHE Compendium of Chemical Hazards Hydrogen Sulphide v1Documento24 paginePHE Compendium of Chemical Hazards Hydrogen Sulphide v1David HernandezNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Fetkovich Gas Well Analysis Example PDFDocumento3 pagineFetkovich Gas Well Analysis Example PDFjorge_h_riveroNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Twin Screws MultiphasepumpDocumento7 pagineTwin Screws MultiphasepumpDavid HernandezNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Heinemann - Reservoir Fluids PropertiesDocumento155 pagineHeinemann - Reservoir Fluids Propertiesrake1981Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 3.1. - SPE Curve Decline AnalysisDocumento9 pagine3.1. - SPE Curve Decline AnalysisJack HarperNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- 3.1. - SPE Curve Decline AnalysisDocumento9 pagine3.1. - SPE Curve Decline AnalysisJack HarperNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Pipesim 2000 User GuideDocumento219 paginePipesim 2000 User GuideMauricio AlvaradoNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Well Control Equations DrillingformulasDocumento13 pagineWell Control Equations DrillingformulastoshoyNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- 1 - 1. - Decline Curve AnalysisDocumento5 pagine1 - 1. - Decline Curve AnalysisDavid HernandezNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- 4 - Strength Design Method Part 1Documento25 pagine4 - Strength Design Method Part 1Mohamad Duhoki100% (1)

- Chapter-Two Part 1Documento26 pagineChapter-Two Part 1Wiz Nati XvNessuna valutazione finora

- AOE 5104 Class Notes and ScheduleDocumento26 pagineAOE 5104 Class Notes and ScheduleverbicarNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Assignment - 13: Name - Harsh Rai Branch - CE Sec-3M1 University Roll No - 1801000029Documento9 pagineAssignment - 13: Name - Harsh Rai Branch - CE Sec-3M1 University Roll No - 1801000029Suraj PatwaNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Equation Sheet For ThermodynamicsDocumento3 pagineEquation Sheet For ThermodynamicsQuazar001Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- (Ebook - English) Gaussian Inc, Exploring Chemistry With Electronic Structure MethodsDocumento335 pagine(Ebook - English) Gaussian Inc, Exploring Chemistry With Electronic Structure Methodsthiagocpimentel12100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Fundamentals of AcousticsDocumento180 pagineFundamentals of Acousticscastro100% (7)

- Deflection Beam Material Modulus Elasticity ExperimentDocumento3 pagineDeflection Beam Material Modulus Elasticity Experimentjon aeliaNessuna valutazione finora

- Seismic Load STG BuildingDocumento6 pagineSeismic Load STG BuildingWahyu MunajatNessuna valutazione finora

- Midas Civil ManualDocumento33 pagineMidas Civil ManualAyoola Oluwadotun100% (2)

- Ad II (Ae6503)Documento2 pagineAd II (Ae6503)Raahini IzanaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Mass Transfer Operations Question BankDocumento2 pagineMass Transfer Operations Question BankSivamani Selvaraju100% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Center of GravityDocumento7 pagineCenter of GravityAnonymous QiMB2lBCJLNessuna valutazione finora

- Analysis of continuous prestressed concrete beamsDocumento14 pagineAnalysis of continuous prestressed concrete beamsChinnu JacobNessuna valutazione finora

- Gear FailureDocumento27 pagineGear FailureSheri KhosoNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Module 11A.1.2 L2 2016-08-12Documento84 pagineModule 11A.1.2 L2 2016-08-12Abdul Aziz KhanNessuna valutazione finora

- PH-1001 (Physics-1) : Dr. A. K. Singh Department of Physics & Astronomy National Institute of Technology Rourkela-769008Documento19 paginePH-1001 (Physics-1) : Dr. A. K. Singh Department of Physics & Astronomy National Institute of Technology Rourkela-769008Partho BiswasNessuna valutazione finora

- NCERT Solutions For Class 11 Physics 15may Chapter 7 System of Particles and Rotational MotionDocumento36 pagineNCERT Solutions For Class 11 Physics 15may Chapter 7 System of Particles and Rotational Motiondaksh tyagiNessuna valutazione finora

- Problem StatementDocumento3 pagineProblem Statementeafz111Nessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Final Project ReportDocumento47 pagineFinal Project ReportShashank Dubey100% (1)

- MT1 Thermodynamics Practice QuestionsDocumento3 pagineMT1 Thermodynamics Practice Questionsmehmet candanNessuna valutazione finora

- What Is Hooke's Law - (Article) - Khan AcademyDocumento11 pagineWhat Is Hooke's Law - (Article) - Khan AcademyDahanyakage WickramathungaNessuna valutazione finora

- Lec 3Documento8 pagineLec 3ummaraNessuna valutazione finora

- Ryu Et Al (2008) Capacity Curves, 14WCEE PDFDocumento8 pagineRyu Et Al (2008) Capacity Curves, 14WCEE PDFsekkeiNessuna valutazione finora

- Pump NPSHa and Suction and Delivery Line Head Loss CalculationDocumento6 paginePump NPSHa and Suction and Delivery Line Head Loss CalculationSugar Technology100% (1)

- Engr 2900 Mech of Materials Exam 2 KeysDocumento8 pagineEngr 2900 Mech of Materials Exam 2 KeysAshleyHeldNessuna valutazione finora

- Lecture Notes PPT 4 PDFDocumento17 pagineLecture Notes PPT 4 PDFDrRoja A RNessuna valutazione finora

- 15 Mark Essay Planner SheetDocumento5 pagine15 Mark Essay Planner SheetsuhaasNessuna valutazione finora

- Letter of Transmittal Report SubmissionDocumento28 pagineLetter of Transmittal Report SubmissionHeart BeatsNessuna valutazione finora

- Chap05 StaticFailureDocumento9 pagineChap05 StaticFailureFatih AŞCINessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)