Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Presentation Luglietti WRS

Caricato da

PREMANUSproject0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

7K visualizzazioni22 paginePresentation Luglietti WRS

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoPresentation Luglietti WRS

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

7K visualizzazioni22 paginePresentation Luglietti WRS

Caricato da

PREMANUSprojectPresentation Luglietti WRS

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 22

PREMANUS

Product Remanufacturing Service System

PREMANUS 2

Personal Information

ROSSELLA LUGLIETTI

Environmental Engineer

POLITECNICO DI MILANO

MAIN TOPIC:

Evaluation of environmental implications of products or services in a lifecycle

perspective, combining different Life Cycle Assessment (LCA) techniques.

PREMANUS:

Developing a Business Decision Support System to evaluate rank

different end-of-Life strategy from an environmental and economic

perspective.

Rossella Luglietti

25

th

26

th

September Rochester New York

Cost and Environmental Impact Evaluation

for End-of-Life Strategies in

Remanufacturing

PREMANUS 4

PREMANUS Context

The research leading to these results has received funding from

the European Communitys Seventh Framework Programme

(FP7/2007-2013) under grant agreement n285541.

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 5

PREMANUS OVERVIEW

PREMANUS is a Software Platform which facilitates the

products End-of-Life management

Remanufacturing Strategy

Environmental and Economic evaluation of End-of-Life

strategies, knowing Product Lifecycle data.

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 6

PREMANUS Architecture

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS Gateway is

responsible for making

services and information

available to the rest of the

PREMANUS.

PREMANUS Client

makes the information,

services and resources of the

Network available to the

client logic, the BDSS

PREMANUS Cloud

provides a number of key

services to the PREMANUS

Clients and Gateways

connected to the

PREMANUS network

PREMANUS 7

PREMANUS Pilots

Waste of Electrical and Electronic Equipment

management strategy

Wind turbine gearbox remanufacturing

strategy

Engine remanufacturing strategy

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 8

PREMANUS Business purpose

B

D

S

S

Evaluates the best End-of-Life option for complex products,

considering both environmental impacts and economic costs,

using lifecycle data.

Focus on the influence of different recycling plant strategies for

WEEE.

ENVIRONMNETAL EVALUATION:

employs a streamlined Life Cycle Assessment (LCA) methodology. The

system boundaries have been extended considering the benefits of the

avoidance of equivalent raw material extraction (for general use) and product

manufacturing.

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

ECONOMIC EVALUATION:

includes all the direct costs: Process costs

Product cost purchasing

Revenue for selling remanufactured/reused product

or fractions after material recovery

PREMANUS 10

PREMANUS Pilots description

Waste of Electrical and Electronic Equipment

management strategy

Wind turbine gearbox remanufacturing

strategy

Engine remanufacturing strategy

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 11

Engine remanufacturing evaluation process

ASKING FOR A QUOTE

A dealer wants to sell

the core to FIAT, and

sends a request for a

quote.

Makes the inspection

and inserts available

lifecycle data.

EVALUATION AND QUOTE

RESULTS

Calculates the overall

cost and environmental

impact, including the

missing information

fetch into the cloud

service.

The dealer receive the

quote

VALIDATION AND REMAN

PROCESSING

A production manager

makes a detailed

inspection and updates

relevant data.

Does remanufacturing

reducing stock, time

and manpower

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 12

Engine BDSS application

ENGINE REMANUFACTURING Strategy

DIFFERENT ASSESSED

ALTERNATIVES CONSIDERING:

Remanufacturing;

Reuse

Recycling;

Raw materials

extraction

Manufacturing Use phase End of Life

Material Recovery

Remanufacturing

Reusing

Disposal

D

i

s

a

s

s

e

m

b

l

y

Washing Sandblasting

Checking

Crankshaft

Con rods

Cylinder head

Cylinder block

Pistons

Flywheel

Camshaft

Turbo

M

a

c

h

i

n

i

n

g

Cores

A

s

s

e

m

b

l

y

T

e

s

t

i

n

g

S

h

i

p

p

i

n

g

New

components

PREMANUS 13

ENVIRONMENTAL ANALYSIS

Streamlined Life Cycle Assessment

all input and output that take part on

the remanufacturing process

the process avoided raw material

production and manufacturing engine

phase

Considering remanufacturing and reusing market:

SCENARIO 1 a remanufactured or reused engine replaces a new one:

Considering a substitution ratio to compare reused engine with a new one.

About remanufactured engine it has been considered an equal product

SCENARIO 2 a remanufactured or reused engine does not replace a new one:

Reused and remanufactured engine generates new demand.

Possible future scenario which will consider different substitution ratio to compare old

engines with new ones.

Engine BDSS application

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 14

Engine remanufacturing results

Environmental impacts

Remanufacturing Reusing Recycling

Reman activity plant

time (h) 8,39 0,79 1,15

Energy consumption kWh 127,20 19,74 17,89

Air compressed m

3

30,71 0,00

Oil liters 0,05 0,00 0,00

Water liters 0,85 0,85 0,85

CO

2

Emissions kg CO

2

eq 81,37 11,49 10,41

Production new engine

Energy consumption for manufacturing (kWh) 1613,56 1613,56

CO

2

Emissions kg CO

2

eq 938,90 938,90

kg CO

2

eq avoided for manufacturing 938,90 375,56

Recycling process

Energy consumption for recycling (kWh) 337,15

kg CO

2

eq avoided for recycling 640,72

Total CO

2

Emissions kg CO

2

eq -858 -364 -293

Different results

without including

impacts avoided

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 15

Engine remanufacturing results - Costs

Remanufacturing Reusing Recycling

Reman activity plant

energy consumption 39,78 6,17 5,60

operator costs 176,27 16,49 24,05

Total operation costs 216,06 22,66 29,64

Revenue selling engine

-2562,00 -612,00

Revenue selling materials

-108,46

Total -858 -364 -293

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 16

Engine DSS benefits

1. Time saving

2. Costs reduction

3. Environmental perception

4. Increasing remanufacturing demand

PREMANUS 18

Waste management BDSS Application

WEEE Strategy

DIFFERENT ASSESSED ALTERNATIVES

CONSIDERING:

the waste treatment;

the fractions as output of recycling plants;

the collection of waste from consumer to

different treatment plants.

DSS gives a quote about the economic cost and environmental implications to

dismantle a non-functional equipment for different treatment plants

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 19

Waste management BDSS Application

Trasportation

from Consumer

to treatment plant

Treatment

process

Recycling of

Secondary Raw

Materials

Disposal

Production of raw

materials

ECONOMIC ANALYSIS

costs of the overall treatment process

the disposal costs and revenues of

hazardous components and different

fractions

transportation costs

ENVIRONMENTAL ANALYSIS

Energy consumption of the overall

treatment process and relative

environmental impacts

Environmental benefits/costs of

commodities recycling

transportation environmental impacts from

consumer to dismantling plant

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 20

Waste management results Environmental

impacts

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 21

Waste management results - Costs

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 22

Waste management plant analysis

Rossella Luglietti, World Remanufacturing Summit, 25

th

-26

th

September 2014

PREMANUS 23

Waste management DSS benefits

1. Best plant options

2. More competitive on waste market

3. Environmental perception

rossella.luglietti@polimi.it

Info about PREMANUS: www.premanus.eu

Contacts:

Rossella Luglietti

Politecnico di Milano

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- All Brochures ETIDocumento33 pagineAll Brochures ETIPuji RahmawatiNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- ML-2010 Series: SAMSUNG Laser Printer User's GuideDocumento120 pagineML-2010 Series: SAMSUNG Laser Printer User's Guidediddi21Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Sir AquinoDocumento12 pagineSir AquinoDarryl PeñaredondoNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Two-Stage Gasification of Wood With Pre-Heated Air SupplyDocumento5 pagineTwo-Stage Gasification of Wood With Pre-Heated Air SupplygvisanNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Modeling The Minetta BrookDocumento18 pagineModeling The Minetta BrookSteve DuncanNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- NORUDIA N HbA1c PDFDocumento3 pagineNORUDIA N HbA1c PDFSinari AlfatNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Community-Based Monitoring System: Barangay Profile QuestionnaireDocumento6 pagineCommunity-Based Monitoring System: Barangay Profile QuestionnaireSonny GasgaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- As 400e Server 170 and 250 Problem Analysis, Repair and PartsDocumento581 pagineAs 400e Server 170 and 250 Problem Analysis, Repair and PartsJose Sancho GarridoNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Lakas Kampi-CMD and Teodoro Platform of GovernmentDocumento11 pagineLakas Kampi-CMD and Teodoro Platform of GovernmentManuel L. Quezon IIINessuna valutazione finora

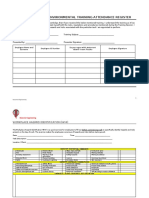

- 3.REG001 Training Attendance RegisterDocumento80 pagine3.REG001 Training Attendance RegisterWelma JohnsonNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Behavioral Economics and Starbuck's Cup ProblemDocumento3 pagineBehavioral Economics and Starbuck's Cup Problemnivetha gnanavel100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Working With Words + Listening & Speaking 2022 - HICHAM OUAZENEDocumento4 pagineWorking With Words + Listening & Speaking 2022 - HICHAM OUAZENENouzha AkohNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Project 1 AcetoneDocumento13 pagineProject 1 AcetoneGustavo Vasquez100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Tugas Kelompok Bahasa Inggris Membuat Empat Puluh SoalDocumento21 pagineTugas Kelompok Bahasa Inggris Membuat Empat Puluh SoalMan Can'tDenyNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Environmental Management System (EMS) : FeaturesDocumento55 pagineEnvironmental Management System (EMS) : Featuresdharmbir kumarNessuna valutazione finora

- Safe Handling CytotoxicDocumento29 pagineSafe Handling CytotoxicAnonymous G6Kv7XWeRNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Bamboo ArticleDocumento7 pagineBamboo ArticlekumaranprasadNessuna valutazione finora

- BioWorld Bioremediation Oil Spill SummaryDocumento16 pagineBioWorld Bioremediation Oil Spill SummaryMarshall-tendai Zifa-sire Zuku-chibikaNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- LEED Implementation Plan Full Draft Nov 23Documento61 pagineLEED Implementation Plan Full Draft Nov 23Chris Gonzales100% (1)

- Krugman - A Country Is Not A Company PDFDocumento9 pagineKrugman - A Country Is Not A Company PDFdavidNessuna valutazione finora

- Sustainable Solid Waste Management System: Barangay Bayog, Los Baños, LagunaDocumento12 pagineSustainable Solid Waste Management System: Barangay Bayog, Los Baños, Lagunabas haNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Sugar IndustryDocumento10 pagineSugar Industryharshu DNessuna valutazione finora

- Colegio Alfonso Reyes Echandia IedDocumento2 pagineColegio Alfonso Reyes Echandia IedJuan Carlos Gutierrez Vélez100% (1)

- Coduri NFRDocumento6 pagineCoduri NFRgeorgianaNessuna valutazione finora

- Geology Essay FinalDocumento4 pagineGeology Essay FinalMomen BtoushNessuna valutazione finora

- Greater Yangon Water Supply Improvement Project (Phase II) Summary 2017Documento66 pagineGreater Yangon Water Supply Improvement Project (Phase II) Summary 2017lwin_oo2435Nessuna valutazione finora

- Operating Instruction TE 70 ATC AVR 80 ATC AVR 03 Operating Instruction PUB 5150798 000Documento168 pagineOperating Instruction TE 70 ATC AVR 80 ATC AVR 03 Operating Instruction PUB 5150798 000Gitu HazarikaNessuna valutazione finora

- Batrec Batery RecyclingDocumento4 pagineBatrec Batery RecyclingVanja LukovicNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Step-By-Step Process: The Rubber Recycling ProcessDocumento5 pagineStep-By-Step Process: The Rubber Recycling Processhamza2595Nessuna valutazione finora

- State of Loc Governance - ILOCOS NORTE VER1Documento50 pagineState of Loc Governance - ILOCOS NORTE VER1JigsIsaacEspinaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)