Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Water Mist

Caricato da

rommel76Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Water Mist

Caricato da

rommel76Copyright:

Formati disponibili

INSPECTION, MAINTENANCE AND

RECHARGE SERVICE MANUAL

P/N 16303

All fire extinguishers should be installed, inspected and maintained

in accordance with the National Fire Protection Association standard

titled "Portable Fire Extinguishers", NFPA-10 and the requirements

of local authorities having jurisdiction.

When maintenance is indicated, it should be performed by trained

persons having proper equipment. Fire extinguishers are pressure

vessels and must be treated with respect and handled with care.

They are mechanical devices and require periodic maintenance to

be sure that they are ready to operate properly and safely. Amerex

strongly recommends that the maintenance of portable fire

extinguishers be done by a trained professional your local

authorized Amerex Distributor.

Amerex Corporation makes original factory parts available to insure

proper maintenance USE OF SUBSTITUTE PARTS RELEASES

AMEREX OF ITS WARRANTY OBLIGATIONS. Amerex parts have

machined surfaces and threads that are manufactured to exacting

tolerances. O-rings, hoses, nozzles, and all metal parts meet

precise specifications and are subjected to multiple in-house

inspections and tests for acceptability. There are substitute parts

available that may be incorrectly labeled as UL component parts,

some are advertised as Amerex type. None of these meet UL

requirements and all of them voids the Amerex extinguisher

warranty and UL listing. DO NOT SUBSTITUTE.

WARNING: DO NOT USE THIS EXTINGUISHER ON CLASS D

FIRES OR ANY FLAMMABLES THAT WILL REACT WITH

WATER.

PROTECT FROM FREEZING.

REFERENCES IN THIS MANUAL: AVAILABLE FROM:

NFPA-10 Portable Fire Extinguishers National Fire Protection Association

1 Batterymarch Park, P.O, Box 9101

Quincy, MA 02269-9101

CGA C-1 Methods for Hydrostatic Testing of Compressed Gas Association, Inc.

Compressed Gas Cylinders 4221 Walney Road, 5

th

Floor

CGA C-6 Standard for Visual Inspection of Chantilly, VA 20151-2923

Compressed Gas Cylinders

AMEREX CORPORATION P.O. BOX 81 TRUSSVILLE, ALABAMA 35173-0081

Phone: 205/655-3271 Fax: 800/654-5980

e-mail: sales@amerex-fire.com Web Page: http://www.amerex-fire.com

Printed in U.S.A. 0M16303A Rev. 03/11

W

A

T

E

R

M

I

S

T

H

A

N

D

P

O

R

T

A

B

L

E

F

I

R

E

E

X

T

I

N

G

U

I

S

H

E

R

S

M

o

d

e

l

B

2

7

0

G

a

l

l

o

n

M

o

d

e

l

B

2

7

2

G

a

l

l

o

n

1

INSPECTING THE EXTINGUISHER

MAINTENANCE

[NFPA-10] At least once a year or more frequently if circumstances require,

maintenance should be performed. Maintenance is a "thorough check" of the

extinguisher. It is intended to give maximum assurance that a fire extinguisher will

operate effectively and safely. It includes a thorough examination for physical damage

or condition to prevent its operation and any necessary repair or replacement. It will

normally reveal if hydrostatic testing or internal maintenance is required.

MAINTENANCE SERVICE PROCEDURE

1. Clean extinguisher to remove dirt, grease or foreign material. Check to make sure that the

instruction nameplate is securely attached and legible. Inspect the cylinders for corrosion,

abrasion, dents or weld damage. If any damage is found, hydrostatically test in accordance with

instructions in CGA C-1 and C-6 and NFPA 10.

Note: When cleaning, avoid use of solvents around the pressure gauge. They could

seriously damage the plastic gauge face.

2. Inspect the extinguisher for damaged, missing or substitute parts. Only factory replacement

parts are approved for use on Amerex fire extinguishers.

3. Weigh the extinguisher and compare with weight printed in the "Maintenance" section on the

nameplate (label). Recharge extinguisher if weight is not within indicated allowable tolerances.

AMEREX CORPORATION DOES NOT SERVICE, MAINTAIN OR RECHARGE FIRE

EXTINGUISHERS. THIS MANUAL IS PUBLISHED AS A GUIDE TO ASSIST QUALIFIED

SERVICE PERSONNEL IN THE INSPECTION, MAINTENANCE AND RECHARGE OF AMEREX

FIRE EXTINGUISHERS ONLY. NO INSTRUCTION MANUAL CAN ANTICIPATE ALL POSSIBLE

MALFUNCTIONS THAT MAY BE ENCOUNTERED IN THE SERVICE OF FIRE

EXTINGUISHERS. DUE TO THE POSSIBILITY THAT PRIOR SERVICE PERFORMED ON THIS

EQUIPMENT MAY HAVE BEEN IMPROPERLY DONE, IT IS EXTREMELY IMPORTANT THAT

ALL WARNINGS, CAUTIONS AND NOTES IN THIS MANUAL BE CAREFULLY OBSERVED.

FAILURE TO HEED THESE INSTRUCTIONS COULD RESULT IN SERIOUS INJURY.

AMEREX ASSUMES NO LIABILITY FOR SERVICE, MAINTENANCE OR RECHARGE OF FIRE

EXTINGUISHERS BY PUBLISHING THIS MANUAL.

This extinguisher should be inspected at regular intervals (monthly or more often if

circumstances dictate) to insure that it is ready for use. Inspection is a "quick check"

that a fire extinguisher is available and is in operating condition. It is intended to give

reasonable assurance that the fire extinguisher is fully charged. This is done by

verifying that it is in its designated place, that it has not been actuated or tampered

with, and that there is no obvious physical damage or condition to prevent its operation.

2

4. Check the date of manufacture printed on the extinguisher label (nameplate) or on the agent

cylinder dome. The agent cylinder must be hydrostatically tested every 5 years to the test

pressure indicated on the nameplate. REPLACE EXTINGUISHING AGENT WITH NEW

AMEREX CHARGE AT TIME OF HYDROTEST.

5. Visually inspect the pressure gauge:

a. If bent, damaged or improper gauge, depressurize and replace.

b. If pressure is low, check for leaks.

c. If over pressurized (overcharged), depressurize the extinguisher and follow recharge

instructions.

6. Check ring pin for freedom of movement. Replace if bent or if removal appears difficult.

7. Inspect discharge lever for any dirt or corrosion which might impair freedom of movement.

Inspect carrying handle for proper installation. If lever, handle or rivets are damaged replace

with proper Amerex part(s).

8. Install new tamper seal if broken and record service data on the extinguisher inspection tag.

9. Remove hose & wand assembly, inspect for damage, replace as necessary. Blow air through

nozzle or hose and horn to insure passage is clear of foreign material.

10. Inspect the valve assembly for corrosion or damage to hose thread connection. Replace valve

assembly or component parts as necessary following the proper depressurization and recharge

procedures. If valve removal is necessary, complete all steps in the Recharge Procedure.

11. Install hose & wand assembly. Torque swivel nut lightly with 15/16" wrench.

12. Replace the extinguisher on the wall hanger or in the vehicle bracket making sure that it fits the

bracket properly and the bracket is securely attached replace the bracket if necessary.

RECHARGE

WARNING:

a. Before attempting to disassemble, be sure the extinguisher is completely depressurized.

b. Use a regulated nitrogen pressurizing source. Set the regulator no more than 125 psi

(862 kPa).

c. Check and calibrate regulator gauge at frequent intervals. The regulator gauge should

be used to determine when the intended charging pressure has been reached. Do not

use the extinguisher for this purpose.

d. Never leave an extinguisher connected to a regulator of a high pressure source for an

extended period of time. A defective regulator could cause the cylinder to rupture due to

excessive pressure.

RECHARGING PROCEDURE

1. Perform steps 1 through 10 of the "Maintenance-Service Procedure" section.

2. Discharge all remaining pressure and contents, making sure that there is no remaining

pressure. Do not top off or reuse water.

3. Remove the valve assembly and disassemble by removing downtube assembly (use a

wrench on the brass retainer, not the plastic tube), spring and valve stem assembly.

Remove the collar o-ring from the valve and plastic fill tube from the cylinder.

3

4. Thoroughly clean all parts of the disassembled valve with a soft bristle brush or soft cloth.

Blow the valve out with air or nitrogen. Inspect the spring and downtube assembly, and

replace parts if worn or damaged. Replace the valve stem and collar o-ring. Lubricate the

collar o-ring and small o-ring on the valve stem with Visilox V-711 (do not lubricate the valve

stem seal). Inspect the downtube. If it is cracked or deformed replace with proper

downtube. Inspect downtube o-ring, replace if necessary.

5. Rinse the cylinder with clean water and inspect the interior following CGA Visual Inspection

Standard C-6.

6. Firmly replace the plastic fill tube and fill cylinder with DE-IONIZED WATER to the bottom of

the fill tube. (Model B270 1.8 U.S. gals./6.81 liters Amerex Charge 670)(Model B272 2-

U.S. gals/9 liters Amerex Charge 671).

NOTE: THE USE OF DE-IONIZED WATER CONFORMING TO NFPA 10 IS REQUIRED.

7. Install a "Verification of Service" collar around neck of cylinder. Install valve assembly to the

cylinder and properly align.

CAUTION: HAND TIGHTEN THE VALVE COLLAR NUT 100-125 IN LBS. MAX (1.15-1.44

KG/M. OVER-TIGHTENING WITH A WRENCH WILL DAMAGE THE VALVE.

8. Install a P/N 09492 Fill Adapter (High Performance) to the male valve outlet (where the hose

assembly attached) and pressurize with nitrogen to 100 psi (690 kPa). The pressure

regulator should be set to no more than 125 psi (862 kPa). Remove Fill Adapter.

CAUTION: DO NOT USE COMPRESSED AIR TO PRESSURIZE THIS EXTINGUISHER.

9. Check the collar, gauge, cylinder welds and valve orifice for leaks using a leak detection

fluid or a solution of soapy water. Remove leak detection fluid from the valve assembly by

blowing out with air and wipe exterior of the extinguisher to dry.

10. Install house & wand assembly into the operating valve

NOTE: CAREFULLY POSITION THE HOSE TO A NATURAL ANGLE BEFORE

TIGHTENING THE HOSE FEMALE SWIVEL NUT. TORQUE SWIVEL NUT LIGHTLY

USING 15/16" WRENCH. INSTALL IN HOSE CLIPS.

11. Install ring pin with ring facing the front of the extinguisher.

12. Install tamper seal. Record recharge date and attach new recharge tag.

13. Weigh assembled extinguisher and confirm that the total weight is within the allowable

tolerances indicated in the Maintenance section of the nameplate (label).

4

TROUBLESHOOTING GUIDE

WARNING: Determine the source of a leak before the extinguisher is depressurized. The

extinguisher must be completely depressurized before any attempt is made to devalve it and

correct a leakage problem. To depressurize hold the extinguisher in an inverted position and

slowly squeeze the discharge handle. Some water remaining in the downtube will be expelled

so care should be taken in the area being used for depressurizing. Thoroughly clean all valve

parts after depressurization and valve removal.

PROBLEM CORRECTIVE ACTION

1. Leak at collar o-ring Remove valve assembly, clean collar

(knurled) nut thoroughly and install new

collar o-ring. Lubricate with Visilox V-711.

2. Leak through valve Check valve stem seating area for scratches

or foreign matter. Clean seating area with a

tooth brush and soft cloth. Install new valve

stem assembly.

3. Leak around gauge Remove gauge*, clean threads and reinstall

using Teflon tape on the gauge threads.

4. Defective gauge Remove defective gauge* an install the

proper Amerex pressure gauge using Teflon

tape on the gauge threads.

5. Leak in the cylinder Contact Amerex if under warranty,

otherwise mark "REJECTED" and remove

from service or return to owner.

* Pressure gauge threads are coated with a special epoxy at the

factory. For easy removal, soak the valve assembly in hot water

(180F) for two to four minutes. Remove gauge with a thin 7/16"

open end wrench.

5

PARTS LIST

for

1-3/4 Gallon "Water Mist" Model B270

2-1/2 Gallon "Water Mist" Model B272

Model 270

Model 272

Item

Part

No.

Description

Std

Pkg

1 17615 Valve Assembly All Models 1

2 14380 Hanger Loop w/Screw (Optional) 6

3

14184

Hose & Wand Asy - all 272

models

1

14318

Hose & Wand Asy all 270

models

4 06901 Ring Pin, SS (Non-Magnetic) 24

4A 00532 Chair (Nylon) for Ring Pin 24

5 01387 Lock Wire Seal (Yellow) 500

6 07762 Lever & Rivet All Models 1

6A 01563 Rivet Only for Lever 24

7 09020 Handle & Rivets All Models 1

7A 01564 Rivets Only for Handle (2 req'd) 24

8 06479 Gauge 100 6

9

05240 Collar O-Ring 24

Collar O-Ring Bulk Bag 100

10

06093 Valve Stem Assembly 6

Valve Stem Assembly Bulk Bag 96

11 05243 Valve Stem O-Ring 24

12 00383 Spring 6

13

15943

Downtube Retainer Assembly

all 272 models

1

15941

Downtube Retainer Assembly

all 270 models

14 05690 O-Ring Downtube/Retainer 12

15

02595 Fill Tube all 272 models

1

14316 Fill Tube all 270 models

16 14187 Foot Stand (blue) 1

17 14838

Strap & Clip Assembly (Blue

plastic 3/8") (2 required)

1

ALL BRACKETS SEE BRACKET PAGE

ALL FILL & HYDROTEST ADAPTERS SEE ADAPTER PAGE

ALL VALVE ASSEMBLIES INCLUDE VALVE BODY, VALVE

STEM ASSEMBLY, SPRING, RETAINER, LEVER & HANDLE

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

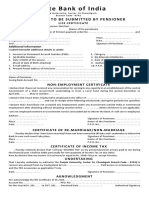

- SBI - Certificate To Be Submitted by Pensioner - ChandigarhDocumento1 paginaSBI - Certificate To Be Submitted by Pensioner - ChandigarhMsinghNessuna valutazione finora

- Age Discrimination PDFDocumento20 pagineAge Discrimination PDFMd. Rezoan ShoranNessuna valutazione finora

- ABS Part4 - Vessel Systems & Machinery - 2001Documento710 pagineABS Part4 - Vessel Systems & Machinery - 2001AndréMenezesNessuna valutazione finora

- Hospital & Clinical Pharmacy Q&ADocumento22 pagineHospital & Clinical Pharmacy Q&AKrishan KumarNessuna valutazione finora

- Transformer Differential ProtectionDocumento5 pagineTransformer Differential Protectionverde24Nessuna valutazione finora

- Transformer Differential ProtectionDocumento5 pagineTransformer Differential Protectionverde24Nessuna valutazione finora

- Top Five Causes of Switchgear FailureDocumento3 pagineTop Five Causes of Switchgear FailureGlenn Adalia Bonita75% (4)

- CSC 326 Transformer Protection Ied Technical Application Manual v1 02Documento329 pagineCSC 326 Transformer Protection Ied Technical Application Manual v1 02rommel76Nessuna valutazione finora

- Terminal Tractors and Trailers 6.1Documento7 pagineTerminal Tractors and Trailers 6.1lephuongdongNessuna valutazione finora

- Siemens VaristorDocumento3 pagineSiemens Varistorrommel76Nessuna valutazione finora

- Nport 5600 Series Quick Installation Guide: Third Edition, November 2010Documento2 pagineNport 5600 Series Quick Installation Guide: Third Edition, November 2010Hermes TrismeNessuna valutazione finora

- Zero-Crossing Breaker Vs Pre-Insertion ResistorDocumento11 pagineZero-Crossing Breaker Vs Pre-Insertion Resistorabhi120783Nessuna valutazione finora

- NPort 5600 Series QIG v4Documento50 pagineNPort 5600 Series QIG v4rommel76Nessuna valutazione finora

- Silent Install FlexView 3.1.xDocumento3 pagineSilent Install FlexView 3.1.xrommel76Nessuna valutazione finora

- Siemens VaristorDocumento3 pagineSiemens Varistorrommel76Nessuna valutazione finora

- Application Note AN-08-04-01: Additional Language InstallationDocumento6 pagineApplication Note AN-08-04-01: Additional Language Installationrommel76Nessuna valutazione finora

- Microprocessor Applications To Substation Control and Protection PDFDocumento5 pagineMicroprocessor Applications To Substation Control and Protection PDFrommel76Nessuna valutazione finora

- User Functions APIDocumento36 pagineUser Functions APIrommel76Nessuna valutazione finora

- Online Transformer Monitor Installation Guide - March 2010Documento37 pagineOnline Transformer Monitor Installation Guide - March 2010rommel76Nessuna valutazione finora

- Water MistDocumento1 paginaWater Mistrommel76Nessuna valutazione finora

- Owners Service Manual NO. 05602 Installation, Operating & Servicing InstructionsDocumento10 pagineOwners Service Manual NO. 05602 Installation, Operating & Servicing Instructionsrommel76Nessuna valutazione finora

- Wheeled Extinguishers: Dry Chemical Stored PressureDocumento1 paginaWheeled Extinguishers: Dry Chemical Stored Pressurerommel76Nessuna valutazione finora

- Protection Scheme: Types and Voltage Level of FeedersDocumento8 pagineProtection Scheme: Types and Voltage Level of Feedersrommel76Nessuna valutazione finora

- PRPI-048 D20 D25 IBOX Automation ApplicationsDocumento49 paginePRPI-048 D20 D25 IBOX Automation Applicationsrommel76Nessuna valutazione finora

- Asat Iec 61850 Client CG r1.1Documento30 pagineAsat Iec 61850 Client CG r1.1rommel76Nessuna valutazione finora

- USB Serial Adapter ManualDocumento8 pagineUSB Serial Adapter Manualrommel76Nessuna valutazione finora

- Auto Transformer ModuleDocumento10 pagineAuto Transformer ModuleIkhwanJackNessuna valutazione finora

- DAPmini Server BrochureDocumento2 pagineDAPmini Server Brochurerommel76Nessuna valutazione finora

- EHC6010 User'SManual V18Documento90 pagineEHC6010 User'SManual V18rommel76Nessuna valutazione finora

- DAPview HMI BrochureDocumento2 pagineDAPview HMI Brochurerommel76Nessuna valutazione finora

- DAPguard BrochureDocumento2 pagineDAPguard Brochurerommel76Nessuna valutazione finora

- DAPmini 61850 GatewayDocumento2 pagineDAPmini 61850 Gatewayrommel76Nessuna valutazione finora

- MOXA NPort 5600 SeriesDocumento4 pagineMOXA NPort 5600 Seriesrommel76Nessuna valutazione finora

- Nport 5600 Series Quick Installation Guide: Third Edition, November 2010Documento2 pagineNport 5600 Series Quick Installation Guide: Third Edition, November 2010Hermes TrismeNessuna valutazione finora

- Indian Boyhood PDFDocumento316 pagineIndian Boyhood PDFHasanNessuna valutazione finora

- Specialized Connective TissueDocumento15 pagineSpecialized Connective TissueSebNessuna valutazione finora

- Mri 7 TeslaDocumento12 pagineMri 7 TeslaJEAN FELLIPE BARROSNessuna valutazione finora

- Volume 1Documento168 pagineVolume 1lalitendu jenaNessuna valutazione finora

- Rajasthan PET Chemistry 1997 Exam with Detailed SolutionsDocumento34 pagineRajasthan PET Chemistry 1997 Exam with Detailed SolutionsYumit MorwalNessuna valutazione finora

- Informática Ejercicios IDocumento10 pagineInformática Ejercicios IAlejandroMendezNessuna valutazione finora

- Otology Fellowships 2019Documento5 pagineOtology Fellowships 2019Sandra SandrinaNessuna valutazione finora

- CHAPTER 15 Managing Current AssetsDocumento26 pagineCHAPTER 15 Managing Current AssetsAhsanNessuna valutazione finora

- Mole Concept: Chemfile Mini-Guide To Problem SolvingDocumento18 pagineMole Concept: Chemfile Mini-Guide To Problem SolvingNaren ParasharNessuna valutazione finora

- 6V Plush Ride-On: Owner'S ManualDocumento26 pagine6V Plush Ride-On: Owner'S ManualVisas LaredoNessuna valutazione finora

- Risk Management in Educational InstitutionsDocumento8 pagineRisk Management in Educational InstitutionsBhoxszKurtjusticePascualNessuna valutazione finora

- CASR Part 830 Amdt. 2 - Notification & Reporting of Aircraft Accidents, Incidents, or Overdue Acft & Investigation OCRDocumento17 pagineCASR Part 830 Amdt. 2 - Notification & Reporting of Aircraft Accidents, Incidents, or Overdue Acft & Investigation OCRHarry NuryantoNessuna valutazione finora

- Edinburgh Postnatal Depression Scale. Detection of Postnatal Depression. Development of The 10-ItemDocumento6 pagineEdinburgh Postnatal Depression Scale. Detection of Postnatal Depression. Development of The 10-ItemKyze LQNessuna valutazione finora

- Training and Supervision of Health Care WorkersDocumento12 pagineTraining and Supervision of Health Care WorkerspriyankaNessuna valutazione finora

- Yanagiba Sharpening: Everything You Need To KnowDocumento16 pagineYanagiba Sharpening: Everything You Need To KnowT ChenNessuna valutazione finora

- Role of Homeostasis in Human Physiology A ReviewDocumento5 pagineRole of Homeostasis in Human Physiology A ReviewNathaly ZiékteNessuna valutazione finora

- India Vision 2020Documento9 pagineIndia Vision 2020Siva KumaravelNessuna valutazione finora

- Adolescent and Sexual HealthDocumento36 pagineAdolescent and Sexual Healthqwerty123Nessuna valutazione finora

- Vacuum Conveyin 5.0Documento56 pagineVacuum Conveyin 5.0Mostafa AtwaNessuna valutazione finora

- Smart Goals ExerciseDocumento2 pagineSmart Goals Exerciseapi-594661640Nessuna valutazione finora

- Impact of Dairy Subsidies in NepalDocumento123 pagineImpact of Dairy Subsidies in NepalGaurav PradhanNessuna valutazione finora

- The Truth About EtawahDocumento4 pagineThe Truth About EtawahPoojaDasgupta100% (1)

- 2022 TESAS PublicationDocumento103 pagine2022 TESAS PublicationNathan LakaNessuna valutazione finora

- Byk-A 525 enDocumento2 pagineByk-A 525 enさいとはちこNessuna valutazione finora

- Evolution Chart 3Documento1 paginaEvolution Chart 3sasupraNessuna valutazione finora