Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Industrial Combustion System Riello PDF

Caricato da

Anonymous QY7Iu8fB0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

247 visualizzazioni8 pagineRIELLO BURNERS is able to offer a complete industrial combustion System, that includes burners and all the other components such as fuel pre-processing units, combustion air fans and control panels. DB series industrial burners are suitable for application in big heating plants (such as district heating, hospitals) as well as in food, chemical and textile industry, for matching with hot water boilers, steam and thermal oil generators and for industrial processes.

Descrizione originale:

Titolo originale

Industrial Combustion System Riello.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoRIELLO BURNERS is able to offer a complete industrial combustion System, that includes burners and all the other components such as fuel pre-processing units, combustion air fans and control panels. DB series industrial burners are suitable for application in big heating plants (such as district heating, hospitals) as well as in food, chemical and textile industry, for matching with hot water boilers, steam and thermal oil generators and for industrial processes.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

247 visualizzazioni8 pagineIndustrial Combustion System Riello PDF

Caricato da

Anonymous QY7Iu8fBRIELLO BURNERS is able to offer a complete industrial combustion System, that includes burners and all the other components such as fuel pre-processing units, combustion air fans and control panels. DB series industrial burners are suitable for application in big heating plants (such as district heating, hospitals) as well as in food, chemical and textile industry, for matching with hot water boilers, steam and thermal oil generators and for industrial processes.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 8

Focus on

Industrial Combustion Systems

2

Industrial Combustion Systems

Standard combustion and low NOx combustion versions

can be supplied according to customers requests.

RIELLO BURNERS is able to offer a complete Industrial Combustion System, that includes burners and all the other components such as

fuel pre-processing units, combustion air fans and control panels; can also offer a great support in terms of burner application consulting,

providing technical solutions for process or special applications.

Several kinds of Gas Trains and Oil Heating Pumping Units

are available according to the plant requirements:

Pressure reduction and regulation units allow to bring gas

pressure in the supply line, sized to values suited to the specic

application.

Gas trains include a series of safety and control devices for gas

feeding to the burner.

The oil unit skids come ready assembled and tested for fast

installation.

Electric or steam/electric oil heaters may be used and a double

system with backup lter and pump is also available.

The use of a separate fan allows:

The matching with high boiler combustion pressure.

The working with pre-heated combustion air to reach a higher

system efciency.

The reduction or the elimination of fan noise on boiler room.

The control panel can be customised according to specications,

directives or other requests:

All the electrical equipment can be included inside.

It can be equipped with variable speed drive control to obtain

lower noise emissions, lower electrical consumption and also

higher turn-down ratio.

Oxygen control module can be included.

Communication with remote boiler room supervision can be

done through common protocols (Modbus - Probus).

Overview

COMBUSTION HEAD

FUEL UNIT

SEPARATE FAN

CONTROL PANEL

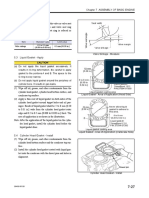

DB 20

DB 16

DB 12

DB 9

DB 6

DB 4

0 2 4 6 8 10 12 14 16 18 20 22 24

OUTPUT MW

Modulation Range

Working Field

DB 20

DB 16

DB 12

DB 9

DB 6

DB 4

0 2 4 6 8 10 12 14 16 18 20 22 24

OUTPUT MW

Modulation Range

Working Field

3

Made up of technology and reliability, DB series industrial burners

are suitable for application in big heating plants (such as district

heating, hospitals) as well as in food, chemical and textile

industry, for matching with hot water boilers, steam and thermal

oil generators and for industrial processes. Various congurations,

as electronic or mechanical air-fuel ratio control, pre-heated

combustion air, multi-fuel combustion, are available according to

customer specications. High Quality and Reliable Combustion

are assured from Riello experience.

DB 6 SE BLU - Air intake from above. Left/right hinge can be supplied for an easier maintenance.

New maintenance concept.

Full modulation and high turn down ratio.

Two combustion versions: low NOx and standard.

Low NOx emissions.

Two fuel-air ratio control versions: mechanical, electronic.

Ignition by gas/lpg pilot ignition system on DB 9, 12, 16, 20 models.

Pre-heated combustion air up to 150C as standard (250C

with special insulation).

Steam/air atomising system to burn high viscosity oil.

DB Series

MAIN FEATURES

DB 20

DB 16

DB 12

DB 9

DB 6

DB 4

0 2 4 6 8 10 12 14 16 18 20 22 24

OUTPUT MW

Modulation Range

Working Field

4

Industrial Combustion Systems

ER Series

ER series, with the considerable output of 2 MW, is the most

powerful burner series within Riello products, and it is suitable for

application on water tube D-shape boilers, thermal oil generators,

multiple-burner systems and process applications.

Thanks to the air register, it allows to get a ame perfectly matched

to the combustion chamber.

ER series is equipped with electronic air-fuel ratio control, but can

be supplied on demand with mechanical cam also, according to

customer specications. The modulating regulation always allows

to reach a wide modulation ratio and optimal fluid-dynamics

conditions for a good combustion and low pollutant emissions.

Flame adaptability to boiler combustion chamber.

Low air pressure drop.

Low NOx emissions.

Easy access to the combustion head components.

Electronic or mechanical air-fuel ratio control.

Ignition by pilot system.

Steam/air atomising system to burn heavy oil up to 80E @ 50C.

Manual fame shape regulation device.

Different types of photocell according to the application.

MAIN FEATURES

Easy access to the combustion head. Low NOx emissions: fuel staging techniques. two internal air distribution circuits.

5

DB and ER Control Equipment

The Digital Burner Management System, also called Electronic Cam, is a microprocessor-based device designed for the control and

supervision of forced draft burners. It includes the standard function of a Flame Control Panel and in the meantime manages the air-fuel ratio

by independent servomotors, with high accuracy position, in order to obtain a perfect output control and to assure a correct combustion

and safe operation on all modulation range.

By the absence of joint clearance and mechanical hysteresis, present in traditional mechanical systems that utilize cams and linkage,

combustion quality is improved.

The addition of the Oxygen Trim Integration Kit can guarantee air-fuel mixing near stoichiometric ratio throughout the whole burner range,

to obtain an higher efciency, and also allows to monitor, store and remote O2, CO2 and CO emissions values.

Electronic cam allows to use bus protocol communication and can be also matched with the Variable Speed Drive operation in order to

obtain low energy consumption, lower sound emissions and a high turn down ratio (over 10:1 on gas DB series).

.ABOUT ELECTRONIC CAM VERSIONS

Micromodulation. On board electronic cam version with ame safeguard

inside reduces installation time and cost.

Separate control panel version according to

customers specication.

Exhaust gas analyser available as option for electronic cam version.

Main features:

- continuous measurement of exhaust gas

- trim operation on air damper

- microprocessor controlled

- automatic calibration

- 4-20 mA analogue output signal for O2-CO-CO2-NO-effciency-exhaust gas temperature.

The air fuel ratio control is available with mechanical or electronic cam:

Mechanical cam: it is the easiest and most known solution. The air-fuel mixture is controlled by a cam according to an adjustable

mechanical prole.

Electronic cam: it represents the high tech confguration.

The air-fuel mixture is controlled by single control position servomotors installed directly on the air damper and on the fuel modulator.

A microprocessor manages the working of single servomotors.

Operation can be:

Intermittent (the burner stops at least one time every 24 hours).

Continuous (the burner control system is equipped with specifc fame detector, control box and hydraulic circuit available to work

continuously for over 24 hours).

6

Industrial Combustion Systems

System components

HEATING PUMPING UNITS

PRESSURE REGULATING / REDUCING UNITS

SAFETY / REGULATING PROPORTIONAL GAS TRAINS

SAFETY / REGULATING GAS TRAINS

BURNER CONTROL PANELS

CENTRIFUGAL AIR FANS

Series SG - DG

SG 160 - 250 - 320 - 400 - 500 - 800 - 1000 - 1500

DG 160 - 250 - 320 - 400 - 500 - 800 - 1000 - 1500

Delivery

Series SN - DN

SN 250 - 320 - 400 - 500 - 650 - 800 - 1000 - 1500

DN 250 - 320 - 400 - 500 - 650 - 800 - 1000 - 1500 - 2000

Series LPRT

LPRT 40 - 80 - 160 - 250 - 500 - 750 - 1000 - 1500 - 2000

Series HPRT

HPRT 80 - 160 - 250 - 500 - 750 - 1000 - 1500 - 2000

Series MBC

MBC 1200 SE 50 - MBC 1200 SE 50 CT

MBC 1900 SE 65 FC - MBC 1900 SE 65 FC CT

MBC 3100 SE 80 FC - MBC 3100 SE 80 FC CT

MBC 5000 SE 100 FC - MBC 5000 SE 100 FC CT

Series VGD

VGD 50 - VGDF 65 - VGDF 80 - VGDF 100

Series GCH

GCH 4020 - 5020 - 5040

GCM 4540 - 5020 - 5040

Series GBJ

GBJ H0 5630 - 6320 - 6330 - 6380 - 712 - 717

GBJ I0 6310 - 6320 - 6360 - 710 - 712 - 800A

Series QA

380 3600 l/h

540 3600 l/h

< 500 mbar

0,5 4 bar

< 360 mbar

< 500 mbar

< 500 mbar

800 5000 m3/h

4000 9500 m3/h

3500 20000 m3/h

_

Inlet pressure

Inlet pressure

Inlet pressure

Delivery

7

In Riello Burners Application Engineering department a dedicated team works in cooperation with major OEMs to perform application

matching and burner integration, optimizing performance to help our Customers achieving the competitive advantage they need.

We can offer a great support in terms of burner application consulting, analysis for product re-engineering, job development, integrated

system proposals and assistance for international standards compliance.

Training, start-up, commissioning and after-sale assistance are also performed by headquarter expert engineers.

Technical Support

Textile factory, Italy: n. 3 units DB 6 SE BLU gas burners.

District heating, Romania: nr. 10 units ER 20 dual fuel burners (gas/heavy oil).

Across the world, Riello sets the standard in reliable, high effciency,

low-maintenance burner maintenance burner from 10 kW to deliver

unbeatable technology.

With burner capacities from 5 kW to 32 MW, Riello oil, gas, dualfuel

and Low NOx burners deliver unbeatable performance across the full

range of residential and commercial heating applications, as well as in

industrial processes.

With headquarters in Legnago, Italy, Riello has been manufacturing

premium quality burners for over 85 years.

The new manufacturing plant is equipped with the most innovated

systems of assembling lines and modern manufacturing cells for a quick

and exible response to the market.

Besides, the Riello Combustion Research Centre, located in Angiari

Italy, represents one of the most modern facility in Europe and one of the

most advanced in the world for the development of the burner technology.

Today, to meet its customers needs, Riello Burners has a sales and

support network that spans over 60 countries

Riello Burners - a world of experience

in every burner we sell.

BURNERS PRODUCTION PLANT

S. Pietro, Legnago (Verona) - Italy

COMBUSTION RESEARCH CENTRE

Angiari (Verona) - Italy

0

2

/

2

0

0

9

-

V

P

0

0

8

2

U

K

0

1

RIELLO S.p.A.

Via Ing. Pilade Riello, 5

37045 Legnago (VR) Italy

Tel. +39.0442.630111 - Fax +39.0442.21980

www.rielloburners.com - info@rielloburners.com

Riello Burners is a brand of Riello Group.

Since the Company is constantly engaged in the production improvement, the aesthetic and

dimensional features, the technical data, the equipment and the accessories can be changed.

This document contains confi dential and proprietary information of RIELLO S.p.A.

Unless authorised, this information shall not be divulged, nor duplicated in whole or in part.

Potrebbero piacerti anche

- 2071 GB 10 08Documento16 pagine2071 GB 10 08otto2212Nessuna valutazione finora

- 2012 Burner Range: Leaders in Combustion TechnologyDocumento5 pagine2012 Burner Range: Leaders in Combustion TechnologyBbaPbaNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Midco-DB Duct BurnerDocumento2 pagineMidco-DB Duct BurnerTot GaNessuna valutazione finora

- Dynaforce Hot Water 300 5000Documento3 pagineDynaforce Hot Water 300 5000Oscar Dario Villada LopezNessuna valutazione finora

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- Technical - Sales Catalogue - 0001101120 - 1.0Documento44 pagineTechnical - Sales Catalogue - 0001101120 - 1.0alejovelNessuna valutazione finora

- Boiler Control Systems Engineering, Second EditionDa EverandBoiler Control Systems Engineering, Second EditionValutazione: 4.5 su 5 stelle4.5/5 (15)

- Full Ahead... ... For: LowerDocumento20 pagineFull Ahead... ... For: LowerQuarkantNessuna valutazione finora

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneDa EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNessuna valutazione finora

- Turbocore ChillersDocumento4 pagineTurbocore Chillerss341232Nessuna valutazione finora

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Bi-Fuel System: Proven Technology / Over 200 Units Operational WorldwideDocumento4 pagineBi-Fuel System: Proven Technology / Over 200 Units Operational WorldwideJosé Miguel LarezNessuna valutazione finora

- Advanced Temperature Measurement and Control, Second EditionDa EverandAdvanced Temperature Measurement and Control, Second EditionNessuna valutazione finora

- Oil & Gas BurnersDocumento8 pagineOil & Gas BurnersgoelamitaNessuna valutazione finora

- Gas fired high efficiency low NOx boilers from 204 kW-472 kWDocumento47 pagineGas fired high efficiency low NOx boilers from 204 kW-472 kWalexfrizNessuna valutazione finora

- Inert Gas System (IGG)Documento3 pagineInert Gas System (IGG)Fadzil NorNessuna valutazione finora

- CB AutoflameDocumento10 pagineCB AutoflameWylbert ConsueloNessuna valutazione finora

- HEATING Catalogue 2014Documento106 pagineHEATING Catalogue 2014sergioNessuna valutazione finora

- SORG EquipmentDocumento56 pagineSORG Equipmentl0% (2)

- Raadman Bunrer - Mechanical Modular - Up To 6200 KW - V1 - NoDocumento28 pagineRaadman Bunrer - Mechanical Modular - Up To 6200 KW - V1 - Nonegar adelniaNessuna valutazione finora

- Gas Turbine Pump Drive Integrated Control System: Petrotech Home PageDocumento4 pagineGas Turbine Pump Drive Integrated Control System: Petrotech Home Pagescribdkhatn100% (1)

- Weishaupt WL30 - WL40Documento12 pagineWeishaupt WL30 - WL40Yacine A. Meziane100% (1)

- Ansalado TurbinesDocumento8 pagineAnsalado Turbinesalexandr_popov_2Nessuna valutazione finora

- Compair Lb55 90 AeDocumento4 pagineCompair Lb55 90 Aearyluck77Nessuna valutazione finora

- 1.0 Chiller UnitDocumento12 pagine1.0 Chiller UnitfebousNessuna valutazione finora

- Boiler Book CBEX Premium 100-800Documento19 pagineBoiler Book CBEX Premium 100-800fauzi endraNessuna valutazione finora

- Oilon 4A Monox en StandardDocumento16 pagineOilon 4A Monox en StandardWilbert Consuelo CotrinaNessuna valutazione finora

- Chamber and Tube Furnaces 0001-G-EDocumento64 pagineChamber and Tube Furnaces 0001-G-EMutsikamahwe BrianNessuna valutazione finora

- Weishaupt WG10 and WG20 Gas Burners Technical SpecificationsDocumento8 pagineWeishaupt WG10 and WG20 Gas Burners Technical SpecificationsbatazivoNessuna valutazione finora

- EDT GBTRDocumento4 pagineEDT GBTRAlistair Ciantar100% (1)

- Jumag Gesamtkatalog enDocumento24 pagineJumag Gesamtkatalog enatisz333Nessuna valutazione finora

- Cooling & Heating: ShellmaxDocumento3 pagineCooling & Heating: Shellmaxvijaysirsat2007Nessuna valutazione finora

- Oil Injected Rotary Screw CompressorsDocumento8 pagineOil Injected Rotary Screw CompressorsscribdkhatnNessuna valutazione finora

- Vectron+1-6 300713 en 1.6Documento24 pagineVectron+1-6 300713 en 1.6kikokadolaNessuna valutazione finora

- Krom Schroder 1Documento10 pagineKrom Schroder 1Sujanto WidjajaNessuna valutazione finora

- COMPRESSED AIR TECHNOLOGY: SCREW COMPRESSORS UP TO 3108 M3/HDocumento4 pagineCOMPRESSED AIR TECHNOLOGY: SCREW COMPRESSORS UP TO 3108 M3/HPlaton MihaiNessuna valutazione finora

- Steam Turbine Gas Turbine 002Documento6 pagineSteam Turbine Gas Turbine 002dheerajdb99100% (1)

- Sa200 1Documento5 pagineSa200 1Alejandra0% (1)

- Aircube-Agu-Mil106e-0909 12-2009 - HQDocumento32 pagineAircube-Agu-Mil106e-0909 12-2009 - HQJoao Pedro MartinsNessuna valutazione finora

- ms5002 AtodDocumento8 paginems5002 AtodhanysramzyNessuna valutazione finora

- APG-Neuros Brochure EnglishDocumento12 pagineAPG-Neuros Brochure EnglishkrustyboxNessuna valutazione finora

- McQuay McEnergy HPI Technical Manual EngDocumento48 pagineMcQuay McEnergy HPI Technical Manual EngZhenqian HNessuna valutazione finora

- GasDocumento8 pagineGasscribdkhatnNessuna valutazione finora

- CompAir L23 - L29 - RS Compressor Brochure PDFDocumento8 pagineCompAir L23 - L29 - RS Compressor Brochure PDFbulentbulutNessuna valutazione finora

- Digital dual fuel burners guideDocumento12 pagineDigital dual fuel burners guidePramudhitya FirzaNessuna valutazione finora

- Folder Glasstec EDocumento8 pagineFolder Glasstec EHardikNessuna valutazione finora

- GE 10-1 Gas TurbineDocumento29 pagineGE 10-1 Gas TurbineAtanda Babatunde Mutiu33% (3)

- SGT-2000E Series: Siemens Gas TurbineDocumento10 pagineSGT-2000E Series: Siemens Gas TurbineRoozbeh PNessuna valutazione finora

- CSB 15 - 40 HP - enDocumento8 pagineCSB 15 - 40 HP - enLeonardo RodriguezNessuna valutazione finora

- 1308172866-Broshure BT GIDocumento20 pagine1308172866-Broshure BT GIcatch_samNessuna valutazione finora

- BurnerDocumento76 pagineBurnersopian320100% (2)

- Bettis Valve Actuator GuideDocumento12 pagineBettis Valve Actuator Guideprufino2Nessuna valutazione finora

- Absorption Chillers 07Documento52 pagineAbsorption Chillers 07Sujadi Cherbond100% (1)

- Ewyq FDocumento54 pagineEwyq FRicardo Molina SánchezNessuna valutazione finora

- GB162 User ManualDocumento28 pagineGB162 User ManualAndrei ClaudiaNessuna valutazione finora

- Modulating Light Oil Burners RL/M SeriesDocumento20 pagineModulating Light Oil Burners RL/M SeriesPinga FlorinNessuna valutazione finora

- Operations Manual Indoor AtmosphericDocumento56 pagineOperations Manual Indoor AtmosphericAnonymous QY7Iu8fBNessuna valutazione finora

- CB-7853 Boiler Room Guide - LR PDFDocumento90 pagineCB-7853 Boiler Room Guide - LR PDFcewaleed2590Nessuna valutazione finora

- Boiler EmergenciesDocumento15 pagineBoiler EmergenciesAnonymous QY7Iu8fB100% (1)

- Boiler EmergancyDocumento35 pagineBoiler EmergancyAshok RasekarNessuna valutazione finora

- Boiler EmergenciesDocumento15 pagineBoiler EmergenciesAnonymous QY7Iu8fB100% (1)

- VIESSMANN - Biomass - BrochureDocumento16 pagineVIESSMANN - Biomass - BrochureAnonymous QY7Iu8fBNessuna valutazione finora

- Combustion and Flue Gas Analysis: Excellence in MeasurementsDocumento37 pagineCombustion and Flue Gas Analysis: Excellence in MeasurementsDaphne Cosi LealNessuna valutazione finora

- Boiler EmergenciesDocumento15 pagineBoiler EmergenciesAnonymous QY7Iu8fB100% (1)

- Spare Parts - GAS7-2 PDFDocumento4 pagineSpare Parts - GAS7-2 PDFAnonymous QY7Iu8fBNessuna valutazione finora

- Service Manual: X-MAX 300 Evolis 300Documento462 pagineService Manual: X-MAX 300 Evolis 300김태완Nessuna valutazione finora

- MPFI System: How It Works and Its ComponentsDocumento6 pagineMPFI System: How It Works and Its Componentsalan kurniawanNessuna valutazione finora

- Manual BookDocumento154 pagineManual BookAnonymous nHT1rzjmcNessuna valutazione finora

- Herrenknecht Raise Boring Rig Rbr400Vf: Powerful Shaft BoringDocumento2 pagineHerrenknecht Raise Boring Rig Rbr400Vf: Powerful Shaft BoringvcampurojasNessuna valutazione finora

- Item Standard Value Limit Value Valve Sinkage - 0.1 To 0.1 MM (-0.004 To 0.004 In.) 0.5 MM (0.020 In.)Documento11 pagineItem Standard Value Limit Value Valve Sinkage - 0.1 To 0.1 MM (-0.004 To 0.004 In.) 0.5 MM (0.020 In.)pearl nojokeNessuna valutazione finora

- Chery QQ 465 Mechanical SystempdfDocumento55 pagineChery QQ 465 Mechanical Systempdfaral77Nessuna valutazione finora

- 2 Flame Retardants by AmpacetDocumento6 pagine2 Flame Retardants by Ampacetnumichem100% (1)

- Power House POF ReportDocumento16 paginePower House POF ReportMuhammad Bilal Sahi100% (1)

- Spider Crane Inspection ReportDocumento6 pagineSpider Crane Inspection ReportBishoo ShenoudaNessuna valutazione finora

- Basic Engine SpecsDocumento4 pagineBasic Engine SpecsOdlanier José Mendoza100% (1)

- Petroleum Refining Process Control and Real-Time OptimizationDocumento11 paginePetroleum Refining Process Control and Real-Time OptimizationLuís Roberto Cavalcanti da SilvaNessuna valutazione finora

- Doosan Basic Excavator TrainingDocumento76 pagineDoosan Basic Excavator TrainingNguyen Ngoc95% (20)

- Gti VR6 1.8L 2004.Documento243 pagineGti VR6 1.8L 2004.Eduardo OlivaNessuna valutazione finora

- Hydraulic PlateDocumento30 pagineHydraulic PlatehoiNessuna valutazione finora

- 32 Equipo de Termofusion TracStar900Documento1 pagina32 Equipo de Termofusion TracStar900coorporativo asociadosNessuna valutazione finora

- BD 50Documento4 pagineBD 50Pankaj TiwariNessuna valutazione finora

- Electrical Safety Standards For LVMVHV Part-2Documento8 pagineElectrical Safety Standards For LVMVHV Part-2isaacwabbiNessuna valutazione finora

- A Technical Report On (Final)Documento27 pagineA Technical Report On (Final)Nohid Chougle50% (2)

- Electrical Wiring Diagrams PDFDocumento39 pagineElectrical Wiring Diagrams PDFfely67% (3)

- Interp1HelpSheetsandCoolant English 18 Feb 2020Documento72 pagineInterp1HelpSheetsandCoolant English 18 Feb 2020jjjNessuna valutazione finora

- Errores IvecoDocumento3 pagineErrores Ivecoenzo725967% (12)

- QSPDocumento20 pagineQSPa k singhNessuna valutazione finora

- D475a-5 Eess017002 0608 23113 PDFDocumento16 pagineD475a-5 Eess017002 0608 23113 PDFDorneanu NarcisNessuna valutazione finora

- MEO Class 4B Examinations Oral Question Bank For Electro Technology and Control EngineeringDocumento8 pagineMEO Class 4B Examinations Oral Question Bank For Electro Technology and Control EngineeringShriram AryanNessuna valutazione finora

- TIO-540-AB1AD Parts Catalog PC-315-3 PDFDocumento69 pagineTIO-540-AB1AD Parts Catalog PC-315-3 PDFCESAR VEGANessuna valutazione finora

- Hydrocarbon Processing Petrochemical Processes 2001Documento144 pagineHydrocarbon Processing Petrochemical Processes 2001Alejandra Arias100% (1)

- 4200 Wet Sump - Engine OverhaulDocumento0 pagine4200 Wet Sump - Engine Overhaulaiigee100% (8)

- Turbo CompoundingDocumento1 paginaTurbo CompoundingPercyLeonNessuna valutazione finora

- 16 Su Brazil-Kd WMDocumento88 pagine16 Su Brazil-Kd WMGustavo Sostenes Rodrigues Nunes100% (1)

- Increased Capacity and Flexibility: Key Advantages of Electric TrainsDocumento43 pagineIncreased Capacity and Flexibility: Key Advantages of Electric TrainsthreephasefaultNessuna valutazione finora