Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sheet Metal Bend Relief

Caricato da

johndesign1230 valutazioniIl 0% ha trovato utile questo documento (0 voti)

585 visualizzazioni17 pagineBend relief helps control sheet metal behavior and prevent unwanted deformation during bending. There are several bend relief options available, including no relief, stretch relief, rip relief, rectangular relief, and obround relief. Rip relief is recommended, as it cuts the material at each bend endpoint normal to the bend line, allowing for an accurate representation of the bend in the flat model. The appropriate bend relief type can be assigned individually or automatically using default settings.

Descrizione originale:

fzdv

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoBend relief helps control sheet metal behavior and prevent unwanted deformation during bending. There are several bend relief options available, including no relief, stretch relief, rip relief, rectangular relief, and obround relief. Rip relief is recommended, as it cuts the material at each bend endpoint normal to the bend line, allowing for an accurate representation of the bend in the flat model. The appropriate bend relief type can be assigned individually or automatically using default settings.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

585 visualizzazioni17 pagineSheet Metal Bend Relief

Caricato da

johndesign123Bend relief helps control sheet metal behavior and prevent unwanted deformation during bending. There are several bend relief options available, including no relief, stretch relief, rip relief, rectangular relief, and obround relief. Rip relief is recommended, as it cuts the material at each bend endpoint normal to the bend line, allowing for an accurate representation of the bend in the flat model. The appropriate bend relief type can be assigned individually or automatically using default settings.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 17

SHOW NAVIGATION << >>

About Bend Relief

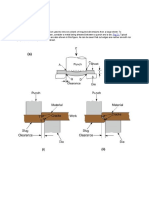

Bend relief helps control the sheet metal material behavior and prevents unwanted

deformation.

For example, an unrelieved bend might not represent the accurate, real life model you

need due to material stretching. By adding the appropriate bend relief, like RipRelief,

your sheet metal bend will meet your design intent and enable you to create an accurate

flat model.

After you sketch and regenerate the bend, the RELIEF menu appears with the following

relief options:

No ReliefCreate the bend without any relief.

StrtchReliefStretch the material to provide relief where the bend crosses an existing

edge of the fixed material.

RipReliefCut the material at each bend endpoint. The cuts are made normal to the bend

line.

RectReliefAdd a rectangular relief at each bend endpoint.

ObrndReliefAdd an obround relief at each bend endpoint.

No Relief StrtchRelief Rip Relief RectRelief ObrndRelief

You can either assign bend relief individually or you can set automatic bend relief using

the SMT_DFLT_BEND_REL_TYPE default.

See Also

About Bends

About Sheet Metal Defaults and Parameters

SheetMetal.Me &

BendAllowance.Com

Sheet Metal Fabrication Resources, Blog and Discussion

Forum

Pages

o Home

o Fabrication Formulas

o Tooling Terminology

o Design Guidelines

o Sheet Metal Gauge Chart

Search for:

Search

Advertisements

Coining Sheet Metal

Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch

and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis

under a high amount of pressure. The term Coining comes from the idea that when it comes to money

each metal coin is made exactly the same as the last despite being mass produced. From this idea

the name Coining was applied to the bending method which creates accurate bends consistently.

There are a few significant advantages to coin bending sheet metal, the first of which are high

repeatability, precision, and the ability to reduce the inside radius to as small as desired. During the

Coining process the material is put under enough pressure that the punch tip penetrates the material

at the bottom of the bend and it begins to flow into the die. Because the sheet metal flows during the

process of Coining the bend radius formed by Coining is always equal to that of the punch tip. The

penetration into the metal also relieves the internal stress and is thought to be a contributing factor to

the elimination of Spring Back.

A final advantage of Coining is that this method does not require sophisticated CNC machines to

execute. It does however very large tonnages compared to the other two bending methods, typically it

will require 5-8 times the tonnage of Bottom Bending. Because of these tonnage requirements, wear

and tear on the machines will be much greater than air or Bottom Bending. Tooling required for

Coining must be robust and this can limit your tooling and geometry options. Because of the tooling

restrictions and the large tonnages required to coin this process is rare in the press brake world.

When determining the V-width for tooling it is preferable to use a v-opening of 5*Mt. This reduces the

initial inside radius, before the punch tip begins to penetrate, and reduces the amount of metal the tip

actually has to penetrate. The smaller v-opening also means that the surface area between the sheet

metal and the bottom die is reduced, this increases the average tonnage per area on the inside of

the v-opening, the keY-Factor in eliminating Spring Back. When selecting the tooling for a Coining

operation the punch and die should have the same angle as the desired finished bend. Spring back is

not taken into consideration when making this selection. If you desire a 90 bend you should select a

90 punch and a 90 die.

Pros:

o Accuracy

o No Spring Back

o Repeatability

o No sophisticated machinery

o Small inside radii are possible

Cons:

o High tonnage required

o Tooling limitations

o Increased wear on machinery

o Larger brakes required to produce extra tonnage

Formulas For Coining

The actual formulas for Coining are fairly simple as they are just based off of the formulas for Air

Bending, modified for the affects of Coining. For the tonnage formula below Ive given 7.5 as a

multiplier, this may be higher or lower depending on the material youre bending. The rule of thumb I

use for this is the higher the tensile strength of the material the higher the tonnage multiplier. You

should always start low and work your way up until you get the desired results. Use the Air Bend

Force Chart to find your initial tonnage. You can also reference the tensile strengths for different

materials below.

Tonnage = L * F * (Tensile Strength / 45) *7.5

V Opening = 5 * Mt.

Inside Radius = Punch Tip Radius

Tensile Strengths

Material Soft (kg/mm^2) Hard (kg/mm^2)

Lead 2.5 - 4 -

Tin 4 - 5 -

Aluminum 9.3 171

Aluminum Alloy Type 4 23 48

Duralumin 26 48

Material Soft (kg/mm^2) Hard (kg/mm^2)

Zinc 15 25

Copper 22-28 30-40

Brass (70:30) 33 53

Brass (60:40) 38 49

Phosphor Bronze / Bronze 40-50 50-75

Nickel Silver 35-45 55-70

Cold Rolled Iron 32-38 -

Steel .1% Carbon 32 40

Steel .2% Carbon 40 50

Steel .3% Carbon 45 60

Steel .4% Carbon 56 72

Steel .6% Carbon 72 90

Steel .8% Carbon 90 110

Steel 1.0% Carbon 100 130

Silicon Steel 55 65

Stainless Steel 65-70 -

Nickel 44-50 57-63

SheetMetal.Me 2011.

SheetMetal.Me &

BendAllowance.Com

Sheet Metal Fabrication Resources, Blog and Discussion

Forum

Pages

o Home

o Fabrication Formulas

o Tooling Terminology

o Design Guidelines

o Sheet Metal Gauge Chart

Search for:

Search

Advertisements

Design Guidelines

Bends

Bends are the most typical feature of sheet metal parts and can be formed by a variety of methods

and machines which negate the absolute need for some of the below tips. However for typical parts

meant to be cost effective and easily produced the following tips should be useful.

o The minumum flange length is based on the die used to bend. Consult and Air Bend Force

Chart to determine typical minimum flange lengths.

o When multiple bends are on the same plane try and design the part so the bends all face the same

direction. This will prevent the need for the operator to flip the part. This also benefits man leaf

and panel benders which can only bend one direction per setup.

o Avoid large parts when possible, and especially large parts with small or detailed flanges. Chasing

a large part through each bend can be dangerous and exhausting for an operator. This also makes

you vulnerable to reduced part accuracy.

o Always consult a tooling profile chart when developing your part. Know the tools available in your

shop or the standards if you are outsourcing production. Specialized tooling cen be

very expensive.

Counterbores & Countersinks

While thinner gauge sheets wont often be countersunk there are a few guidelines to try and follow on

thicker sheets to preserve the strength of the material and prevent deformation fo the features during

forming.

o The distance between two countersinks should be kept to at least 8 times the material thickness.

o To ensure strength the distance between a countersinks edge and the edge of the material should

be 4 times the material thickness.

o There should be at least %50 contact between the fastener and the surface of the countersink.

o To prevent any deformation of the hole the edge of the countersink should be at least 3 times the

material thickness from the tangent point of the bend.

Curls

When adding a Curl to the edge of a sheet the following guidelines will ensure that no special tooling

is required.

o The outside radius of a curl can be no smaller than 2 times the material thickness. This will create

an opening with a 1 material thickness radius.

o A hole should be at least the radius of the curl plus material thickness from the curl feature.

o A bend should be at least the radius of the curl plus 6 times the material thickness from the curl

feature.

Dimples

o The diameter of a dimple should be no more than 6 times the material thickness.

o The inside depth of a dimple should be no more than the inside radius.

o A hole should be at least three times material thickness away from the edge of the dimple. Or the

inside radius of the dimple plus 3 times material thickness.

o From the parts edge, dimples should be at least 4 times material thickness plus the radius of the

dimple.

o From a bend, dimples should be at least 2 times material thickness plus the dimple radius plus the

bend radius.

o From another dimple, dimples should be 4 times material thickness plus the inside radius of each

dimple.

Embossments & Ribbing

o Embossments and offsets should be measured to the same side of material unless it is necessary

to hold an outside dimension.

o For round embossments or ribs, maximum depth is equal to the internal radius of the embossment.

o For flat embossments, the maximum depth is equal to the inside radius plus the outside radius.

o For V embossments the maximum depth is equal to 3 times material thickness.

o Embossments should be at least 3 times material thickness from a holes edge.

o Between two parallel ribs, minimum distance is 10 times material thickness plus the radius of the

ribs.

Extruded Holes

o Between two extruded holes, distance should be at least 6 times material thickness.

o From edge to extruded hole, distance should be at least 3 times material thickness.

o From bend to extruded hole, distance should be 3 times material thickness plus bend radius.

Gussets

Gussets are used to strengthen a flange without the need for secondary processes such as

welding. While gussets will almost always require custom tooling some basic guidlines should

help. Be sure to consult with your factorys Brake Press department to learn what they are equipped

to bend.

o 45 gussets shouldnt be designed to be more than 4 times material thickness on their flat edge

o For holes, the distance between the gusset and the holes edge should be at least 8 times material

thickness.

Hems

Hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to

touch.

o For tear drop hems, the inside diameter should be equal to the material thickness.

o For open hems, the bend will lose its roundness when the inside diameter is greater than the

material thickness.

o For holes, the minimum distance between the holes edge is 2 times the material thickness plus the

hems radius.

o For bends, the minimum distance between the inside edge of the bend and the outside of the hem

should be 5 times material thickness plus bend radius plus hem radius.

Holes / Slots

o Distance from outside mold line to the bottom of the cutout should be equal to the minimum flange

length prescribed by the air bend force chart.

o Rule Of Thumb: 2.5* Material Thickness + Bend Radius.

o When using a punch press the diameter of a hole should always be equal to that of your tooling

and you should never use a tool whos diameter is less than that of the materials thickness.

o Rule Of Thumb: Never design a hole smaller than .040 Diameter unless laser cutting.

o When using a punch press holes should be at least 1 material thickness from any edge. This

prevents bulging along the edge.

Lances & Louvers

Formed lances and louvers will almost always require specialized tooling so be sure to understand

what is available to you before designing the feature.

o The minimum depth of a lance should be twice the material thickness and at least .125

o If the lance if formed with standard tooling be sure that the length of the bend is dividable by a

standard set of Sectionalized Tooling.

o From a bend, lances should be at least 3 times material thickness plus bend radius, however the

actual minimum is often much greater than this and driven by the tooling profile.

o From a hole, lances should be at least 3 time material thickness from the edge of the hole.

Notches & Reliefs

o The minimum width of a notch is equal to the material thickness and at least .04. This is negated if

the blank is being cut by a Laser System in which case the minimum is only the kerf of the laser.

o When determining the length of a notch it is very important to understand the tooling used to cut the

notch. When possible the notch should be equal to a multiple of the punchs length in order to

prevent nibbling from occurring.

o From a bend, the minimum distance is 3 times material length plus the bend radius.

o When fabricating with a Punch Press the minimum space between two notches should be at least 2

time material thickness and at least .125

Welding

o Welding by hand should be restricted to gauges thicker than 20 gauge.

o Spot welding should be used for joining equally thick co-planar surfaces. The arm geometry and

throat depth of the spot welder will be a limiting factor.

o Welded joints should be designed with as tight of tolerances as possible to remove the need for a

welder to add wire.

o Wire material should always be the same as the material being welded.

Plating

o Sharp edges and corners will typically receive about twice as much as the plating material because

of the current density in these areas.

o If possible tap and thread after plating, else assume that the material will grow up to 4 times the

typical platting thickness, compensate pitch and depth accordingly.

o Avoid recessed areas which are difficult to reach.

o Because the parts are going to be hung from hooks and dipped it is beneficial to design hanging

holes into your part rather than leaving the decision to the plater. These holes can be small, just

enough to get a wire hook through. These holes will also give you control over how the part is

positioned when it is dipped.

o In addition to hanging holes design drainage holes. Knowing the orientation of the part from your

hanging holes make sure the part can be easily cleaned after plating.

o Assume all areas of the part will be plated, masking is not recommended.

Sheet Metal Fabrication Resources, Blog and Discussion

Forum

Pages

o Home

o Fabrication Formulas

o Tooling Terminology

o Design Guidelines

o Sheet Metal Gauge Chart

Search for:

Search

Advertisements

Tooling Terminology

Tooling Terminology:

o Acute - Tooling with an angle less than 90.

o Adapter - Intermediate tooling which converts an American Style punch holder to a European

Style, or vice versa. They can also be used to lengthen the punch holder.

o Adjustable - A die where the v opening can be changed by turning a screw mechanism to spread

the two sides of the v.

o American Style - Tooling for press brakes comes in two main forms; American and European.

o Box - Tooling specifically designed to form boxes with flanges on 2, 3 and 4 sides.

o Channel - Tooling which is used to form sheet metal channels.

o Curling - Tooling which creates an open circular roll at the end of the sheet, this is different than

hemming.

o Die - The bottom section of a press brake tool which typically features a v shaped groove.

o Die Holder - Attached permanently to the lower beam this clamping mechanism will hold the die or

rail in position.

o Die Set - The term applied to a specific combination of holder, die, punch and any spacers or rails.

o European Style - Press brake tooling comes in two main forms, European and

American. European style tooling has an offset between the center of the tool and where it is

clamped to the brake.

o Goose Neck Punch - A term for punches with deep profiles to allow for large return flanges when

bending.

o Hemming - Tooling which is specially designed to produce hems in to stages, without tool change

over.

o Offset - Offset tooling is a combination punch and die which has a Z shape and performs two bends

in one stroke to produce a jog, or offset, in the metal.

o Punch - The upper section of tooling which generally features a v shaped profile matching the die.

o Punch Holder - A clamping mechanism which holds the punch, allowing for easy switching of

punches.

o Radius - Tooling specifically designed for forming a larger radius in the work piece.

o Ribbing - Tooling which ads a round or v shaped grooved to the sheet metal in a single stroke.

o Sash Punch - A generally straight thin tool with a sharp relief offset at the bottom, used for bending

special relief profiles.

o Sash Die - A thin single v die with a center tang, allowing for tighter profiles to be bent around the

die.

o Seaming - Punch and Die sets which are designed to prepare and close seams on one or more

pieces of sheet metal.

o Shimming - The act of adding material to the bend process in order to compensate for distortion

along the bend line.

o Spacer Block - An intermediate piece of tooling which adds height to the die holder.

o Squaring Arm - A device which attaches to and moves with the press brake and work piece to hold

work pieces square, or at a set angle.

o Straight Punch - Also known as sword punches these are characterized by long, straight, thin

punches used for bending symmetrical profiles.

o Two, Three & Four Sided Die - A specialized die which has a square shape and a special profile

cut into each side to allow for multiple setups from a single die.

o Rail - An intermediary holder which is seated in the die holder and adds height, or a special profile,

to the die holder. This also allows for quick accurate switching of dies.

o Rolla V - A specialized die which has two half cylinders which support the flanges as the work piece

is bent.

o Rotary Die - Rotary dies have a cylindrical shape with v cut along its axis is seated in a saddle.

o Tang - A locating protrusion on a piece of tooling which fits into a matching groove. Typically found

at the center of American Tooling.

o Unbalanced - Tooling which does not evenly distribute the tonnage front to back and thus creates

a thrust force on the punch holder. Often seen in 30-60 type tooling.

o Urethane Die - Press brake dies which incorporate a urethane pad to aid in the bending process.

o Window Punch - A bend setup which creates an open area above the punch to allow deep

drawn parts to pass through.

o Wipe Die - Wiping die bending is performed by holding the sheet between a pad and die then

sliding the wiping punch across the face bending the sheet metal which protrudes from the pad and

die.

Machine Specific:

o Brake Press

o Laser

o Panel Bender

o Punch Press

o Pyramid Roller

o Shear

o Water Jet

SheetMetal.Me 2011.

Deal Keeper Advertisement

Air Bending

Air bending is the most common type of 3 Types Of Bending used in sheet metal shops today. In this

process the workpiece comes in contact with the outside edges of the die, as well as the punch tip.

The punch is then forced past the top of the die into the v-opening without coming into contact with

the bottom of the v. The v opening is typically deeper than the angle which is sought in the work

piece. This allows for over bending to compensate for the Spring Back of the work piece.

Typically Acute Angle Tooling can be used to fully air bend and 90 or 88 tooling can be used to

partially air bend. There has recently been the introduction of 75 tooling to allow for full Air Bending,

without the tooling restrictions of acute punches. (Acute punches are almost always knife dies with no

goose-neck.)

Because the punch tip does not penetrate the workpiece the inside radius of the bend is controlled

almost entirely by the size of the v opening of the bottom die. The larger the v opening the larger the

radius. This means that the operator can control the radius of a bend even when working with the

same material and thickness just by changing the bottom die. This can be used to compensate for

errors in the layout or achieve a wider variety of design options. This is the reason why the inside

radius of your finished product is not the same as your punch tip. If it is your intended goal to achieve

a radius equal to your punch tip you will actually have to force the tip into the metal, this is known

as Bottom Bending. Below you can see an example of Air Bending, notice there are only three points

of contact.

This same versatility can work against you as well as it can lead to bad parts if the wrong Press Brake

Dies are used. It is my recommendation that the dies you are using be clearly marked for their

intended gauges and that using the larger dies to achieve larger radii be done only with knowledge of

how it will affect the part. Be aware that you should never use smaller dies to bend heavier gauges

due to the risk of damaging the die. For a list of radii compared to v openings refer to your Air Bend

Force Chart. A further note on Air Bending is that it should almost never be used on older,

mechanical, Brake Presses because of their inherent margin of error; even the difference of a few

thousandths of an inch can result in bad parts. These press brakes are more suited for Bottom

Bending and Coining.

Advantages Of Air Bending

Because the punch tip does not need to be forced past the surface of the metal much less tonnage is

required to bend compared to Bottom Bending and Coining. This gives Air Bending a significant

advantage in terms of tooling, both in geometry and longevity. Air bending also means that non

specific tooling can be used, within reason, the inside radius is determined by the die width, not

the punch tip.

SheetMetal.Me 2011.

Sheet Metal Fabrication Resources, Blog and Discussion

Forum

Pages

o Home

o Fabrication Formulas

o Tooling Terminology

o Design Guidelines

o Sheet Metal Gauge Chart

Search for:

Search

Advertisements

3 Types Of Bending

There are three types of bends used to form metal that any sheet metal engineer or press brake

operator must be familiar with; Air Bending, Bottom Bending and Coining.

Air Bending

Air Bending is the most common type of bending process used in sheet metal shops today. In this

process the work piece is only in contact with the edge of the Die and the tip of the Punch. The punch

is them forced past the top of the die into the v-opening without coming into contact with the bottom of

the v. The v opening is typically deeper than the angle which is sought in the work piece. This allows

for over bending, compensating for the Spring Back of the work piece. Typically 30 degree tooling

can be used to fully air bend and 90 or 88 degree tooling can be used to partially air bend. There has

recently been the introduction of 75 degree tooling to allow for full Air Bending, without the tooling

restrictions of Acute Angle Tooling. (Acute punches are almost always knife dies with no goose-

neck.) Because the punch tip does not penetrate the work piece the inside radius of the bend is

controlled almost entirely by the size of the v-opening of the bottom die. The larger the v-opening the

larger the radius will be. This has both pros and cons, the pros being that the operator can control the

radius of a bend even when working with the same material and thickness just by changing the

bottom die. This can be used to compensate for errors in the layout or achieve a wider variety of

design options. This same versatility can work against you as well as it can lead to bad parts if the

wrong dies are used. Dies should be clearly marked for their intended gauges. The determination of

tooling is done with the assistance of an Air Bend Force Chart. A further note on Air Bending is that it

should almost never be used on older, mechanical, Brake Presses because of their inherent margin of

error, even the difference of a few thousands of an inch can result in bad parts.

Coining

Coining is a very basic type of bending in which the work piece is stamped between the punch and

die. The material is put under enough pressure that the punch tip penetrates the material and it

begins to flow into the die. This method produces excellent accuracy and repeatability, and does not

require sophisticated machines to execute. It does however very large tonnages compared to Air

Bending. Often times in excess of 50 tons per inch of material, compared to 1 or 2 tons per inch

for Air Bending. Because of these tonnage requirements wear and tear on the machines will be much

greater than air or Bottom Bending. Tooling required for Coining must be robust and this can limit

your tooling and geometry options. Because of the tooling restrictions and the large tonnages

required to coin this process is rare in the press brake world.

Bottom Bending

Bottom Bending has similarities to both Air Bending and Coining. In this process the die angle should

match the intended angle of the work piece, adjusting a few degrees for Spring Back, hence

the existence of 88 degree tooling to achieve 90 degree angles. The work piece is first bottomed

against the die, then the radius of the punch is forced into the work piece which achieves the angle of

the punch, it is then released and the work piece springs back to meet the die again. Unlike Coining

however the material is not under so much tonnage that the metal flows. Because of this there is still

Spring Back which must be compensated for. In order to do compensate the angle of the punch can

be smaller than the angle of the die by a few degrees allowing an over-bend when the punch tip is

forced into the work piece, it should not be larger or else you will damage the tooling. This method

can give an operator excellent repeatability if properly set up. Setting up a Bottom Bending operation

accurately requires knowledge in the tooling, material, tonnages and even the timing of the different

steps so it lends itself to a more skilled operator.

SheetMetal.Me 2010.

Deal Keeper Advertisement

Corner relief and Bend relief

Corner Relief Relief the Sheet metal Corners

Bend Relief Use the Between Bending Areas

Sheet Metal Fabrication Resources, Blog and Discussion

Forum

Pages

o Home

o Fabrication Formulas

o Tooling Terminology

o Design Guidelines

o Sheet Metal Gauge Chart

Search for:

Search

Advertisements

K-Factor

The K-Factor in sheet metal working is the ratio of the neutral axis to the material thickness. When

metal is bent the top section is going to undergo compression and the bottom section will be

stretched. The line where the transition from compression to stretching occurs is called the neutral

axis. The location of the neutral axis varies and is based on the materials physical properties and its

thickness. The K-Factor is the ratio of the Neutral Axis Offset (t) and the Material Thickness

(MT). Below the image shows how the top of the bend is compressed, and the bottom is stretched.

The K-Factor is used to calculate flat patterns because it is directly related to how much material is

stretched during the bend. Its used to determine Bend Allowances and Bend Deductions ahead of

the first piece. Having an accurate idea of your K-Factor is key to designing good parts because it

can anticipate Bend Deductions for a variety of angles without relying on a chart. Because of this it is

often used by design software such as Solid Edge, Solid Works and Pro-Engineer, though Pro-

Engineer uses a variation called the Y-Factor.

If you have a Bend Allowance (BA) you can derive the K-Factor from it. This is useful if you are

transitioning from hand layouts to an advanced design software. Subsequently you can use the K-

Factor to extrapolate allowances for new angles and radii.

Calculating the K-Factor

Since the K-Factor is based on the property of the metal and its thickness there is no simple way to

calculate it ahead of the first bend. Typically the K-Factor is going to be between 0 and .5. In order to

find the K-Factor you will need to bend a sample piece and deduce the Bend Allowance. The Bend

Allowance is then plugged into the above equation to find the K-Factor.

1. Begin by preparing sample blanks which are of equal and known sizes. The blanks should be at

least a foot long to ensure an even bend, and a few inches deep to make sure you can sit them

against the back stops. For our example lets take a piece that is 14 Gauge, .075, 4 Wide and

12 Long. The length of the piece wont be used in our calculations. Preparing at least 3 samples

and taking the average measurements from each will help

2. Set up your press brake with the desired tooling youll be using to fabricate this metal thickness

and place a 90 bend in the center of the piece. For our example this means a bend at the 2

mark.

3. Once youve bent your sample pieces carefully measure the flange lengths of each

piece. Record each length and take the average of lengths. The length should be something

over half the original length. For our example the average flange length is 2.073

4. Second measure the inside radius formed during the bending. A set of radius gauges will get you

you fairly close to finding the correct measurement, however to get an exact measurement an

optical comparator will give you the most accurate reading. For our example the inside radius is

measured at .105

5. Now that you have your measurements, well determine the Bend Allowance. To do this first

determine your leg length by subtracting the material thickness and inside radius from the flange

length. (Note this equation only works for 90 bends because the leg length is from the tangent

point.) For our example the leg length will be 2.073 .105 .075 = 1.893.

6. Subtract twice the leg length from the initial length to determine the Bend Allowance. 4 1.893 *

2 = .214.

7. Plug the Bend Allowance (BA), the Bend Angle (B<), Inside Radius (IR) and Material Thickness

(MT) into the below equation to determine the K-Factor (K). For our example it comes to

K-Factor Chart

A K-Factor will typically range between 0 and .5 for standard materials and thicknesses though

smaller and larger K-Factors are possible. To help you begin Ive included a K-Factor Chart below

which contains common K-Factor starting points, good for general fabrication, for steel, aluminum and

stainless steel.

Radius Soft / Aluminum Medium / Steel Hard / Stainless Steel

Air Bending

0 - Mt. .33 .38 .40

Mt. - 3*Mt. .40 .43 .45

3*Mt. - >3*Mt. .50 .50 .50

Bottom Bending

0 - Mt. .42 .44 .46

Mt. - 3*Mt. .46 .47 .48

3*Mt. - >3*Mt. .50 .50 .50

Coining

0 - Mt. .38 .41 .44

Mt. - 3*Mt. .44 .46 .47

3*Mt. - >3*Mt. .50 .50 .50

The K-Factor of a 180 Bend (Hem)

The K-Factor for a 180 bend is going to be meaningless because its tied to the Outside Setback

which approaches infinity as the bend approaches 180. Because of this K-Factors are not used to

calculate allowances over 174. Instead a hem allowance of 43% of the material thickness is

used. See our post on Sheet Metal Hems for more information.

SheetMetal.Me 2011.

Potrebbero piacerti anche

- Dimitris Achlioptas Ucsc Bsoe Baskin School of EngineeringDocumento22 pagineDimitris Achlioptas Ucsc Bsoe Baskin School of EngineeringUCSC Students100% (1)

- Basic Die MakingDocumento2 pagineBasic Die MakingJimmy Clavel0% (1)

- DGA Furan AnalysisDocumento42 pagineDGA Furan AnalysisShefian Md Dom100% (10)

- How To Calculate The Torsional Stiffness of Rubber Shock MountsDocumento4 pagineHow To Calculate The Torsional Stiffness of Rubber Shock MountsspibluNessuna valutazione finora

- FloodDocumento9 pagineFloodapi-352767278Nessuna valutazione finora

- Ramrajya 2025Documento39 pagineRamrajya 2025maxabs121Nessuna valutazione finora

- Lesson Plan Outline - Rebounding - Perez - JoseDocumento7 pagineLesson Plan Outline - Rebounding - Perez - JoseJose PerezNessuna valutazione finora

- Design Tips For Sheet Metal BendingDocumento2 pagineDesign Tips For Sheet Metal Bendingjitendertalwar1603Nessuna valutazione finora

- EML2322L Sheetmetal DesignDocumento9 pagineEML2322L Sheetmetal DesignHimanshu SagarNessuna valutazione finora

- Tolerancies Generals EstampacioDocumento2 pagineTolerancies Generals EstampacioAlbert SolsonaNessuna valutazione finora

- Sheetmetal Design GuidelinesDocumento20 pagineSheetmetal Design Guidelinesbrpnaidu2157Nessuna valutazione finora

- Sheet Metal Design-Handbook-Rev3 PDFDocumento12 pagineSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Sheet Metal FastenersDocumento15 pagineSheet Metal FastenersSudath KularathnaNessuna valutazione finora

- Bend Allowance - SheetMetal PDFDocumento3 pagineBend Allowance - SheetMetal PDFsunilbholNessuna valutazione finora

- Sheet Metal Design ConsiderationsDocumento3 pagineSheet Metal Design ConsiderationsVino KumarNessuna valutazione finora

- Rapid Sheet Metal Design GuideDocumento17 pagineRapid Sheet Metal Design GuideNageswar ReddyNessuna valutazione finora

- 12 - Sheet Metalworking (Chapter 16)Documento51 pagine12 - Sheet Metalworking (Chapter 16)Taher al suhamiNessuna valutazione finora

- (B) Testing Machine ToolsDocumento100 pagine(B) Testing Machine ToolsHyeonggil JooNessuna valutazione finora

- Length: If in Doubt, Make A Test PieceDocumento66 pagineLength: If in Doubt, Make A Test PiecepaulenewNessuna valutazione finora

- LIT00569 UltraThickTurret PN 2014 RevC Lo-ResDocumento96 pagineLIT00569 UltraThickTurret PN 2014 RevC Lo-ResAntonio AguilarNessuna valutazione finora

- Sheet Metal BendingDocumento2 pagineSheet Metal BendingSelva KumarNessuna valutazione finora

- SHEARINGDocumento6 pagineSHEARINGanmol6237Nessuna valutazione finora

- Milling MachineDocumento43 pagineMilling MachineJUAN DAVID MOSQUERA GARCIANessuna valutazione finora

- Fundamentals of Joining ProcessesDocumento21 pagineFundamentals of Joining ProcessesNosta Silva100% (1)

- K-Factor - SheetMetal PDFDocumento2 pagineK-Factor - SheetMetal PDFsunilbholNessuna valutazione finora

- Sheet Metal OperationsDocumento3 pagineSheet Metal OperationsDineshNessuna valutazione finora

- Press Tool Components Die MakingDocumento29 paginePress Tool Components Die Makingmayank123100% (1)

- Deep DrawingDocumento2 pagineDeep Drawingalexmonse2014Nessuna valutazione finora

- Metal Forming TechniquesDocumento49 pagineMetal Forming TechniquesSachinBhagiNessuna valutazione finora

- THE PRACTICAL USE OF SIMULATION IN THE Sheet Metal Forming IndustryDocumento17 pagineTHE PRACTICAL USE OF SIMULATION IN THE Sheet Metal Forming IndustryripanumariusionutNessuna valutazione finora

- Speeds and Feeds - Wikipedia, The Free EncyclopediaDocumento10 pagineSpeeds and Feeds - Wikipedia, The Free EncyclopediarajeshjvarmaNessuna valutazione finora

- Broaching BasicsDocumento5 pagineBroaching Basicssaritha0003Nessuna valutazione finora

- Metal Stamping DiesDocumento7 pagineMetal Stamping DiesedpsousaNessuna valutazione finora

- Ch21 Fundamentals of CuttingDocumento56 pagineCh21 Fundamentals of CuttingImGlobalCitizenNessuna valutazione finora

- Gear Cutting AttachmentDocumento40 pagineGear Cutting AttachmentGoutham Reddy100% (1)

- Amada Turret PunchDocumento9 pagineAmada Turret PunchPriyansh Tiwari100% (1)

- 06 GearsDocumento22 pagine06 GearsTeaching ClubNessuna valutazione finora

- Autodesk® Inventor™ and Sheet Metal Manufacturing From Drawing To FabricationDocumento15 pagineAutodesk® Inventor™ and Sheet Metal Manufacturing From Drawing To FabricationGraham MooreNessuna valutazione finora

- Automotive Gaskets and FastenersDocumento42 pagineAutomotive Gaskets and FastenersRhenzCarloLeonatoNessuna valutazione finora

- Plastic Fasteners Welding BondingDocumento28 paginePlastic Fasteners Welding BondingcfcshakerNessuna valutazione finora

- Collet ChuckDocumento4 pagineCollet ChuckAndrei IftincaNessuna valutazione finora

- Catalog - Actassi - Part2 (En)Documento87 pagineCatalog - Actassi - Part2 (En)Anonymous FTBYfqkNessuna valutazione finora

- Avdel Threaded Inserts enDocumento28 pagineAvdel Threaded Inserts enkamaleshaiahNessuna valutazione finora

- Base Chassis Drawing PDFDocumento10 pagineBase Chassis Drawing PDFMatias Ulloa SaavedraNessuna valutazione finora

- Lecture 1 - Intro To Single Point Cutting Tool GeometryDocumento16 pagineLecture 1 - Intro To Single Point Cutting Tool GeometryMuhammad Umar IqtidarNessuna valutazione finora

- Metal LatheDocumento25 pagineMetal Lathebogesz68Nessuna valutazione finora

- Gears Cutting and GrindingDocumento8 pagineGears Cutting and GrindingАлександар ВујаковићNessuna valutazione finora

- Sheet Metal Form Vinay 1226927986919169 9Documento83 pagineSheet Metal Form Vinay 1226927986919169 9Nhan LeNessuna valutazione finora

- Die Set Engineering Handbook and CatalogDocumento144 pagineDie Set Engineering Handbook and CatalogEduardo Medel50% (2)

- Rotary BroachDocumento2 pagineRotary BroachpeterNessuna valutazione finora

- Principles of CuttingDocumento81 paginePrinciples of CuttingTiago Camargo AlvesNessuna valutazione finora

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsDa EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNessuna valutazione finora

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Da EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Nessuna valutazione finora

- Project Street Rod: The Step-by-step Restoration of a Popular Vintage CarDa EverandProject Street Rod: The Step-by-step Restoration of a Popular Vintage CarNessuna valutazione finora

- SolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Da EverandSolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Valutazione: 4.5 su 5 stelle4.5/5 (5)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- The Iron Puddler My life in the rolling mills and what came of itDa EverandThe Iron Puddler My life in the rolling mills and what came of itNessuna valutazione finora

- SolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)Da EverandSolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)Valutazione: 4.5 su 5 stelle4.5/5 (5)

- SolidWorks 2018 Learn by doing - Part 2: Surface Design, Mold Tools, WeldmentsDa EverandSolidWorks 2018 Learn by doing - Part 2: Surface Design, Mold Tools, WeldmentsValutazione: 2 su 5 stelle2/5 (1)

- Mensuration for Sheet Metal Workers - As Applied in Working Ordinary Problems in Shop PracticeDa EverandMensuration for Sheet Metal Workers - As Applied in Working Ordinary Problems in Shop PracticeNessuna valutazione finora

- Crossing the Line Baja 1000: What Secrets Starts as Fortune Might Cost Him His LifeDa EverandCrossing the Line Baja 1000: What Secrets Starts as Fortune Might Cost Him His LifeNessuna valutazione finora

- Sheet Metal PDF 0Documento27 pagineSheet Metal PDF 0Vikrant PathaniaNessuna valutazione finora

- List of Manufacturing Processes: CastingDocumento10 pagineList of Manufacturing Processes: Castingjohndesign123Nessuna valutazione finora

- How To Determine Size of PulleysDocumento1 paginaHow To Determine Size of PulleysAnonymous u7Zq9FZkqNessuna valutazione finora

- English Through TamilDocumento90 pagineEnglish Through TamilKhalifullah100% (1)

- 146454Documento133 pagine146454johndesign123Nessuna valutazione finora

- 82Documento28 pagine82johndesign123Nessuna valutazione finora

- WhatsNew PDFDocumento223 pagineWhatsNew PDFMohamed AhmedNessuna valutazione finora

- Mechanical Design ProcessDocumento17 pagineMechanical Design Processjohndesign123Nessuna valutazione finora

- Design Document Template - ChaptersDocumento17 pagineDesign Document Template - ChaptersSuresh SaiNessuna valutazione finora

- Springs TextDocumento0 pagineSprings Texter_wenNessuna valutazione finora

- Alpha Tech India Limited - FinalDocumento4 pagineAlpha Tech India Limited - FinalRahul rNessuna valutazione finora

- NS1 UserManual EN V1.2Documento31 pagineNS1 UserManual EN V1.2T5 TecnologiaNessuna valutazione finora

- Cavitation in Francis PDFDocumento373 pagineCavitation in Francis PDFAlberto AliagaNessuna valutazione finora

- Computerised Project Management PDFDocumento11 pagineComputerised Project Management PDFsrishti deoli50% (2)

- Biology Concepts and Applications 9th Edition Starr Solutions ManualDocumento9 pagineBiology Concepts and Applications 9th Edition Starr Solutions Manualscarletwilliamnfz100% (31)

- Compressed Air Source BookDocumento128 pagineCompressed Air Source Bookgfollert100% (1)

- Anin, Cris Adrian U. Experiment Water Flirtation ELECTIVE 103Documento2 pagineAnin, Cris Adrian U. Experiment Water Flirtation ELECTIVE 103Cris Adrian Umadac AninNessuna valutazione finora

- A Modified Linear Programming Method For Distribution System ReconfigurationDocumento6 pagineA Modified Linear Programming Method For Distribution System Reconfigurationapi-3697505Nessuna valutazione finora

- UN Layout Key For Trade DocumentsDocumento92 pagineUN Layout Key For Trade DocumentsСтоян ТитевNessuna valutazione finora

- Tutorial 4 QuestionsDocumento3 pagineTutorial 4 QuestionshrfjbjrfrfNessuna valutazione finora

- Upend RA Kumar: Master List of Approved Vendors For Manufacture and Supply of Electrical ItemsDocumento42 pagineUpend RA Kumar: Master List of Approved Vendors For Manufacture and Supply of Electrical Itemssantosh iyerNessuna valutazione finora

- Control Flow, Arrays - DocDocumento34 pagineControl Flow, Arrays - DocHARIBABU N SEC 2020Nessuna valutazione finora

- First Certificate Star SB PDFDocumento239 pagineFirst Certificate Star SB PDFPatricia Gallego GálvezNessuna valutazione finora

- Segmentation of Qarshi Industries Private Limited PakistanDocumento6 pagineSegmentation of Qarshi Industries Private Limited PakistanReader100% (1)

- Toeic VocabularyDocumento10 pagineToeic VocabularyBrian Niblo80% (5)

- PET Formal Letter SamplesDocumento7 paginePET Formal Letter SamplesLe Anh ThuNessuna valutazione finora

- Industrial Training ReportDocumento19 pagineIndustrial Training ReportKapil Prajapati33% (3)

- Omegas Prezentacija 01Documento20 pagineOmegas Prezentacija 01Predrag Djordjevic100% (1)

- UTM Firewalls: AR3050S and AR4050SDocumento8 pagineUTM Firewalls: AR3050S and AR4050SChristian Javier Lopez DuranNessuna valutazione finora

- List of Every National School Walkout PDF LinksDocumento373 pagineList of Every National School Walkout PDF LinksStephanie Dube Dwilson100% (1)

- MKT STGDocumento106 pagineMKT STGAmeya Singh RajputNessuna valutazione finora

- 05271/MFP YPR SPL Sleeper Class (SL)Documento2 pagine05271/MFP YPR SPL Sleeper Class (SL)Rdx BoeNessuna valutazione finora

- Making Sense of The Future of Libraries: Dan Dorner, Jennifer Campbell-Meier and Iva SetoDocumento14 pagineMaking Sense of The Future of Libraries: Dan Dorner, Jennifer Campbell-Meier and Iva SetoBiblioteca IICENessuna valutazione finora

- CHAPTER I KyleDocumento13 pagineCHAPTER I KyleCresiel Pontijon100% (1)

- 1 s2.0 S0955221920305689 MainDocumento19 pagine1 s2.0 S0955221920305689 MainJoaoNessuna valutazione finora